Soil cleaning mechanism with feeding function for potato harvesting

A technology of timing and soil, which is applied in the direction of digging harvesters, harvesters, applications, etc., can solve the problems of poor separation of soil and potatoes, soil cannot be cleaned, inconvenience, etc., to achieve improved storage environment, simple structure, Ease of sale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

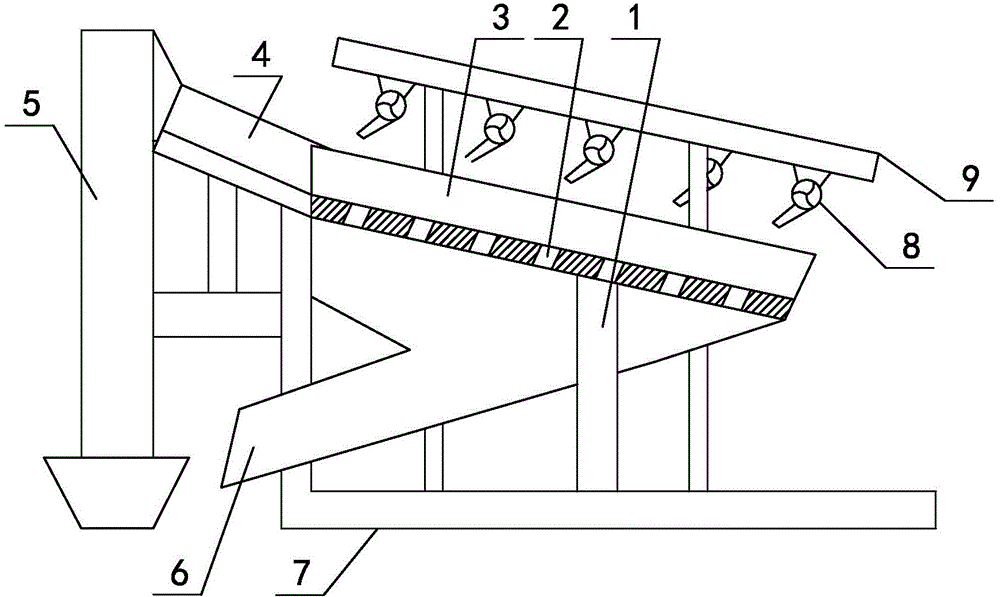

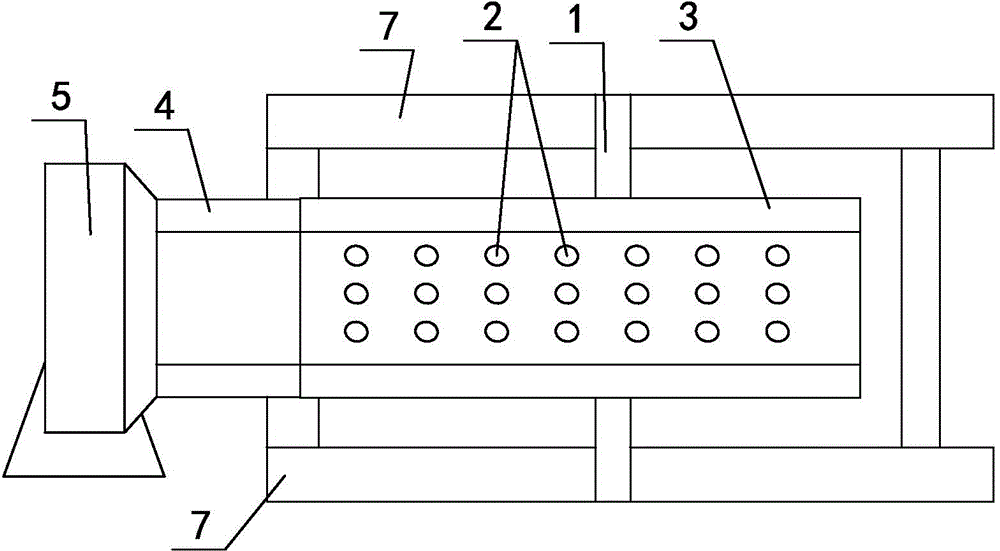

[0017] Such as figure 1 , figure 2 As shown, the soil cleaning mechanism with feeding for potato harvesting includes a support 7 with an L-shaped structure as a whole. On the support 7, a chute 3 with a high left and a low right is arranged obliquely. The bottom of the chute 3 is provided with several diameters. It is a 20mm soil leakage hole 2, and a lifting conveying device 5 is vertically installed on the left side wall of the support 7, and the outlet end of the lifting conveying device 5 top is connected with a feeding chute 4 made of soft material, and the outlet of the feeding chute 4 It is connected with the inlet in the upper left corner of the chute 3, and corresponding to the excavation direction of the soil leakage hole 2, a soil collection and processing channel 6 is arranged below the chute 3, and a fan installation bracket 9 is vertically arranged on the horizontal support 7, and the fan installation bracket 9 Some small blowers 8 are installed on the top, the...

Embodiment 2

[0021] Change on the basis of embodiment one, soil leakage hole 2 diameters become 30mm; The vertical distance of described small fan 8 to the bottom of chute 3 grooves becomes 400mm; The inclination angle of described chute 3 becomes 40 degrees; So The overall length of the chute 3 becomes 2500mm. Others are the same as embodiment one.

Embodiment 3

[0023] Change on the basis of embodiment one, soil leakage hole 2 diameters become 25mm; The vertical distance of described small fan 8 to the bottom of chute 3 grooves becomes 500mm; The inclination angle of described chute 3 becomes 30 degrees; So The overall length of the chute 3 becomes 2000mm. Others are the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com