Precooling technique and device for recovering turpentine

A turpentine and pre-cooling technology, applied in turpentine, chemical industry, sustainable manufacturing/processing, etc., can solve the problems of unsatisfactory cooling effect, loss of heat energy turpentine, slow cooling speed, etc., and achieve good oil-water separation effect and easy production , fast cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

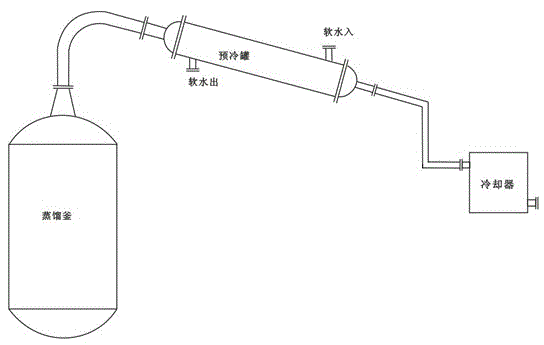

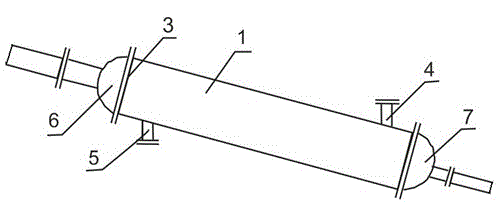

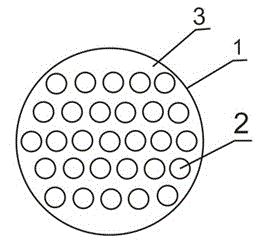

[0016] Embodiment: the pre-cooling process of the present invention is realized by adding a section of pre-cooling process in the traditional process flow, that is, a pre-cooling device is set between the still and the turpentine cooler, and each part of the pre-cooling device is made of stainless steel Production, the steam pipe 2 is parallel to the longitudinal axis of the tank body, and the sealing layer 3 is welded on both sides of the pre-cooling tank 1 to seal the tank body. The upper cover 6 and the lower cover 7 are movably connected to the tank body with bolts. The kettles and the lower cover 7 and the cooler are connected by pipes. The cooling water enters the tank from the water inlet 4 and flows out through the water outlet 5. It is in a flowing state during the entire cooling process; the temperature in the rosin distillation kettle is as high as 180°C When the oil-water mixture gas passes through the steam pipe 2, it is cooled by the cooling water to about 80°C, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com