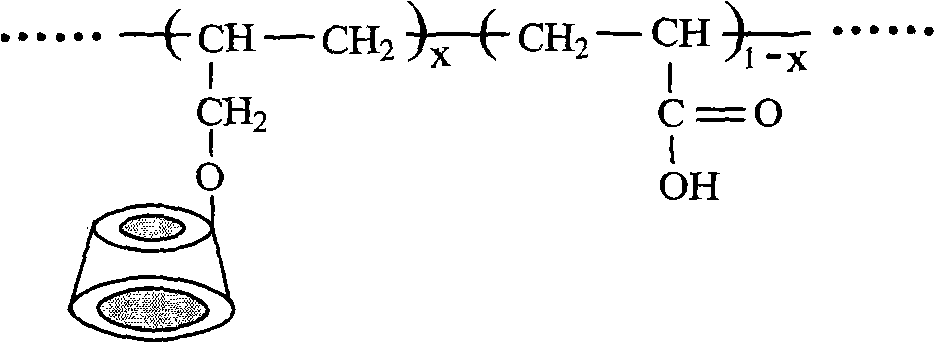

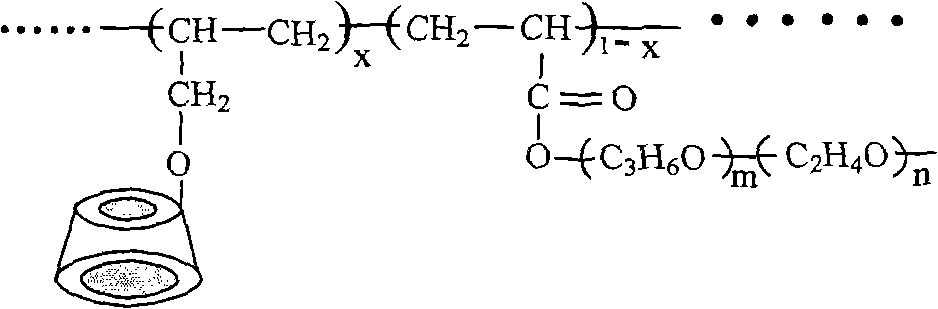

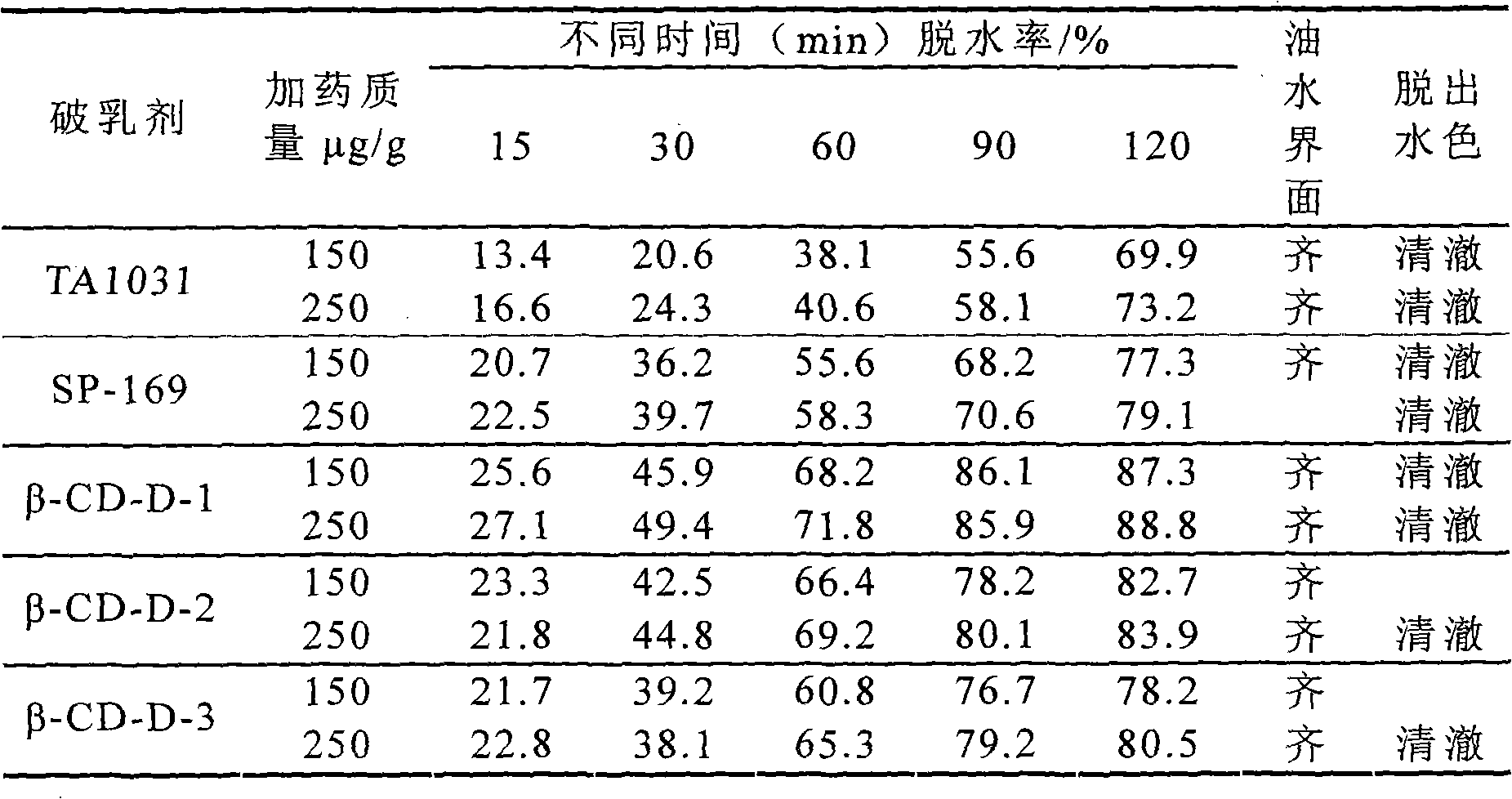

Preparation method and application of block polyether-beta-CD comb type demulsifying agent

A technology of block polyether and demulsifier, which is applied in the direction of chemical dehydration/demulsification, etc., to achieve the effect of easy industrial production, simple equipment and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0022] Take 5.7mmol of β-cyclodextrin and put it into a three-necked flask with a constant pressure titration funnel and a stirring paddle, then add 30ml DMSO, 2.0gNaOH, stir well for 1h to completely dissolve the cyclodextrin, and then slowly Add 8 ml of allyl bromide dropwise, and continue the constant temperature reaction for 48 hours. After the reaction, vacuum filter and wash with acetone to obtain a white powder, and obtain allyl-β-cyclodextrin.

[0023] Then use allyl-β-cyclodextrin and acrylic acid as raw materials, according to the raw material molar ratio of 1:2, in the aqueous solution at 60°C, add a mixed system of sodium bisulfite and ammonium persulfate with a mass ratio of 1:1 as an initiator , constant temperature polymerization reaction for 8 hours, after the reaction, the precipitate was washed with absolute ethanol, dried and pulverized to obtain an allyl-β-cyclodextrin / acrylic acid main chain polymer.

[0024] Finally, weigh 15g of the above-mentioned main ...

example 2

[0026] Take 5.7mmol of β-cyclodextrin in a three-neck flask with a constant pressure titration funnel and a stirring paddle, then add 30ml DMSO, 2.0gNaOH, stir well for 1h to completely dissolve the cyclodextrin, and then slowly Add 8 ml of allyl bromide dropwise, and continue the constant temperature reaction for 48 hours. After the reaction, vacuum filter and wash with acetone to obtain a white powder, and obtain allyl-β-cyclodextrin.

[0027] Then use allyl-β-cyclodextrin and acrylic acid as raw materials, according to the molar ratio of raw materials of 1:1, in the aqueous solution at 60 ° C, add a mixed system of sodium bisulfite and ammonium persulfate with a mass ratio of 1:1 as an initiator , constant temperature polymerization reaction for 8 hours, after the reaction, the precipitate was washed with absolute ethanol, dried and pulverized to obtain an allyl-β-cyclodextrin / acrylic acid main chain polymer.

[0028] Finally, weigh 15g of the above-mentioned main chain pol...

example 3

[0030] Take 5.7mmol of β-cyclodextrin in a three-neck flask with a constant pressure titration funnel and a stirring paddle, then add 30ml DMSO, 2.0gNaOH, stir well for 1h to completely dissolve the cyclodextrin, and then slowly Add 8 ml of allyl bromide dropwise, and continue the constant temperature reaction for 48 hours. After the reaction, vacuum filter and wash with acetone to obtain a white powder, and obtain allyl-β-cyclodextrin.

[0031] Then use allyl-β-cyclodextrin and acrylic acid as raw materials, according to the molar ratio of raw materials 1:0.5, in the aqueous solution at 60°C, add a mixed system of sodium bisulfite and ammonium persulfate with a mass ratio of 1:1 as an initiator , constant temperature polymerization reaction for 8 hours, after the reaction, the precipitate was washed with absolute ethanol, dried and pulverized to obtain an allyl-β-cyclodextrin / acrylic acid main chain polymer.

[0032] Finally, weigh 15g of the above-mentioned main chain polyme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dehydration rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com