Treatment method for recovery of emulsion explosive waste

A technology for the recovery of emulsion explosives and waste materials, which is applied to chemical instruments and methods, explosives, and separation methods, etc. It can solve the problems of difficult oil-water phase separation of emulsion explosives, safety risks, and easy adhesion to the heating pipe wall, etc., to achieve Good demulsification effect, improve heating effect, avoid uneven heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

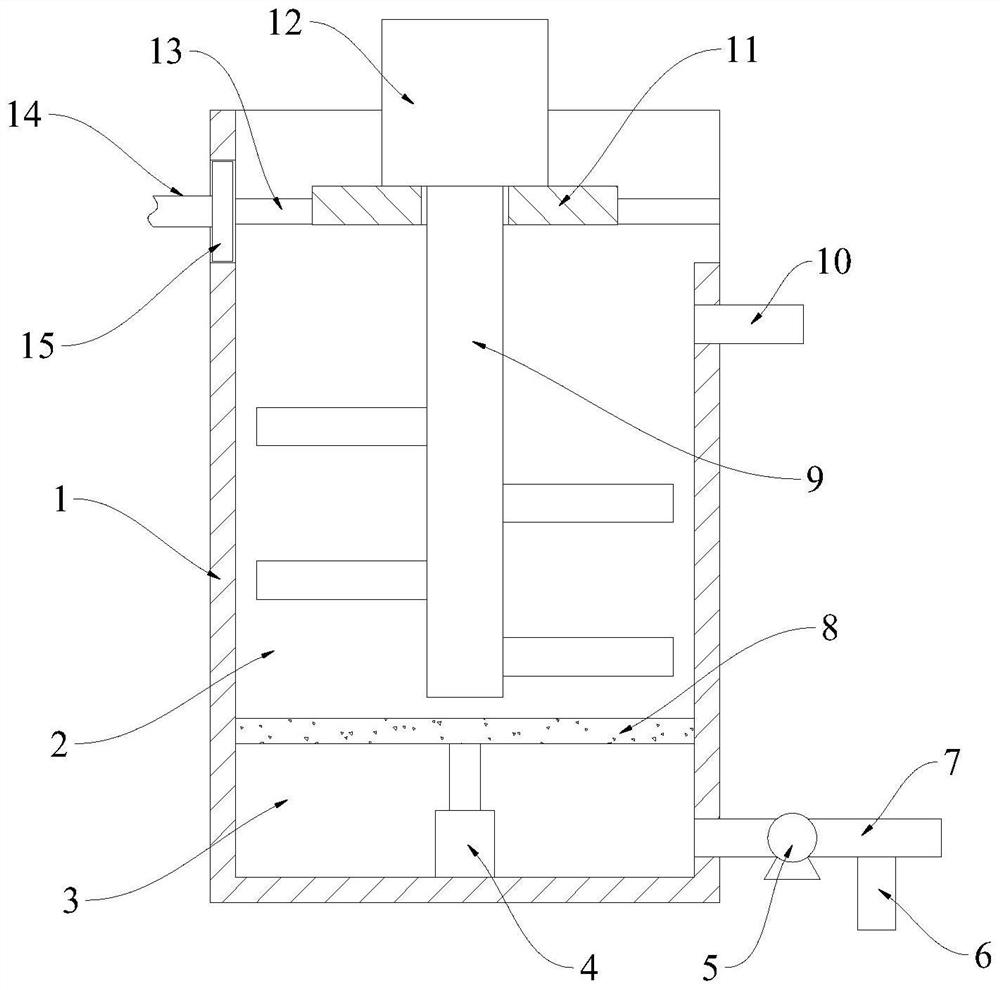

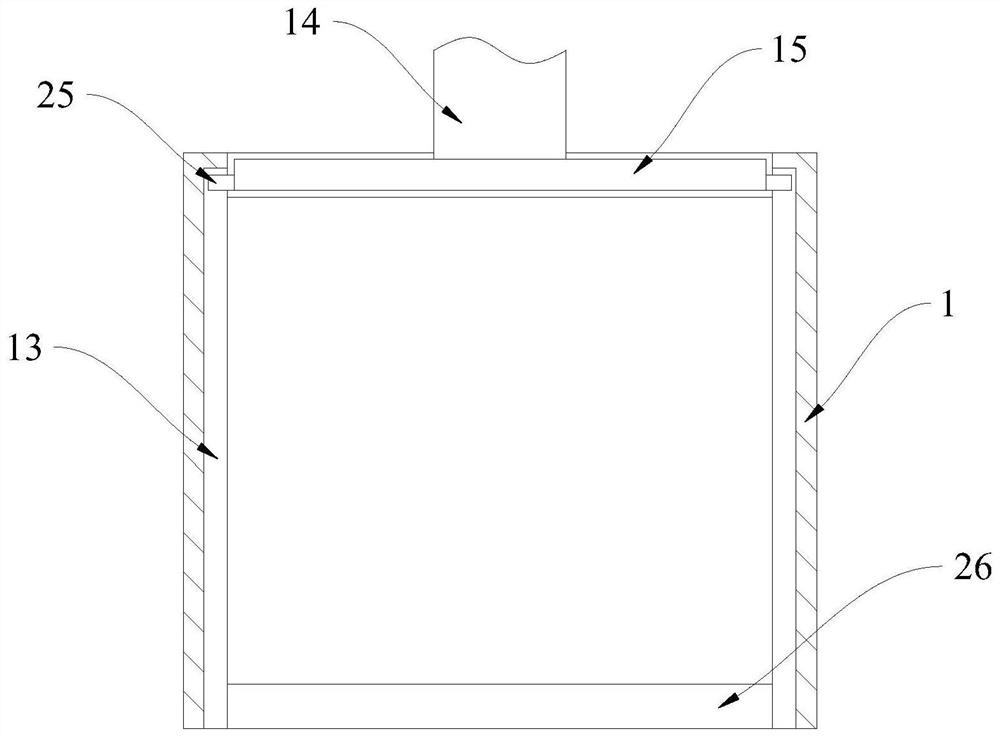

[0037] The processing method that the emulsion explosive waste material that the present invention proposes reclaims, method step is as follows:

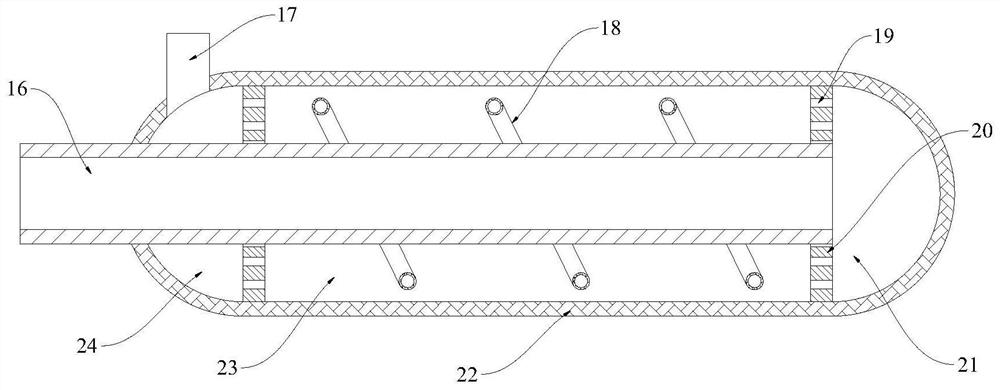

[0038]S1: Put the emulsion explosive waste and water into the separation device, and heat the emulsion explosive waste through the heating circulation system;

[0039] S2: adding a demulsifier to the material of S1, and simultaneously stirring the material to break the demulsification;

[0040] S3: After the demulsification is completed, the separation device is used to separate the waste material matrix and the water phase;

[0041] S4: transporting the water phase in S3 to a water phase preparation tank for water phase preparation;

[0042] S5: Use the waste matrix in S3 as the raw material for the production of ammonium oil explosives, or add it and normal matrix into the waste sensitization machine, add foaming agent and accelerator for re-sensitization, and re-produce qualified emulsion explosives .

[0043] The demulsifier ...

Embodiment 2

[0046] The processing method that the emulsion explosive waste material that the present invention proposes reclaims, method step is as follows:

[0047] S1: Put the emulsion explosive waste and water into the separation device, and heat the emulsion explosive waste through the heating circulation system;

[0048] S2: adding a demulsifier to the material of S1, and simultaneously stirring the material to break the demulsification;

[0049] S3: After the demulsification is completed, the separation device is used to separate the waste material matrix and the water phase;

[0050] S4: transporting the water phase in S3 to a water phase preparation tank for water phase preparation;

[0051] S5: Use the waste matrix in S3 as the raw material for the production of ammonium oil explosives, or add it and normal matrix into the waste sensitization machine, add foaming agent and accelerator for re-sensitization, and re-produce qualified emulsion explosives .

[0052] The demulsifier...

Embodiment 3

[0055] The processing method that the emulsion explosive waste material that the present invention proposes reclaims, method step is as follows:

[0056] S1: Put the emulsion explosive waste and water into the separation device, and heat the emulsion explosive waste through the heating circulation system;

[0057] S2: adding a demulsifier to the material of S1, and simultaneously stirring the material to break the demulsification;

[0058] S3: After the demulsification is completed, the separation device is used to separate the waste material matrix and the water phase;

[0059] S4: transporting the water phase in S3 to a water phase preparation tank for water phase preparation;

[0060] S5: Use the waste matrix in S3 as the raw material for the production of ammonium oil explosives, or add it and normal matrix into the waste sensitization machine, add foaming agent and accelerator for re-sensitization, and re-produce qualified emulsion explosives .

[0061] The demulsifier...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com