Contact system capable of automatically change-over switching electric appliance

An automatic transfer switch, contact system technology, applied in electrical switches, high-voltage/high-current switches, contacts, etc., can solve the problem that the contacts cannot resist arc burning, movement, poor thermal stability, and it is difficult to achieve short-term tolerance. and other problems, to achieve the effect of improving short-time tolerance, high making and breaking capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

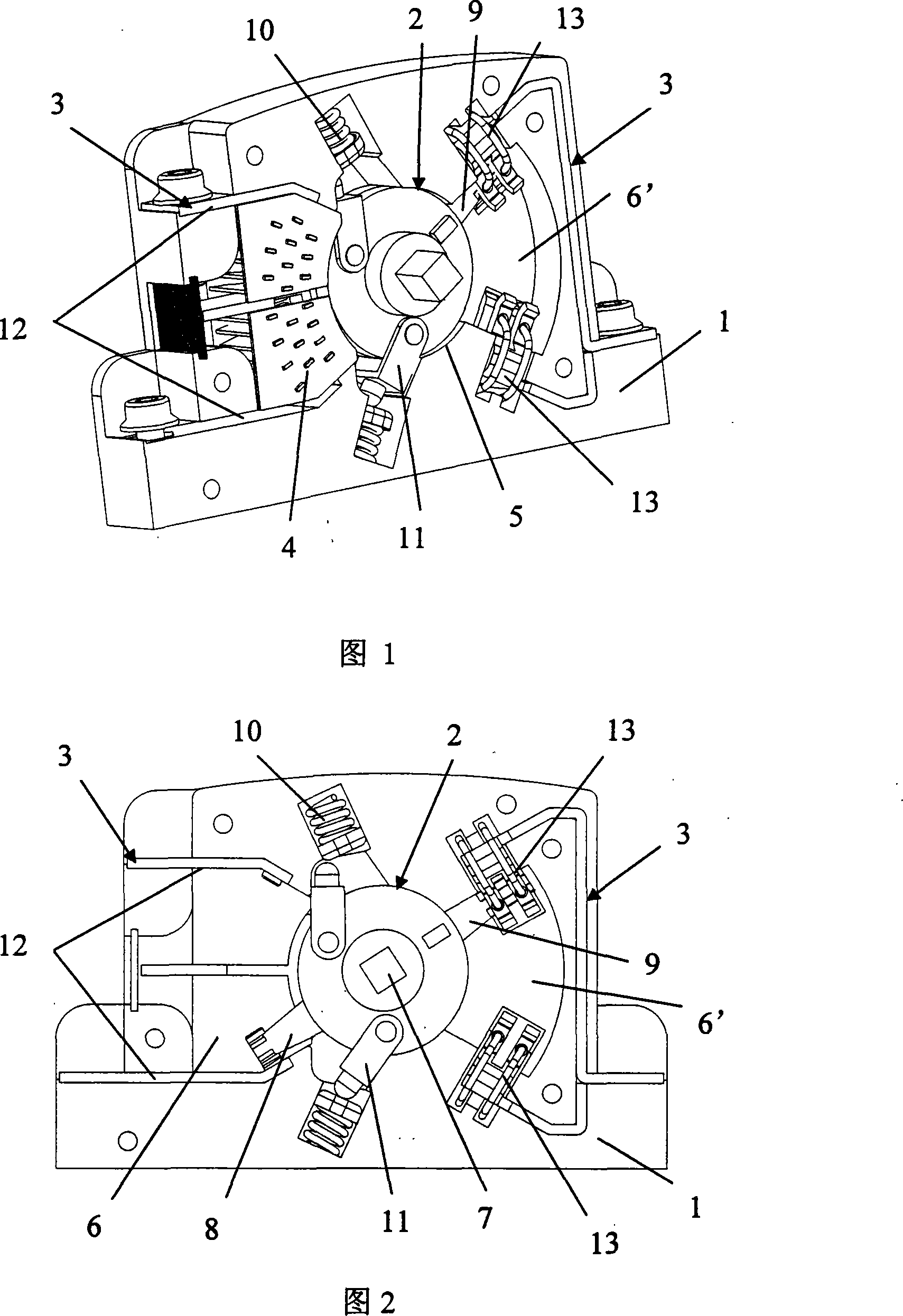

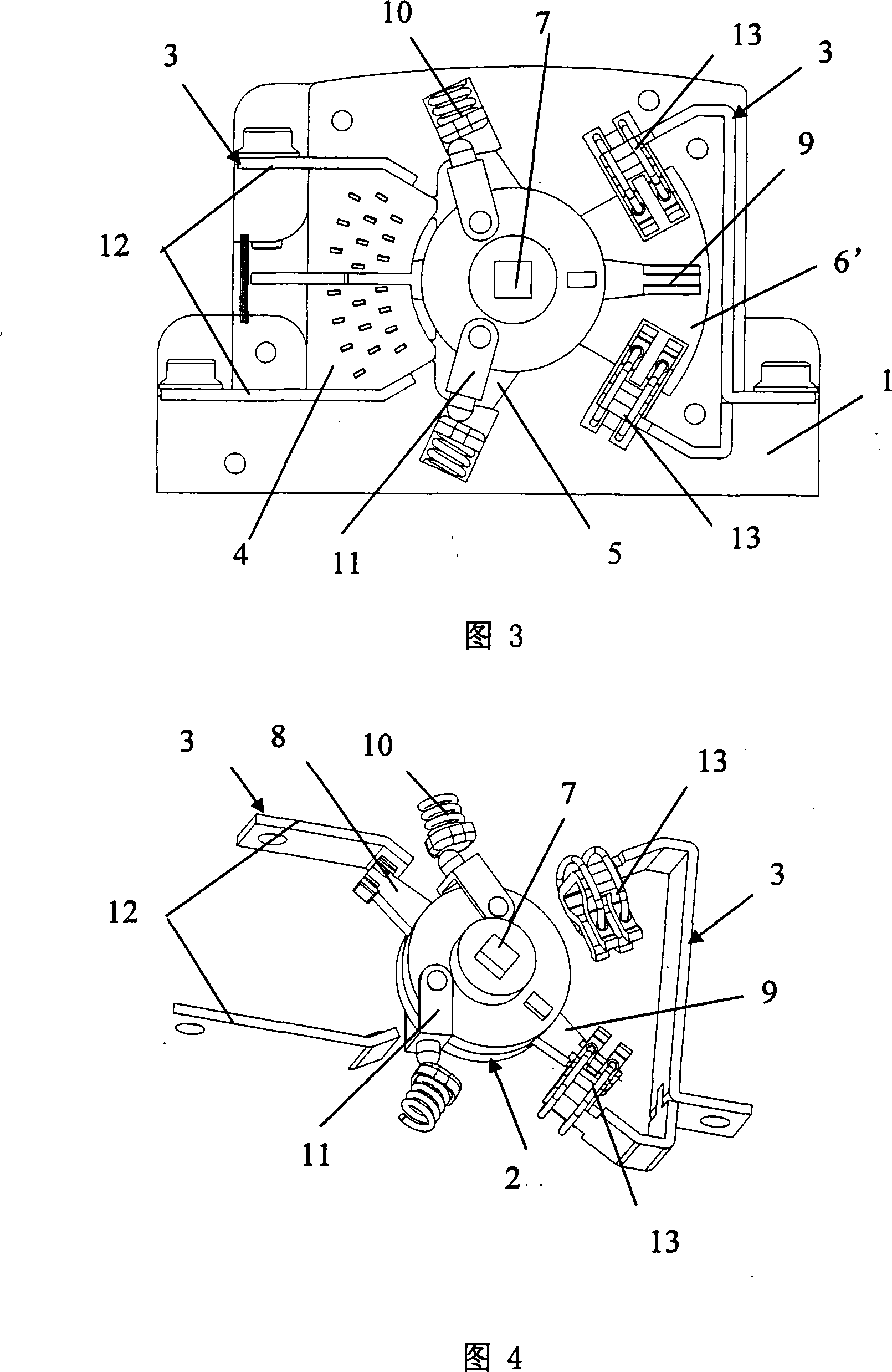

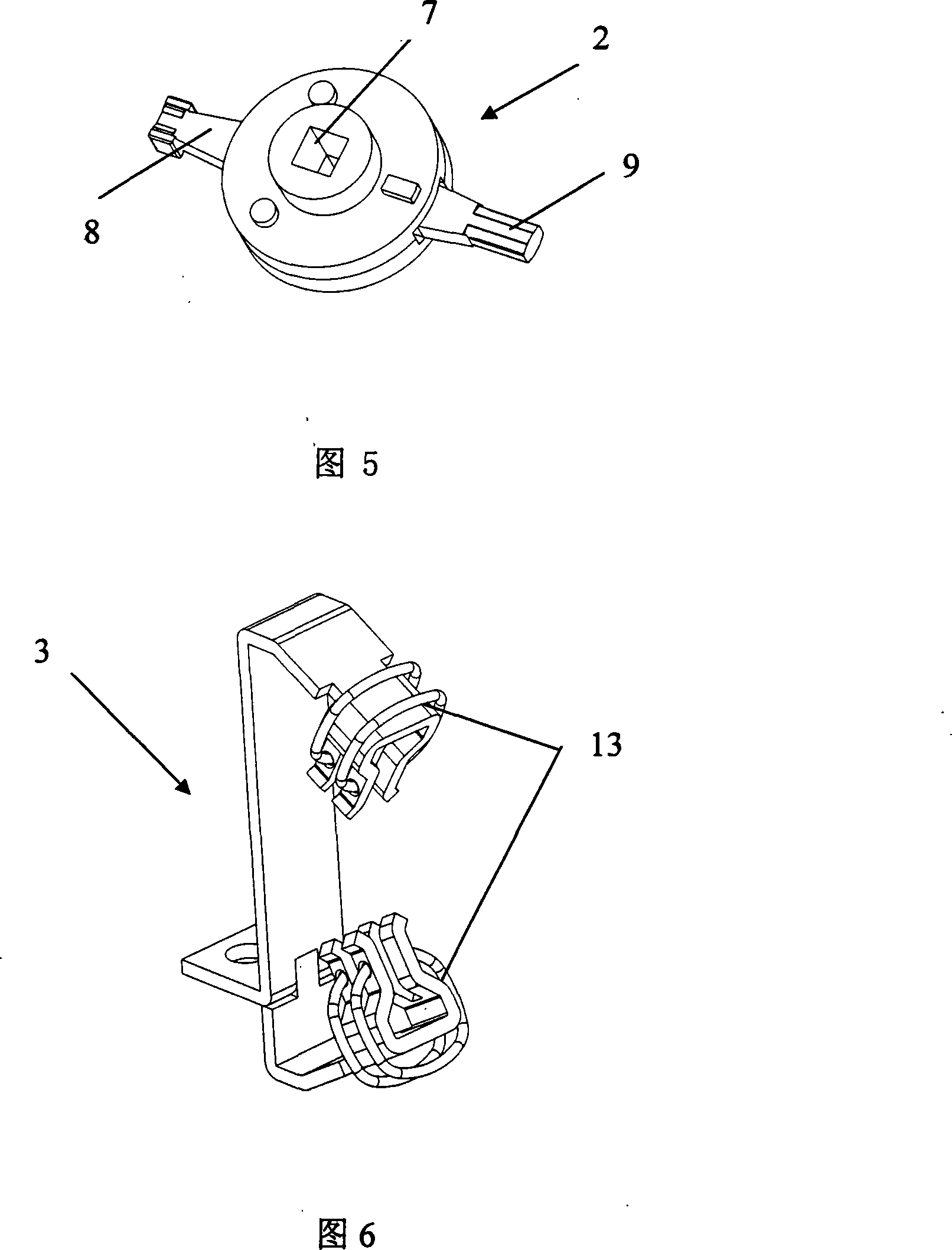

[0015] The contact system of the automatic transfer switch appliance provided by the present invention will be described in detail below with reference to the drawings and specific embodiments.

[0016] As shown in Figures 1 to 6, the contact system of the automatic transfer switching device provided by the present invention includes a housing 1, a moving contact assembly 2, a static contact assembly 3 and an arc extinguishing chamber 4; wherein the housing 1 is in the shape of a flat cuboid, The central part of one side is recessed to form a moving contact assembly setting hole 5, and the two ends of the side are recessed to form static contact assembly setting holes 6, 6' communicating with the moving contact assembly setting hole 5; The central part of the head assembly 3 is formed with a central hole 7 that can be connected with the output shaft of the power source, so that it can be rotated in the hole 5 of the movable contact assembly. The static contact assembly is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com