Preparation method of colophony and turpentine

A technology for turpentine and rosin, which is applied to the production field of turpentine, can solve the problems of long self-separation time, slow dissolution rate, incomplete separation, etc., and achieves the effects of improving efficiency, rapid separation, and improving fat liquid clarification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

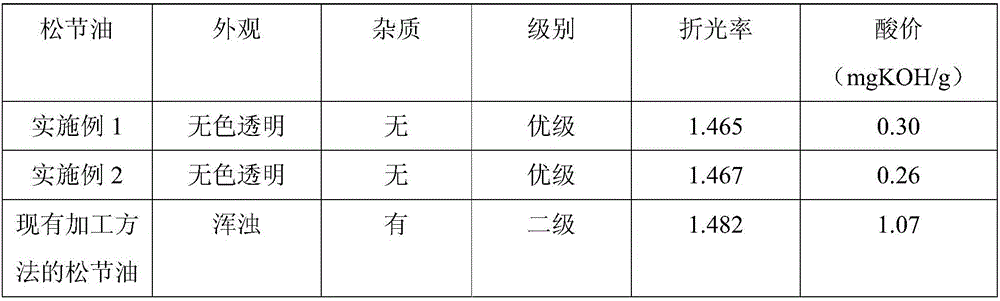

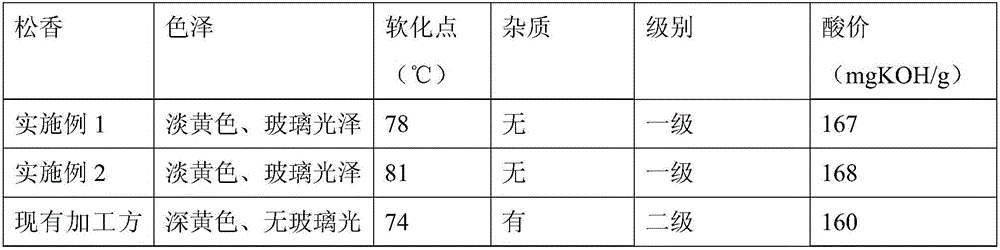

Examples

Embodiment 1

[0027] A kind of preparation method of rosin and turpentine, concrete steps are as follows:

[0028] (1) Cleaning the rosin with a cleaning solution, wherein the cleaning solution is a mixture of dimethylacetamide and hot water with a weight ratio of 1:10, wherein the temperature of the hot water is 60-70°C;

[0029] (2) dissolving: the rosin is transported into the dissolving pot, and at the bottom of the dissolving pot, it is heated by water vapor at a temperature of 90-100° C. to make the rosin dissolve in the dissolving solution in the dissolving pot, wherein the added weight of the dissolving solution is as described 40% of the turpentine weight, the dissolving solution is made up of the following components by weight: 10 parts of water, 20 parts of dimethylacetamide, 10 parts of turpentine and 0.1 part of oxalic acid;

[0030] (3) Water washing: add the dissolved fat liquid into hot water at a temperature of 80-90°C for washing, so as to wash off the dimethylacetamide, p...

Embodiment 2

[0035] A kind of preparation method of rosin and turpentine, concrete steps are as follows:

[0036] (1) cleaning the rosin with a cleaning solution, wherein the cleaning solution is a mixture of dimethylacetamide and hot water with a weight ratio of 1.2:10, and the temperature of the hot water is 60-70°C;

[0037] (2) dissolving: the rosin is transported into the dissolving pot, and at the bottom of the dissolving pot, it is heated by water vapor at a temperature of 90-100° C. to make the rosin dissolve in the dissolving solution in the dissolving pot, wherein the added weight of the dissolving solution is as described 40% of the turpentine weight, the dissolving liquid is made up of the following components by weight: 20 parts of water, 30 parts of dimethylacetamide, 20 parts of turpentine and 0.3 part of oxalic acid;

[0038] (3) Water washing: add the dissolved fat liquid into hot water at a temperature of 80-90°C for washing, so as to wash off dimethylacetamide, pigments ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com