Integrated contact arc extinguishing system with movable fixed contact

A dynamic and static contact, integrated technology, used in circuit breaker contacts, circuit breaker parts and other directions, can solve the problems of circuit breaker burnout, difficult to improve production efficiency, poor air tightness, etc., to improve breaking capacity and improve production. Efficiency, the effect of improving the separation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

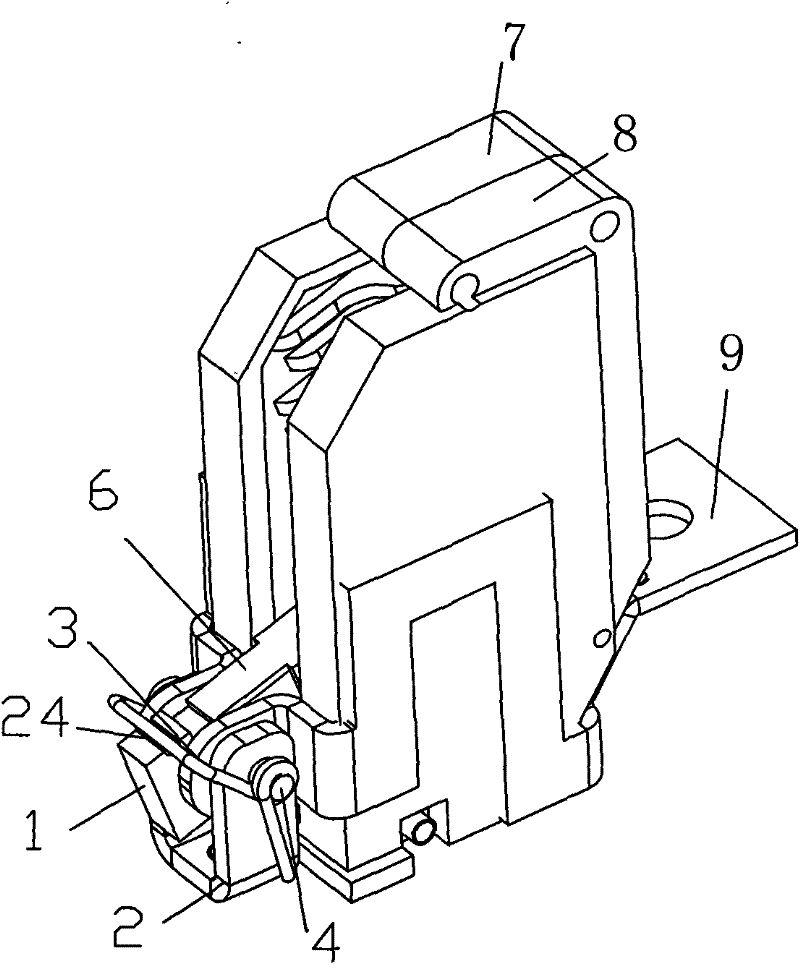

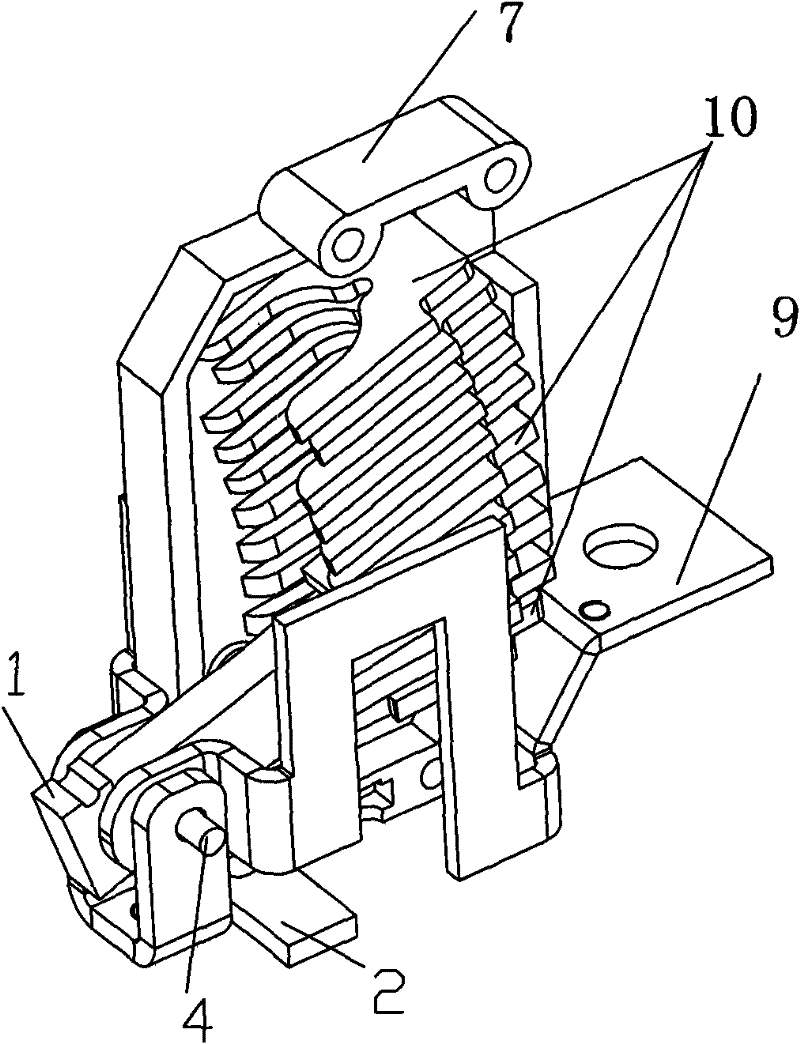

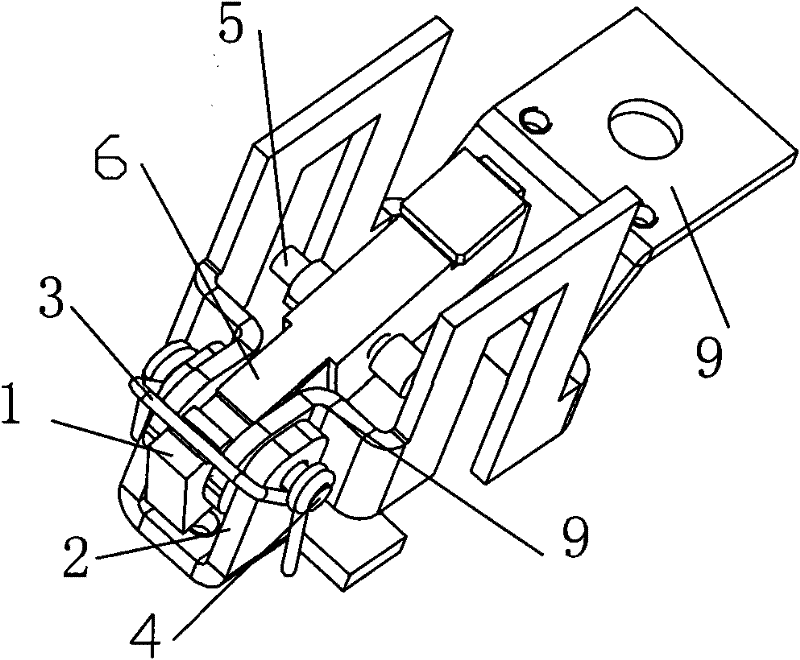

[0022] Such as figure 1 , 2 As shown, the present invention includes movable and static contacts 1 , bracket 2 , spring 3 , pin shaft 4 , conductive copper bar 9 and insulating shells 7 and 8 . Such as Figure 3-9 As shown, the movable and static contact 1 is placed between the two ends of 212 and 213 of the conductive copper bar 9, the 212 and 213 ends of the conductive copper bar 9 are provided with brackets 2 connected thereto, and one end of the movable and static contact 1 is provided with a through The hole 11 is provided with a through hole 12 on the support 2, and the end of the conductive copper bar 9 212, 213 is provided with a through hole 18. There are coil holes 13 on both sides of the spring 3, and the pin shaft 4 connects the through hole 11 on the movable and static contact 1, the through hole 12 on the bracket 2, the through hole 18 on the conductive copper bar 9 and the coils on both sides of the spring 3 When the hole 13 and the pin shaft 4 pass through, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com