Saponifiable matter extraction method and saponifiable matter extraction device

An extraction method and technology of an extraction device, which is applied to a device for extracting saponified matter, in the field of extracting saponified matter from black liquor, can solve the problems of low separation speed, low extraction rate of saponified matter, and difficulty in achieving ideal residence separation time, etc. problems, to achieve the effect of improving the extraction rate, accelerating the separation and rising speed, and preventing deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

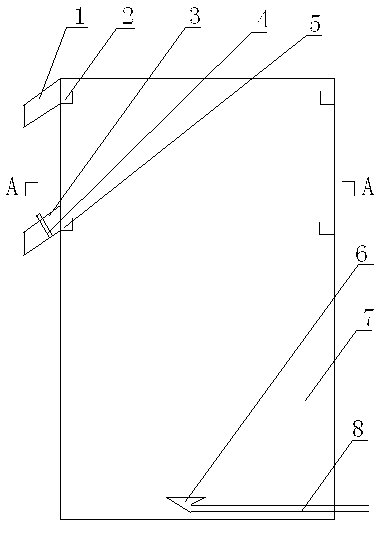

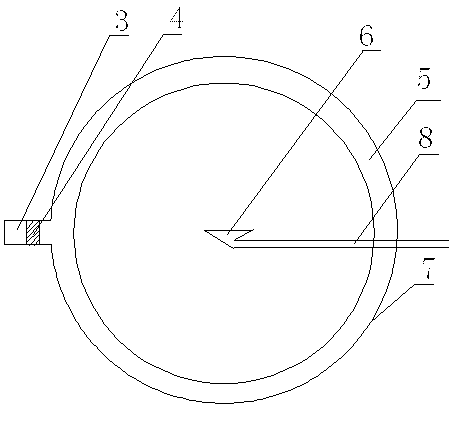

[0022] Example 1: When using the aforementioned saponified matter extraction device to extract saponified matter, the black liquor obtained by pulping and extraction is concentrated to a temperature of 75°C during the evaporation process, and the black liquor with a black liquor solid concentration of 24% is sent to the black liquor tank In 7, in this black liquor, add black liquor amount 0.2wt% sodium dodecylbenzene sulfonate surfactant, also pass to the bottom of black liquor tank 7 from compressed air pipeline 8 and sparger 6 in the separation process of staying Inject compressed air to speed up the separation of saponified matter. After the black liquor stayed in the black liquor tank 7 for 3.5 hours, part of the saponified matter was analyzed and rose to the top of the black liquor tank 7, and passed through the cofferdam 2 from the first saponified matter Outlet 1 flows out, thereby obtaining saponified product.

Embodiment 2

[0023] Example 2: When the aforementioned saponified matter extraction device is used to extract saponified matter, the black liquor obtained by pulping extraction is concentrated to a temperature of 85°C during the evaporation process, and the black liquor with a black liquor solid concentration of 27% is sent to the black liquor tank In 7, in this black liquor, add the polypeptide base surfactant of black liquor amount 0.5wt%, also pass into the bottom of black liquor tank 7 from compressed air pipeline 8 and distributor 6 to the bottom of black liquor tank 7 during the separation process, quicken The separation of saponified matter, after this black liquor stays in black liquor tank 7 for 2.5 hours, part of saponified matter wherein separates day, rises to the top of black liquor tank 7, flows out from first saponified matter outlet 1 through cofferdam 2, thereby Saponification is obtained.

Embodiment 3

[0024] Example 3: When the aforementioned saponified matter extraction device is used to extract saponified matter, the black liquor extracted by pulping is concentrated to a temperature of 84°C during the evaporation process, and the black liquor with a black liquor solid concentration of 27.5% is sent to the black liquor tank In 7, add the alpha-olefin sulfonate sodium surfactant of black liquor amount 0.35wt% in this black liquor, also pass into the bottom of black liquor tank 7 from compressed air pipeline 8 and sparger 6 in the separation process of staying Compress the air to speed up the separation of saponified matter. After the black liquor stays in the black liquor tank 7 for 3 hours, part of the saponified matter will rise to the top of the black liquor tank 7 and exit from the first saponified product through the cofferdam 2. 1 flowed out to obtain a saponified product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com