Temperature control component, temperature control pipe and heat management system for lithium battery pack

A thermal management system, a technology for lithium battery packs, applied in battery temperature control, batteries, electrical components, etc., can solve the problems of inconsistent battery cell temperature and inability to effectively control the temperature of lithium battery packs, achieving good consistency and improving service life , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

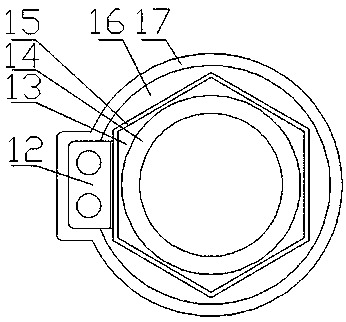

[0037] Such as figure 1 As shown, a lithium battery pack temperature control component proposed by the present invention is a multi-layer pipe, and an internal water pipe 14, a heat-conducting filler 13, a PTC heating plate 15, a glue filler 16, and a packaging shell 17 are sequentially arranged from the inside to the outside. A PTC heating control board 12 is arranged between the PTC heating board 15 and the packaging shell 17 . The use of lithium battery pack temperature control components has the advantages of constant temperature heating, energy saving, good safety performance, and long service life.

[0038] The PTC heating plate 15 is composed of a plurality of heating plates to form a polygonal pipe wrapping the internal water pipe 14, each heating plate is located at a corresponding tangent position of the pipeline, and the PTC heating control plate 12 is attached to one of the heating plates. In this embodiment, a hexagonal heating pipe is used to expand the area to ...

Embodiment 2

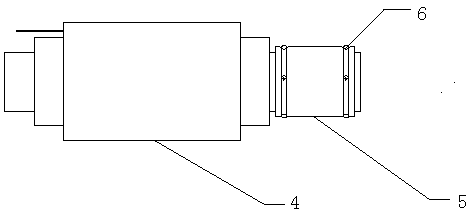

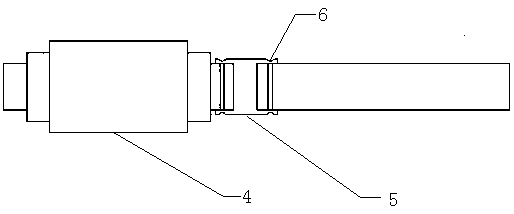

[0040] Such as Figure 2-4 As shown, the present invention proposes a temperature control pipe for a lithium battery pack, using the temperature control part, wherein the inner water pipe 14 is provided with a straight pipe and a spiral pipe surrounded by an outer spiral, and rubber is used at the junction of the two temperature control pipes. The connecting pipe 11 is connected, and the spiral pipe and the straight pipe of the two temperature control pipes are switched inside the rubber connecting pipe. The straight pipe of one section is connected to the spiral pipe of the other section, and the spiral pipe of one section is connected to the straight pipe of the other section. The rubber connecting pipe is connected, and the rubber connecting pipe includes a rubber pipe clip 5 and a sealing rubber pipe 6 . Among them, the rubber pipe clamp 5 is used to fix the two sections of pipes, and realize the internal switching between the spiral pipe and the straight pipe.

[0041] D...

Embodiment 3

[0048] Such as Figure 5 The heat management system of a lithium battery pack proposed by the present invention includes at least two liquid cooling plates (1) arranged opposite to each other, and each liquid cooling plate (1) is respectively provided with a water inlet (9) and a water outlet (10), the liquid cooling plate (1) adopts an aluminum plate, and a groove is opened on the aluminum plate, and a copper tube suitable for the injection of the tempering liquid is embedded in the groove, and aluminum and copper have high thermal conductivity.

[0049] The water inlet pipe (2) communicates with the water outlet pipe (18), and is installed in parallel on the connecting part of the opposite liquid cold plate (1), and is connected with the water inlet (9) and the water outlet (10) on the cold liquid plate, and Install the temperature control part of the lithium battery pack. In order to realize the insulation between the liquid cooling plate (1) and the battery module (8), a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com