Heat-shrinkable polyester film

A polyester film, heat shrinking technology, used in polyester coatings, heat-sensitive coatings, thin material processing, etc., can solve non-uniform heat shrinkage, damage the appearance and quality of marked containers, and cannot effectively protect containers or mark goods, etc. problems, to achieve the effect of improving shrinkage ability, maintaining appearance quality, and good appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

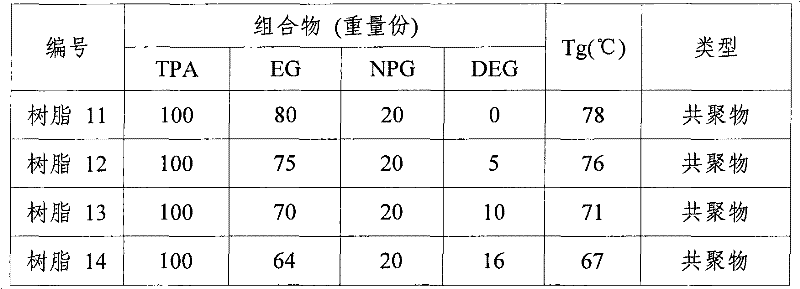

[0037] 1. Preparation of copolyester resin and polyester film

[0038] Copolyester resins were prepared according to the compositions and contents in Table 1 by using conventionally used and well-known copolyester standard preparation methods (for example, Examples 1-7 of Korean Patent No. 10-0987065).

[0039] Table 1

[0040]

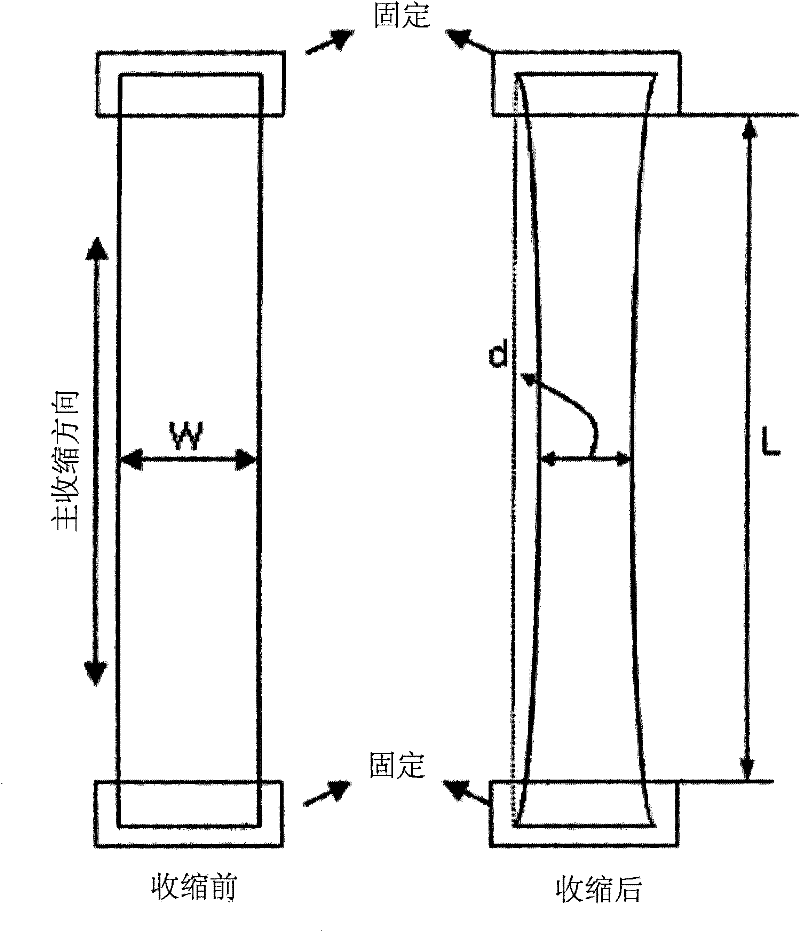

[0041] The polyester films prepared with Resins 11-14 are shown in Table 2. Each resin was melt-extruded to form a sheet, and an oriented film was prepared at a rate of 4.0 in the main shrinkage direction at 80°C. Fix the two ends of the oriented film along the main shrinking direction, and then quickly pass through a heat treatment zone with a temperature range of 85° C. to 105° C. to heat-set the fixed film to obtain a heat-shrinkable polyester film with a thickness of 40 μm.

[0042] Table 2

[0043]

[0044]

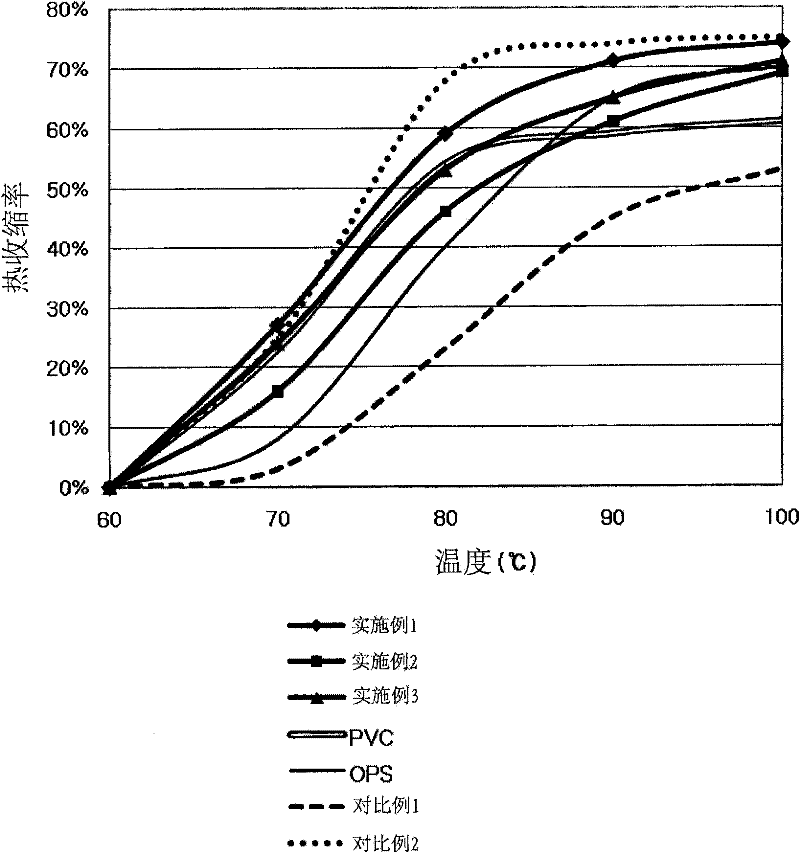

[0045] 2. Properties of polyester film

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat shrinkage ratio | aaaaa | aaaaa |

| heat shrinkage ratio | aaaaa | aaaaa |

| heat shrinkage ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com