Patents

Literature

43results about How to "Play a warm-up effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

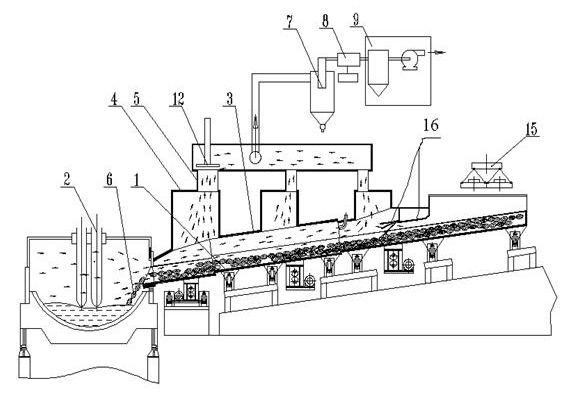

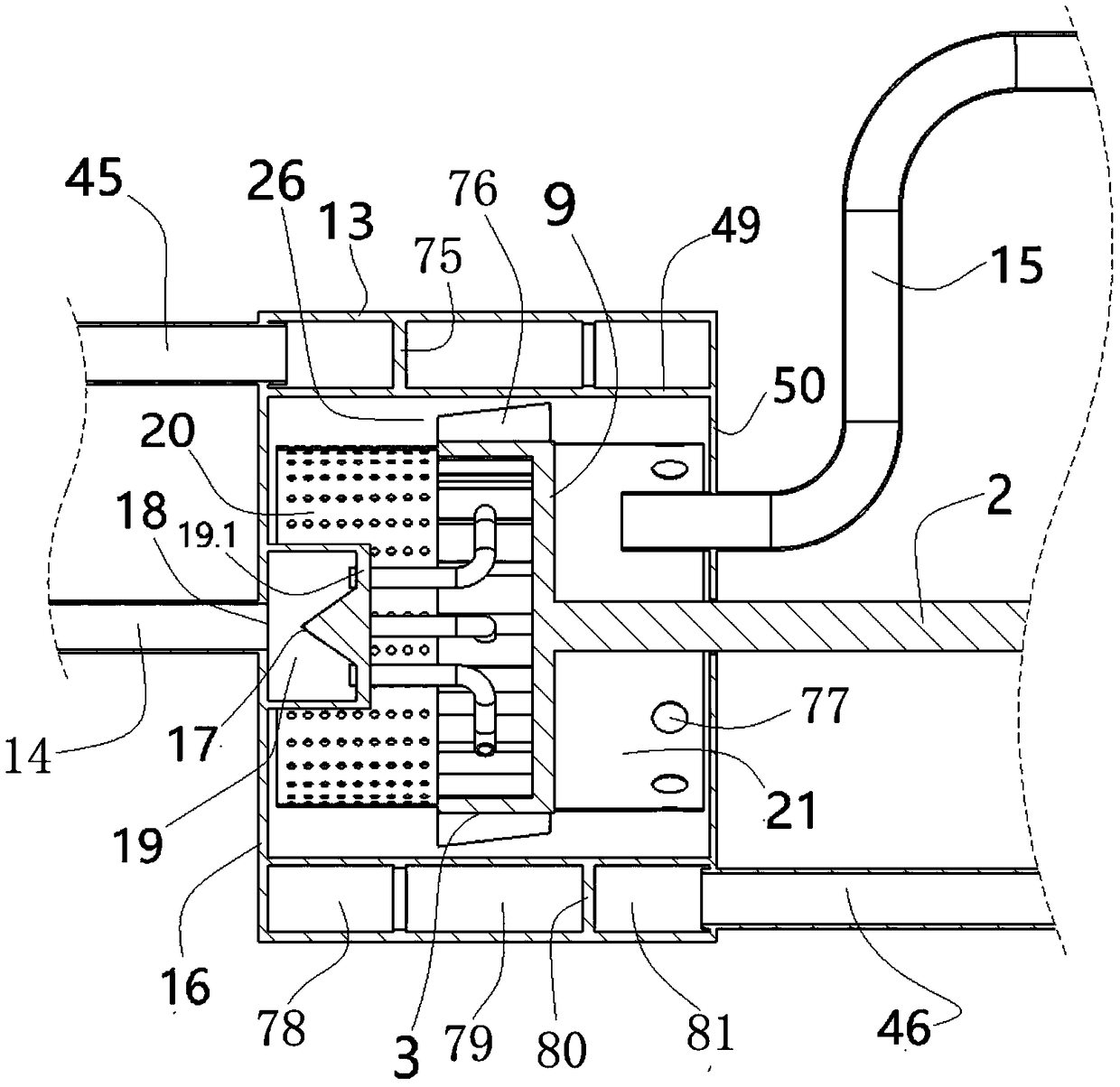

Sludge treatment apparatus for water conservancy project

ActiveCN107381987AAvoid damageAvoid the impact of product qualitySludge treatment by de-watering/drying/thickeningHydraulic engineering apparatusExpanded clay aggregateHydraulic engineering

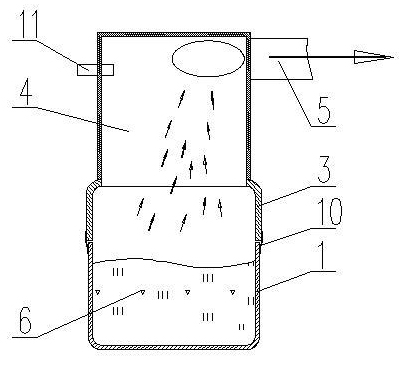

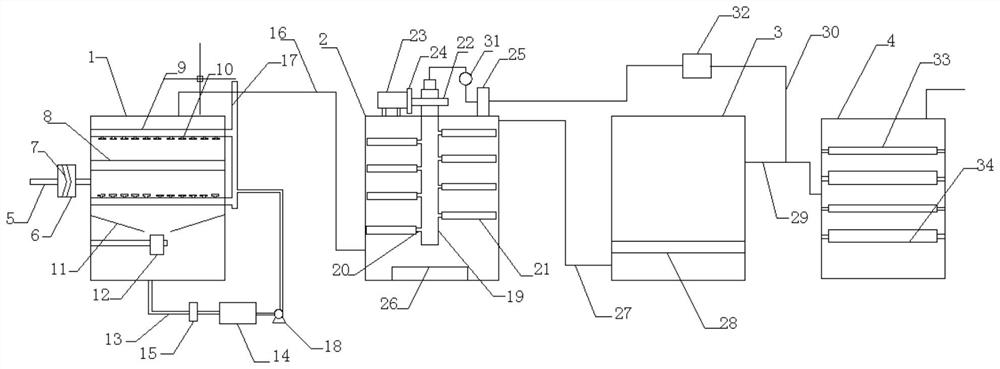

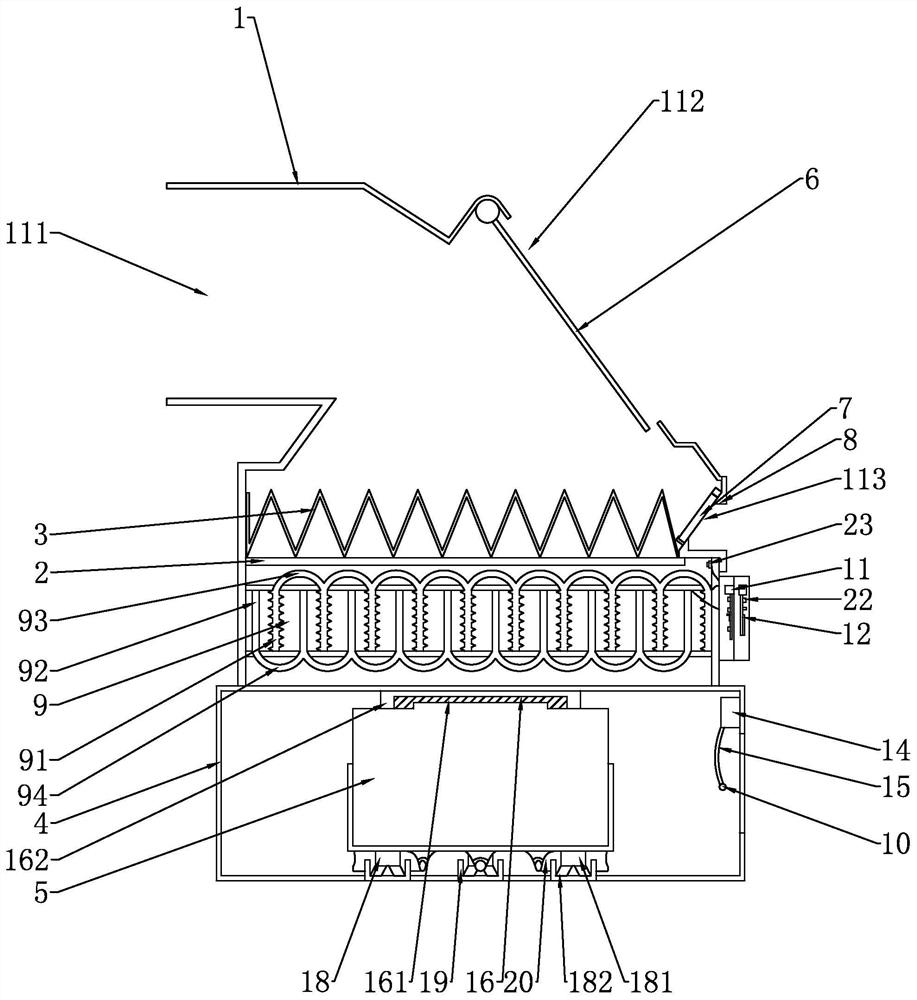

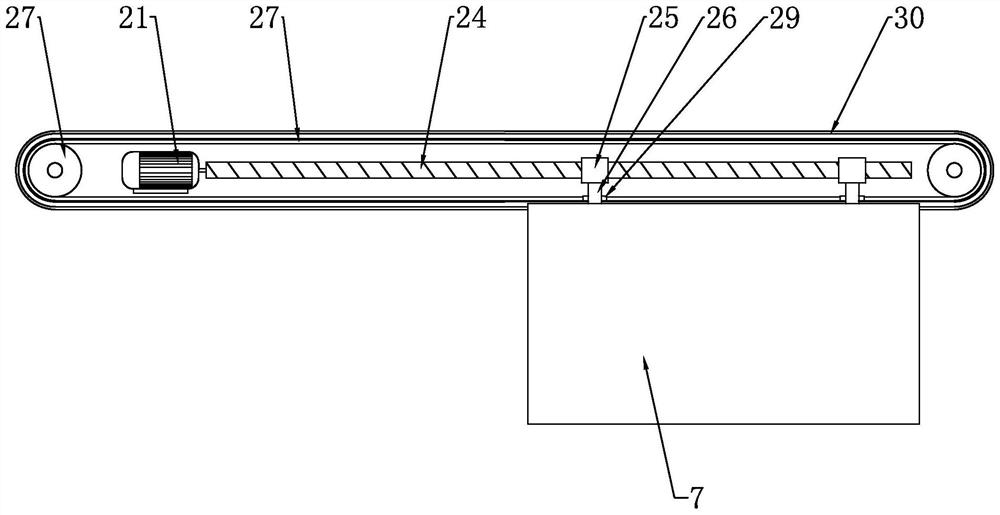

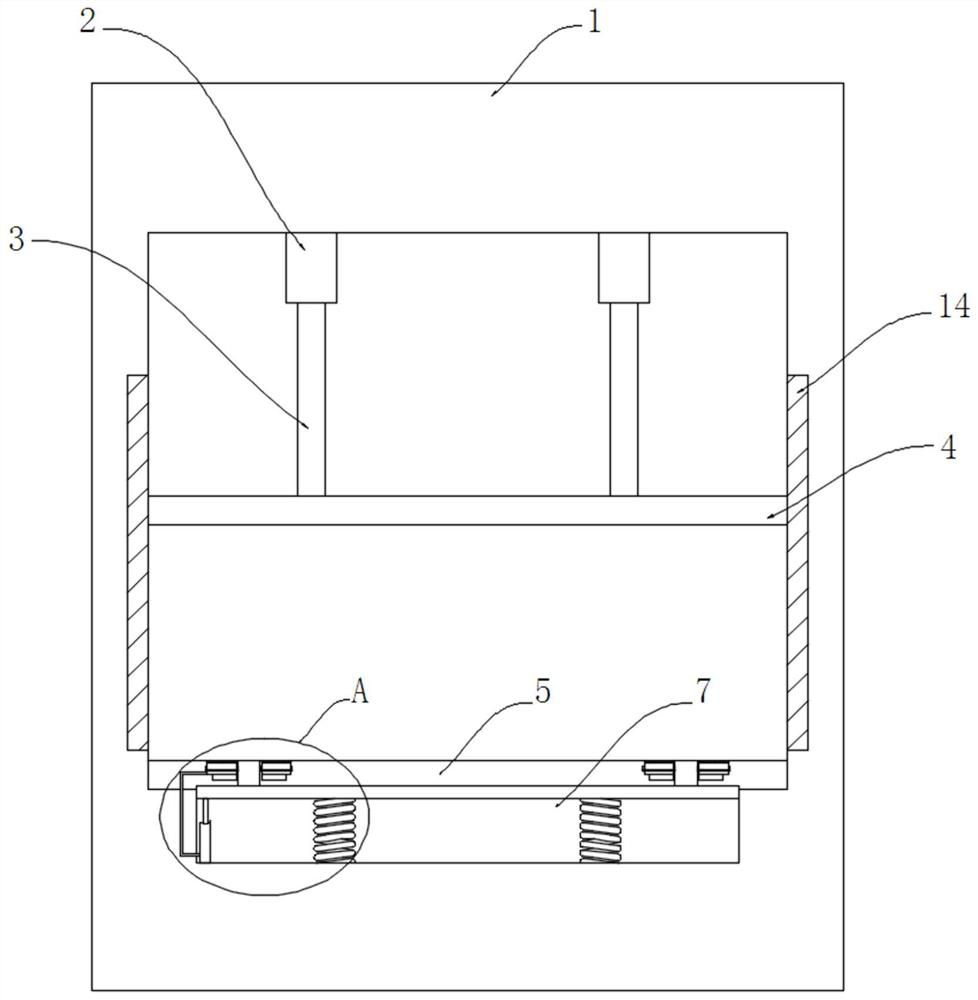

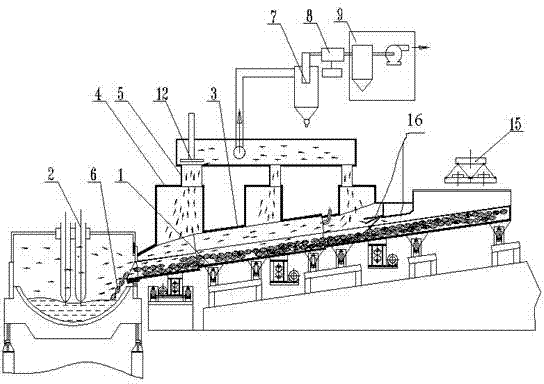

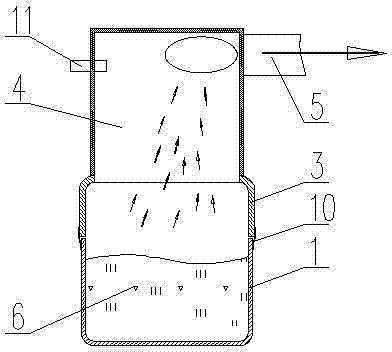

The invention relates to a sludge treatment apparatus for a water conservancy project. The sludge treatment apparatus comprises a transport apparatus, a stirring chamber, a transport pipeline part, a sludge filter chamber, a sludge mixing and drying part, a mixing and granulating chamber and a ceramsite heating chamber. By arranging various parts, the sludge treatment, the ceramsite preparation from sludge and the ceramsite forming can be continuously carried out, so that not only can the sludge containing heavy metal be removed and the secondary pollution of the sludge to a water body be avoided, but also heavy metal elements are secondarily utilized for the ceramsite, and the harmful sludge can be actually turned into benefit.

Owner:畅庆环保科技(太仓)有限公司

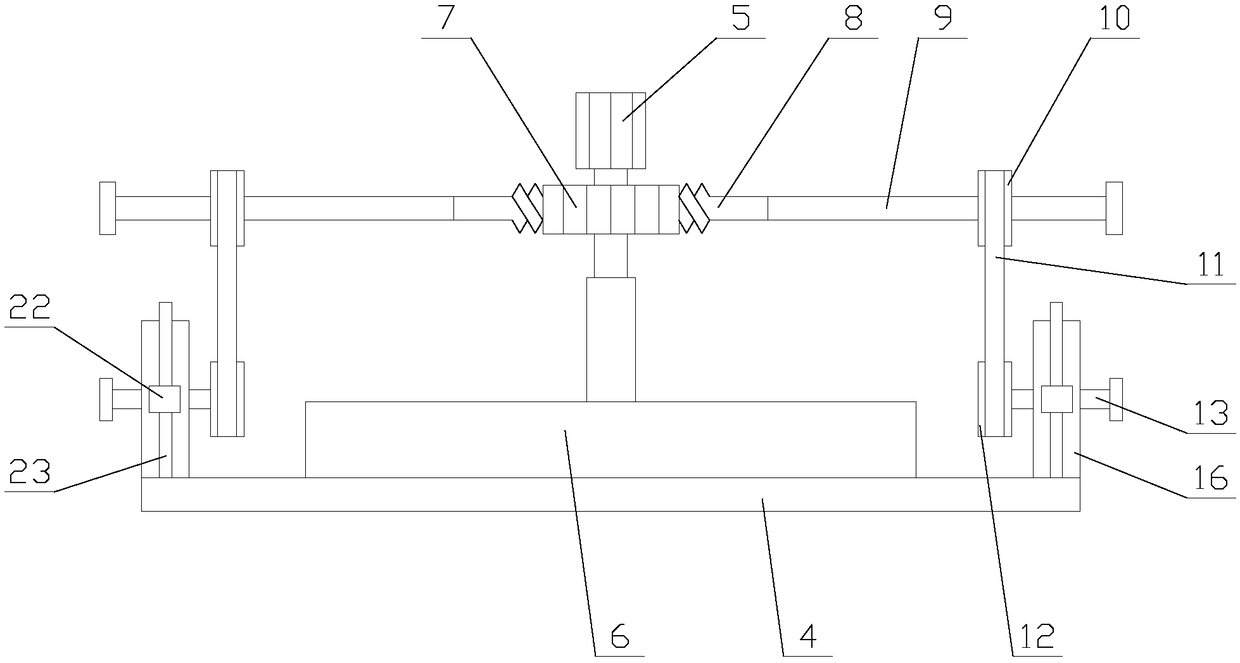

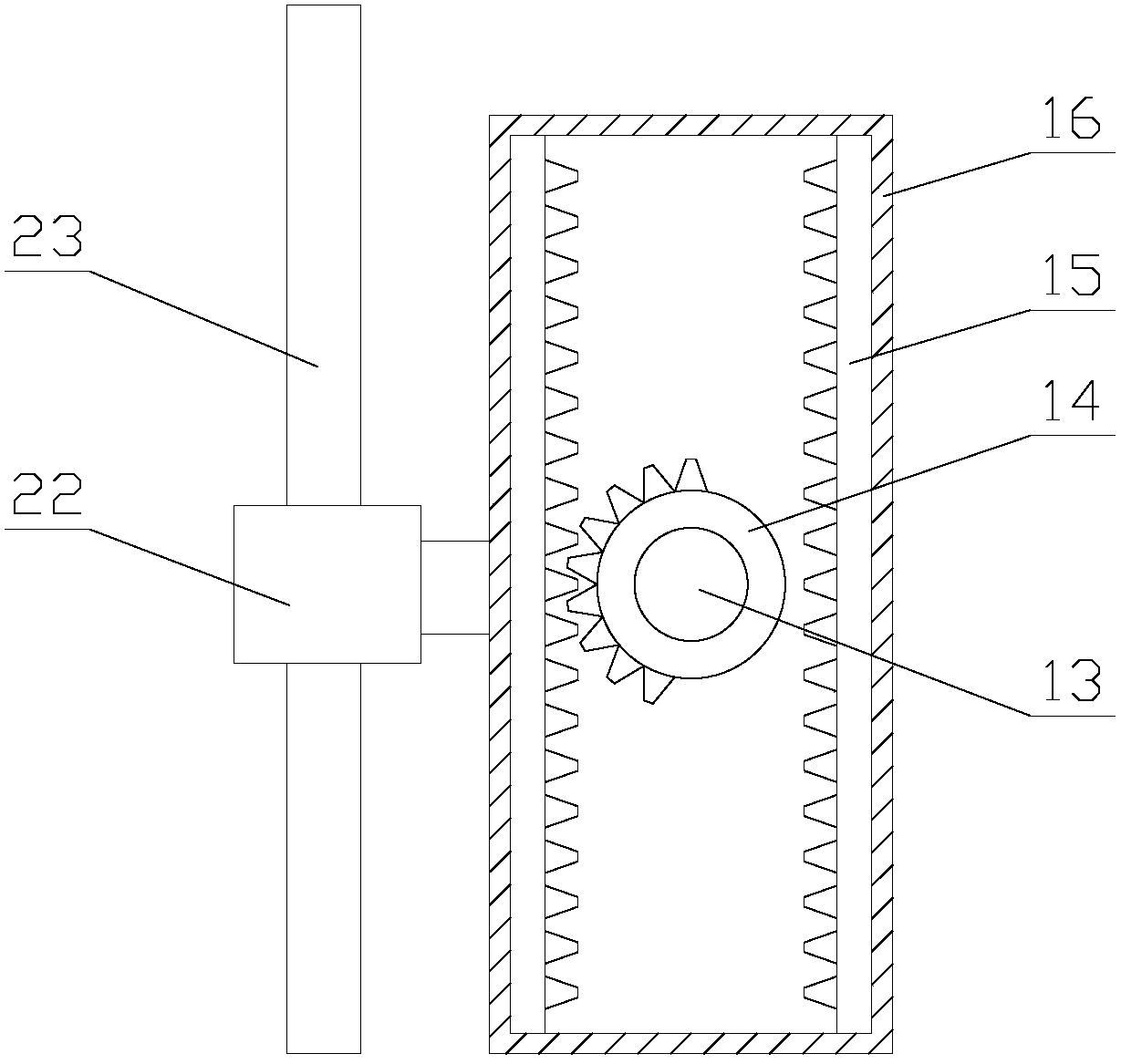

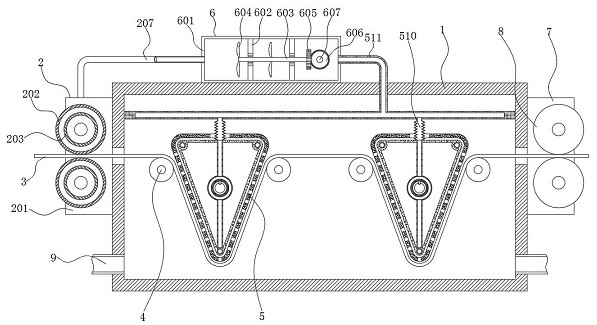

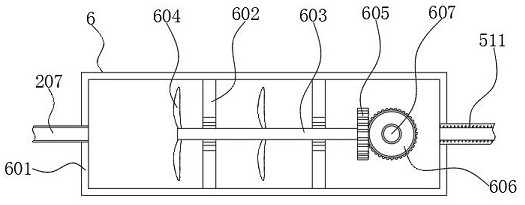

Drying equipment for novel material treatment with good using effect

InactiveCN108397996AImprove drying effectGood drying effectDrying gas arrangementsDrying chambers/containersExhaust heatWaste heat

The invention relates to drying equipment for a novel material treatment with a good using effect. The drying equipment comprises a main body, an air inlet pipe and an exhaust pipe and also comprisesa treatment mechanism and a preheating mechanism, wherein the treatment mechanism comprises a tray, a motor, a stirrer, a cylindrical gear, a worm and two mobile assemblies; the preheating mechanism comprises a connecting pipe, an air pump, a heat-dissipating pipe and a sleeve. According to the drying equipment for the novel material treatment with the good using effect provided by the invention,all surfaces of the material can be mixed fully with hot air through the treatment mechanism, so that the drying effect is improved, the drying effect is better, and follow-up processing and treatmentare prevented from being affected as the material is not uniformly dried. Waste hot air in the main body heats fresh air in the air inlet pipe through the preheating mechanism to play a pre-heating role, so that the heat waste in the drying process is reduced to play a role of recovering waste heat; the drying efficiency is improved greatly, the drying equipment is more energy-saving and environment-friendly, and the practicality and reliability of the drying equipment are improved greatly.

Owner:合肥广能新材料科技有限公司

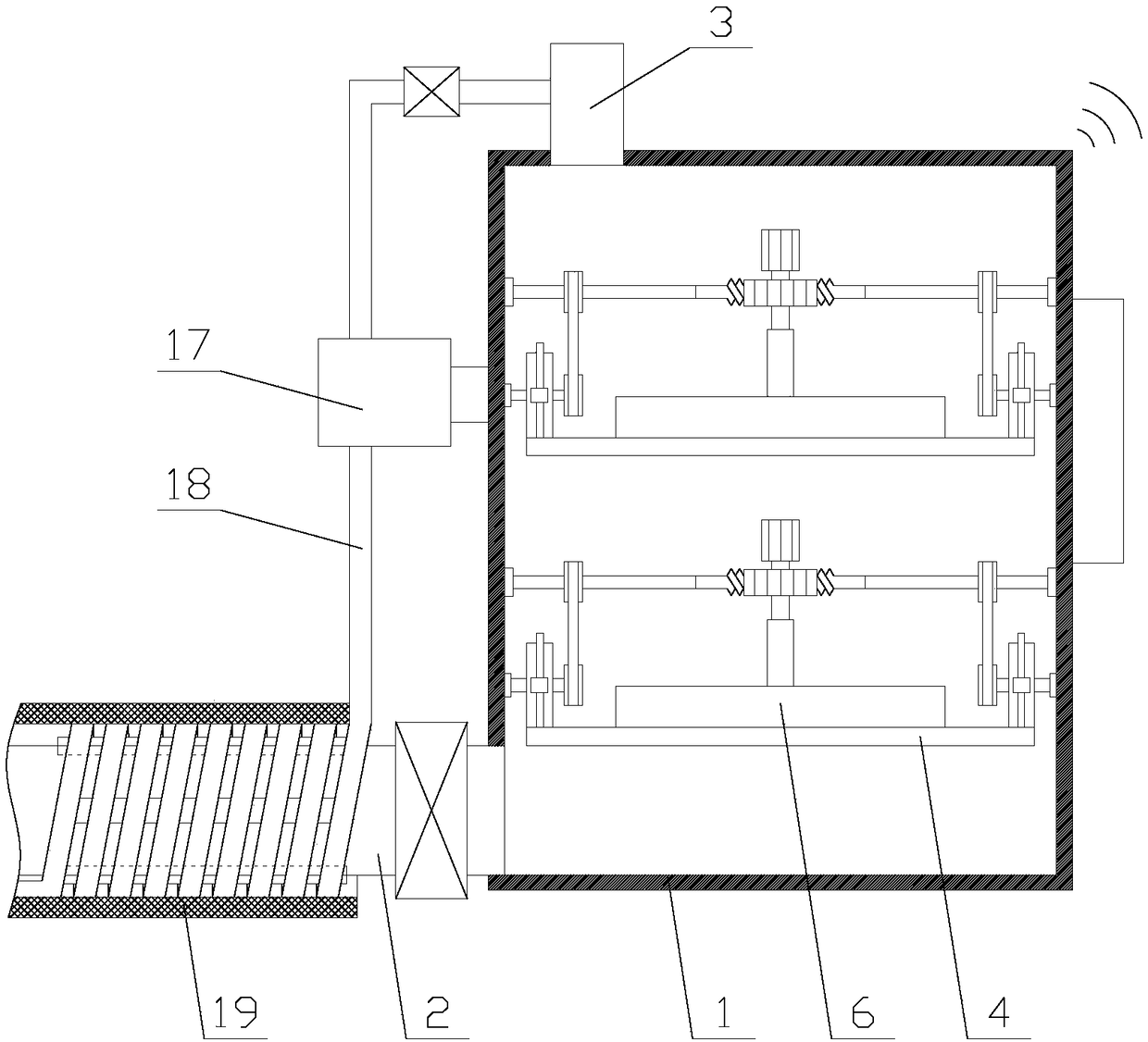

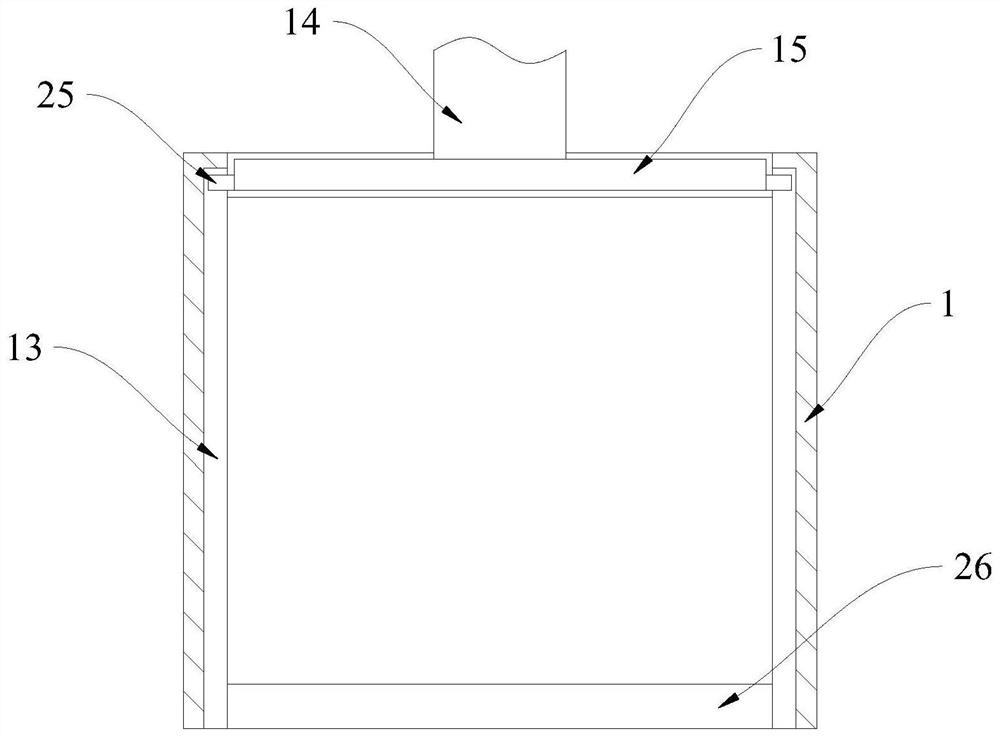

Gas-saving type protective gas drying box

ActiveCN106052322AReduce usageLow costDrying gas arrangementsDrying solid materialsElectric energyProcess engineering

The invention relates to the technical field of a coal sample detecting device, in particular to a gas-saving type protective gas drying box. The gas-saving type protective gas drying box comprises a plurality of drying cavities, a main air inlet pipe, a main exhaust pipe and a control unit. Gas channels of the plurality of drying cavities are arranged in series. The main air inlet pipe is used for pumping protective gas into the plurality of drying cavities and the protective gas after use is discharged through the main exhaust pipe. A heating component is arranged in each drying cavity. The control unit is used for controlling the heating speed of each heating component and the on-off of the main air inlet pipe. According to the gas-saving type protective gas drying box provided by the invention, the repeated usage of the protective gas can be realized, the usage amount of the protective gas can be greatly saved, the cost can be saved and the labour intensity of the operating personnel can be reduced. The protective gas carries a part of heat when getting into one drying cavity from another drying cavity, so that a preheating effect can be played and the warming time of the drying cavity where the protective gas enters is shortened. Accordingly, the electric energy consumption can be reduced and the cost can be further saved.

Owner:长沙开元仪器有限公司

Culvert raw material delivery and smoke dust recovery device and method for smelting container

ActiveCN102003876AIncrease profitReduce dust contentElectric furnaceProcess efficiency improvementScrapEngineering

The invention discloses a culvert raw material delivery and smoke dust recovery device and method for a smelting container. The device comprises a raw material delivery trough, wherein, the upper part of the raw material delivery trough is equipped with a sealing cover; a raw material delivery and flue gas circulation channel is formed between the sealing cover and the raw material delivery trough; and at least one settling chamber for settling dust in flue gas is communicated above the sealing cover. In the invention, the flue gas enters the settling chamber through a channel composed of theraw material delivery trough and the sealing cover, the flow velocity of the flue gas is reduced in the settling chamber and rotational flow or refraction is formed; and part of the dust in the flue gas falls on the surfaces of raw materials to be taken back to the melting container, thus improving the utilization ratio of the raw materials and the utilization effect of a subsequent flue gas waste heat boiler, lowering load of a subsequent dedusting system and reducing equipment maintenance. The invention is applicable to an electric furnace for smelting steel scrap and is also suitable for other smelting containers with smelting characteristics.

Owner:CISDI ENG CO LTD

Cold light source cutting device for processing light-resistant screen

PendingCN112372149APlay a pulling effectStable and stableLaser beam welding apparatusEngineeringLaser cutting

The invention discloses a cold light source cutting device for processing a light-resistant screen, and belongs to the technical field of light-resistant screens. The cold light source cutting devicecomprises a base, wherein a first side plate base is fixedly connected to the top of the base, a first bearing is clamped on the side surface of the first side plate base, and an adapter shaft is sleeved with the first bearing. According to the cold light source cutting device for processing the light-resistant screen, under the mutual cooperation of the designed structures such as a first hot ironing roller, a second hot ironing roller, a cold ironing roller, a pressing plate, a supporting spring, a lifting base, a connecting sleeve, toothed plates, a gear and a connecting frame, a certain pulling effect can be achieved on a to-be-cut light-resistant screen flatly laid on the base, it can be avoided that a cut part deforms under heat and affects the flatness of a non-cut part, it can be avoided that the to-be-cut light-resistant screen deforms under instantaneous overhigh heat when the to-be-cut light-resistant screen is subjected to the action of a cold light source laser cutter, theflatness of the cut part of the cut light-resistant screen can be ensured, and the stability of the light-resistant screen is rapidly stabilized by utilizing cold ironing.

Owner:SHENZHEN POLYTECHNIC +1

Metal surface pretreatment method

InactiveCN109321859AGood removal effectImprove processing efficiencyMolten spray coatingForeign matterPretreatment method

A metal surface pretreatment method comprises the following steps that after a metal surface of a metal workpiece is subjected to degreasing treatment, supersonic flame spraying equipment is used forconducting sandblasting roughening treatment, thus, the metal surface is uniformly roughed, and then the metal surface is sprayed with a coating, wherein a sandblasting roughening treatment method comprises the steps that ignition is conducted according to procedures of the supersonic flame spraying equipment, the flame temperature is adjusted to be lower than the melting point of sand, a powder feeder with sand is started, thus, a spraying gun is kept away from the metal surface of the metal workpiece by a certain distance, then the metal workpiece is driven to rotate, and the spray gun is moved relative to the metal surface at a certain speed for spraying. By ingeniously using the supersonic flame spraying equipment for conducting the sandblasting roughening treatment, oxide skins and other foreign matter on the metal surface are quickly removed, hot sand achieves a good preheating effect during sandblasting, time is further saved, and cost is further reduced. Moreover, the roughnessof the treated metal surface is quite uniform, and damage to the metal surface is slight.

Owner:GUANGDONG INST OF NEW MATERIALS

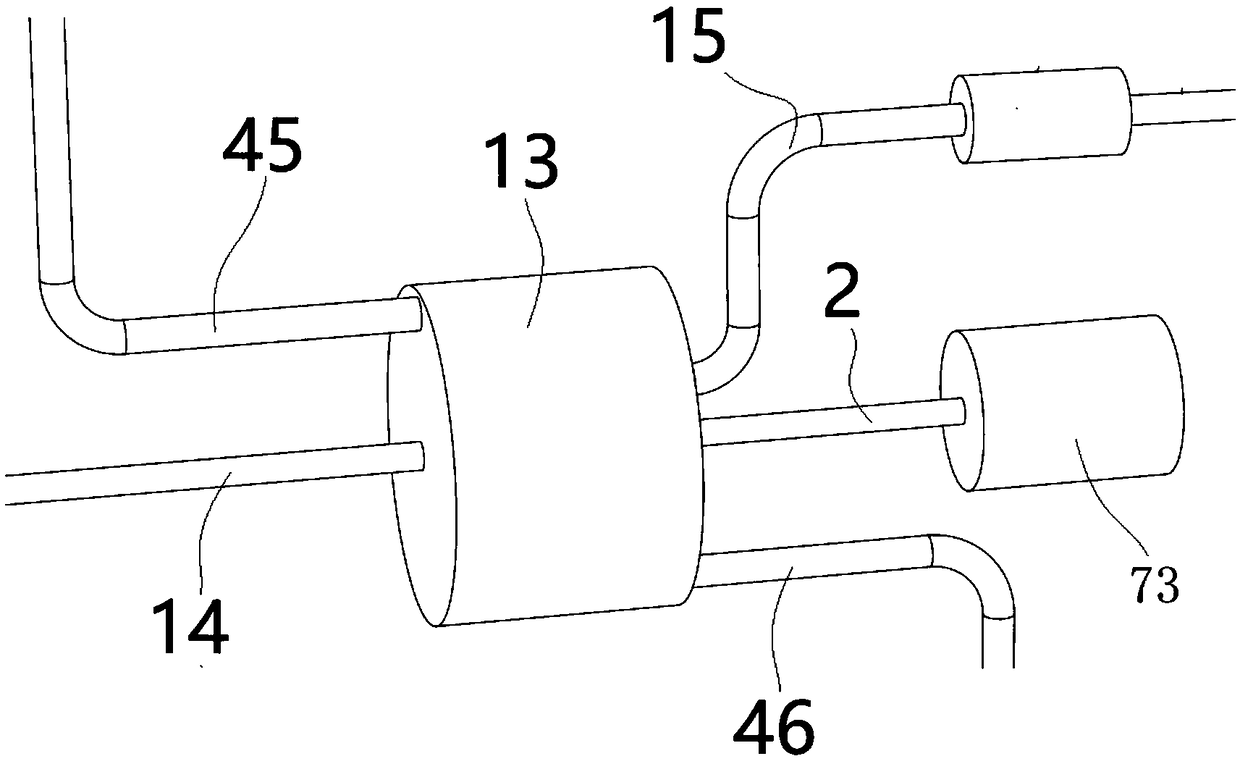

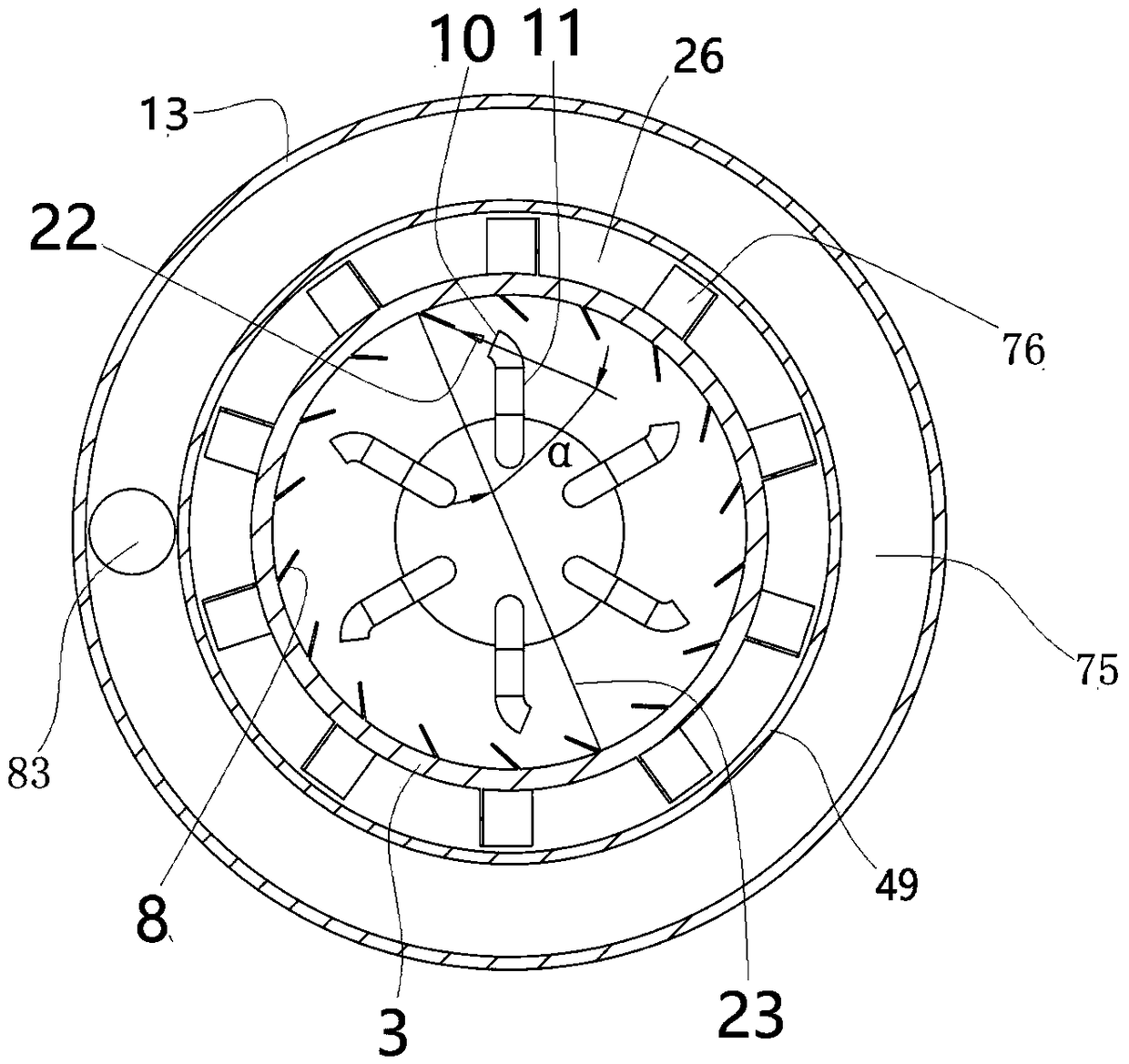

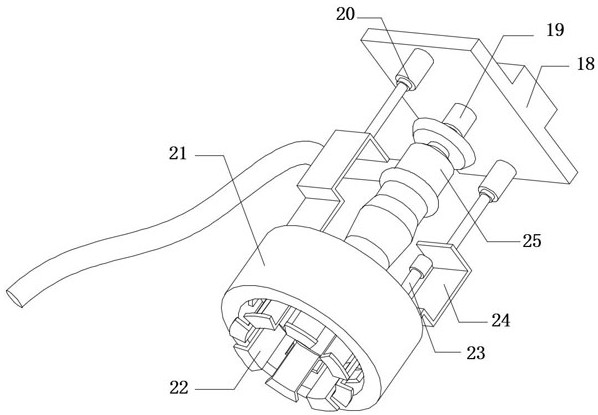

Power generation device of new-energy vehicle and method thereof

ActiveCN108825340APlay a warm-up effectMake full use of waste heatInternal combustion piston enginesExhaust apparatusImpellerNew energy

The invention discloses a power generation device of a new-energy vehicle. The power generation device of the new-energy vehicle comprises a cylindrical inner shell. An inner cavity of the inner shellis a tail gas energy-converting cavity. A rotating impeller is coaxially arranged in the tail gas energy-converting cavity. The rotating impeller is of a ring body cylindrical structure coaxial withthe tail gas energy-converting cavity. A smoke heat exchange channel is formed between the rotating impeller and the inner wall of the inner shell. The rotating impeller sequentially comprises a leftring body, a middle ring body and a right ring body in the axial direction, wherein the left ring body, the middle ring body and the right ring body are connected in an integrated manner. The power generation device of the new-energy vehicle is simple in structure, in the process that air sequentially passes through a left ring cavity, a middle ring cavity and a right ring cavity, a large amount of heat released by high-temperature tail gas in the inner shell is absorbed by the air flowing in the left ring cavity, the middle ring cavity and the right ring cavity, and then the effect of preheating the air which is about to enter an intake valve of an engine is achieved.

Owner:蒋祥初

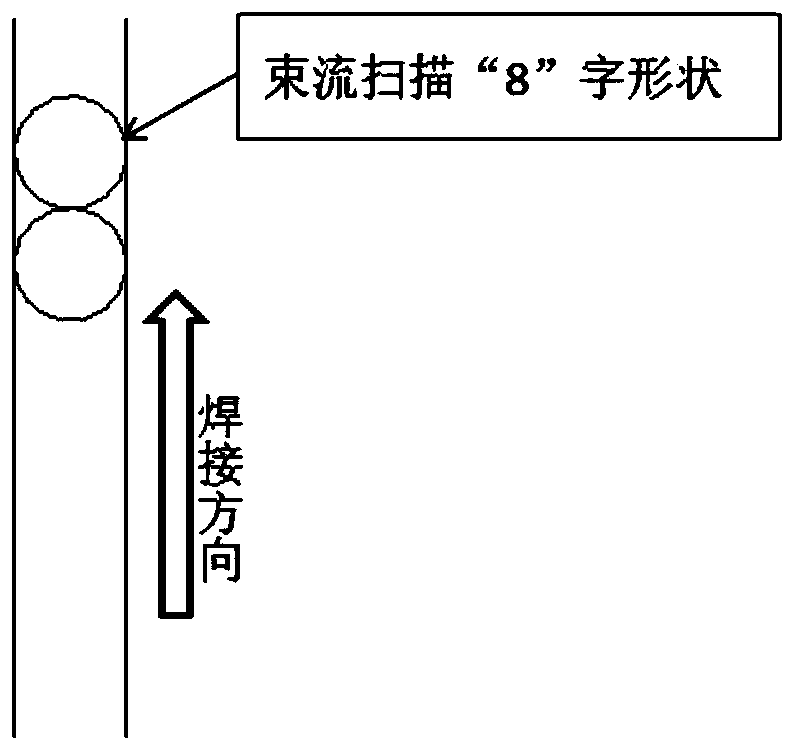

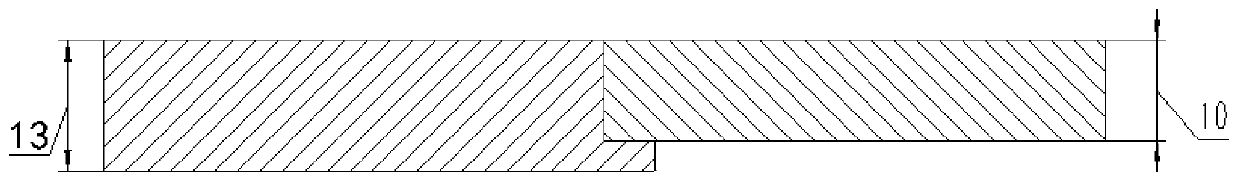

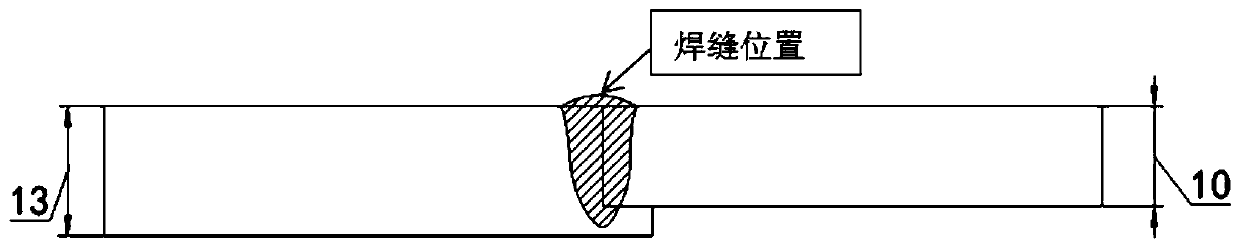

Welding method for eliminating pore defects of aluminum alloy electron beam weld joint

PendingCN111014927AReduce defectsWide applicabilityElectron beam welding apparatusWelding/soldering/cutting articlesElectron bunchesAluminium alloy

The invention provides a welding method for eliminating pore defects of an aluminum alloy electron beam weld joint. The vacuum electron beam welding method is applied to the welding method, welding isperformed through electron beams in the form of swing scanning, an 8-shaped scanning trace serves as a repeating unit in a scanning trajectory formed through swing scanning, and the scanning trajectory is formed by arraying the 8-shaped scanning traces in a staggered mode, wherein the longitudinal direction of the 8-shaped scanning traces is the direction of the weld joint, and the transverse direction of the 8-shaped scanning traces is perpendicular to the direction of the weld joint. The welding method is suitable for materials with large pinhole inclination and poor compactness caused whencast aluminum alloy absorbs hydrogen due to the addition of a strontium alterant, can also be suitable for welding ordinary cast aluminum alloy, is wide in application range, has a magnificent effectof eliminating pores, and greatly enhances the tensile strength of the weld joint.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

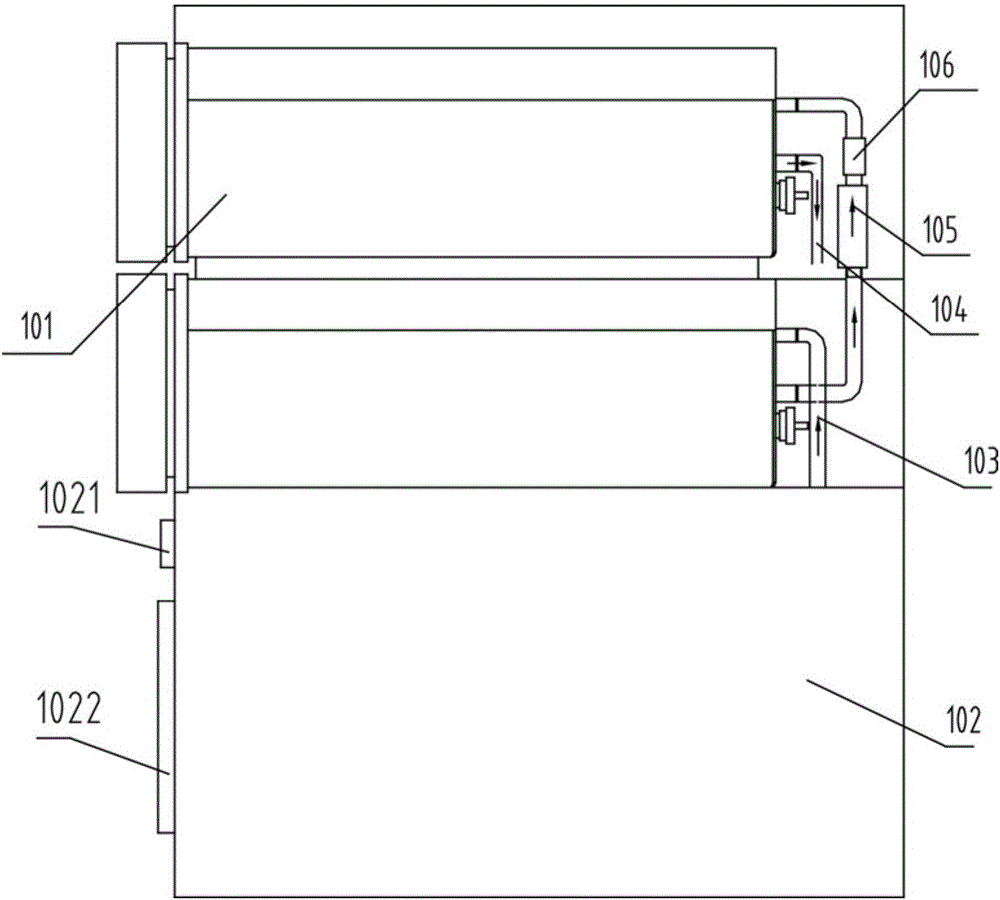

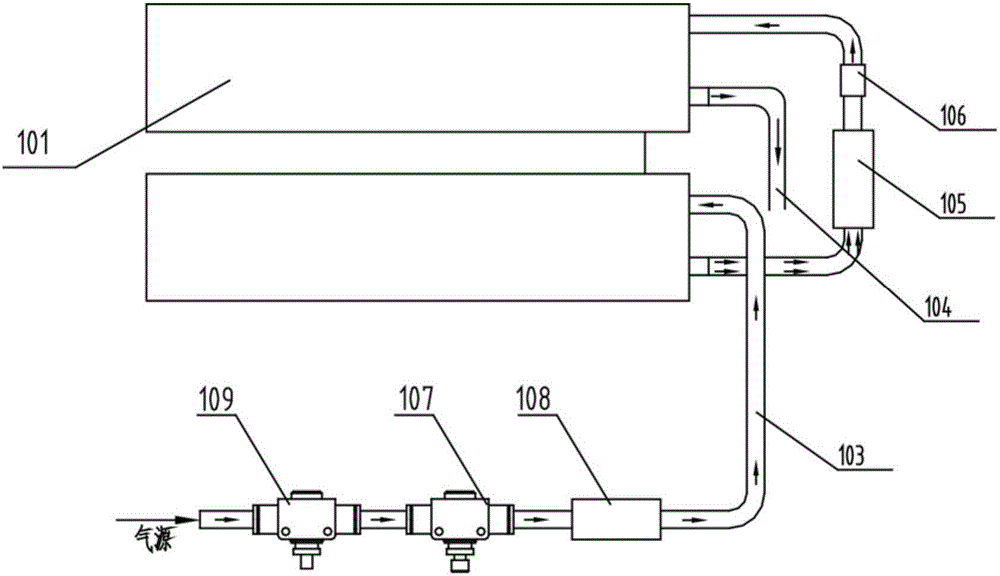

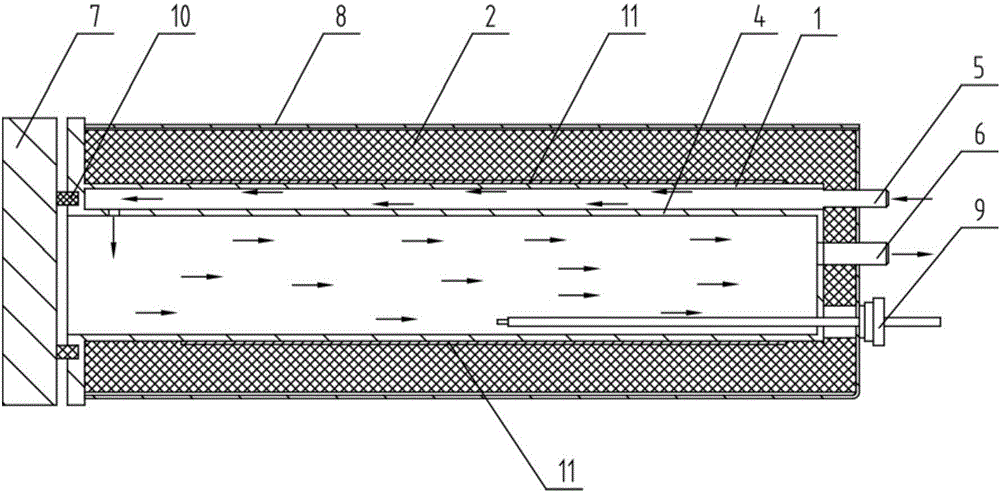

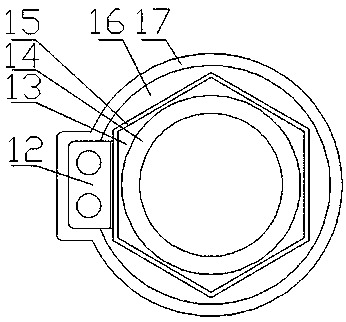

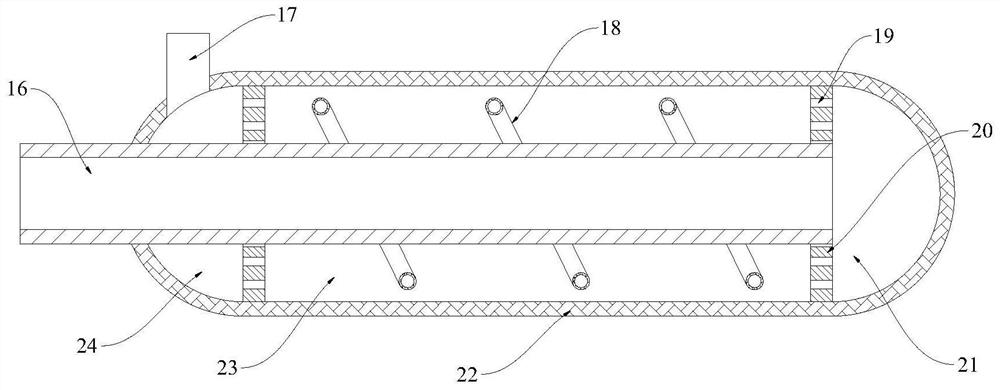

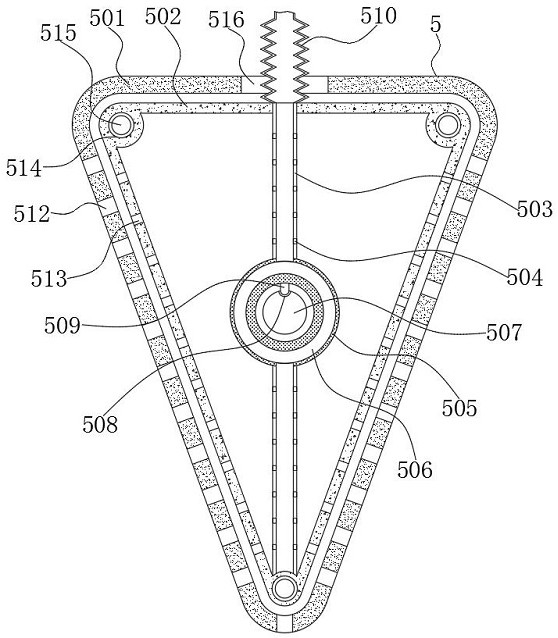

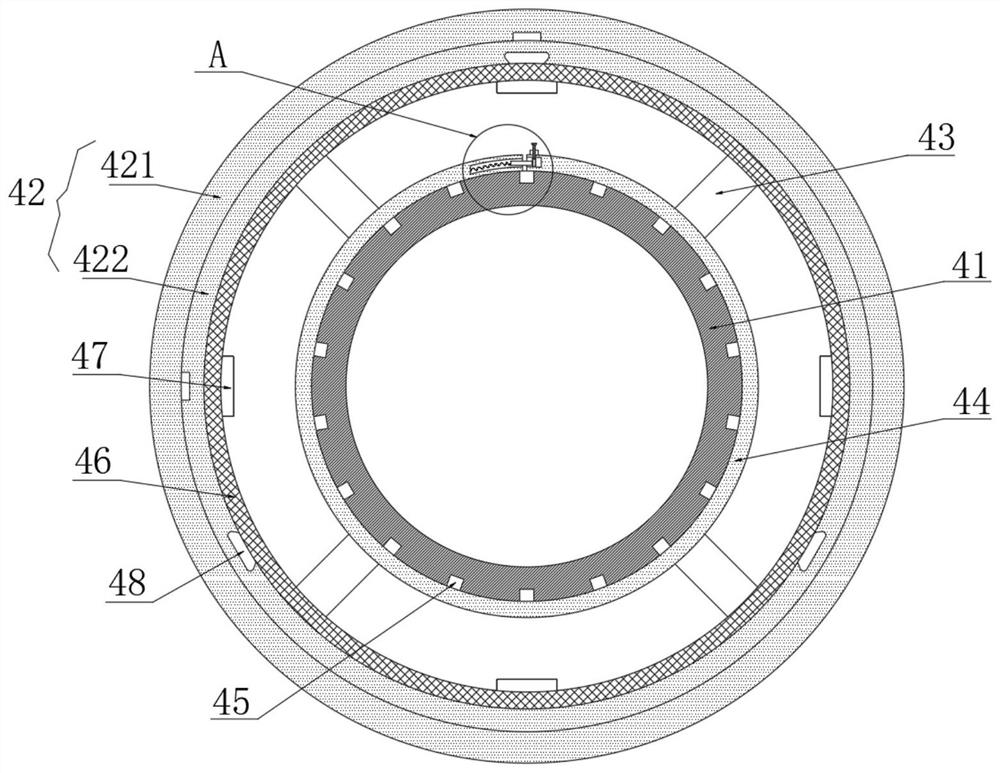

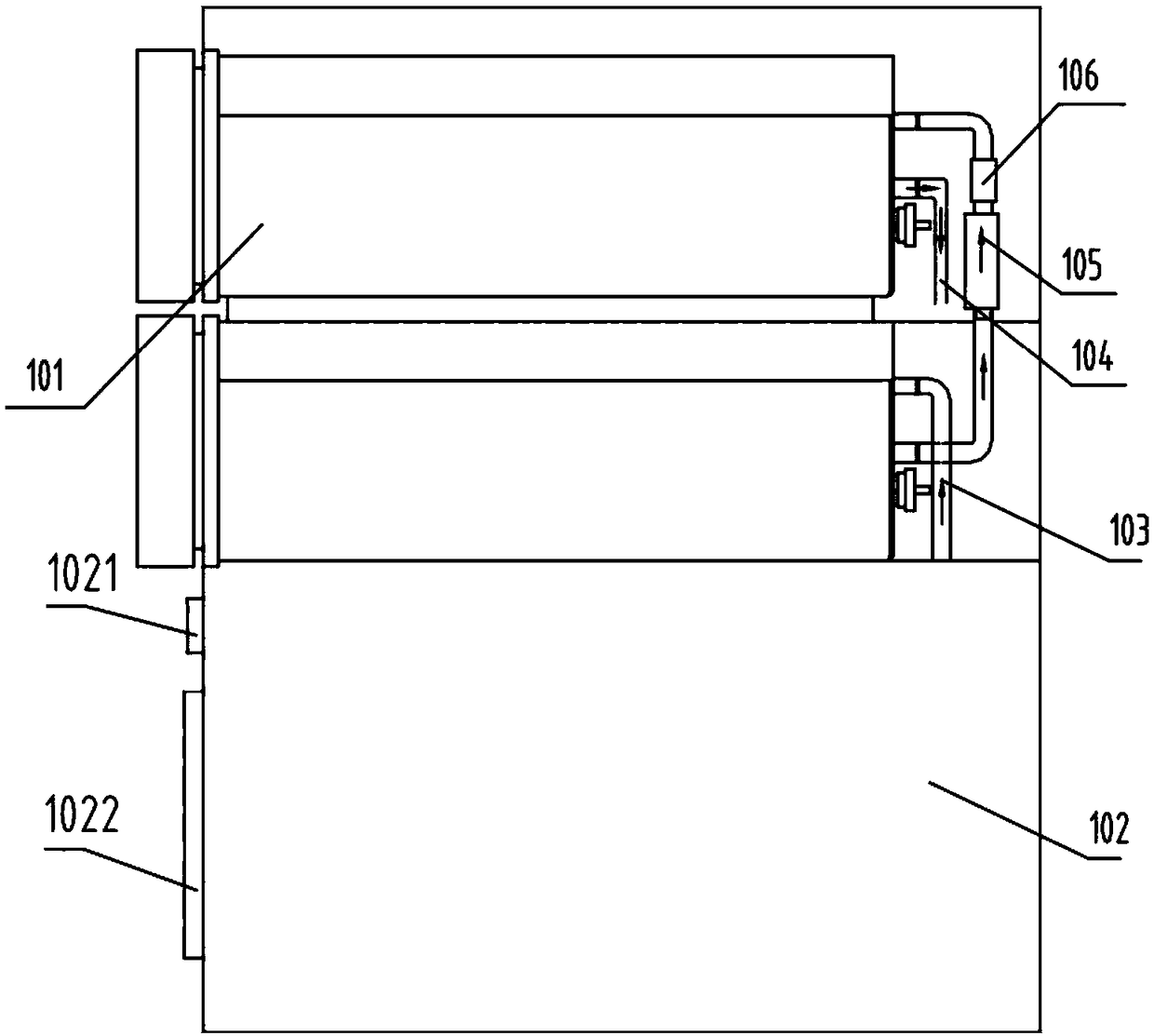

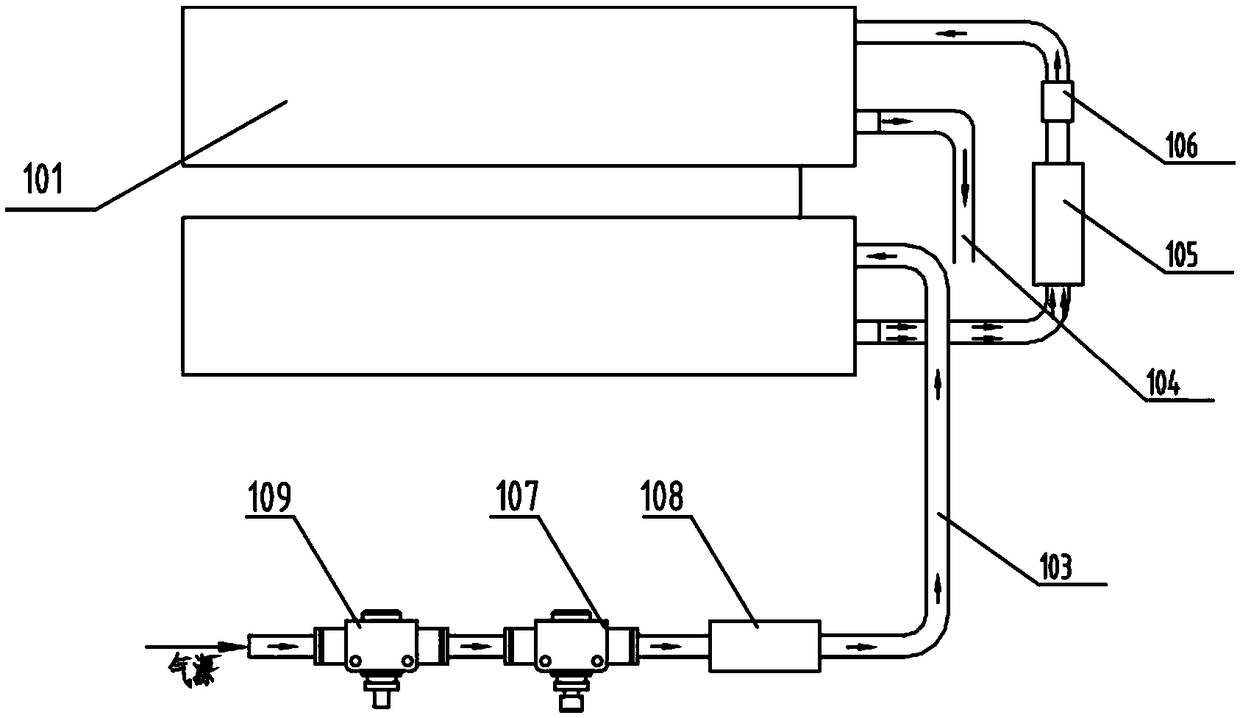

Temperature control component, temperature control pipe and heat management system for lithium battery pack

PendingCN107681226ATemperature controlThe temperature is suitable for regulationCell temperature controlBatteriesTemperature controlHeat management

The invention discloses a temperature control component, temperature control pipe and heat management system for a lithium battery pack. The temperature control component is a multi-layer pipe and issequentially provided with an internal water pipe, a heat-conducting filler, a PTC heating panel, a glue filler and a packaging housing from inside to outside; and a PTC heating control panel is arranged between the PTC heating panel and the packaging housing. The heat management system comprises at least two or more oppositely arranged liquid cooling plates; each liquid cooling plate is providedwith a water inlet and a water outlet separately; a water inlet pipe and a water outlet pipe communicate with each other, are arranged on connection parts of the oppositely arranged liquid cooling plates in parallel and are connected with corresponding water inlets and water outlets in the liquid cooling plates; and the temperature control component for the lithium battery pack is arranged on thewater inlet pipe. According to the temperature control component, the temperature control pipe and the heat management system for the lithium battery pack, the temperature in the lithium battery packcan be effectively controlled, the temperature uniformity of battery units at different positions in the lithium battery pack is achieved and the service life of the lithium battery pack is prolonged.

Owner:苏州正力新能源科技有限公司

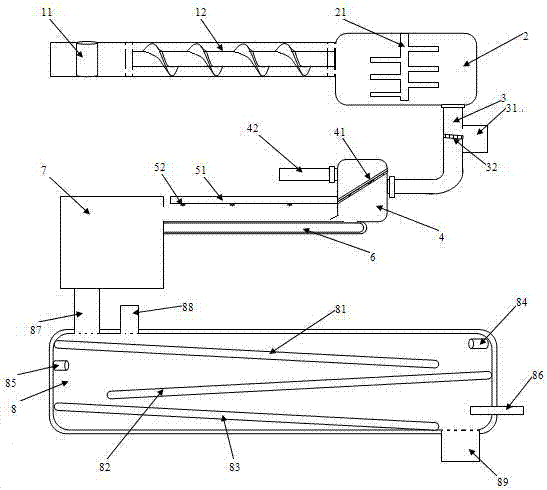

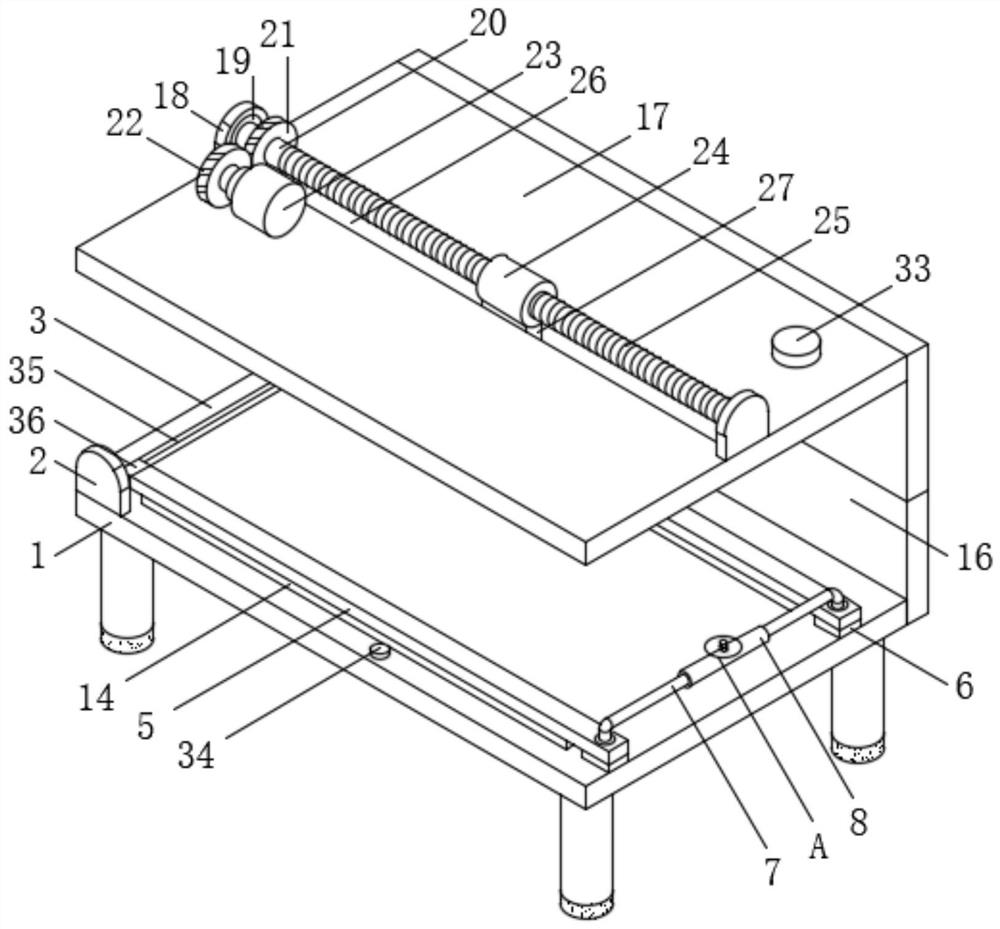

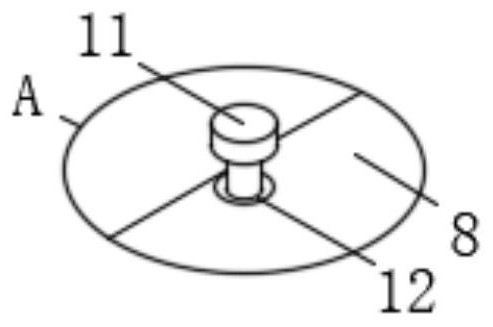

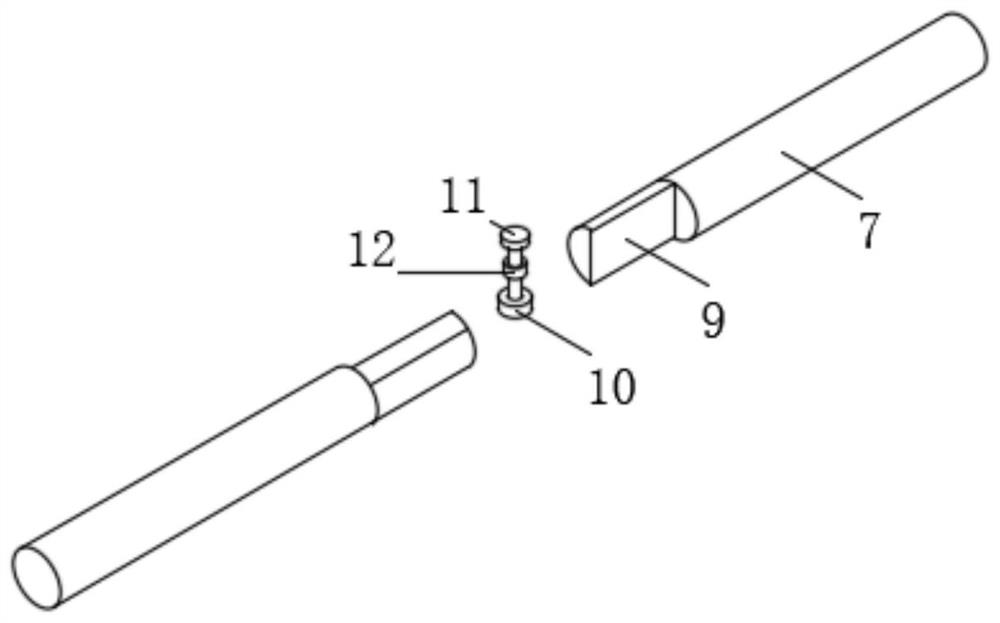

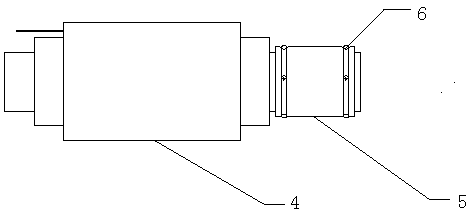

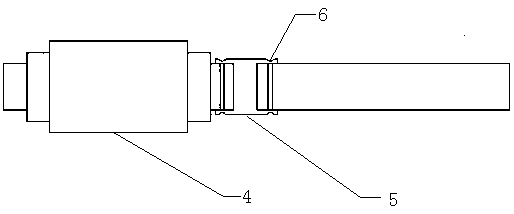

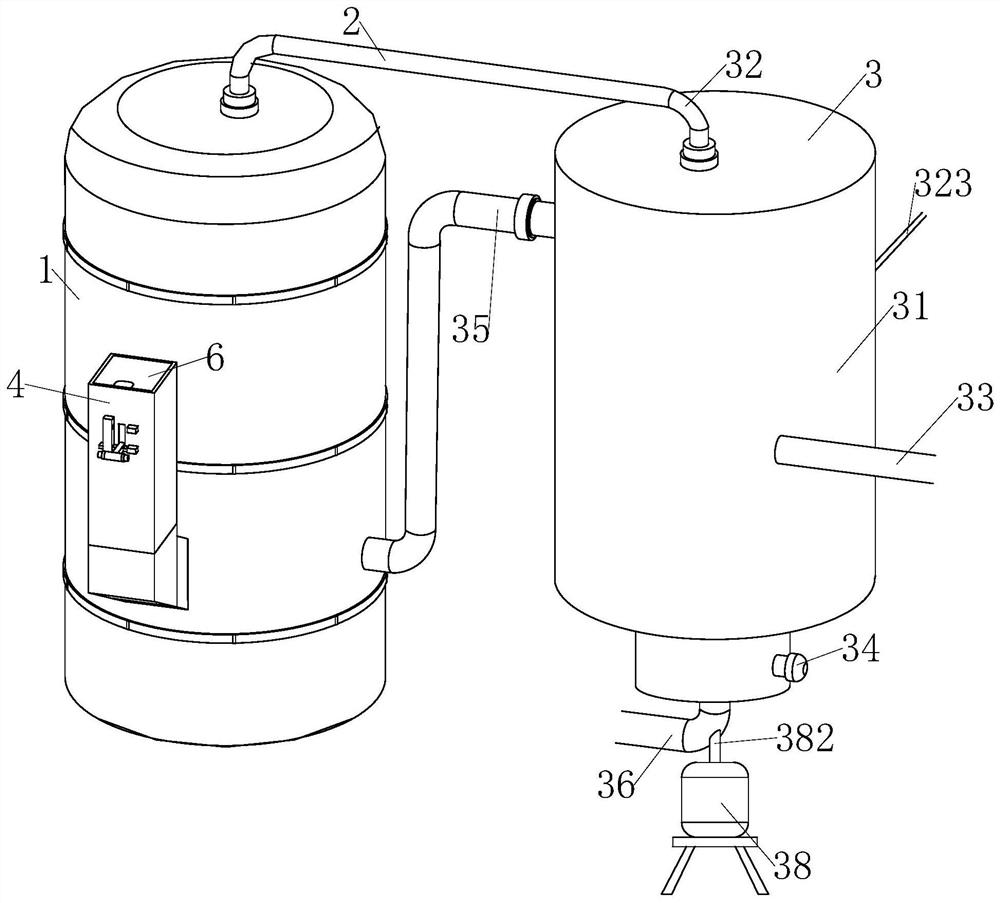

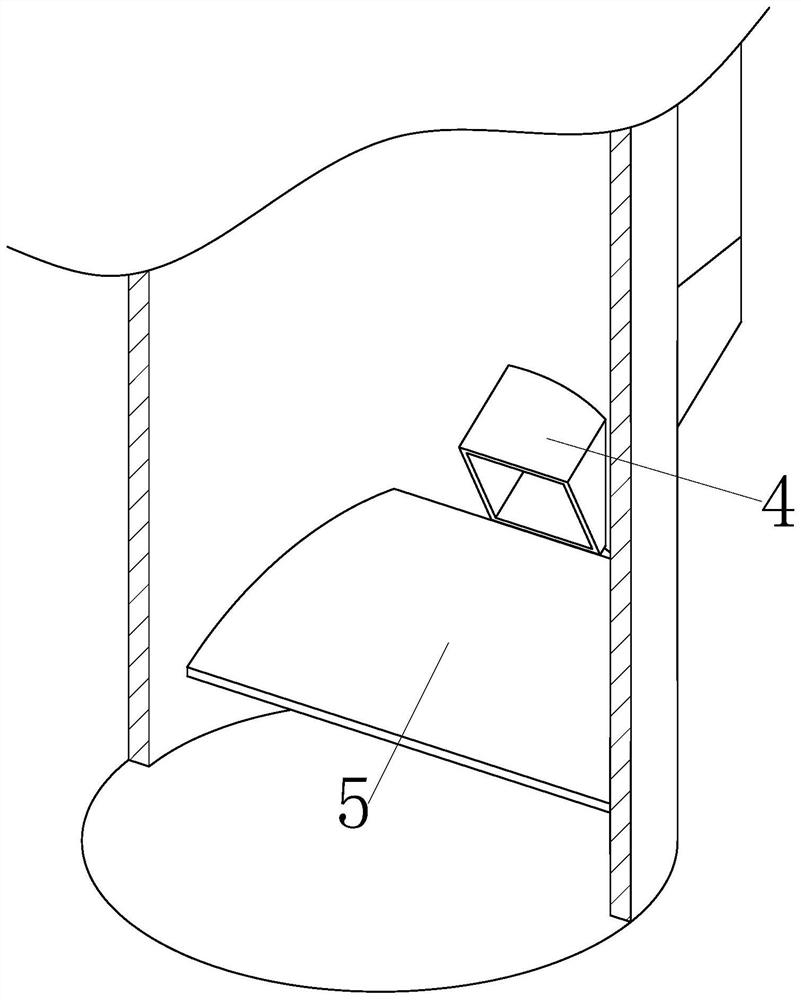

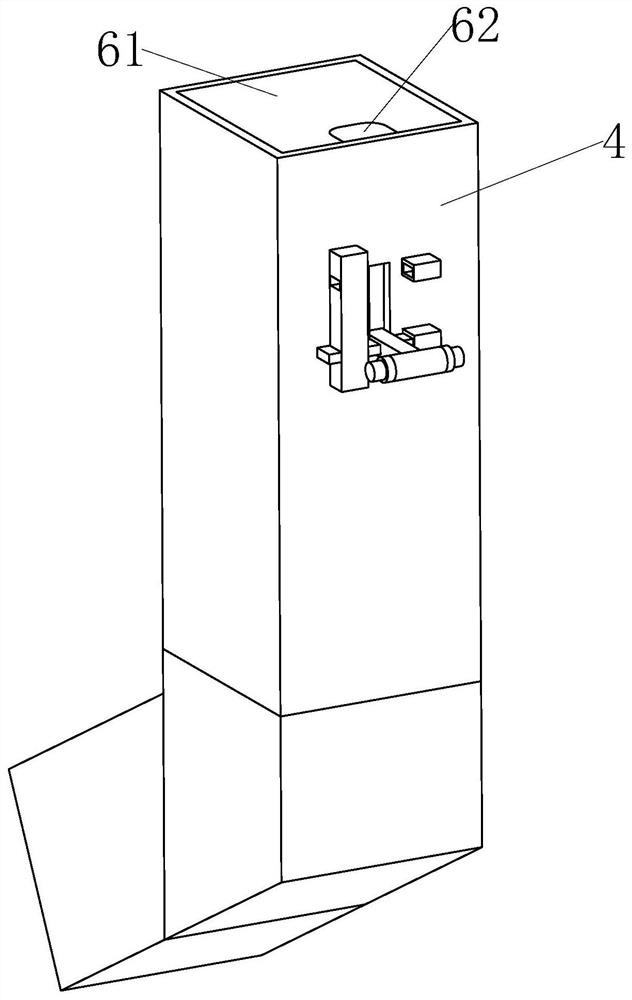

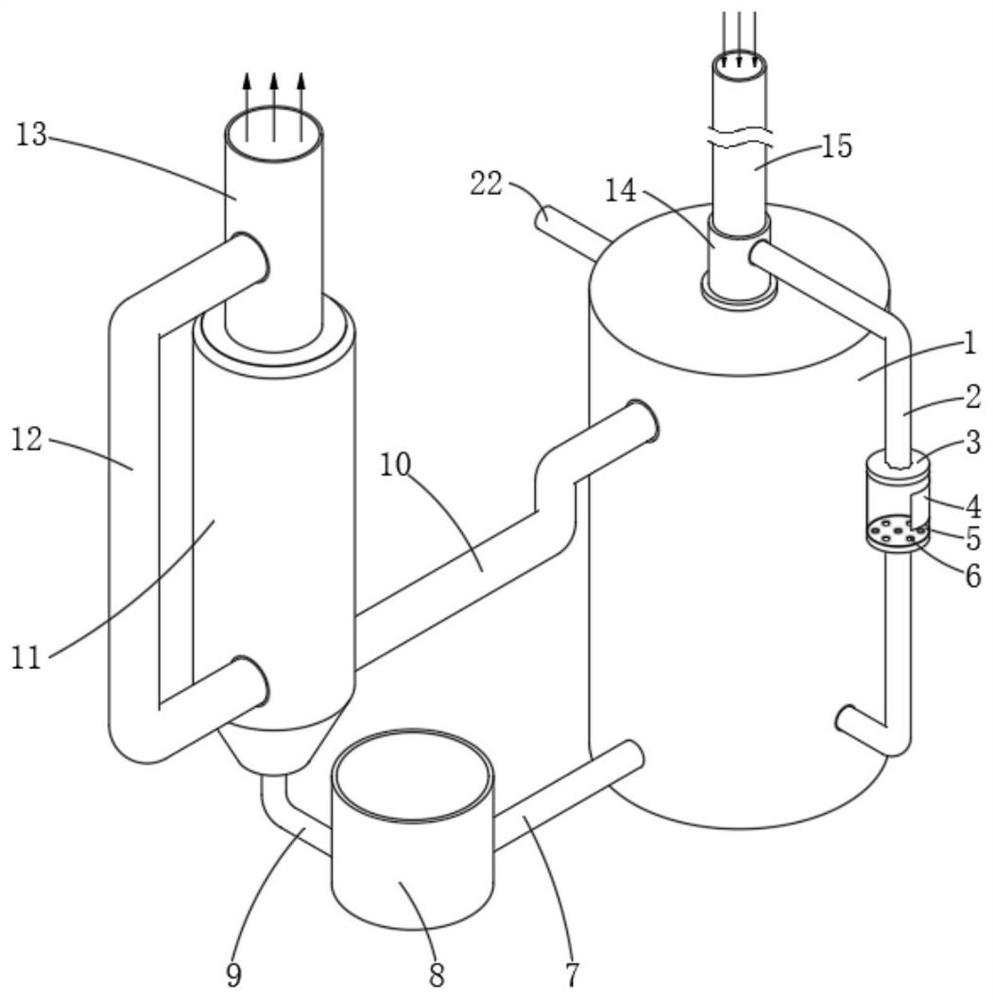

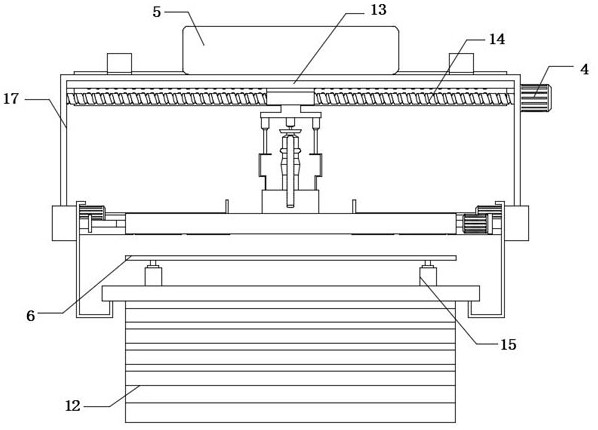

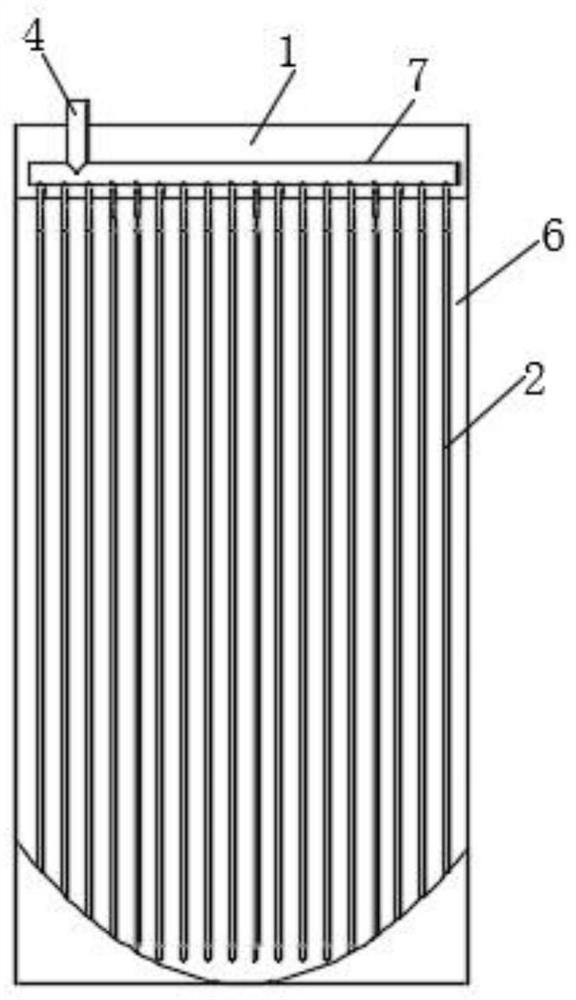

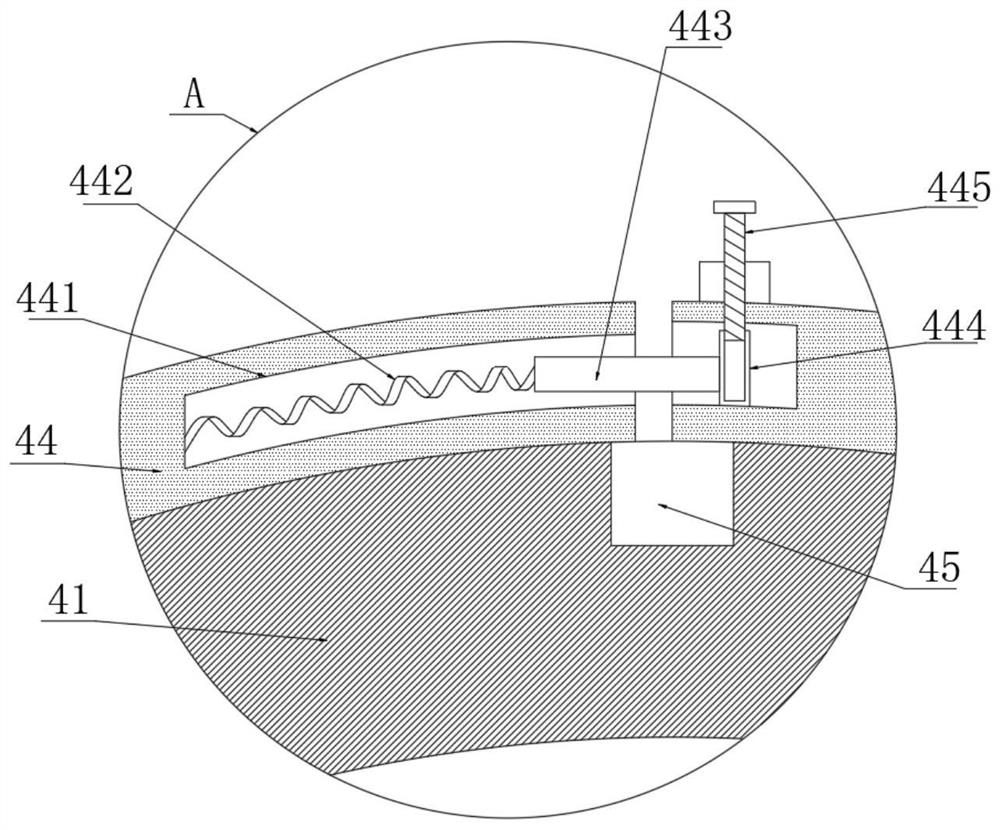

Feeding pipe preheating device of molecular distillation equipment

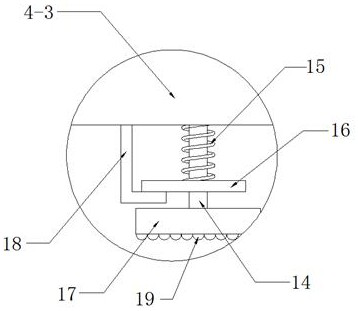

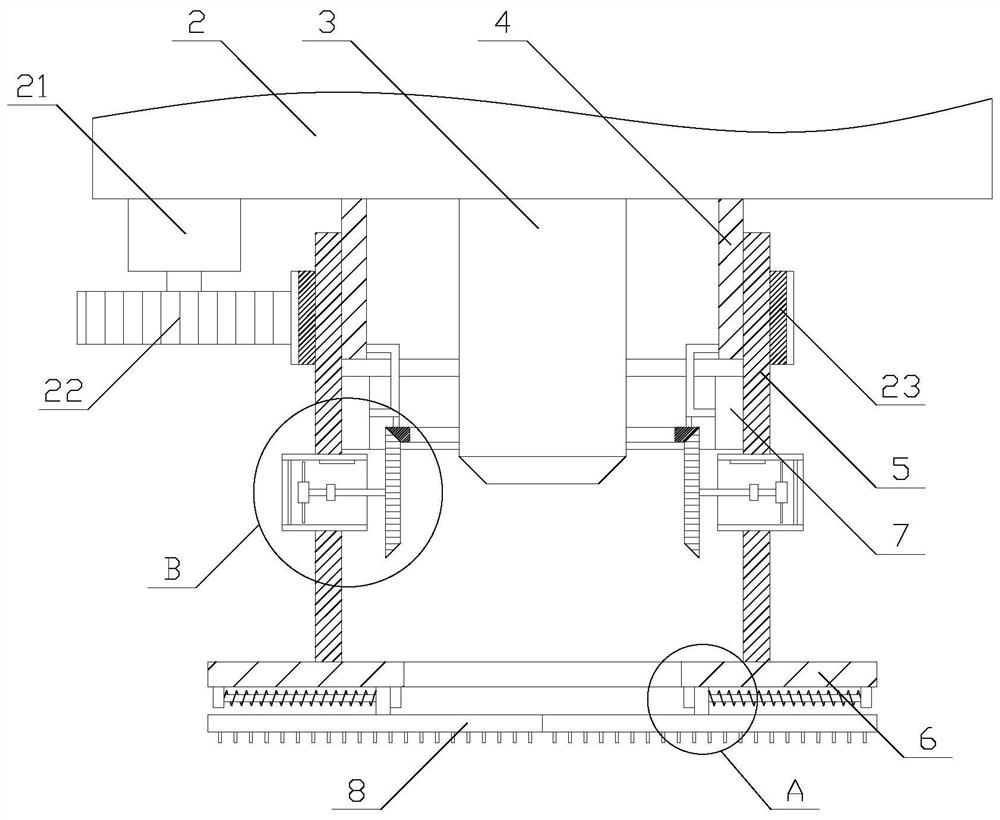

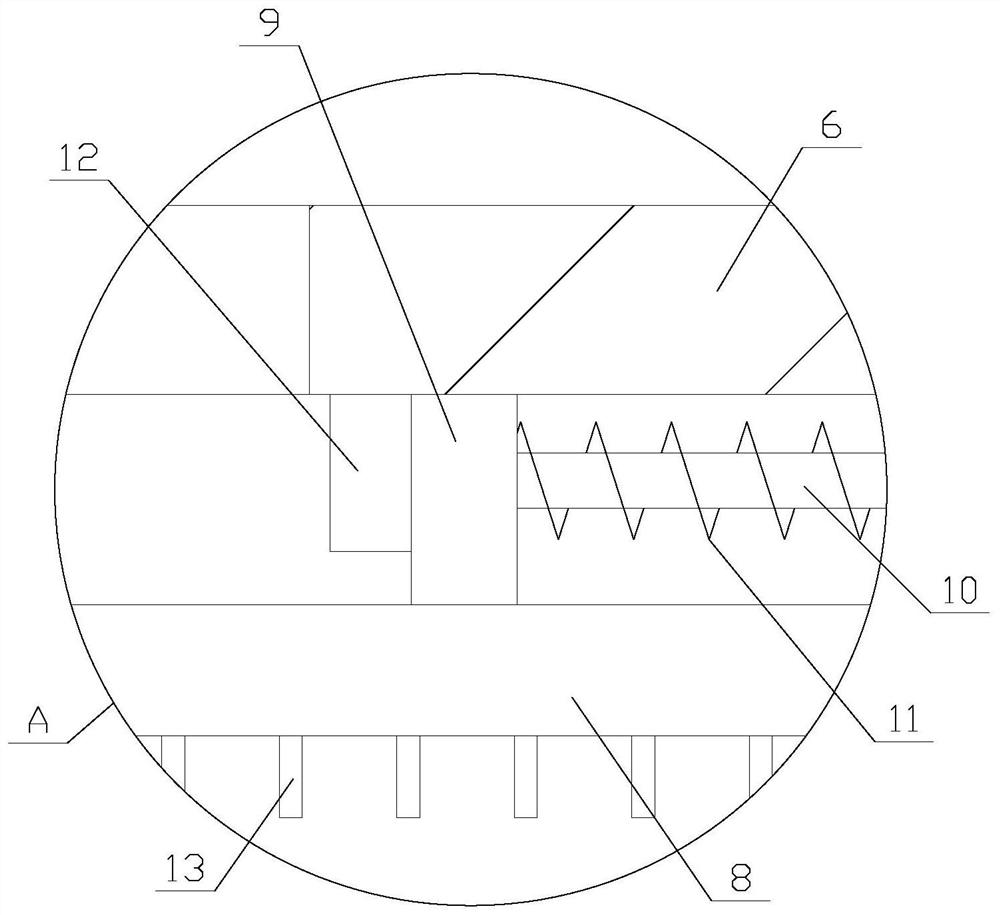

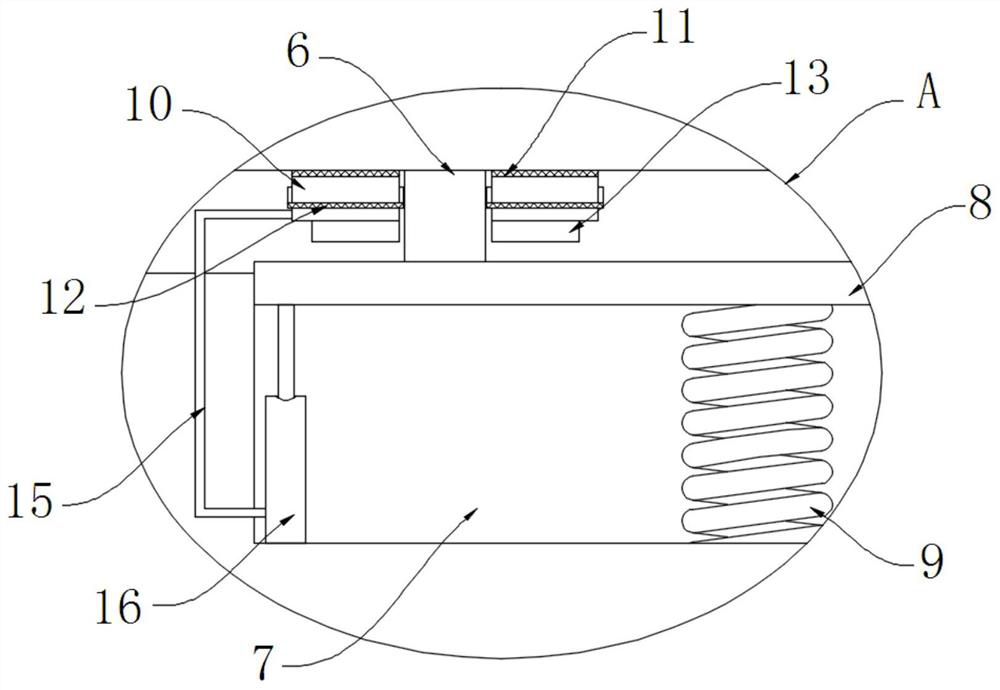

ActiveCN111760318APlay a warm-up effectCause damageMolecular distillationStationary tubular conduit assembliesBuffer tankMechanical engineering

The invention discloses a feeding pipe preheating device of molecular distillation equipment, and belongs to the technical field of molecular distillation equipment. A shaft sleeve on one side wall ofan upper fixing plate is connected with a shaft sleeve on one side wall of a lower fixing plate through a shaft pin; the lower fixing plate is arranged on the lower side of the upper fixing plate; the upper fixing plate and the lower fixing plate are both set to be a semi-cylindrical shape; the upper fixing plate and the lower fixing plate are spliced into a cylinder; a first connecting piece isfixed to the other side wall of the upper fixing plate; the first connecting piece is fixed to a second connecting piece through a bolt; the second connecting piece is fixed to the other side wall ofthe lower fixing plate; a plurality of preheating mechanisms are arranged between the lower fixing plate and the upper fixing plate at equal angles; and a supporting mechanism is arranged on the lowerside of the lower fixing plate; when a feeding pipe is connected with a heavy component buffer tank and the molecular distillation equipment, the feeding pipe is wrapped by part of heat in the heavycomponent buffer tank, so that the preheating effect on the feeding pipe is achieved. The feeding pipe preheating device has the advantages of reasonable arrangement, low manufacturing cost and the like.

Owner:CHANGZHOU TIANMA GROUP CO LTD

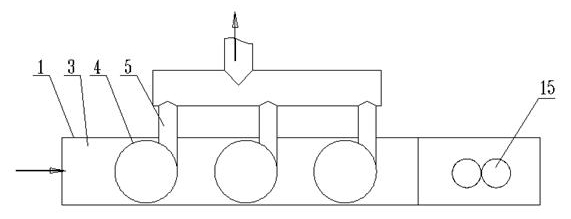

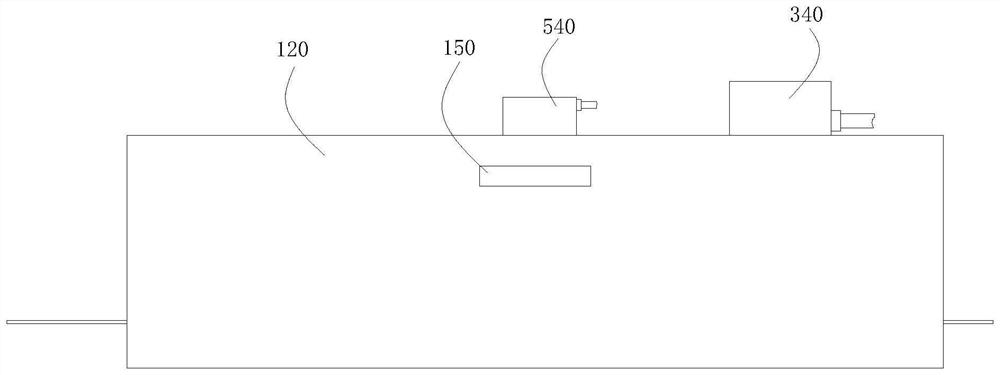

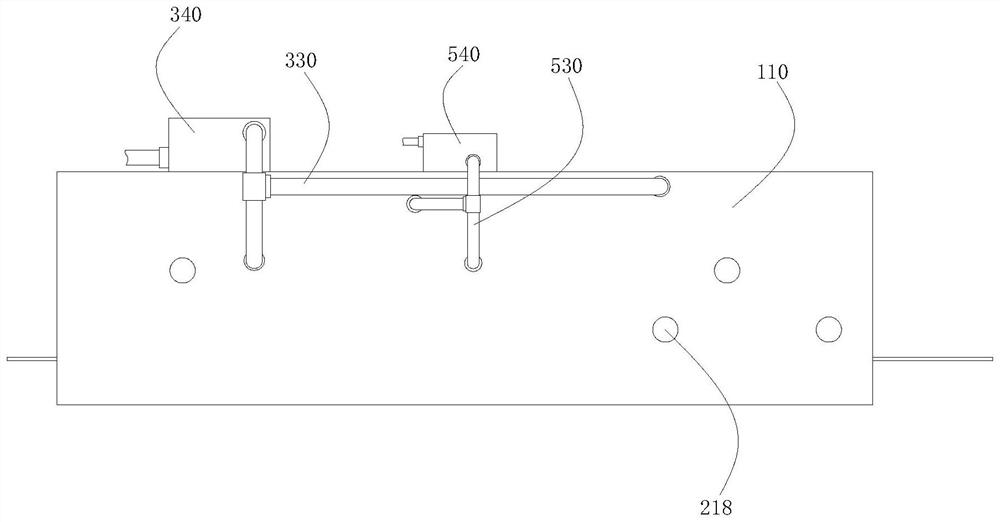

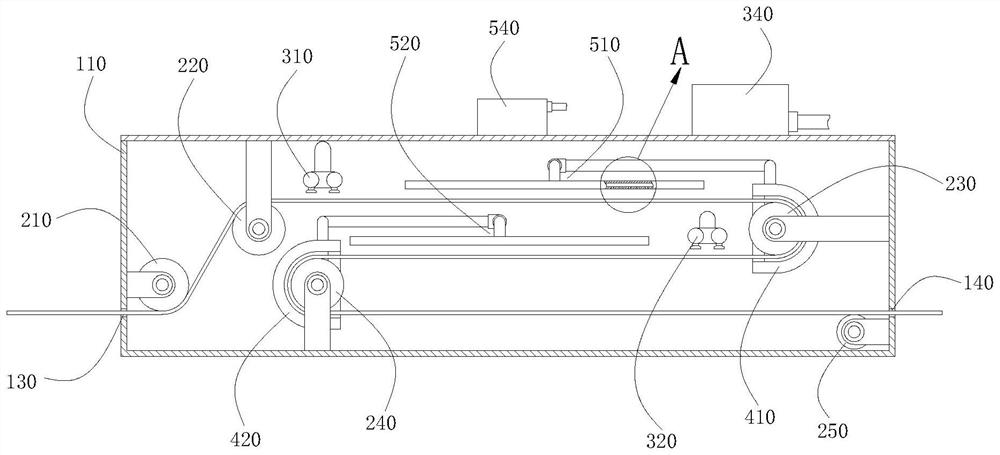

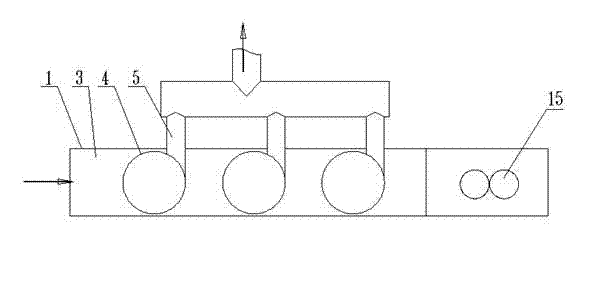

Spraying device for aluminum strip continuous production line

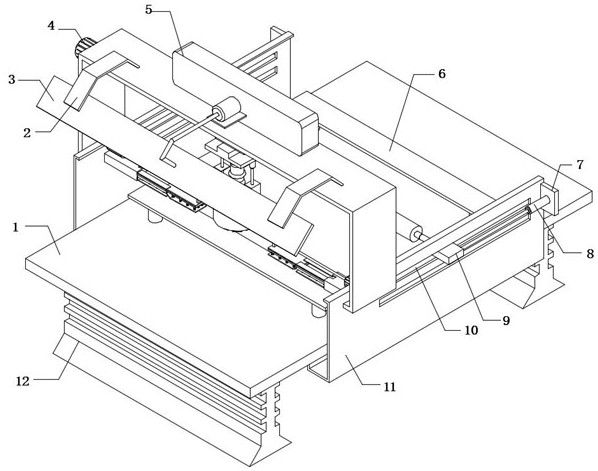

According to the spraying device for the aluminum strip continuous production line, the first supporting roller, the second supporting roller, the third supporting roller, the fourth supporting roller and the fifth supporting roller are erected in the box body, and an aluminum strip entering through the feeding port bypasses the lower portion of the first supporting roller and bypasses the top of the second supporting roller and the top of the third supporting roller; and finally, the material passes through the top of the fifth supporting roller and is discharged from the discharging opening. The first spraying pipe is used for spraying the upper strip surface of the aluminum strip, and the second spraying pipe is used for spraying the lower strip surface of the aluminum strip; through the design of a first suction cover, a second suction cover, a second collecting pipe and a suction pump, the mode that air flow on the surface of the aluminum strip is accelerated through suction is adopted, and therefore the mild air drying effect is achieved; and a first light curing mechanism is arranged on the outer side of the third supporting roller, a second light curing mechanism is arranged on the outer side of the fourth supporting roller, the outer side of the bent area of the aluminum strip is subjected to covering irradiation, a coating is reinforced and dried through a UV light pipe, and the drying effect of the coating is improved.

Owner:清远市邦丽特金属制品有限公司

Catalytic low-energy-consumption waste gas treatment equipment

ActiveCN113230877AIncrease contact areaEffective filteringCombination devicesGas treatmentCombustion chamberEmission standard

Disclosed catalytic low-energy-consumption waste gas treatment equipment comprises a spraying chamber, an adsorption chamber, a combustion chamber and a photocatalysis chamber, a gas inlet formed in one side of the spraying chamber is connected with a waste gas inlet pipe, and a gas outlet formed in the other side of the spraying chamber is connected with a gas inlet of the adsorption chamber through a gas outlet pipeline; and a gas outlet of the adsorption chamber is connected with a gas inlet of the combustion chamber through a combustion pipeline, a gas outlet of the combustion chamber is connected with the photocatalysis chamber through a catalysis pipeline, meanwhile, a branch pipeline is arranged on the catalysis pipeline, and the catalysis pipeline is connected with the adsorption chamber through the branch pipeline. Treated waste gas can reach the emission standard, no pollution is caused, and meanwhile, the energy consumption can be effectively reduced.

Owner:江苏亿超环境科技有限公司

Welding device with air purification function

InactiveCN111872553APlay a warm-up effectAvoid burnsLaser beam welding apparatusEngineeringErbium lasers

The invention relates to a welding device with an air purification function. The device comprises a workbench, a control box and a laser device, wherein the control box is arranged above the workbenchand fixedly connected with the workbench, the laser device is arranged at the bottom of the control box, an execution system is arranged in the control box, and a purification mechanism and an auxiliary mechanism are arranged at the bottom of the control box; the auxiliary mechanism comprises a fixed pipe, a rotating pipe, a rotating ring, a first bearing, a driving assembly and two auxiliary assemblies; each auxiliary assembly comprises a cleaning rod, a sliding block, a supporting rod, a spring and two fixed blocks; and the purification mechanism comprises a fixed bevel gear and two purification assemblies. According to the welding device with the air purification function, the function of removing impurities on a workpiece is achieved through the auxiliary mechanism, so that the welding effect is prevented from being affected by the impurities; and in addition, the air purification function is achieved through the purification mechanism.

Owner:GUANGZHOU LINDIAN TECH CO LTD

Air filtering device of automobile air conditioner and using method thereof

InactiveCN112572103AReduce pollutionEffective filteringAir-treating devicesDispersed particle filtrationAir filtrationAir filter

The invention relates to an air filtering device of an automobile air conditioner. The device comprises an inlet pipeline, an air filter mounting shell, an air filter, a volute shell and an air blower, wherein the air filter mounting shell is arranged in the inlet pipeline, the air filter is arranged on the air filter mounting shell, and the air blower is arranged on the volute shell; the inlet pipeline is provided with an external air inlet and a passenger cabin air inlet, an air inlet switching door is arranged in the inlet pipeline and located between the external air inlet and the passenger cabin air inlet, the inlet pipeline is provided with a second passenger cabin air inlet, and the second passenger cabin air inlet is located below the passenger cabin air inlet; the second cabin airinlet is provided with a hoist, which can selectively open or close the second cabin air inlet. Compared with the prior art, the device is advantaged in that heating efficiency of the automobile airconditioner is improved through preheating, the automobile air conditioner is simple in structure, production cost is reduced, and the automobile assembling time is shortened.

Owner:林凯

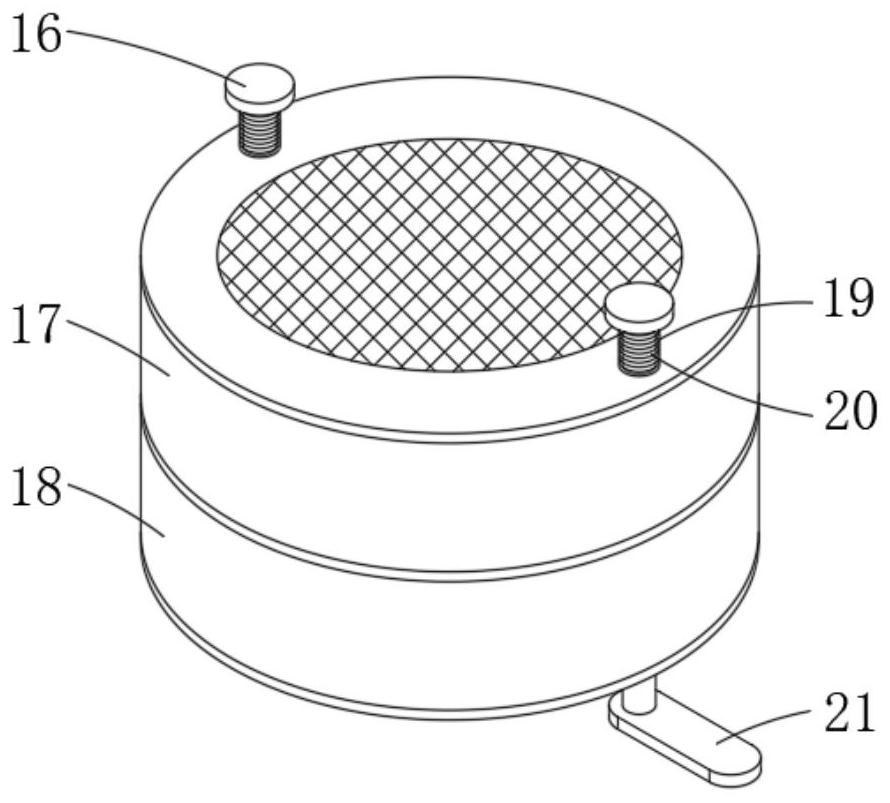

Self-locating and rapid cooling structure for cold pressing machine

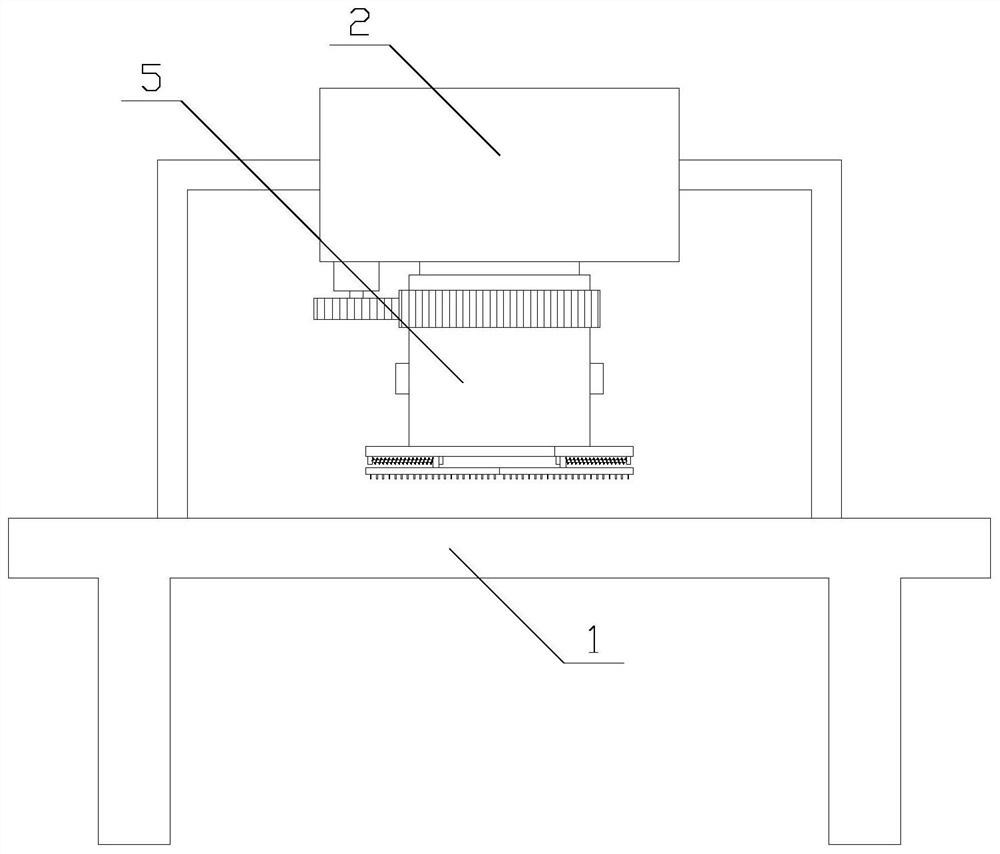

ActiveCN111633779AAvoid secondary adjustmentsNo displacementWood working apparatusFlat articlesEngineeringMechanical engineering

The invention discloses a self-locating and rapid cooling structure for a cold pressing machine. The self-locating and rapid cooling structure comprises an outer frame and multiple oil cylinders. A hydraulic lifting rod is connected into each oil cylinder. The multiple hydraulic lifting rods are connected with a pressing plate together. A fixing platform is arranged on the portion, directly facingthe pressing plate, of the outer frame. A fixing structure is connected into the fixing platform. The fixing structure comprises a ring-shaped channel formed in the fixing platform. The other side ofthe ring-shaped channel is provided with a negative pressure cavity formed in the inner wall of the outer frame in a penetrating manner. A sealing plate is connected into the negative pressure cavityin a sealing and sliding manner. The structure has the advantages that by means of the vacuum effect of the negative pressure groove, a plate body, located on a bottom layer, of the fixing platform can be located and strengthened, when the pressing plate moves down, vibrating occurs, but the displacement phenomenon is avoided, the situation that the position of the plate body is adjusted for a second time is avoided, under the magnetothermal effect, rapid cooling and heat absorbing are carried out on a plate to be machined, and local overheating is avoided.

Owner:南通市征荣冷冻设备制造有限公司

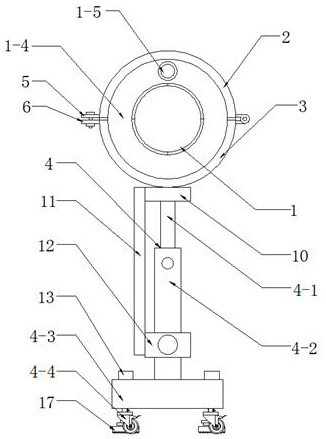

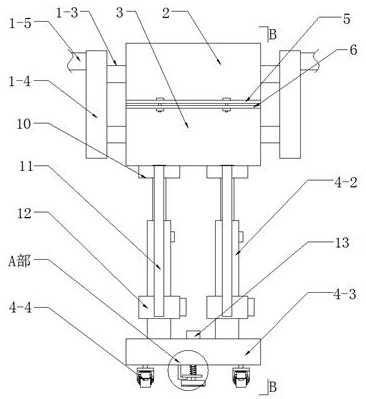

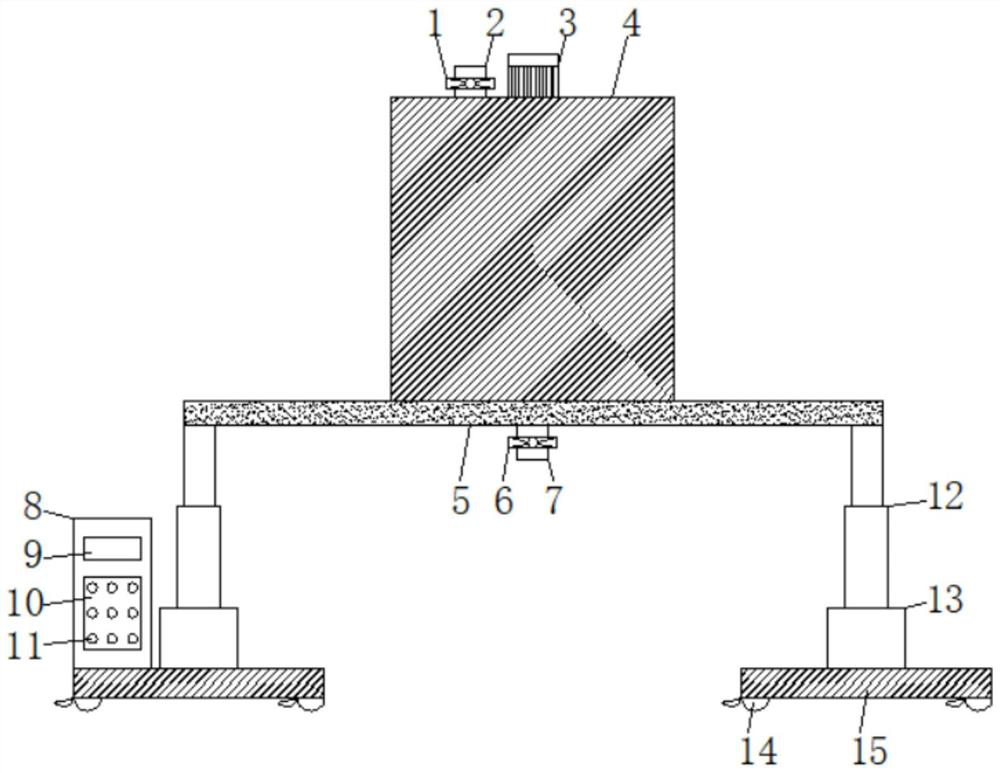

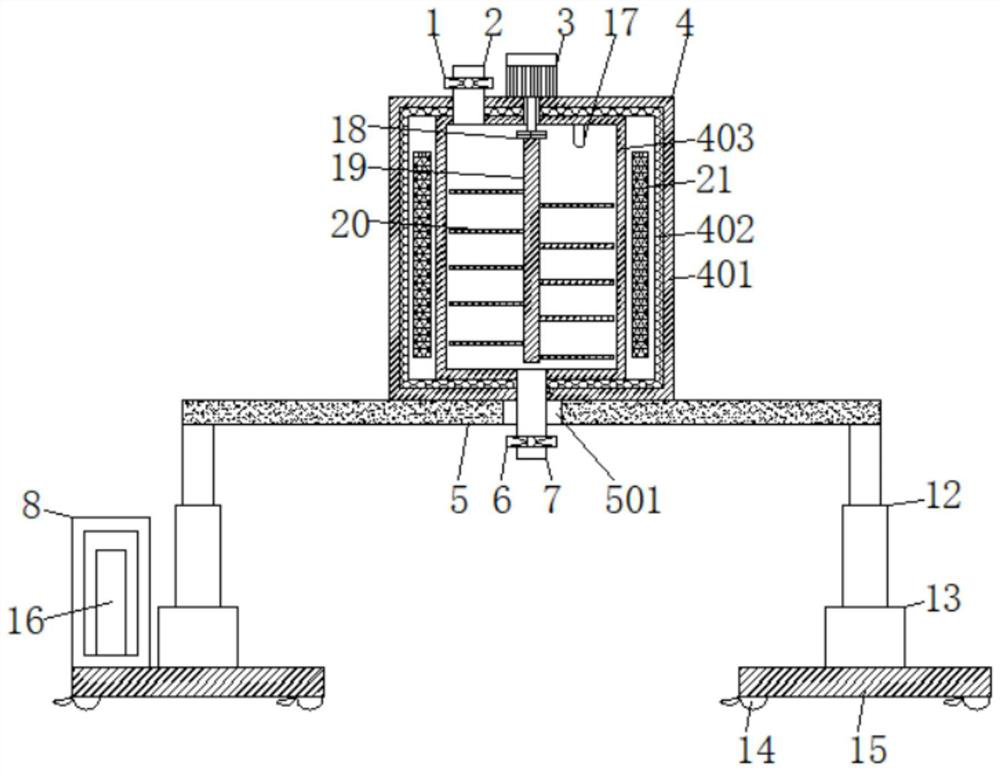

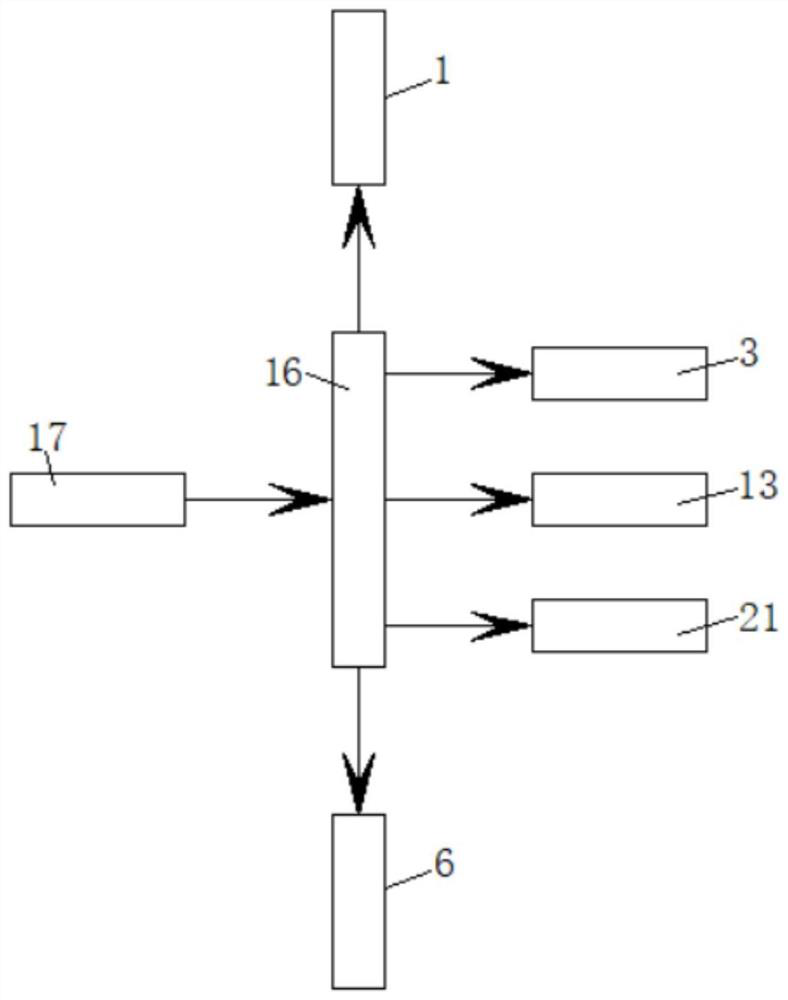

Feeding mechanism of color sand preparation kiln

InactiveCN112146444AImprove work efficiencyReal-time warm-upCharge manipulationPreheating chargesPhysicsElectric heating

The invention discloses a feeding mechanism of a color sand preparation kiln. The feeding mechanism comprises a supporting seat, a shell is installed in the center of the upper surface of the supporting seat, the shell comprises an outer shell, a heat preservation layer and an inner shell, the outer shell, the heat preservation layer and the inner shell are sequentially arranged from outside to inside, an electric heating coil is arranged between the heat preservation layer and the inner shell, a gear motor is installed in the center of the top of the outer shell, an output shaft of the gear motor sequentially penetrates through the tops of the outer shell, the heat preservation layer and the inner shell to be connected with a coupler, the coupler is located in the inner shell, a materiallevel sensor is arranged on one side of the top end in the inner shell, and a feeding pipe is arranged on one side of the top of the inner shell. With the feeding mechanism, the problems that an existing feeding mechanism of the color sand preparation kiln can only realize the feeding function and is single in function are solved, the device is simple in structure, and capable of preheating raw materials, so that the working efficiency is improved, the use and operation are convenient, and the practicability is high.

Owner:CHANGZHOU HONGCHENG SAND

Culvert raw material delivery and smoke dust recovery device

ActiveCN102003876BReduce flow rateIncrease profitProcess efficiency improvementElectric furnaceFlue gasEngineering

The invention discloses a culvert raw material delivery and smoke dust recovery device and method for a smelting container. The device comprises a raw material delivery trough, wherein, the upper part of the raw material delivery trough is equipped with a sealing cover; a raw material delivery and flue gas circulation channel is formed between the sealing cover and the raw material delivery trough; and at least one settling chamber for settling dust in flue gas is communicated above the sealing cover. In the invention, the flue gas enters the settling chamber through a channel composed of theraw material delivery trough and the sealing cover, the flow velocity of the flue gas is reduced in the settling chamber and rotational flow or refraction is formed; and part of the dust in the flue gas falls on the surfaces of raw materials to be taken back to the melting container, thus improving the utilization ratio of the raw materials and the utilization effect of a subsequent flue gas waste heat boiler, lowering load of a subsequent dedusting system and reducing equipment maintenance. The invention is applicable to an electric furnace for smelting steel scrap and is also suitable for other smelting containers with smelting characteristics.

Owner:CISDI ENG CO LTD

Engine vent gas purification system with front and rear catalysis bodies and utilization of waste gas secondary combustion

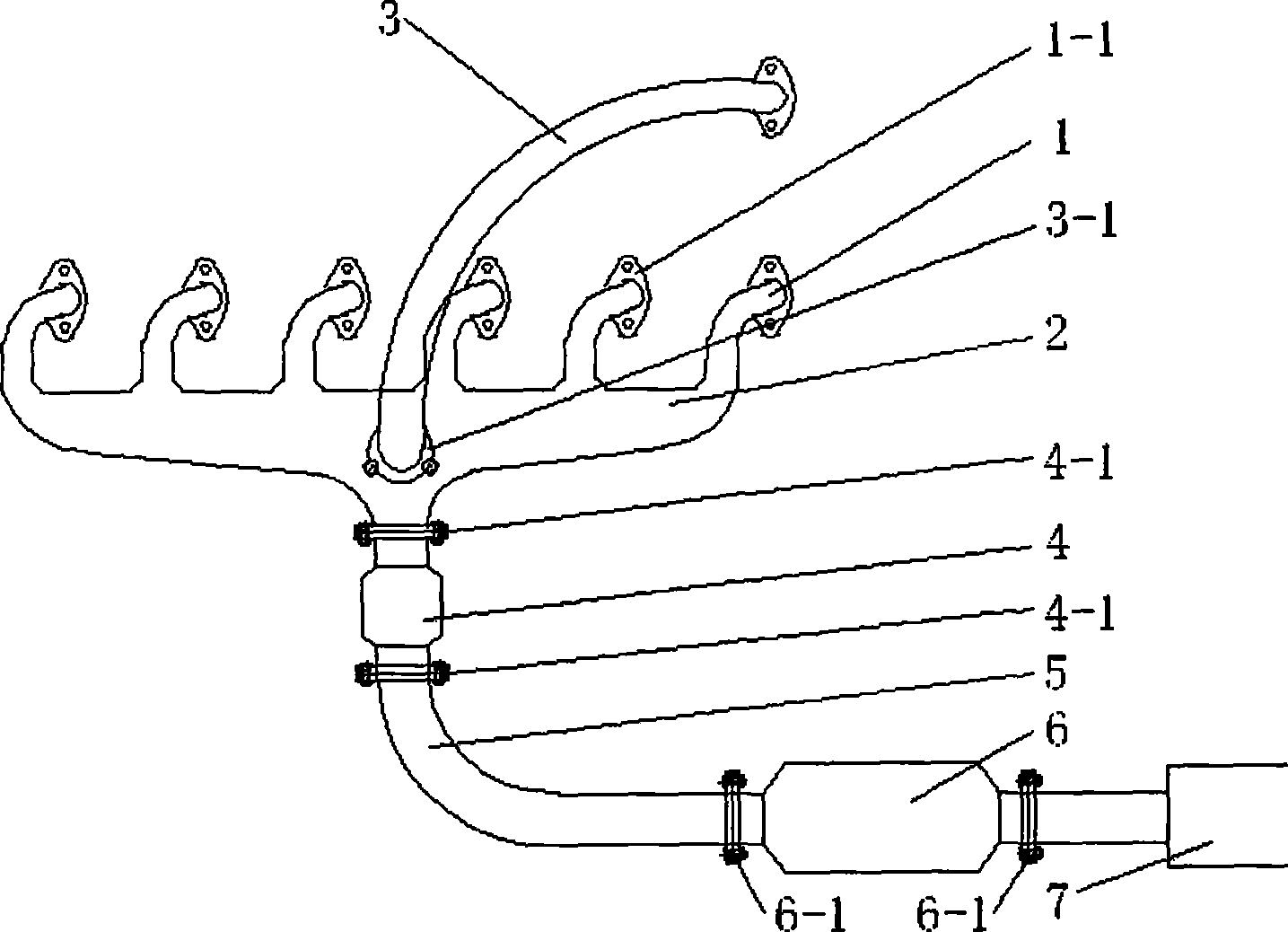

InactiveCN101482048AEmission controlImprove emission standardsExhaust apparatusDispersed particle separationCombustionExhaust fumes

The invention discloses an engine exhaust gas purification system which adopts exhaust gas re-combustion and is provided with a pre-catalysis body and a post- catalysis body. Though the existing engine exhaust pipes all apply catalysts to purify, the engine exhaust gas can not be completely purified and cleared up. The invention is provided with an exhaust gas inlet pipe, a pre-catalysis body and a post-catalysis body; the exhaust gas discharge can meet a higher standard after the three process steps of exhaust gas re-combustion, the pre-catalysis and the post-catalysis; on one hand, the incompletely combusted fuel and hot gas in the exhaust gas can be fully used, on the other hand, the key component in the exhaust gas can be individually pre-purified in a target-oriented way to reduce the work load of the post-catalysis body, thus the discharge standard of the exhaust gas is enhanced, the exhaust discharge amount is reduced to be close to zero discharge.

Owner:刘光文

A coke oven flue gas treatment system

ActiveCN113368633BStop floatingEasy to addUsing liquid separation agentOven incrustations prevention/removalParticulatesThermodynamics

Owner:临沂钢铁投资集团不锈钢有限公司

Treatment method for recovery of emulsion explosive waste

ActiveCN113582784BImprove demulsification efficiencyEmulsification does not affectTransportation and packagingRotary stirring mixersDemulsifierExplosive Agents

The invention discloses a treatment method for recycling waste emulsion explosives. The steps of the method are as follows: S1: add waste emulsion explosives and water to a separation device, and heat the waste emulsion explosives through a heating cycle system; S2: add Demulsifier, stirring and demulsifying the material at the same time; S3: After the demulsification is completed, the separation device is used to separate the waste material matrix and the water phase; S4: The water phase in the S3 is transported to the water phase preparation tank for demulsification. Preparation of water phase; S5: use the waste matrix in S3 as the raw material for ammonium oil explosives, or add it and normal matrix into the waste sensitizer, add foaming agent and accelerator to sensitize again, and re-sensitize Get qualified emulsion explosives. The treatment method of the invention has the advantages of good oil-water separation effect, simple operation and the like.

Owner:四川省南部永生化工有限责任公司

Non-woven fabric drying device and using method thereof

ActiveCN112254484ADry thoroughlyEfficient dryingDrying using combination processesDrying machines with progressive movementsSuction forceNonwoven fabric

The invention discloses a non-woven fabric drying device and a using method thereof.The non-woven fabric drying device comprises a drying shell, a preheating assembly is fixedly arranged at one end ofthe drying shell, non-woven fabric is arranged in the preheating assembly in a transmission mode, and the non-woven fabric movably penetrates through and extends to the two ends of the drying shell.Suction force is generated in a second three-way pipe, the second three-way pipe enables a movable frame to generate suction force through a corrugated pipe, an air suction pipe, second through holesand fourth through holes, and hot air in the drying shell penetrates through non-woven fabric to achieve the drying effect on the non-woven fabric; and meanwhile, the non-woven fabric is attached to the surface of a contact frame through hot air to achieve a flattening effect, a reciprocating moving column rotates to be matched with a driving column through a driving groove to drive a second fixing ring to do reciprocating motion, the second fixing ring drives the hot air to do concentrated reciprocating motion through the air suction pipe and the movable frame to penetrate through the non-woven fabric, so that the non-woven fabric is dried more thoroughly, and the purposes of high-efficiency drying and flattening are achieved.

Owner:SIXN SPINNING WHOLE SUZHOU

Production process tail gas cleaning treatment device

PendingCN114832599AImprove absorption treatment effectSave resourcesGas treatmentDispersed particle filtrationExhaust gasProcess engineering

The invention discloses a production process tail gas cleaning treatment device, which relates to the technical field of tail gas treatment, and comprises a purification box, a gas inlet mechanism, a spraying mechanism, a backflushing mechanism, a backflow preheating mechanism, a discharge box, a dehumidification adsorption mechanism, a backflow dehumidification mechanism and an absorption liquid discharge mechanism, a plurality of evenly-distributed electric heating wires are installed at the bottom end of the interior of the purification box, and a gas inlet mechanism used for tail gas treatment is installed in the purification box. Cold waste gas can be preheated through a backflow preheating mechanism, so that the absorption treatment effect on the waste gas is improved, and when the device is used, the waste gas can be recycled. And hot air in the purification box can enter the heat return pipe and enter the air inlet pipe through the top end of the heat return pipe, so that the hot air is in contact with cold air in the air inlet pipe, the heat transfer effect is achieved, the effect of preheating cold waste gas is achieved, resources consumed by subsequent air heating are reduced, and the neutralization reaction effect with absorption liquid is improved.

Owner:江苏爱尚环境科技有限公司

A welding device for steel structure installation

ActiveCN113492286BPlay the role of limit protectionAchieve warm-upWelding/cutting auxillary devicesAuxillary welding devicesClassical mechanicsElectric machinery

The invention belongs to the technical field of steel structure installation, especially a welding equipment for steel structure installation. The following proposal is proposed, including an operation table and a hanging plate. The outer wall of the bottom of the hanging plate is fixedly connected with a No. 1 hydraulic rod, and a The outer wall of the bottom of the hydraulic rod No. 2 is fixedly connected with a welding torch, and the outer wall of the bottom of the suspension plate located at both ends of the welding torch is fixedly connected with a No. 2 hydraulic rod. The present invention is provided with a rotating motor, a rotating shaft, an extrusion roller, an air cylinder and a sliding rod. Before the installation and welding of the steel structures, the two steel structures are stacked together, and the two steel structures are stacked together through the hierarchical extrusion assembly and the lower support plate below. Carry out clamping and fixing, after fixing, start the rotating motor, and the rotating motor drives the extrusion roller to rotate through the rotating shaft, so as to move and squeeze the steel structure, eliminate the gap between the two before, and prevent the welding effect from being reduced due to the gap after welding. Thereby ensuring the firmness between the steel structures after welding.

Owner:南通泽云机械有限公司

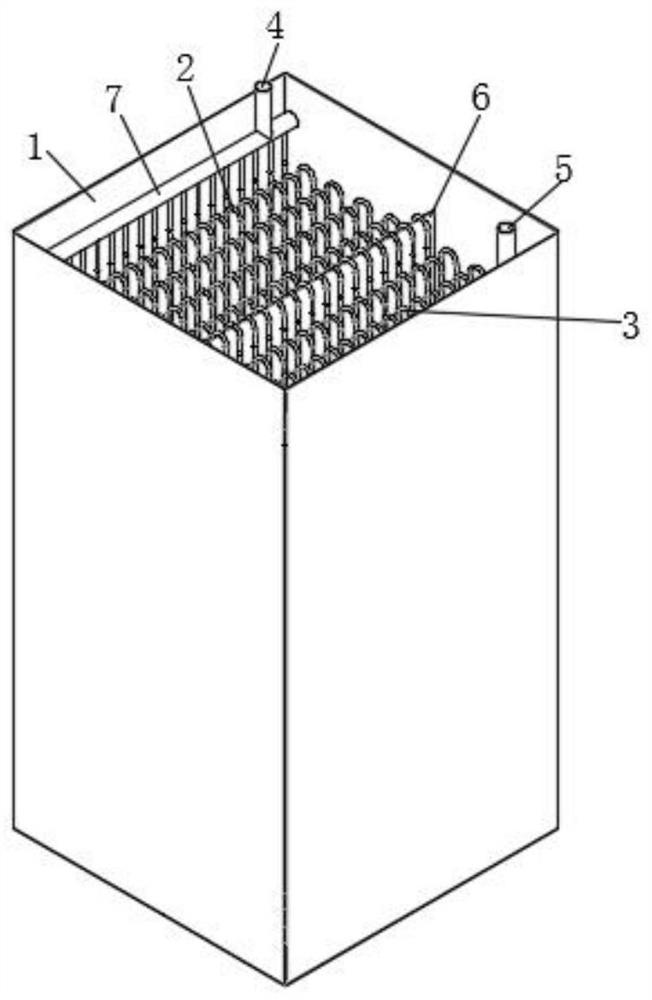

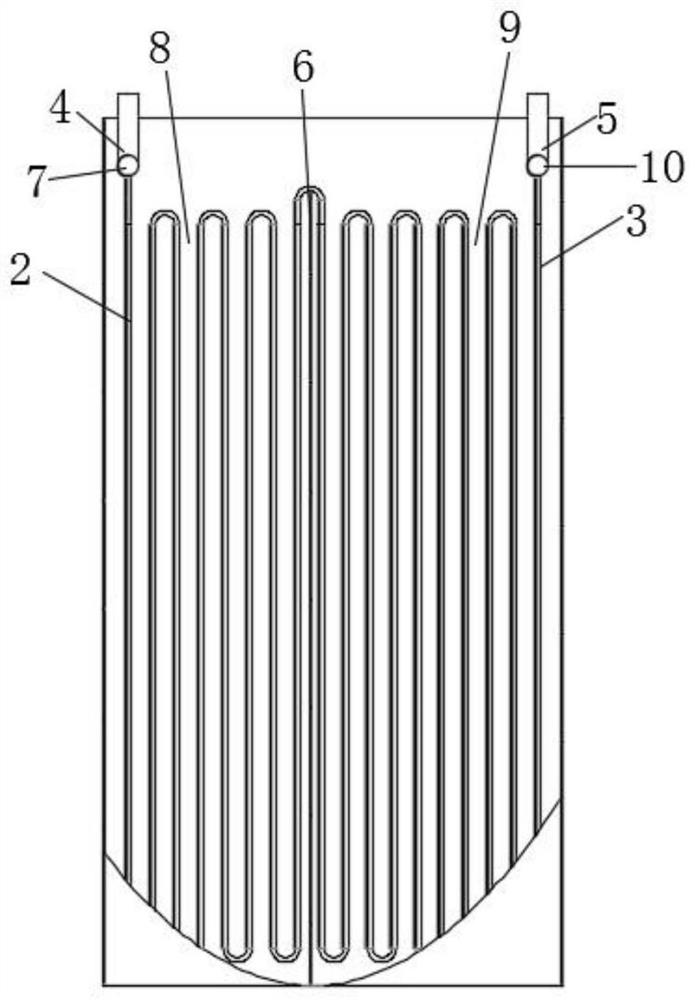

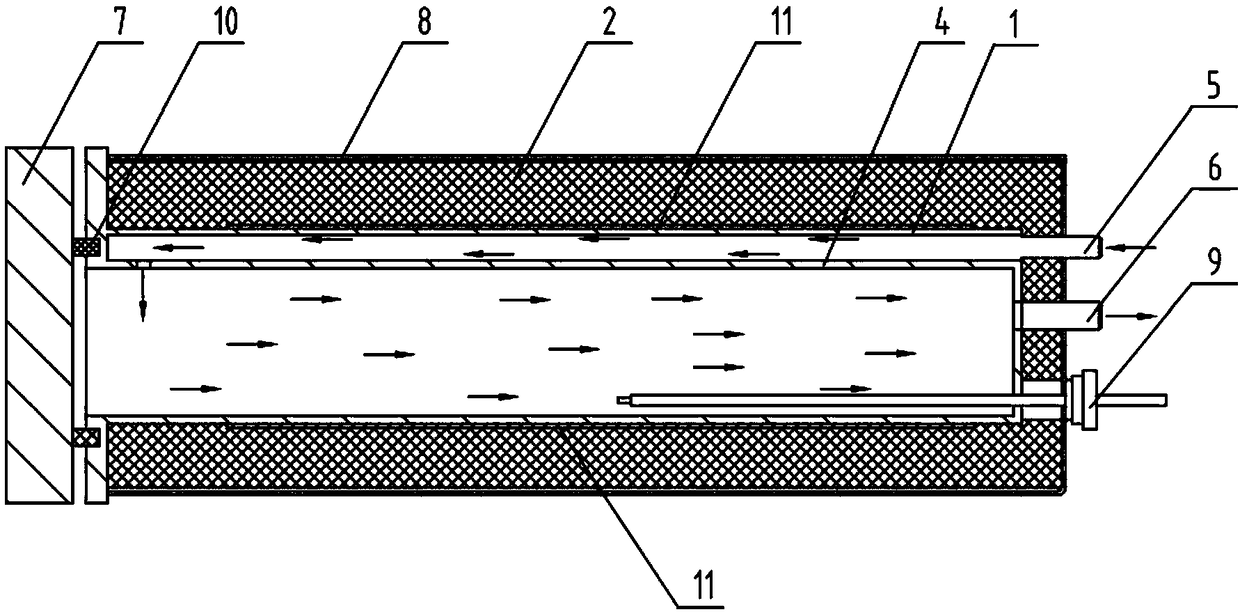

Cascade phase change heat reservoir

PendingCN113028874APlay a warm-up effectImprove warm-up effectHeat storage plantsStationary tubular conduit assembliesEngineeringMechanical engineering

The invention provides a cascade phase change heat reservoir which comprises a box body, a plurality of first snakelike heat exchange pipes arranged in the box body and a plurality of second snakelike heat exchange pipes arranged in the box body. A partition plate is arranged in the box body, the interior of the box body is divided into a first cavity and a second cavity which are relatively independent by the partition plate, an inlet collecting pipe is arranged on one side of the top of the box body, an outlet collecting pipe is arranged on the other side of the top of the box body, one ends of the first snakelike heat exchange pipes communicate with the inlet collecting pipe, the other ends of the first snakelike heat exchange pipes communicate with one ends of the second first snakelike heat exchange pipes, and the other ends of the second first snakelike heat exchange pipes communicate with the outlet collecting pipe. The second cavity is filled with a second phase change heat storage medium. According to the cascade phase change heat reservoir, the problem that in the prior art, a snakelike pipe phase change heat exchanger conducts heat exchange through a single phase change material, and the heat exchange effect is poor is solved, design is reasonable, and the cascade phase change heat reservoir is suitable for production, popularization and application.

Owner:强野机械科技(上海)有限公司

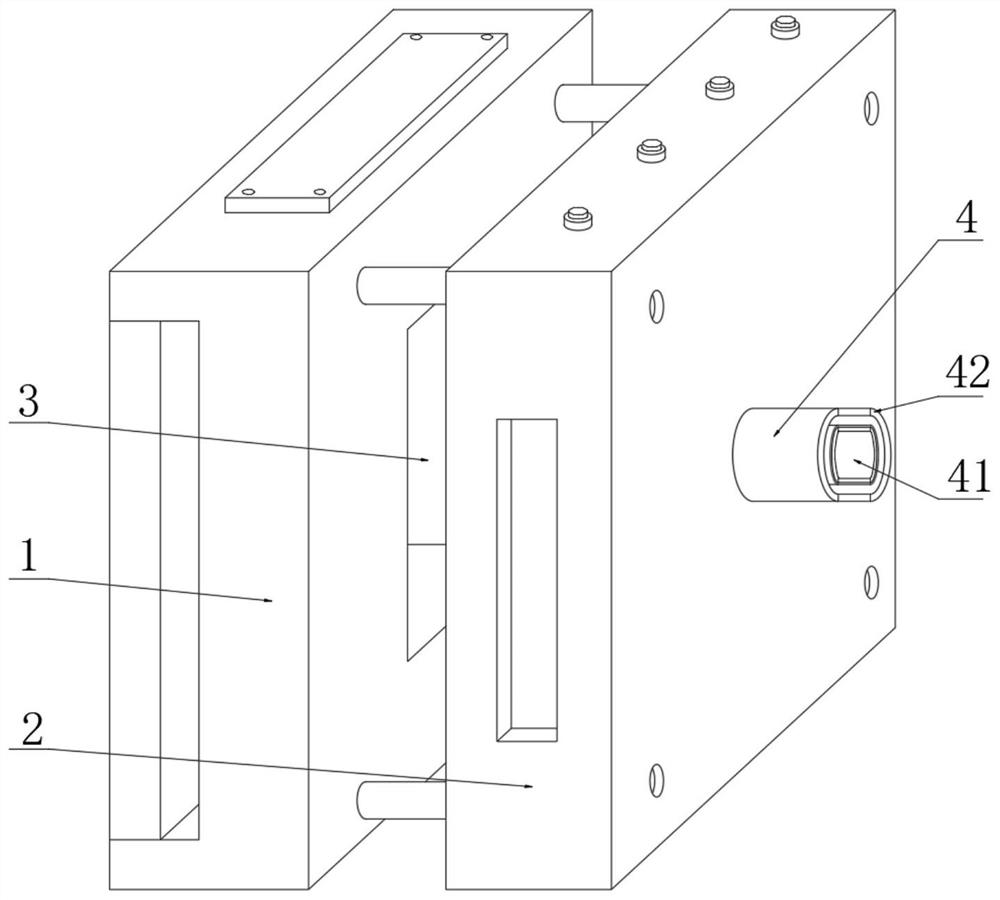

Die-casting die of horizontal cold chamber die-casting machine and process thereof

InactiveCN112589070AThe temperature drop is reducedAvoid rapid coolingEngineeringMechanical engineering

The invention discloses a die-casting die of a horizontal cold chamber die-casting machine. The die comprises a movable die and a fixed die, wherein the movable die is arranged on the left side of thefixed die, a cavity is formed in the outer wall of the right side of the movable die, the outer wall of the right side of the fixed die communicates with a pouring pipeline, and the pouring pipelinecomprises an inner pipe communicating with the outer wall of the right side of the fixed die; the outer wall of the inner pipe is sleeved with an outer pipe, supporting rods are evenly arranged between the outer wall of the inner pipe and the inner wall of the outer pipe, a filling pipeline in the device is composed of the outer pipe and the inner pipe, a cavity is formed by separating the supporting rods to have an heat insulation effect, and the temperature drop amplitude of a metal liquid raw material added into the filling pipeline is reduced, so that the metal liquid raw material in the pouring pipeline is prevented from being cooled rapidly, and the use performance of the die-casting die is improved. The temperature in the pouring pipeline cannot be too low through an heat insulationlayer and a heating piece, and the probability that the metal liquid raw material is cooled in the pouring pipeline is further reduced.

Owner:诸暨市旭祥弹簧有限公司

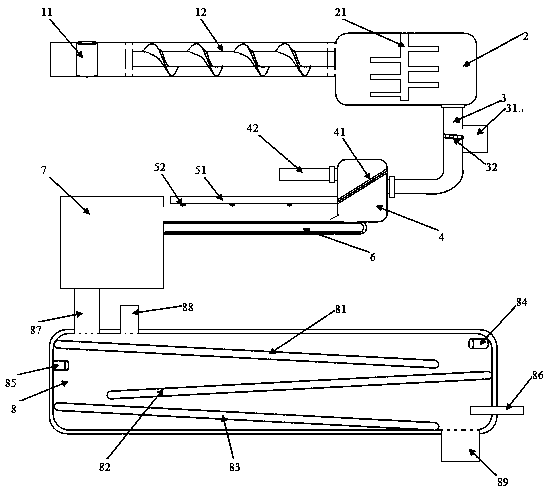

Coke oven flue gas treatment system

ActiveCN113368633AStop floatingEasy to addUsing liquid separation agentOven incrustations prevention/removalParticulatesThermodynamics

The invention relates to the technical field of coke oven flue gas treatment, in particular to a coke oven flue gas treatment system. The system comprises a coke oven body; a dust remover is arranged on one side of the coke oven body; a connecting pipe is connected between the coke oven body and the dust remover; a feeding pipe is arranged on the surface of the coke oven body; an opening is formed in one end of the feeding pipe; and the interior of the feeding pipe is movably connected with a feeding and smoke blocking device. A filter screen, a cooling fin, an auger, a motor, a fan and the like are arranged in the dust remover, particulate matter in smoke can be separated out and fed into a combustion furnace again to be combusted, and excessive waste of resources is avoided. According to the coke oven flue gas treatment system disclosed by the invention, when fuel is added, flue gas can be prevented from flying out of the oven, so that the environment can be protected, and the harm of the flue gas to workers can be reduced.

Owner:临沂钢铁投资集团不锈钢有限公司

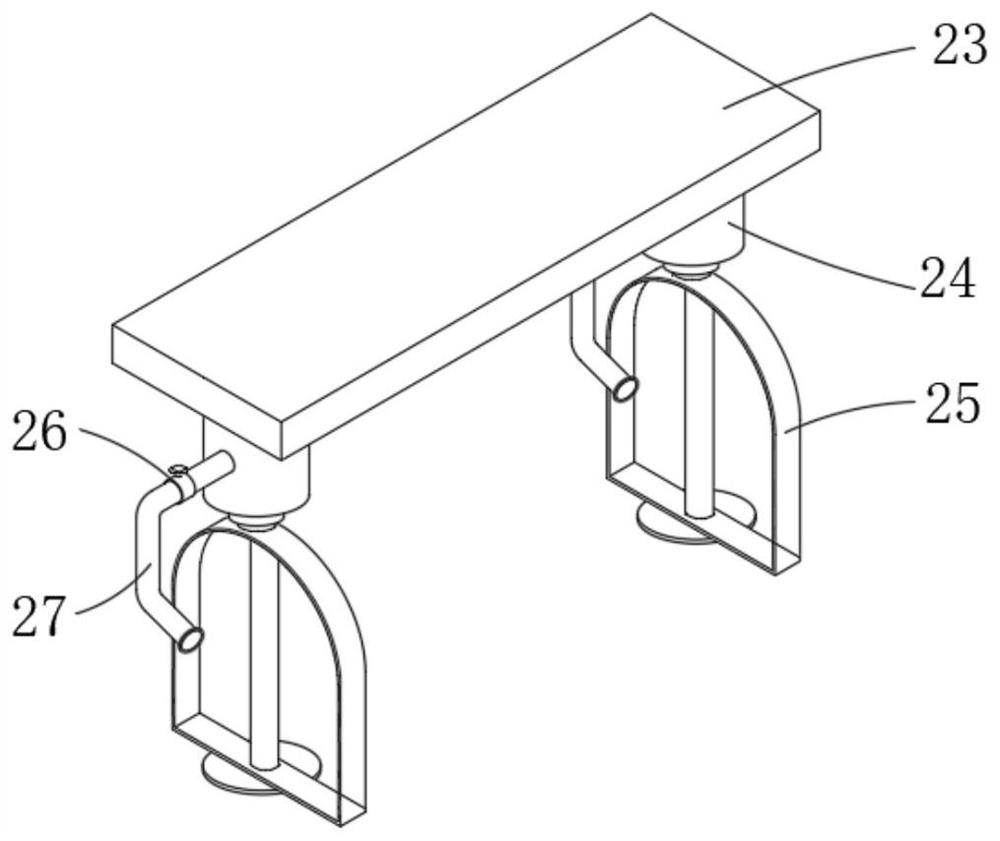

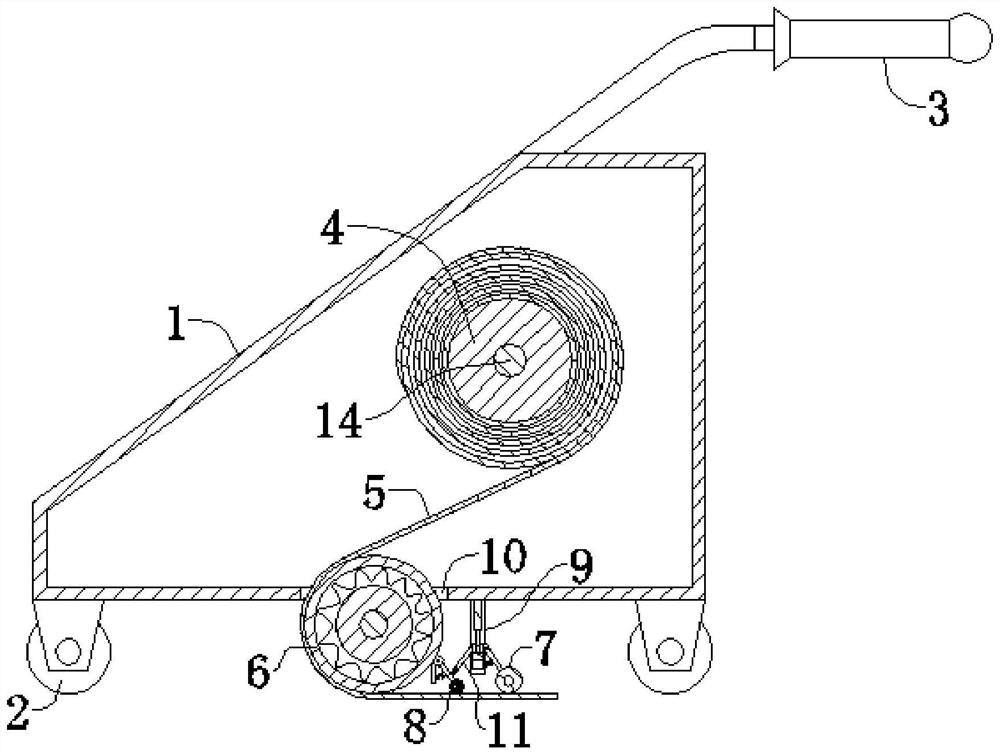

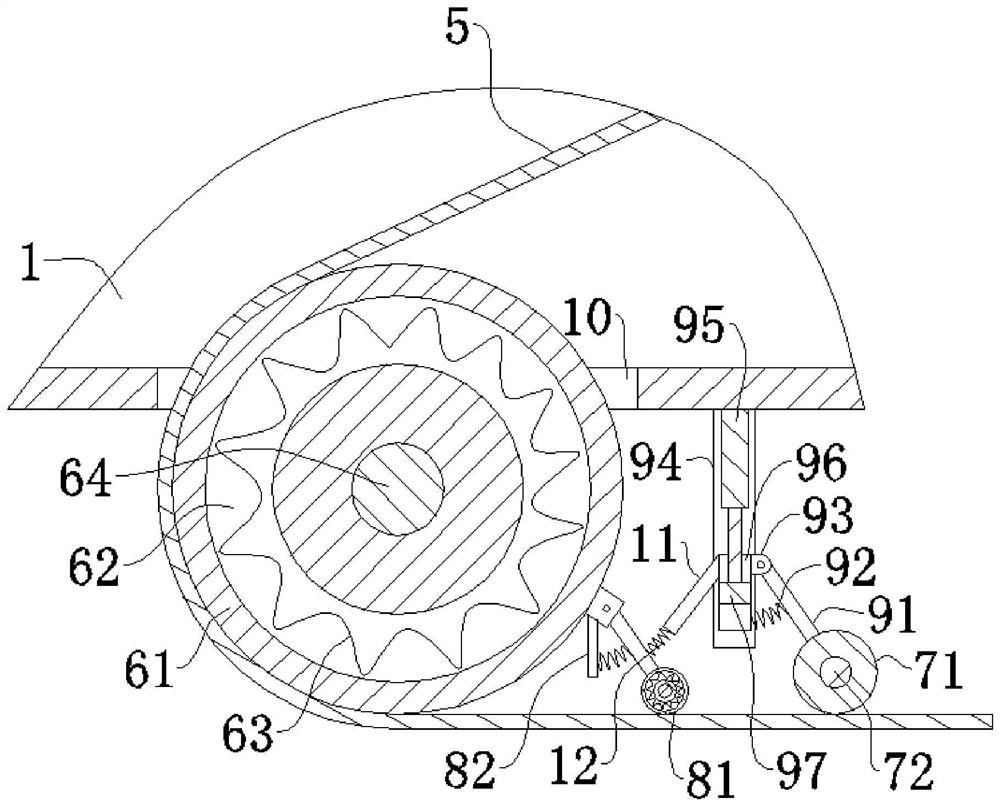

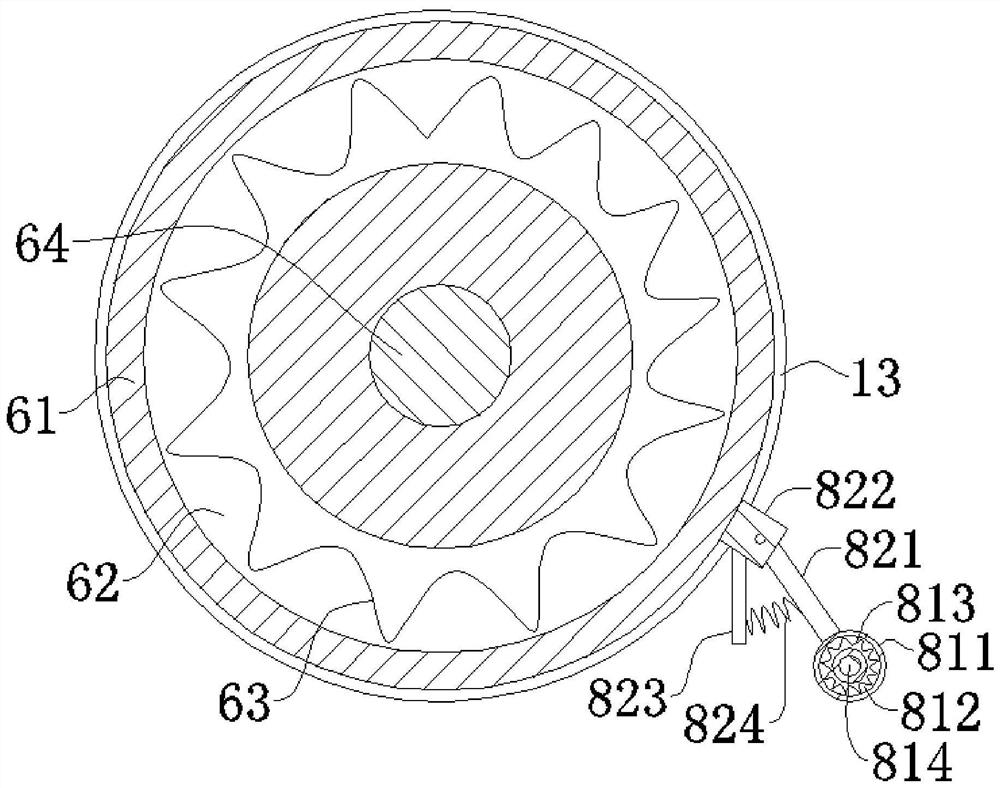

Road marking piece pasting device

PendingCN114875816AImprove sticking firmnessImprove paste strengthTraffic signalsRoad signsRoad surfaceHandrail

The invention discloses a road marking piece pasting device, and belongs to the technical field of marking piece pasting, the pasting device comprises a shell, a winding drum, a preheating mechanism, a driving mechanism and a rolling mechanism used for pressing a marking piece on a road surface; a handrail is fixed to the top of the shell, wheels are installed at the bottom of the shell, the winding drum is rotationally connected into the shell, the preheating mechanism comprises a preheating rotary drum, an opening is formed in the bottom of the shell, and the preheating rotary drum is located in the opening and rotationally connected to the bottom of the shell; the driving mechanism is located below the shell and used for adjusting the vertical height of the rolling mechanism, the marking piece is wound around the winding drum, one end of the marking piece is wound around the circumferential surface of the preheating rotary drum and extends in the direction of the rolling mechanism, and the rolling mechanism is located above the marking piece. The adhesive tape is good in adaptability, does not need manual pasting, and is time-saving and labor-saving.

Owner:湖南福米工程塑料有限公司

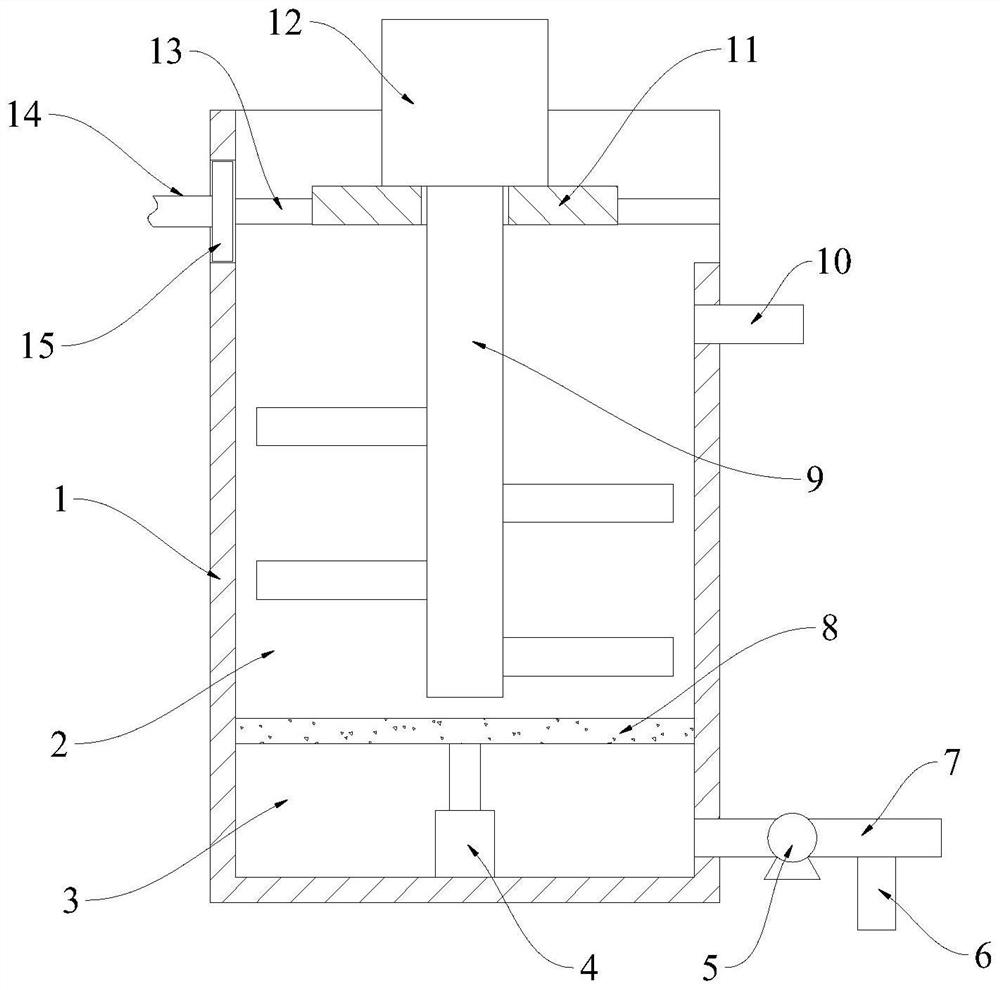

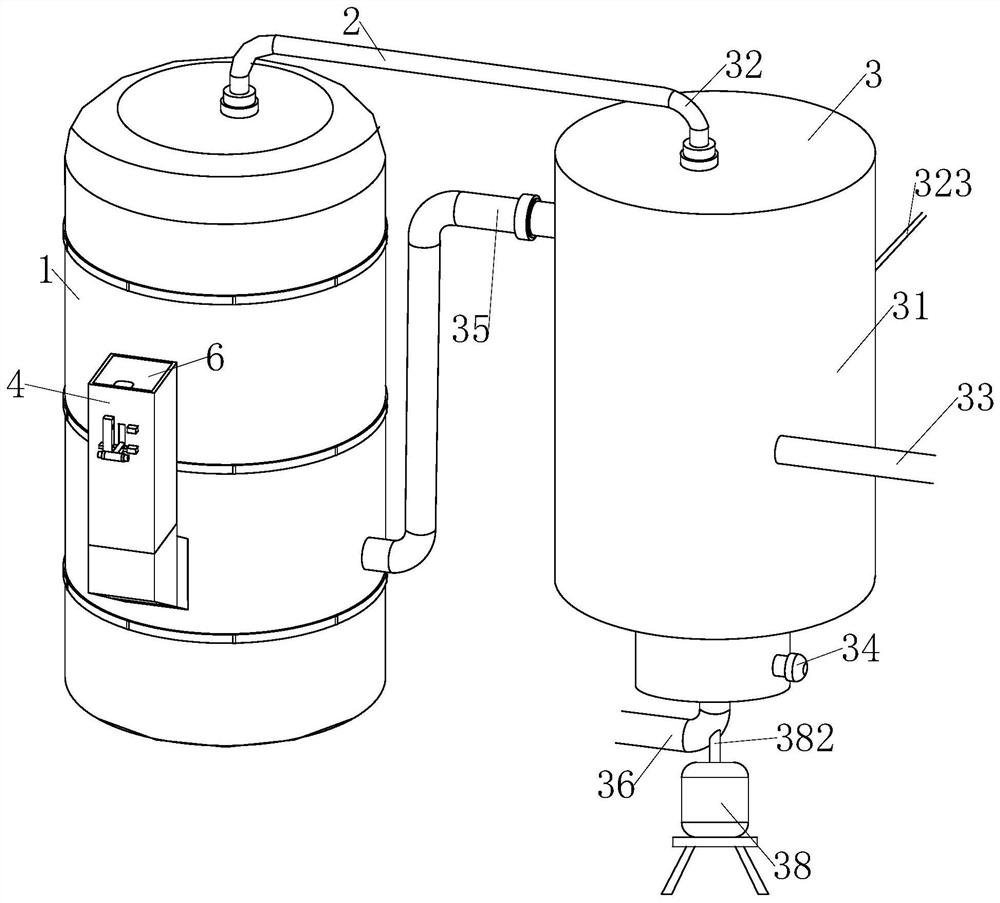

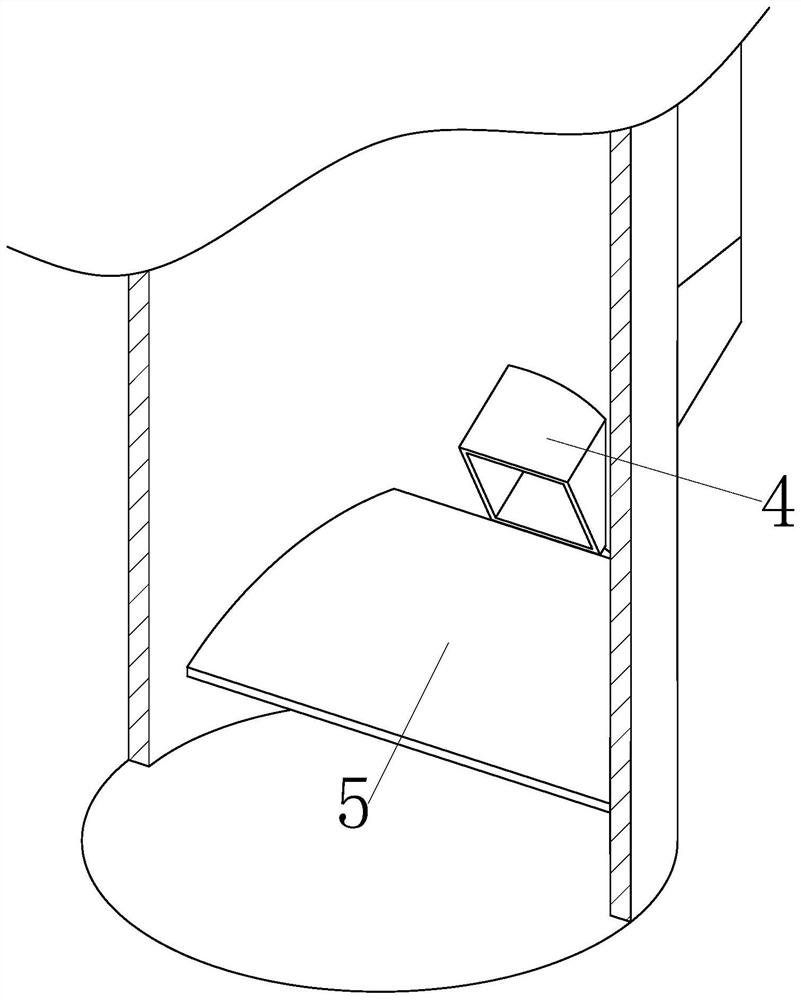

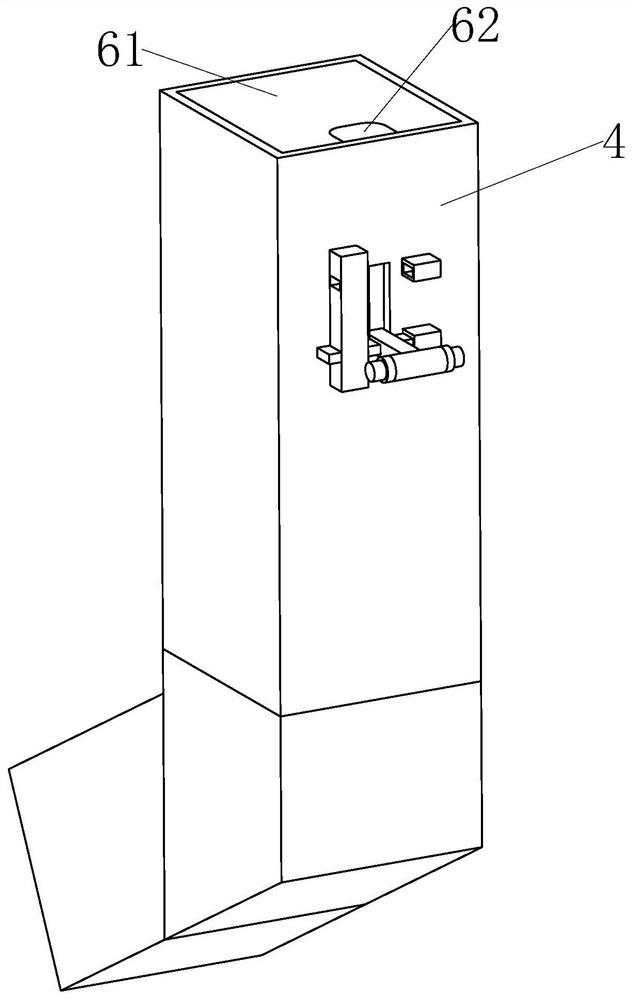

Sludge treatment device for water conservancy projects

ActiveCN107381987BAvoid damageAvoid the impact of product qualitySludge treatment by de-watering/drying/thickeningHydraulic engineering apparatusExpanded clay aggregateHydraulic engineering

The invention relates to a sludge treatment apparatus for a water conservancy project. The sludge treatment apparatus comprises a transport apparatus, a stirring chamber, a transport pipeline part, a sludge filter chamber, a sludge mixing and drying part, a mixing and granulating chamber and a ceramsite heating chamber. By arranging various parts, the sludge treatment, the ceramsite preparation from sludge and the ceramsite forming can be continuously carried out, so that not only can the sludge containing heavy metal be removed and the secondary pollution of the sludge to a water body be avoided, but also heavy metal elements are secondarily utilized for the ceramsite, and the harmful sludge can be actually turned into benefit.

Owner:苏州畅庆智能科技有限公司

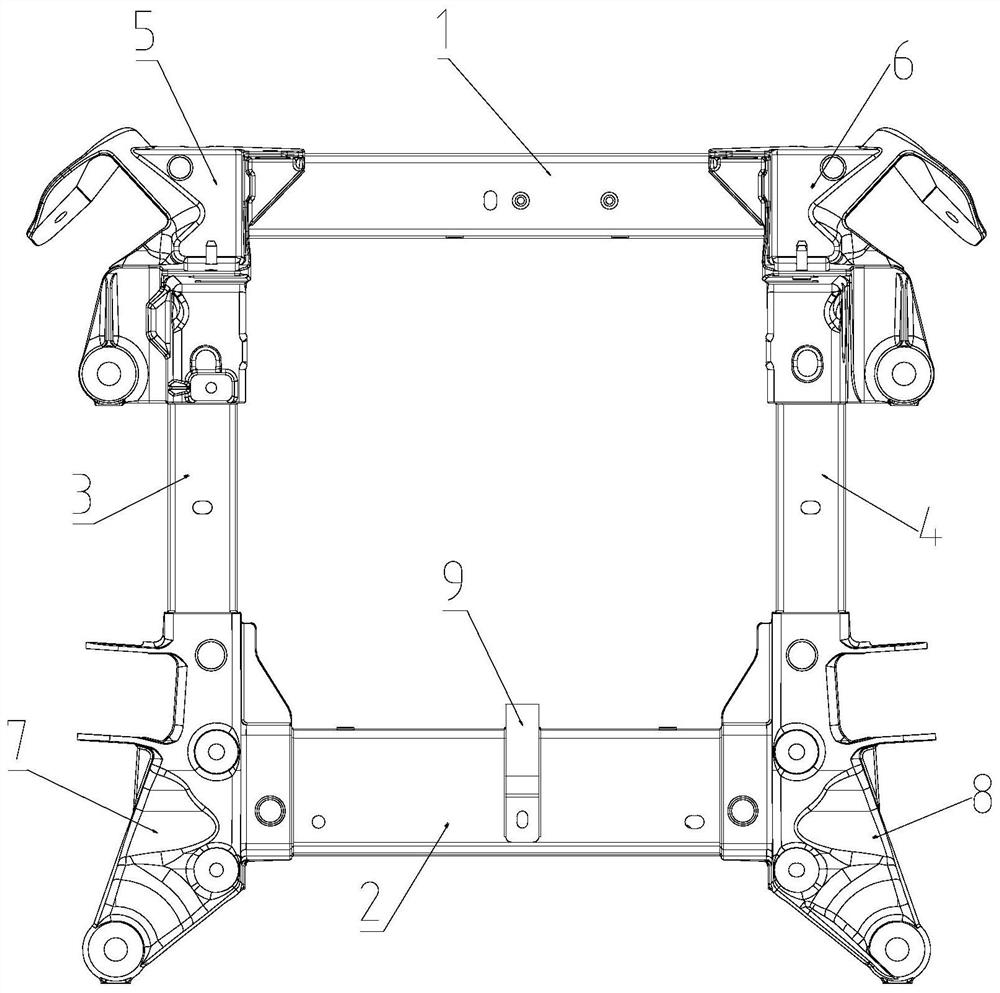

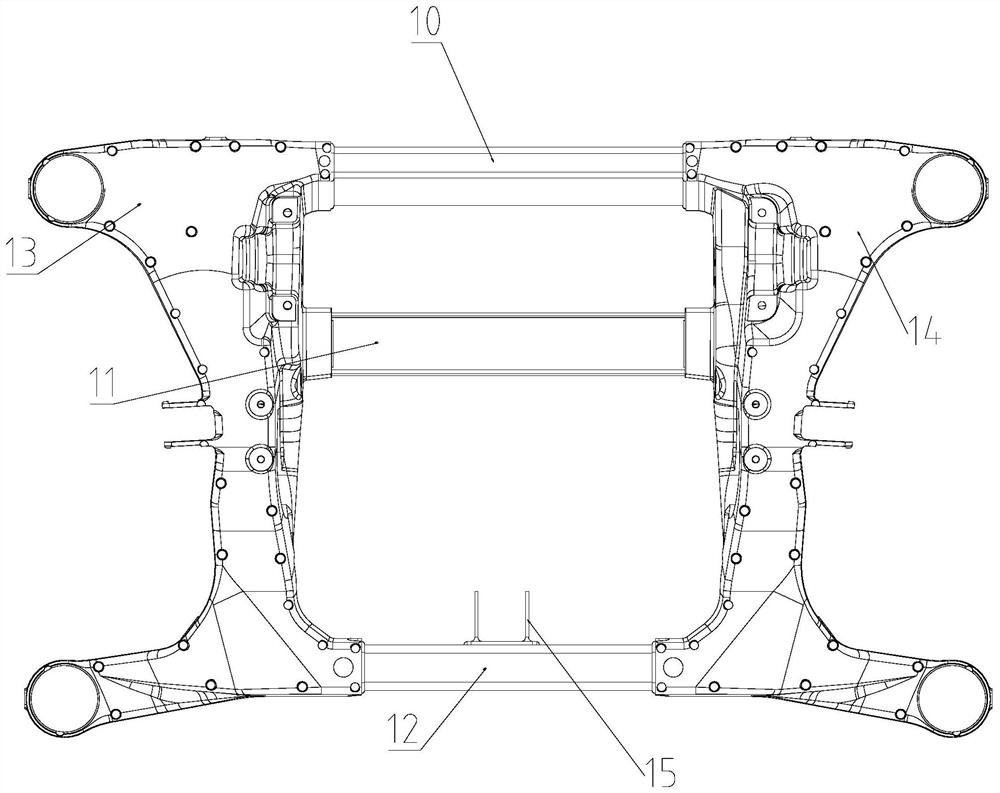

A welding process for front and rear sub-frames of lightweight dissimilar aluminum materials

ActiveCN110666304BPlay a warm-up effectStrong penetrating powerArc welding apparatusVehicle componentsFillet weldVehicle frame

The invention belongs to the technical field of vehicle manufacturing, and relates to a welding process for the front and rear sub-frames of lightweight dissimilar aluminum materials. During welding, the flat corner welds are welded first, and then the vertical corner welds are welded. The heat input at the position where the flat corner welds are welded first can play The effect of preheating the casting increases the depth of penetration and avoids the occurrence of non-fusion defects. The weight of the front and rear sub-frames after welding through this welding process is only one-third of the original, which reduces the weight of high-end vehicles and increases the weight of the entire vehicle. The cruising range, and the front and rear sub-frames are corrosion-resistant, do not need anti-rust paint, reasonable welding sequence and welding parameters effectively control the welding deformation, provide a reliable welding process for the connection of dissimilar aluminum materials, and ensure welding quality.

Owner:辽宁忠旺铝合金精深加工有限公司

A gas-saving protective gas drying box

ActiveCN106052322BRealize multiple useReduce usageDrying gas arrangementsDrying solid materialsShielding gasProcess engineering

The invention relates to the technical field of a coal sample detecting device, in particular to a gas-saving type protective gas drying box. The gas-saving type protective gas drying box comprises a plurality of drying cavities, a main air inlet pipe, a main exhaust pipe and a control unit. Gas channels of the plurality of drying cavities are arranged in series. The main air inlet pipe is used for pumping protective gas into the plurality of drying cavities and the protective gas after use is discharged through the main exhaust pipe. A heating component is arranged in each drying cavity. The control unit is used for controlling the heating speed of each heating component and the on-off of the main air inlet pipe. According to the gas-saving type protective gas drying box provided by the invention, the repeated usage of the protective gas can be realized, the usage amount of the protective gas can be greatly saved, the cost can be saved and the labour intensity of the operating personnel can be reduced. The protective gas carries a part of heat when getting into one drying cavity from another drying cavity, so that a preheating effect can be played and the warming time of the drying cavity where the protective gas enters is shortened. Accordingly, the electric energy consumption can be reduced and the cost can be further saved.

Owner:长沙开元仪器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com