Patents

Literature

307results about How to "Good recombination" patented technology

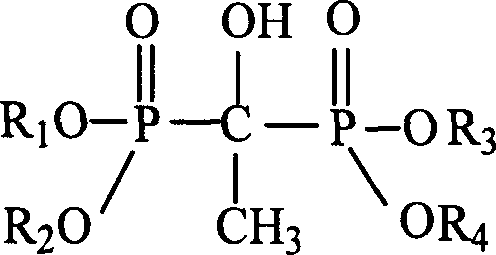

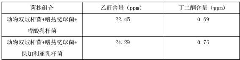

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nonionic waterborne polyurethane dispersoid and preparation method thereof

InactiveCN102690404AWide range of usesGood acid and alkali resistancePolyurethane dispersionPolymer science

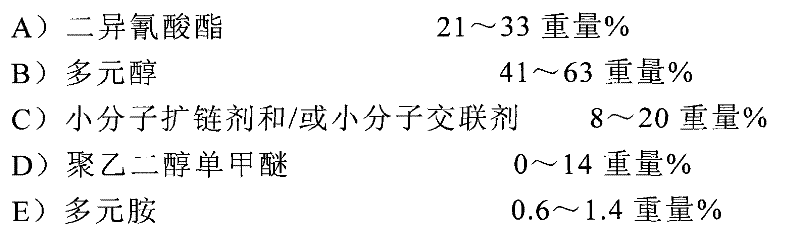

The invention discloses a nonionic waterborne polyurethane dispersoid and a preparation method thereof. The dispersoid is mainly made from raw materials of A) diisocyanate, B) one or more than two polyols containing at least two hydroxy groups, wherein number average molecular weight of the polyols is 1000-4000, C) a small molecule chain extender and / or a small molecule cross-linking agent, D) methoxy polyethylene glycol with medium-low molecular weight, and E) one or more than one polyamines with number average molecular weight smaller than 500. According to the invention, the prepared dispersoid is with a small particle size, has long storage time and has great stabilities of acid tolerance, alkali tolerance and salt tolerance, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Combination of general gear oil

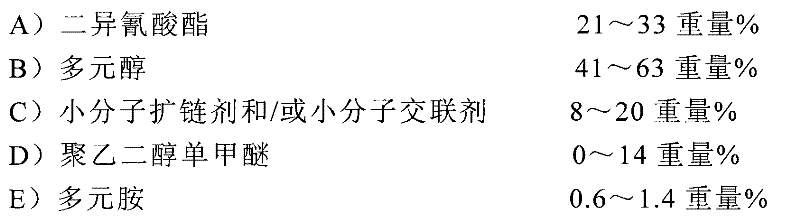

A universal oil composition for gear contains mineral lubricating oil or synthetic lubricating oil or their mixture, at least one viscosity index improver and / or pour depressor, at least one S-contained extreme-pressure agent, at least one P-contained antiwear agent, phosphate-type multi-effect agent, oil agent (1-hydroxyethylene-1, 1-biphosphonate), and at least one metallic deactivator and / or antirust agent.

Owner:CHINA PETROLEUM & CHEM CORP +1

Polyacrylamide microsphere deep profile control agent and preparation method and application thereof

ActiveCN108315003AHigh solid contentHigh effective solid contentDrilling compositionMicrosphereEngineering

The invention relates to a polyacrylamide microsphere deep profile control agent and a preparation method thereof, and mainly solves the problems that in the prior art polymer microspheres used for profile control, plugging oil displacement of medium-high-permeability oil reservoirs are poor in effects, deep profile control cannot be realized, and cost is increased by increasing of the concentration of the polymer microspheres. The polyacrylamide microsphere deep profile control agent includes the following components by weight: 0.05-0. 5 parts of a polymer microsphere emulsion, 0.1 to 1 partof an oil-displacing surfactant, and 0 to 99.85 parts of water; wherein the polymer microsphere core-shell structure comprises a core and a shell, the core is a crosslinked polymer gel microsphere containing an ionic monomer structural unit, the shell is a crosslinked polymer gel containing an ionic monomer structural unit different or same in electrical property with the ionic monomer structuralunit in the core. The polyacrylamide microsphere deep profile control agent solves the problems well and can be used for field enhanced oil recovery application such as deep profile control, water shutoff and oil displacement in the medium-high-permeability oil reservoirs.

Owner:CHINA PETROLEUM & CHEM CORP +1

Animal Bifidobacterium and use method thereof

ActiveCN102191192AGood synergistic growthGood recombinationMilk preparationBacteriaEscherichia coliMicrobiological culture

The invention relates to an animal Bifidobacterium and a use method thereof. The animal Bifidobacterium is the Bifidobactrium amimalis Subsp Lactis B174, the CGMCC No. is 4182, the conservation date is September 16, 2010 and the conservation unit is the China General Microbiological Culture Collection Center. The Bifidobactrium amimalis Subsp Lactis B174 can colonize in human body and resist the gastric acid and cholate of human body. Meanwhile, the strain has better inhibitory action on Escherichia coli and can survive for 30 days at the room temperature. The strain and other lactic acid bacteria have better synergic action for growth; the strain has better combination effect with lactic acid bacteria; the product has better flavor, can be used to prepare fermented yoghurt, animal feed additives and antibacterial solution and can be widely used in the fields of other foods and biological products.

Owner:BEIJING BOJINYUAN BIOTECH

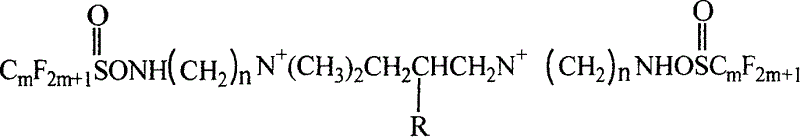

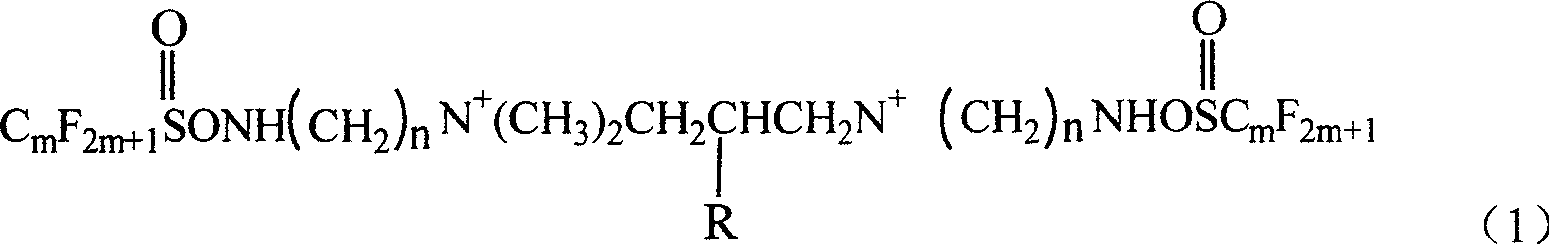

Fluorine-carbon sufactant and preparing method

InactiveCN1743062AReduce surface tensionImprove solubilityTransportation and packagingMixingEthylenediamineDichloropropane

The present invention discloses a new-type double-ion type fluorocarbon surfactant. It is a double-ion type fluorocarbon surfactant using hydrophilic monoester dichloropropane as new-type hydrophilic flexible space group of coupling group, its chemical name is N,N,N',N'-tetramethyl-N,N'-bis [(perfluoroalkyl sulamine)-alkyl]-2-monoester group-propylenediammonium. Said surfactant utilizes reaction of perfluoroalkyl sulfuryl fluoride and N,N-dimethyl-1,2-ethylenediamine or N,N-dimethyl-1,3-propylenediamine to obtain intermediate product N-[(dimethylamino)-alkyl] perfluoroalkyl sulfamine, then makes the intermediate product and monoester dichloropropane undergo the process of quaterisation so as to obtain the invented product.

Owner:NANJING TECH UNIV

Summer using type automobile windscreen cleaning agent

InactiveCN101041791AWith hydrophobic and dust-repelling effectImprove permeabilityNon-ionic surface-active compoundsOrganic detergent compounding agentsAlcoholEther

The invention discloses a summer type windscreen cleaning agent, which is characterized by the following: allocating fatty alcohol polyoxyethylene ether, polyether, inhibitor, ethylene glycol monobutyl ether, alcohol and water; producing the cleaning agent. This invention possesses good penetrability, emulsibility and dewatering and lean dust behavior, which can drop the tensile force of each phase interface.

Owner:BEIJING JIAOTONG UNIV

Process for preparing transparent polypropylene

This invention relates to preparation method of a transparent polypropylene, which takes nano silicasol and organophosphate type polypropylene nucleating agent as materials. Mix the nanometer silicasol and organophosphate type polypropylene nucleating agent and polypropylene by weight ratio of 0.05- 1: 0.1- 1: 100 at 160 to 230deg C.

Owner:贵州省材料技术创新基地

Calcium-doped inorganic nanocomposite material for 3D printing and preparation method of calcium-doped inorganic nanocomposite material

The invention discloses a calcium-doped inorganic nanocomposite material for 3D printing. The calcium-doped inorganic nanocomposite material comprises the following components in percentage by weight: 73-80% of ceramic precursor powder, 5-10% of nano-powder reinforcing material, 2-5% of calcium powder, 2-5% of a surfactant, 2-5% of an organic solvent, 1-4% of an inorganic binder and 5-10% of a low-temperature curing agent, wherein the particle size of the nano-powder reinforcing material is 20-200nm. By adopting the surfactant to perform deaggregation treatment on nano-powder, the nano-powder has excellent dispersivity; by adding the nano-powder into the ceramic precursor powder, the density and strength of ceramic can be improved, and the toughness of a product can be further upgraded; by mutually coordinating and matching the inorganic mixed powder, the inorganic binder and the low-temperature curing agent, the fast binding can be realized at low temperature; and the inorganic nanocomposite material can be used as a molding raw material of a 3D printing fast molding machine, the fast molding on the 3D printing machine can be effectively realized, and the calcium-doped inorganic nanocomposite material can be applied to a variety of types of 3D printing machines.

Owner:QINGDAO MATE RUIOU NEW MATERIAL TECH CO LTD

Material for rapid three dimensional printing forming and preparation method thereof

Owner:广州魁科机电科技有限公司

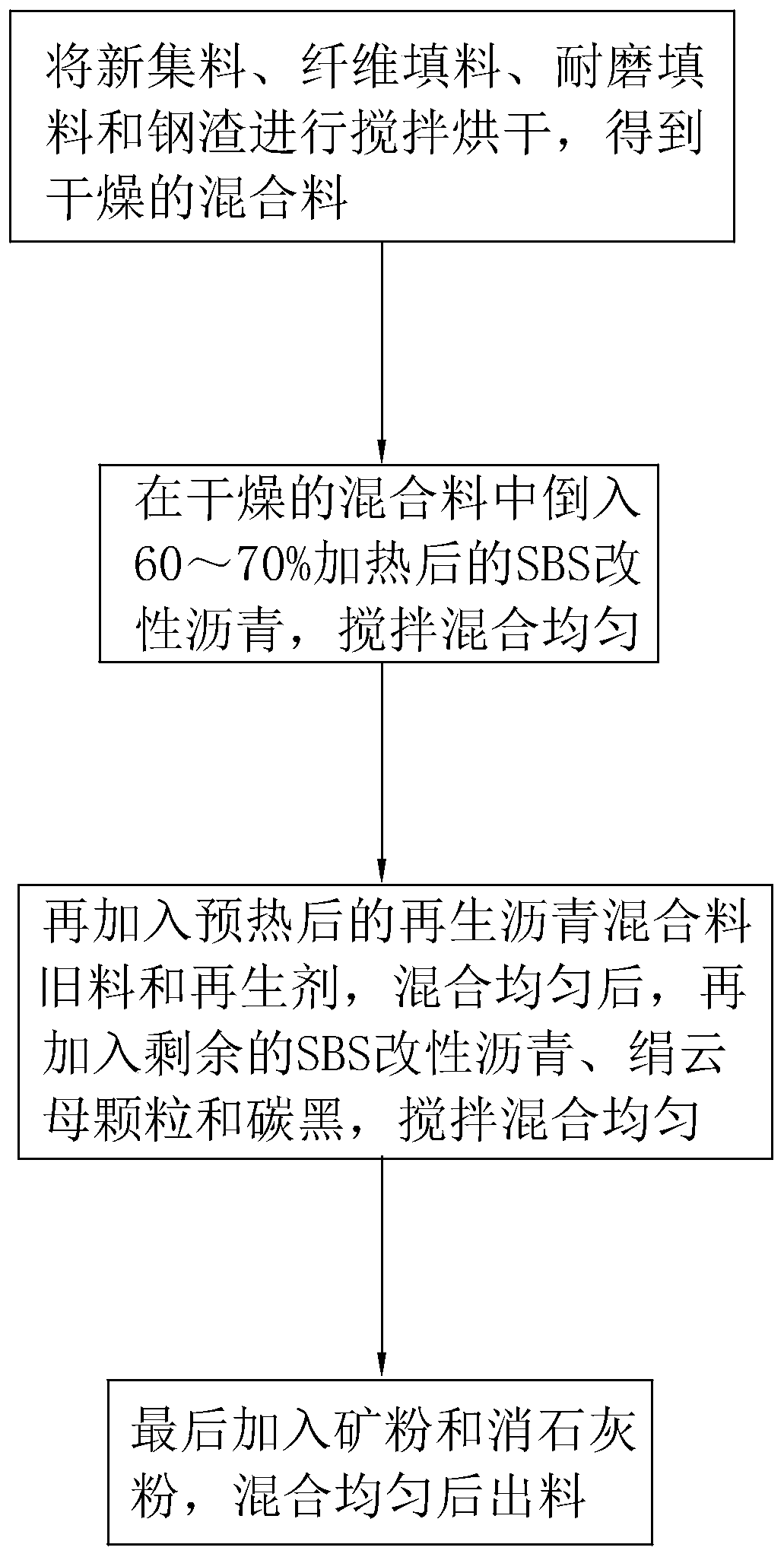

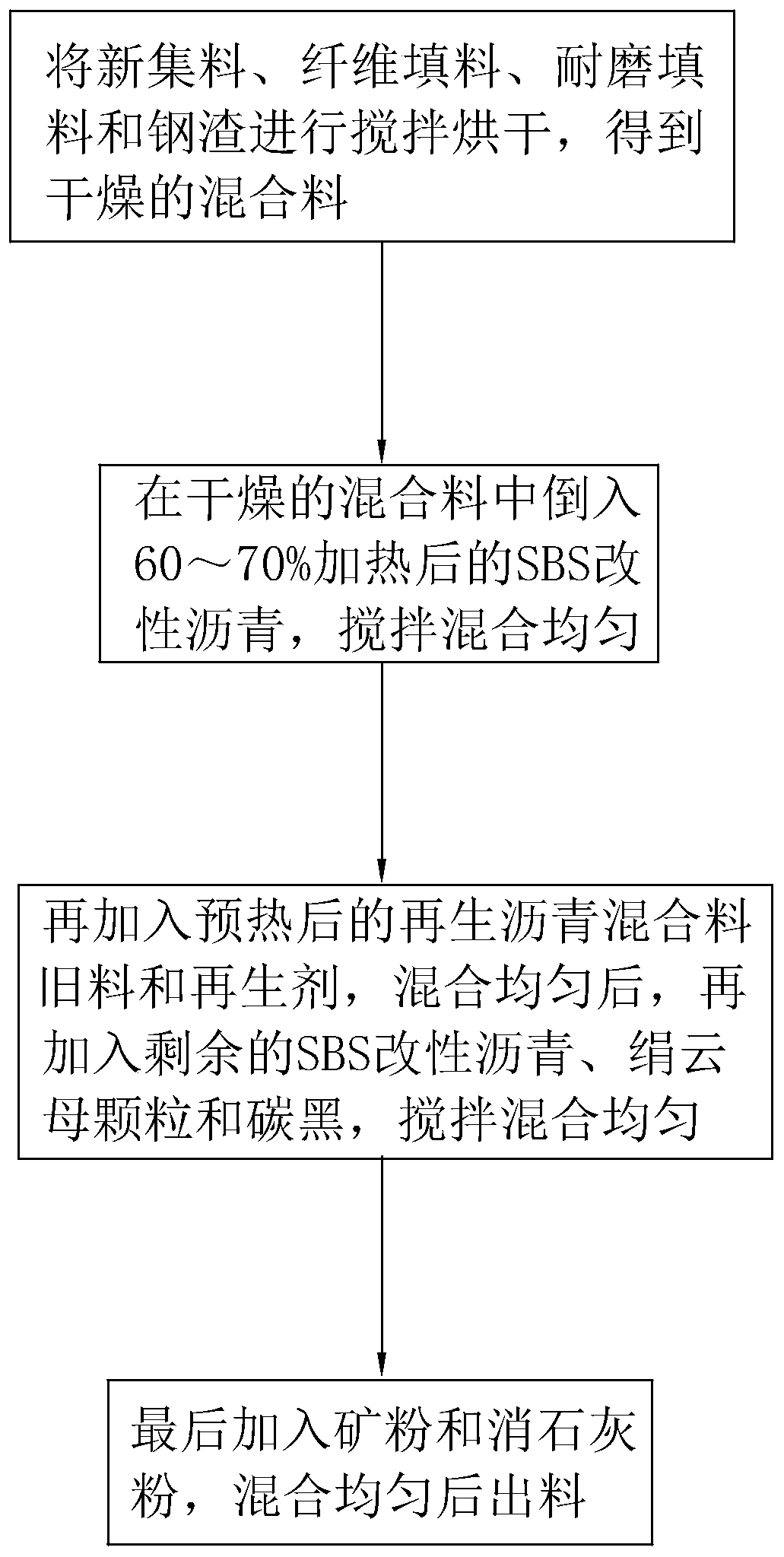

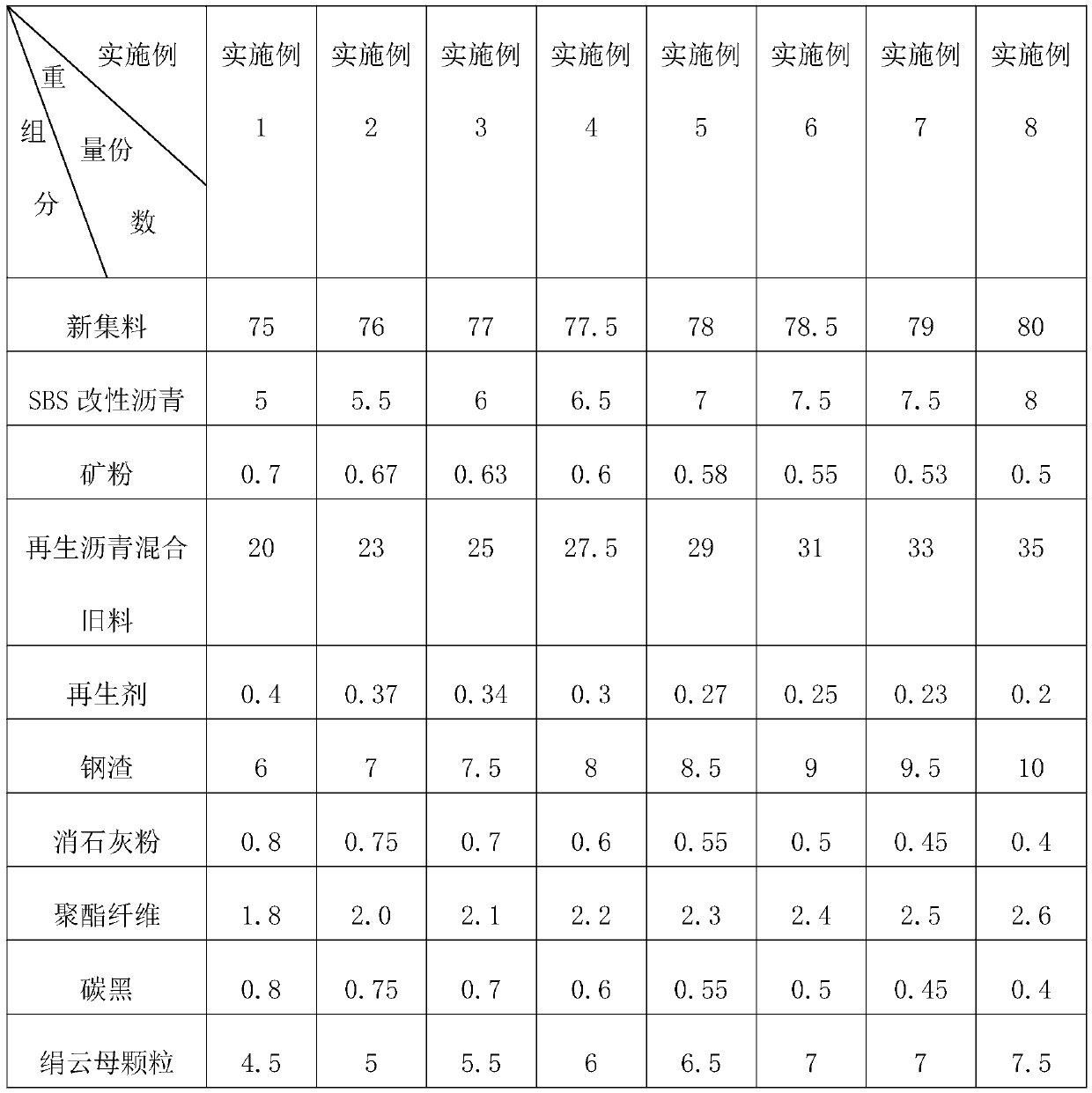

Abrasion-resistant recycled asphalt concrete and preparation process thereof

The invention discloses an abrasion-resistant recycled asphalt concrete and a preparation process thereof, relates to the technical field of asphalt concrete processing, and solves the problem that asphalt concrete pavement is prone to ageing due to frequent temperature changes and is prone to large abrasion during use. The abrasion-resistant recycled asphalt concrete comprises the following components in parts by weight: 75 to 80 parts of new aggregate, 5 to 8 parts of SBS modified asphalt, 0.5 to 0.7 part of mineral powder, 20 to 35 parts of a recycled asphalt mix old material, 0.2 to 0.4 part of a regenerating agent, 6 to 10 parts of steel slag, 0.4 to 0.8 part of hydrated lime powder, 1.8 to 2.6 parts of fiber filler, 0.5 to 1.5 part of abrasion-resistant filler, 0.4 to 0.8 part of carbon black, 4.5 to 7.5 parts of sericite particles. The abrasion-resistant recycled asphalt concrete in the invention has good stability in the use process, is not easy to age due to intermittent friction heat generated between the abrasion-resistant recycled asphalt concrete and a wheel, and is not easy to greatly wear.

Owner:上海宝新特种沥青混凝土有限公司

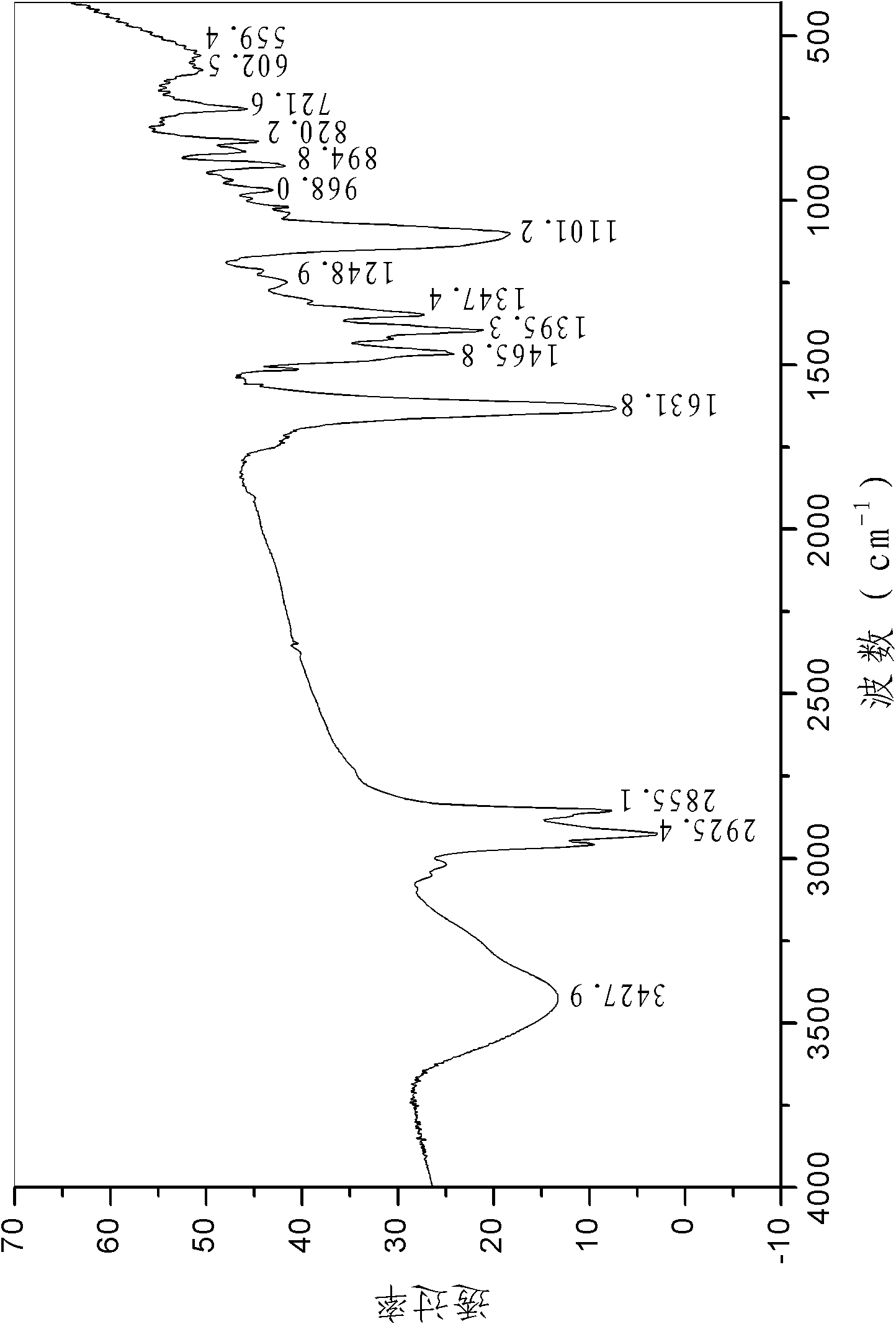

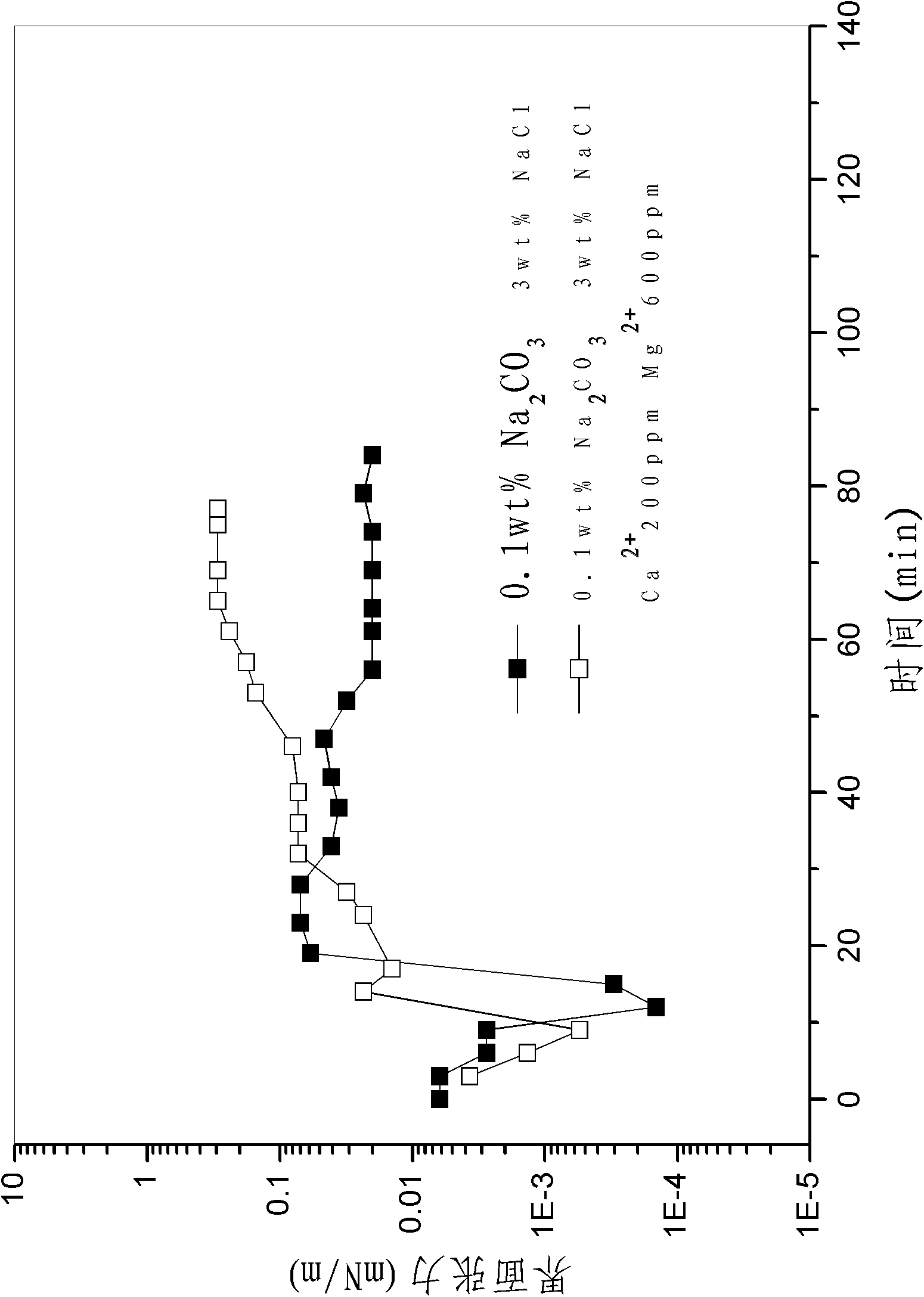

Alkylbenzyl polyoxyethylene ether betaine surfactant and its preparation method and use

ActiveCN102974268AGood water solubilityGood resistance to hard wateOrganic compound preparationTransportation and packagingSolubilityBenzene

The invention relates to an alkylbenzyl polyoxyethylene ether betaine surfactant and its preparation method and use. The alkylbenzyl polyoxyethylene ether betaine surfactant is a zwitterionic surfactant. Alkyl benzene undergoes a series of reactions to produce the alkylbenzyl polyoxyethylene ether betaine surfactant. Through a unique molecular structure, the alkylbenzyl polyoxyethylene ether betaine surfactant has excellent water-solubility, water hardening resistance, a wide pH application scope, low toxicity, good degradability, and good compatibility with other types of surfactants, can be used for fields of washing, weaving and tertiary oil recovery, has high activity, a critical micelle concentration of 10<-5> to 10<-6>mol / L, and surface tension of 23 to 30mN / m at the critical micelle concentration. Through alone use or compounding with other auxiliaries, the alkylbenzyl polyoxyethylene ether betaine surfactant can form ultralow interfacial tension having the magnitude of 10<-3>mN / m with simulated oil alkane or crude oil and can be used in tertiary oil recovery. The alkylbenzyl polyoxyethylene ether betaine surfactant has a structural formula shown in the patent specification.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI +1

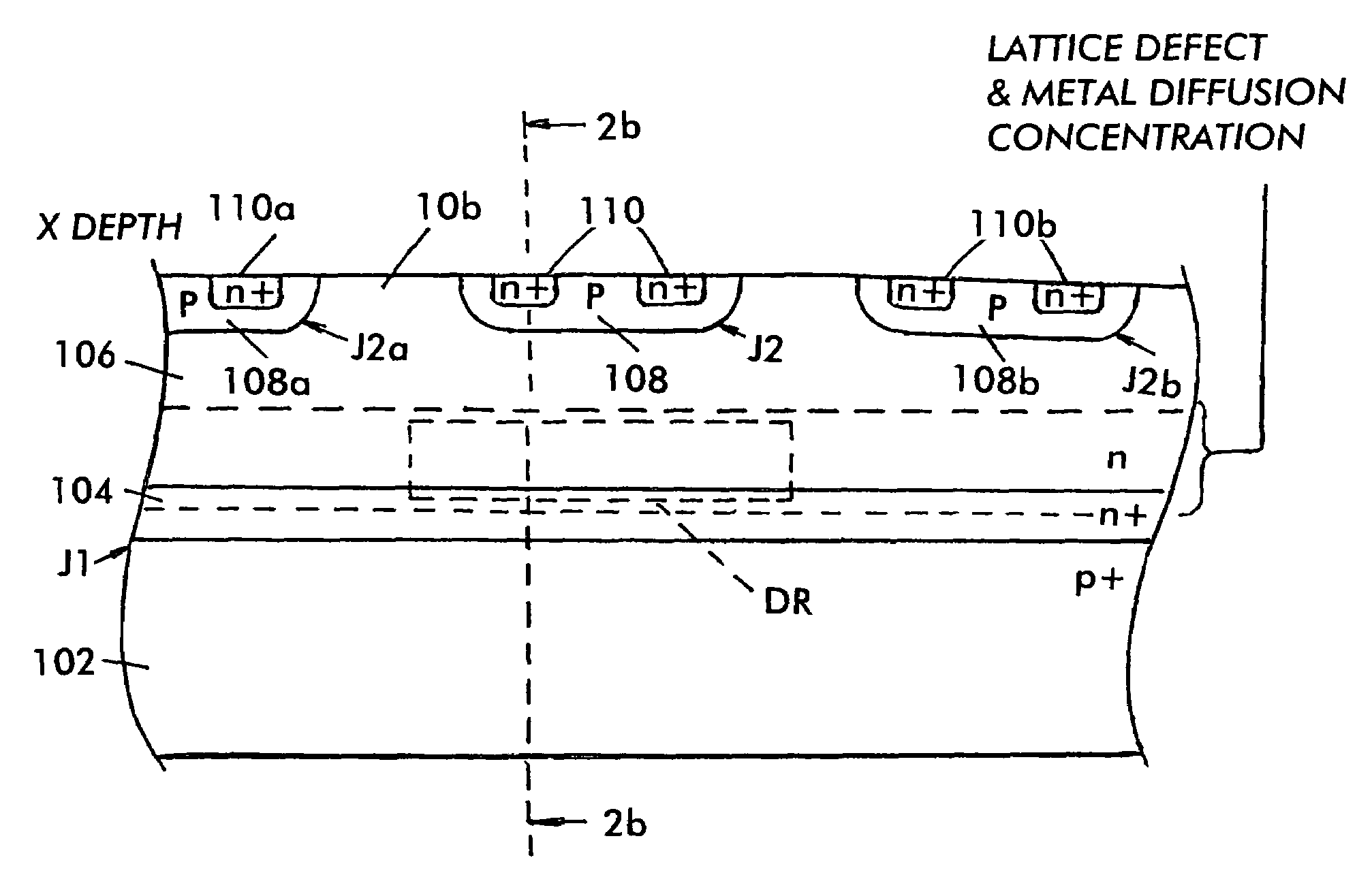

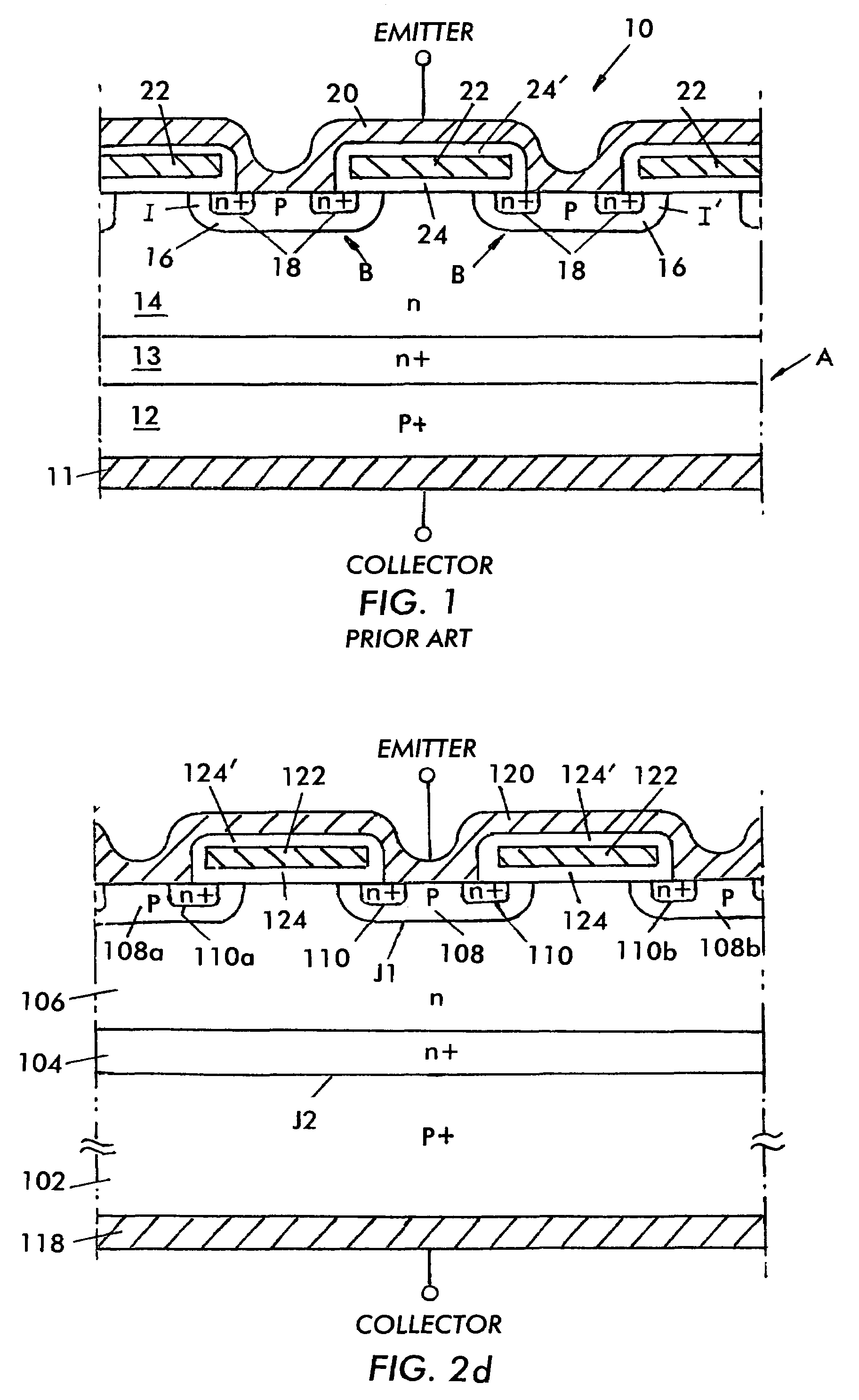

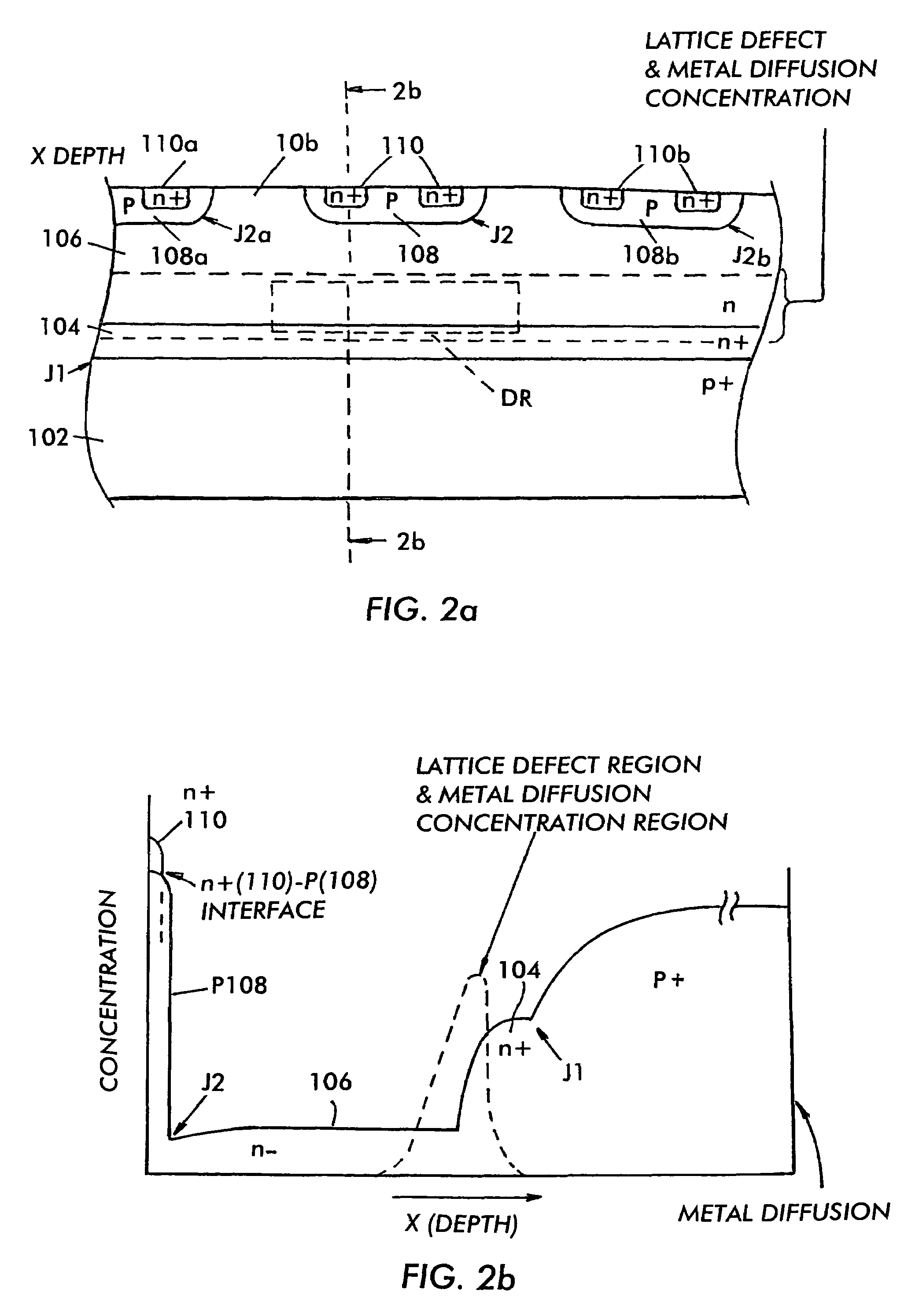

Process to create buried heavy metal at selected depth

InactiveUS7485920B2Reduced carrier lifetimeReduce disadvantagesTransistorThyristorLattice defectsParticle beam

Semiconductor devices having recombination centers comprised of well-positioned heavy metals. At least one lattice defect region within the semiconductor device is first created using particle beam implantation. Use of particle beam implantation positions the lattice defect region(s) with high accuracy in the semiconductor device. A heavy metal implantation treatment of the device is applied. The lattice defects created by the particle beam implantation act as gettering sites for the heavy metal implantation. Thus, after the creation of lattice defects and heavy metal diffusion, the heavy metal atoms are concentrated in the well-positioned lattice defect region(s).

Owner:INFINEON TECH AMERICAS CORP

Oil displacing agent for increasing oil recovery in high temperature high salt mid-low permeability oil reservoir, preparation method and applications thereof

ActiveCN105505364AGood temperature and salt resistanceGood thermal stabilityDrilling compositionChemistryChromatographic separation

The invention relates to an oil displacing system for increasing oil recovery in high temperature high salt mid-low permeability oil reservoir, and a preparation method thereof, and aims to solve the problems that in the prior art, hydrophobic associated polymer can easily obstruct the holes of sandstone formation, the injection performance of oil displacing agent is bad in the immediate vicinity of wellbore, the oil displacing agent can only applied to mid-high permeability oil reservoirs, and the hydrophobic associated polymer can easily react with oil displacing surfactant to generate chromatographic separation. The oil displacing agent comprises the following components in parts by weight: 0.01 to 1 part of adsorption resisting agent, 0.05 to 3 parts of hydrophobic associated polymer, 0.2 to 5 parts of oil displacing surfactant, and 91 to 99.8 parts of water; wherein the adsorption resisting agent is one or more of nonionic surfactant and anionic surfactant. The provided oil displacing agent well solves the problems mentioned above, and can be applied to the onsite oil displacing in a mid-low permeability oil reservoir.

Owner:CHINA PETROLEUM & CHEM CORP +1

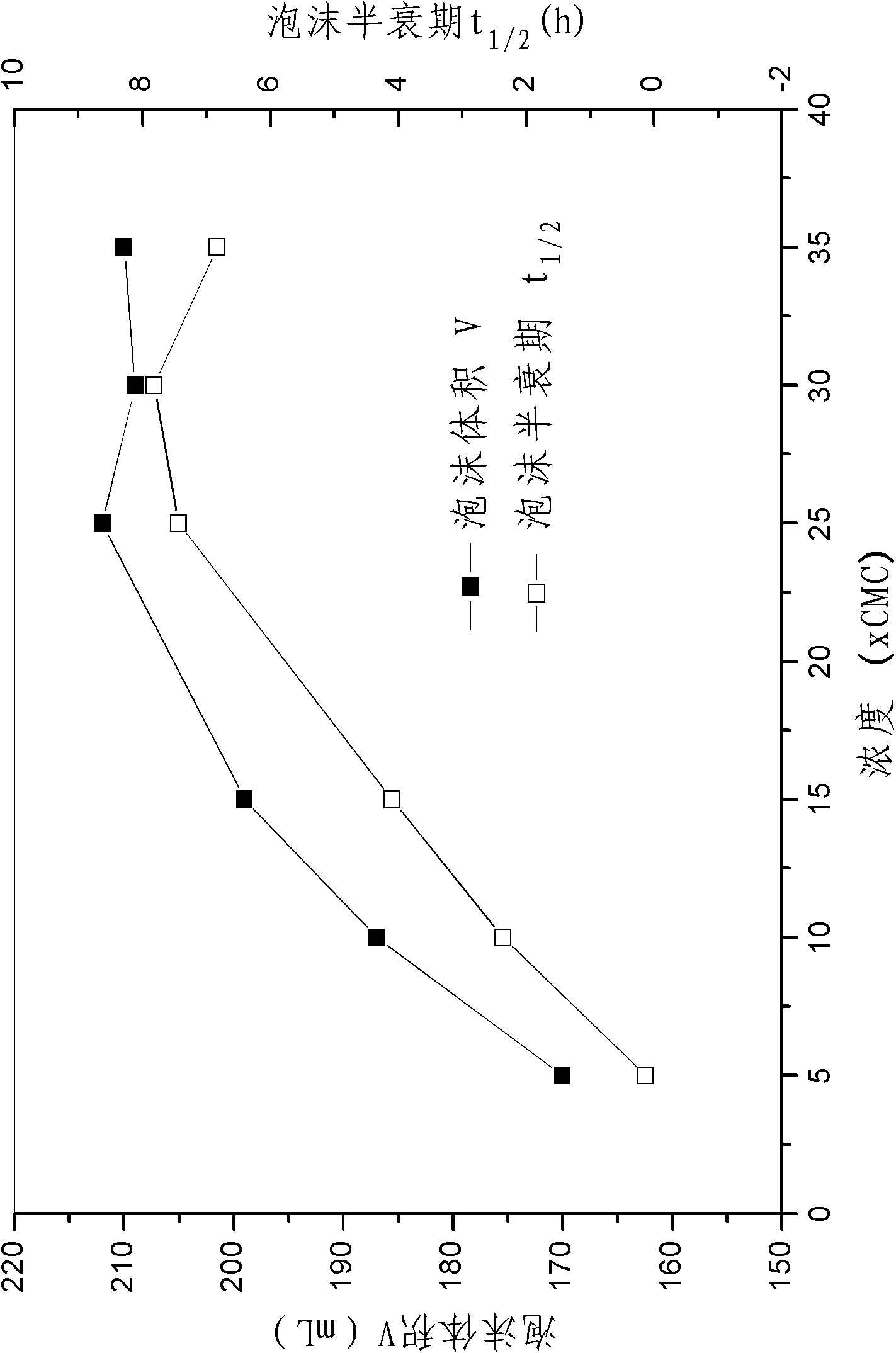

Low-tension polymer microsphere profile control and flooding agent, and preparation method and application thereof

The invention relates to a low-tension polymer microsphere profile control and flooding agent, and a preparation method and an application thereof and mainly solves the problems that polymer microspheres and oil displacement surfactants are poor in compatibility with an oil displacement surfactant and slug injection is necessary in the prior art. The low-tension polymer microsphere profile controland flooding agent includes, by weight, 0.05-0.5 parts of a polymer microsphere emulsion, 0.1-1 parts of the oil displacement surfactant, and 0-99.85 parts of water. The profile control and floodingagent has high effective solid content, good stability, and ultralow oil-water interface tension. The polymer microspheres have effect of deep profile control while the surfactant has the effect of oil displacement, so that the product has both profile control and flooding functions. The profile control and flooding agent has convenience in site operation and can be used for site application, suchas deep profile control, water plugging and oil displacement, of tertiary oil recovery of high-temperature and high-salt oil fields for increasing recovery efficiency.

Shoe and sock anti-bacterium and odor eliminating agent and preparation method thereof

InactiveCN105875621AStrong ability to kill bacteriaChemically stableBiocideDead animal preservationSolventPhenol

The invention relates to a shoe and sock anti-bacterium and odor eliminating agent and a preparation method thereof. The existing product for eliminating odor of shoes and socks sold in the market has the defects that the odor eliminating function is weakened after the use for a period of time; the bacterium growth and breeding cannot be effectively inhibited; or even some formulas contain nonyl phenol type substances with poor biological degradability, so that the environment pollution can be easily caused. A product comprises a solvent, an antibacterial agent, an odor eliminating agent, a mildewproof agent, deionized water, essence and pigments; the materials are mixed and prepared; two efficacies of anti-bacterium and odor elimination are achieved; the defects in the prior art are overcome; the shoe and sock anti-bacterium and odor eliminating agent is mild and inirritative; the shoe and sock contamination is avoided; safety and environment protection are realized; the use is convenient.

Owner:于文 +1

Preparation method of de-filtration plugging agent for water-base drilling fluids

ActiveCN104497188AGood recombinationControl high temperature and high pressure filtration lossDrilling compositionWater basedPolymer science

The invention relates to a preparation method of a de-filtration plugging agent for water-base drilling fluids. The de-filtration plugging agent is prepared by carrying out emulsion polymerization on styrene monomer, acrylate monomer and polymerizable emulsifier monomer as main raw materials by using deionized water as a solvent. The de-filtration plugging agent for water-base drilling fluids has favorable compounding performance in polysulfonate and polymer water-base drilling fluids and alkyl glycoside soil-phase-free water-base drilling fluids, and can effectively control the high-temperature high-pressure filtrate rate of the water-base drilling fluids within the addition range of 2-3%. By properly introducing the benzene-ring-containing crosslinked structure, the temperature resistance of the plugging agent can reach 130 DEG C.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

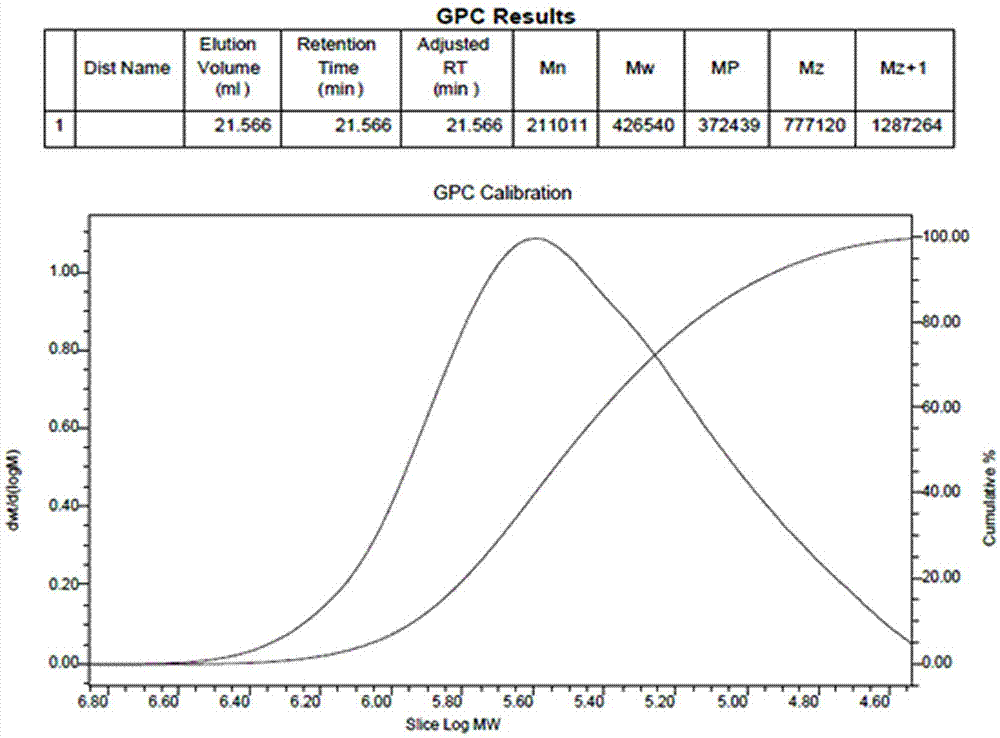

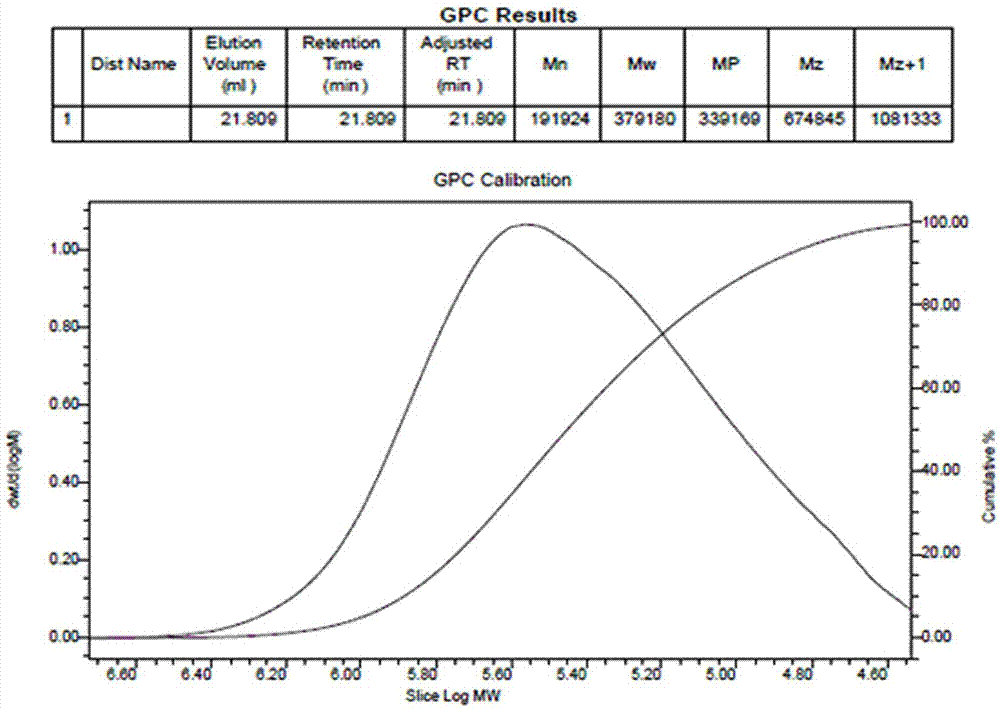

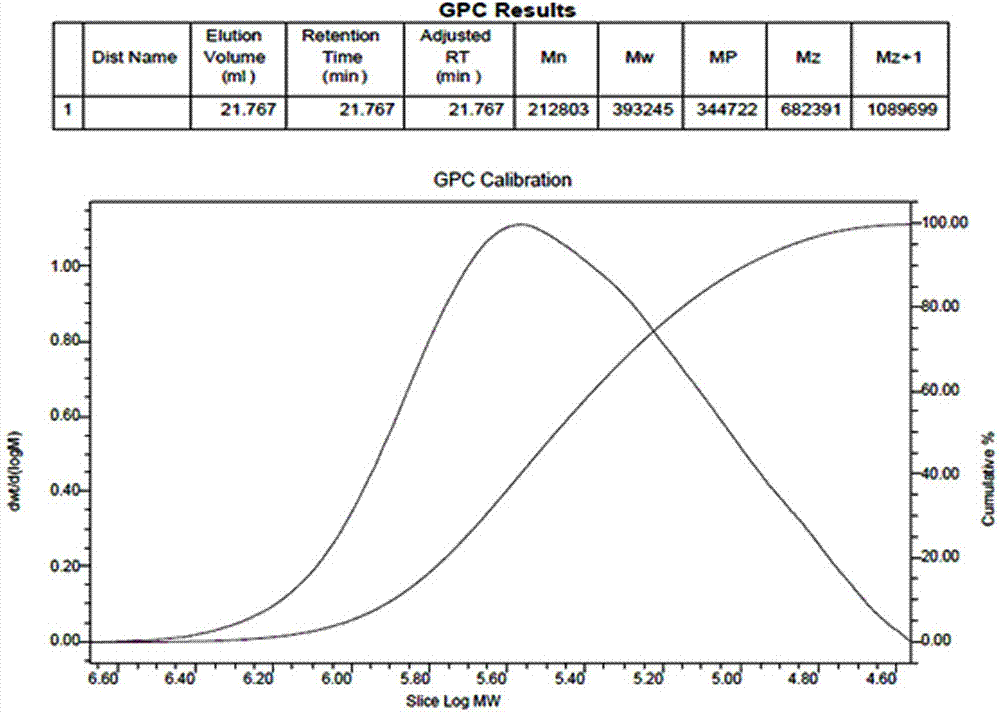

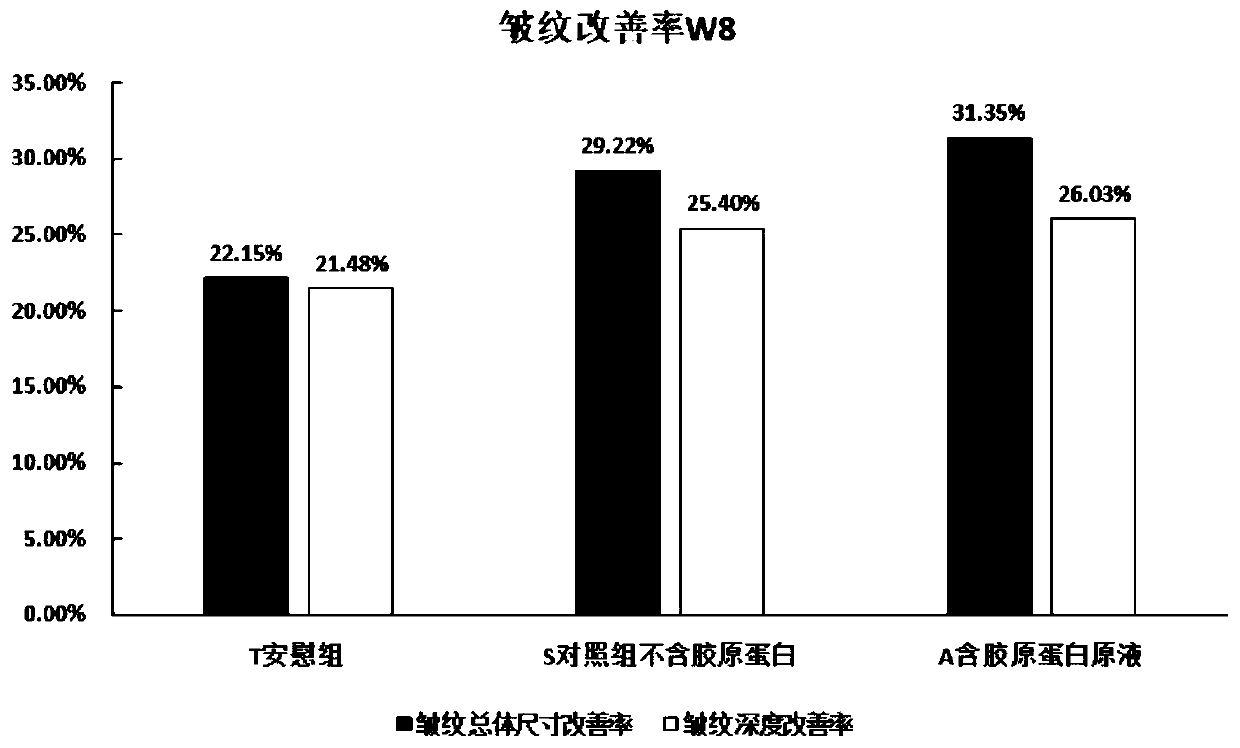

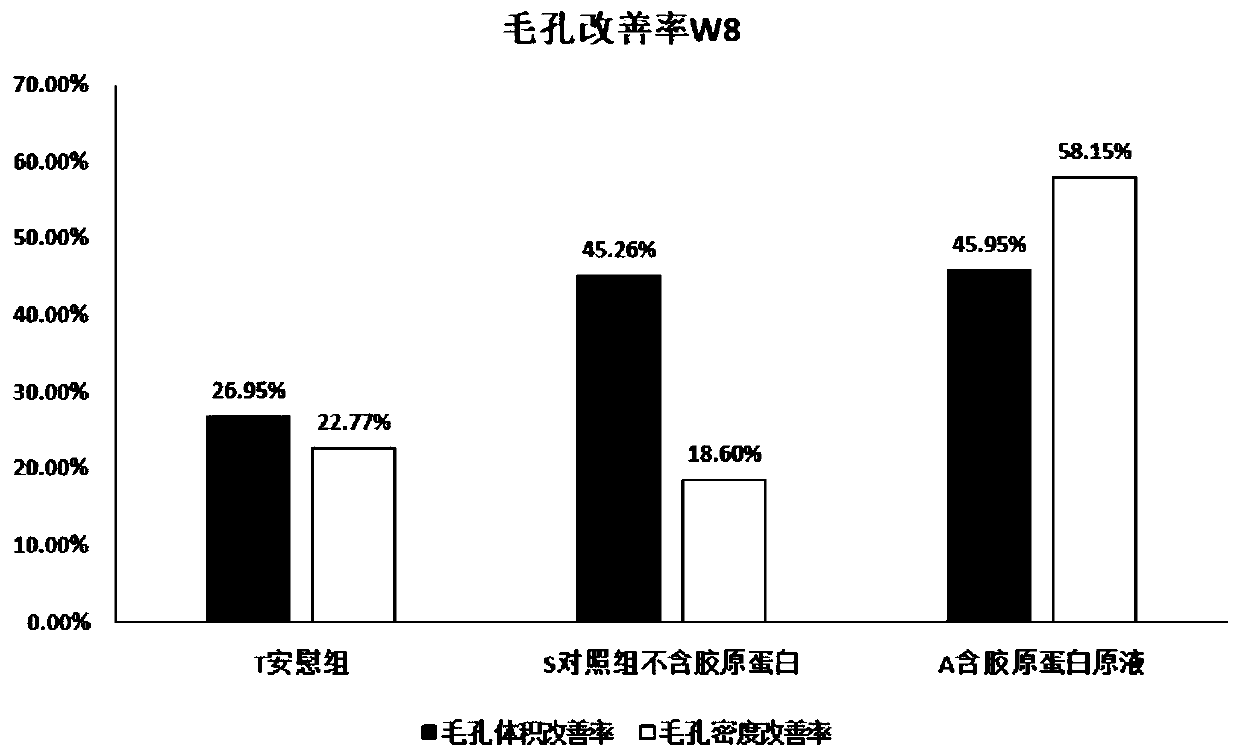

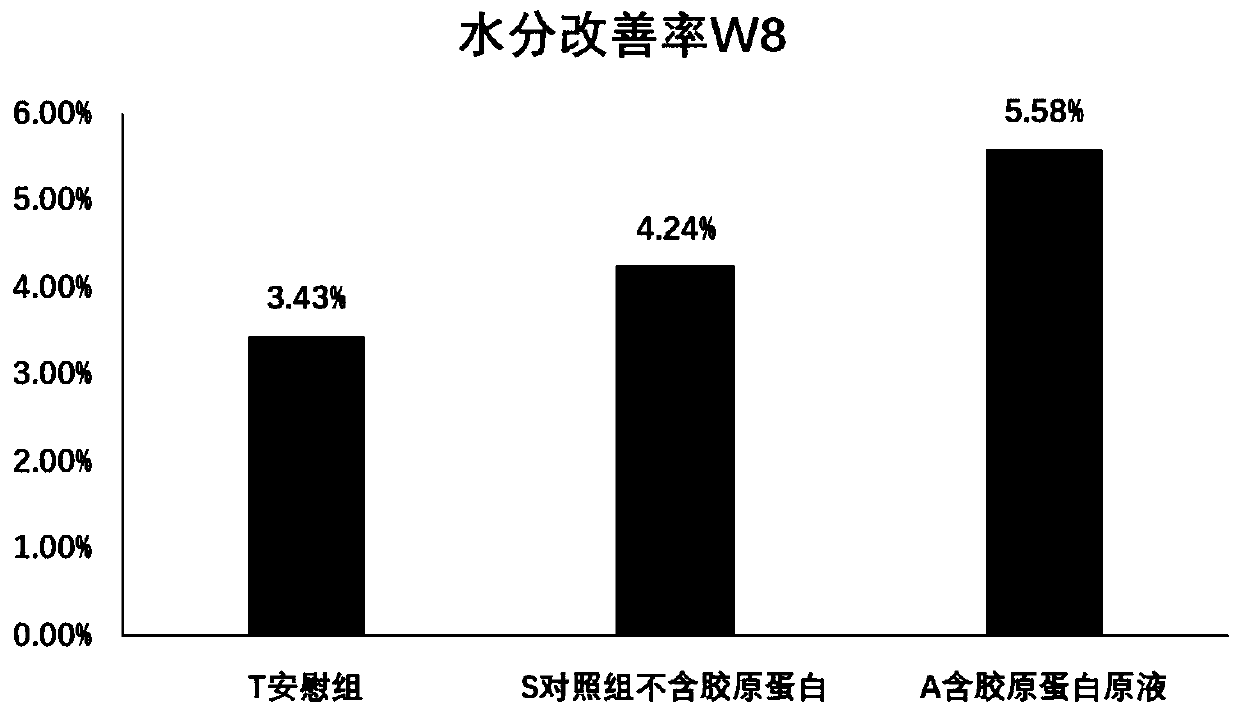

Wrinkle-removing essence containing recombinant collagen

ActiveCN110934766APlay the effect of firming and anti-wrinkleNo smellCosmetic preparationsToilet preparationsGlycerolCollagenan

The invention discloses wrinkle-removing essence containing recombinant collagen, which belongs to the field of cosmetics. The wrinkle-removing essence is prepared from the following components in percentage by mass: 0.1%-1% of recombinant collagen, 10%-30% of glycerol, 1%-5% of 1, 2-hexanediol, 0.1%-0.5% of sodium hyaluronate, 0.1%-0.5% of polyglutamic acid, 0.05%-2% of acetyl hexapeptide-8, 0.03%-2% of elastin, 0.01%-1.5% of fibronectin and the balance of water. The recombinant collagen from microbial fermentation is compounded with other raw materials, so that the problems of precipitation,discoloration, precipitation and the like are avoided. According to the wrinkle-removing essence disclosed by the invention, the recombinant collagen, the sodium hyaluronate, the sodium polyglutamateand the like are compounded for use, so that the effects of tightening and removing wrinkles of the recombinant collagen can be better exerted while moisturizing and water locking are realized.

Owner:JIANGSU JLAND BIOTECH CO LTD

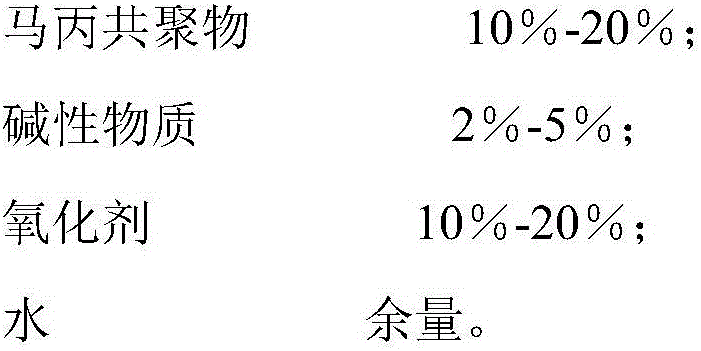

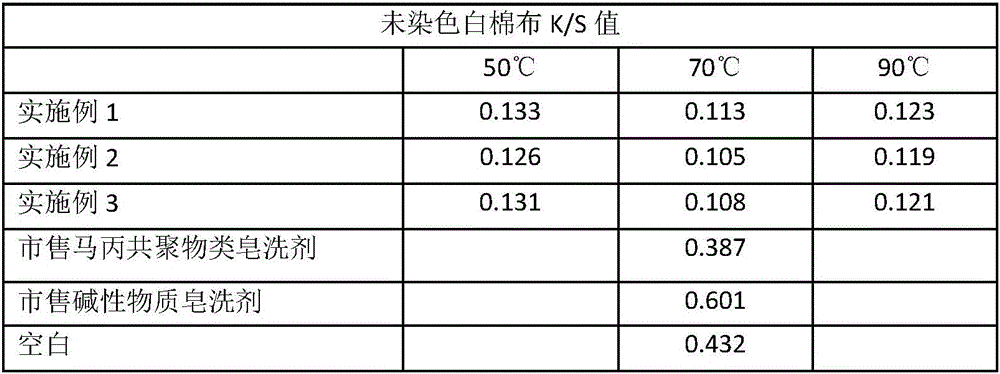

Low-temperature reactive dye soaping agent as well as preparation method and application thereof

InactiveCN106566726AGuaranteed anti-staining effectGood compounding effectDetergent compounding agentsOrganic non-surface-active detergent compositionsReactive dyeMethyl acrylate

The invention discloses a low-temperature reactive dye soaping agent as well as a preparation method and an application thereof. The low-temperature reactive dye soaping agent comprises the following components in percentage by mass: 10%-20% of a maleic-methyl acrylate copolymer, 2%-5% of an alkaline substance, 10%-20% of an oxidant and the balance of water.

Owner:苏州联胜化学有限公司

Halogen-free flame-retardant antibacterial anti-aging polypropylene composite material and preparation method thereof

The invention relates to a halogen-free flame-retardant antibacterial anti-aging polypropylene composite material and a preparation method thereof. The preparation method comprises the following steps: weighing a polypropylene raw material, a halogen-free flame retardant and modified nano zinc oxide, and mixing to be uniform; adding a mixture into a double screw extruder, and granulating at a certain temperature and rotary speed of a screw rod to obtain halogen-free flame-retardant antibacterial anti-aging polypropylene master batch. Halogen-free flame-retardant antibacterial anti-aging polypropylene prepared by adopting the method is excellent in flame retardant property, good in antibacterial and anti-aging performance and mechanical property, low in cost, convenient to prepare and suitable for industrialized production.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Preparation method for inorganic-organic modified attapulgite clay

InactiveCN102701230AExcellent pH stability and shear thinning propertiesGood compatibility and recombinationSilicon compoundsChemistryPhosphate

The invention discloses a preparation method for inorganic-organic modified attapulgite clay. The preparation method comprises the steps as follows: dissolving phosphate in water while stirring, then adding the preprocessed attapulgite clay to prepare a suspension liquid with the mass concentration of 5 to 20%; enabling the suspension liquid to pass through a 200-mesh sieve so as to remove impurities, reacting for 1 to 3 h at room temperature, then adding a certain amount of cationic surfactant, and continuously reacting for 1 to 2 h at the temperature of 20 to 90 DEG C so as to obtain pulp; and centrifuging, dehydrating, drying and grinding the obtained pulp so as to obtain the inorganic-organic modified attapulgite clay, wherein the addition amount of the phosphate is 1 to 10% of the attapulgite clay by mass, and the addition amount of the cationic surfactant is 0.05 to 5% of the attapulgite clay by mass. According to the preparation method, the process is easy to operate, the obtained inorganic-organic modified attapulgite clay has the characteristics of high viscosity, shear thinning and the like, and the requirements of fine chemical engineering industries, such as coatings, printing inks and cosmetics, on mineral thickeners are satisfied.

Owner:中国科学院兰州化学物理研究所盱眙凹土应用技术研发中心

Water-based metal rust inhibitor and preparation method thereof

The invention provides a water-based metal rust inhibitor and a preparation method thereof. The rust inhibitor comprises sorbitan monooleate, inositol hexaphosphate, zinc dihydrogen phosphate, acrylamide, glutamic acid, dinonyl-naphthalenesulfonate, dicyclohexylamine, octadecylamine oleyl sarcosinate, oxidized barium petrotate, sodium ethylenediamine teramethylene phosphonate, 1-hydroxyethylidene, dimethylaminoethyl acrylate, sulfomethylated polyacrylamide, a film forming agent and deionized water. The preparation method comprises the steps of firstly, mixing sorbitan monooleate, inositol hexaphosphate, zinc dihydrogen phosphate and water, and adding octadecylamine oleyl sarcosinate; then, adding acrylamide, glutamic acid, dinonyl-naphthalenesulfonate, dicyclohexylamine and oxidized barium petrotate into the deionized water, and adding 1-hydroxyethylidene; and mixing a mixture I and a mixture II, and adding the left components to obtain the water-based metal rust inhibitor. The rust inhibitor can be attached to the surface of metal, so that the metal has better wear resistance and corrosion resistance.

Owner:NINGBO SHEN XIN ELECTRONICS CO LTD

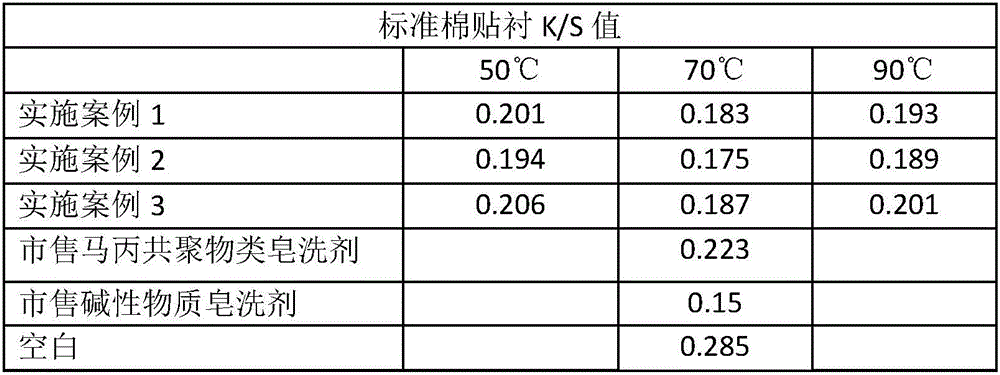

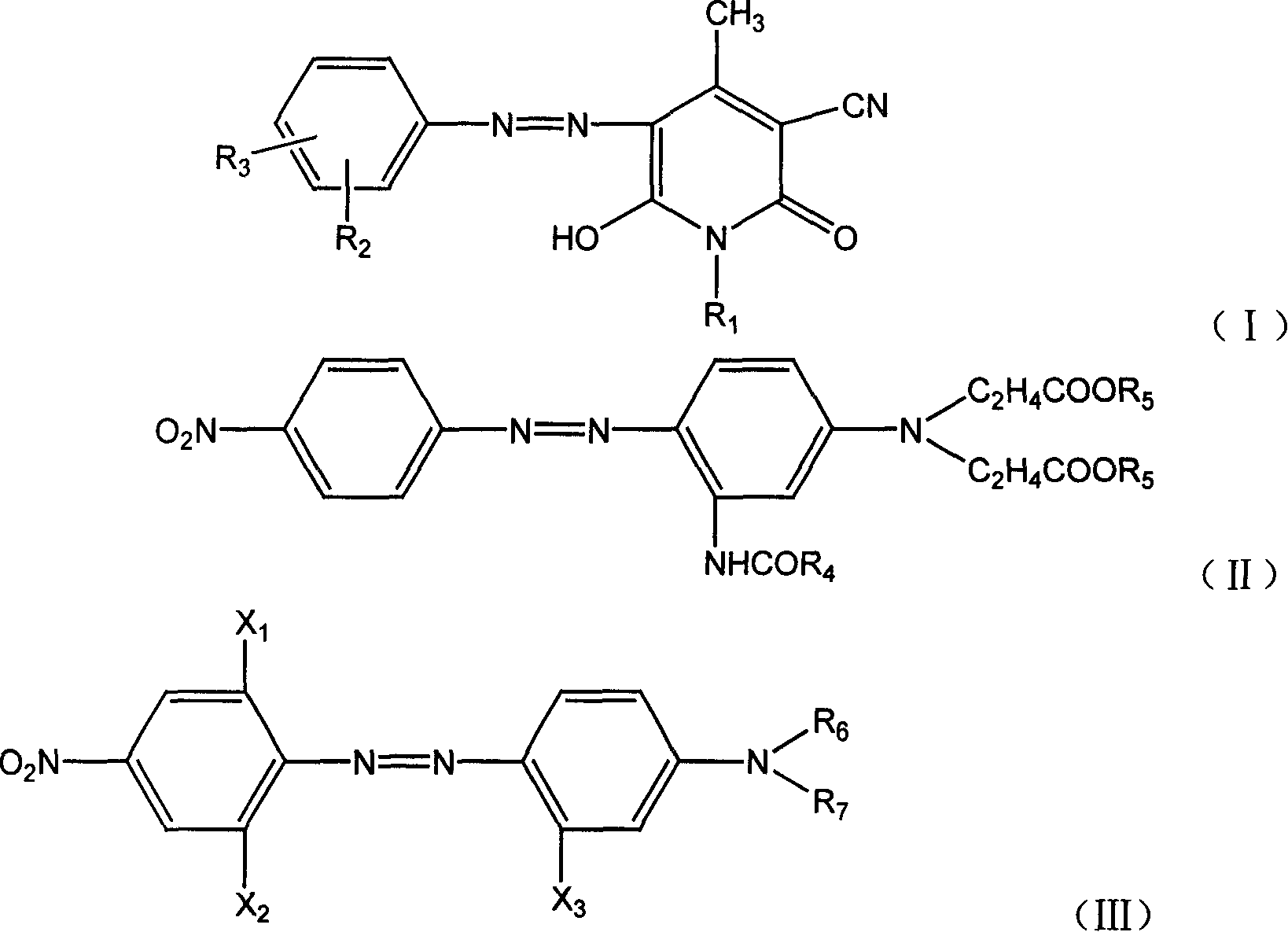

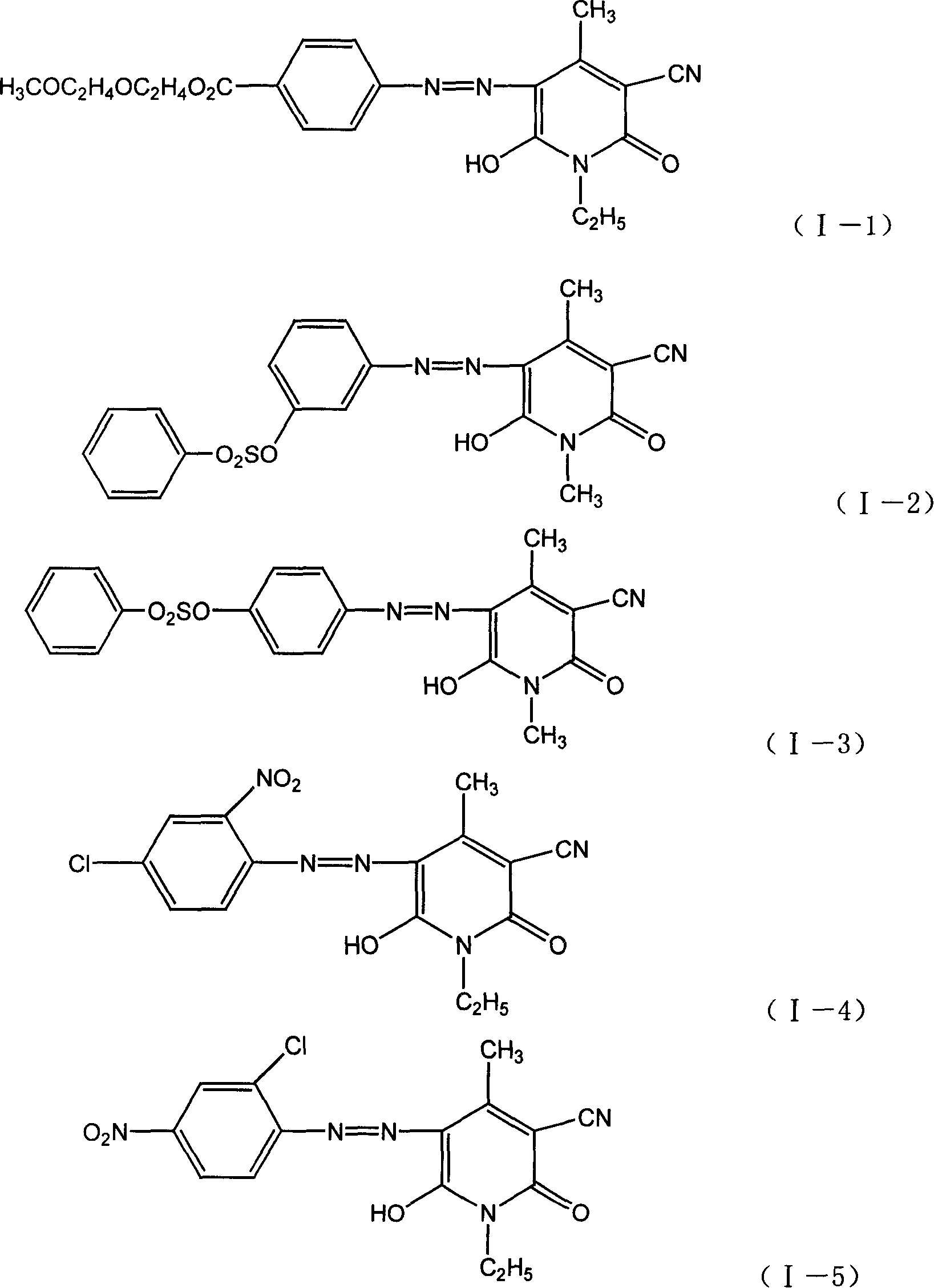

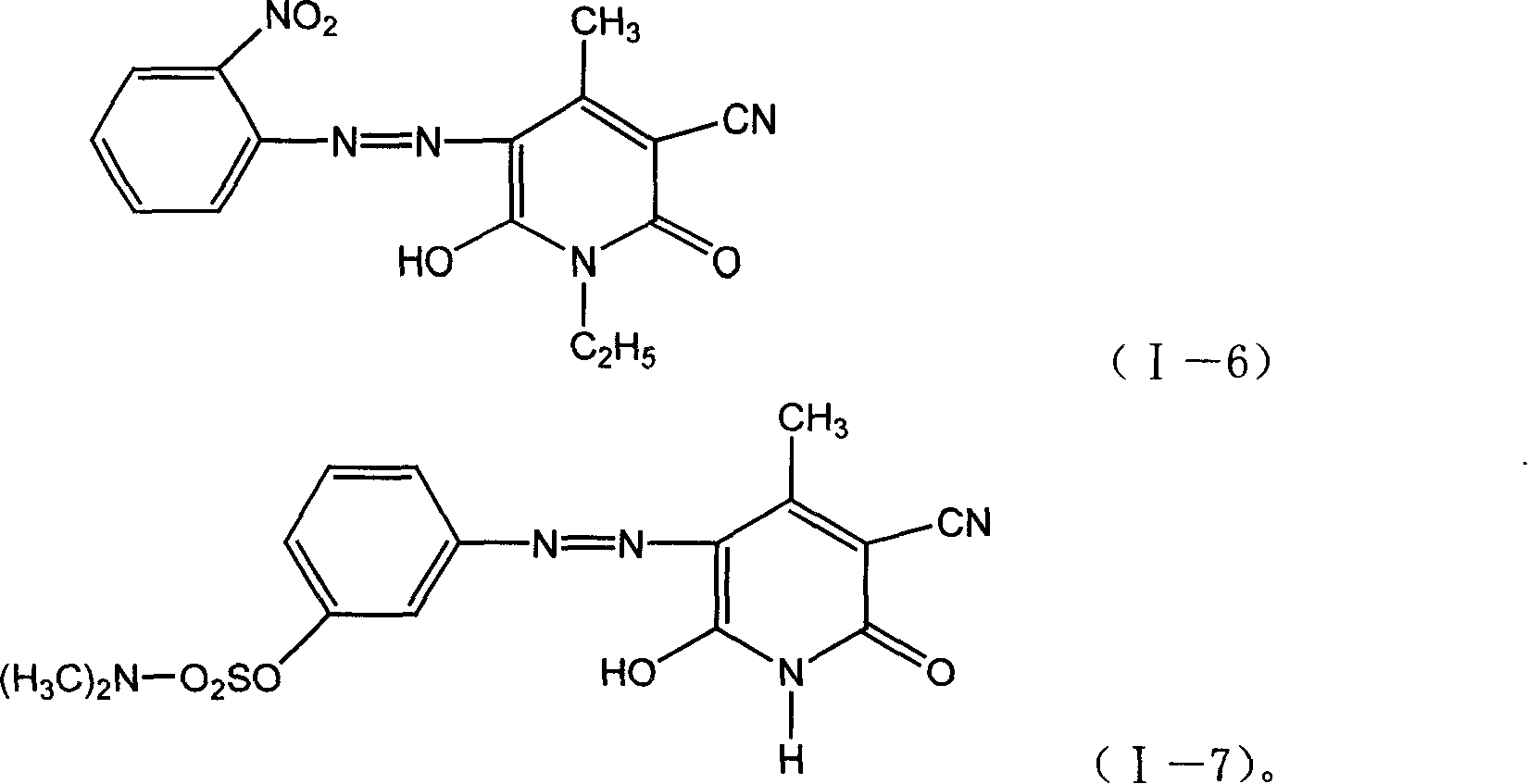

Admixture of disperse dyes

InactiveCN1916083AExcellent fastness performanceGood recombinationOrganic dyesDyeing processPhotochemistryDisperse dye

This invention discloses a mixture of dispersed dyes, which is composed of: one or more dyes (shown in formula I) 55-95 wt.%, one or more dyes (shown in formula II) 1-30 wt.%, and one or more dyes (shown in formula III) 1-15 wt.%. When then mixture of dispersed dyes is used to dye polyester fiber materials, by adjusting the ratio of different components, organic fabrics with such advantages as good luster, high dispersibility, high sunlight resistance, high washing resistance and high sweat resistance can be obtained.

Owner:ZHEJIANG LONGSHENG GROUP

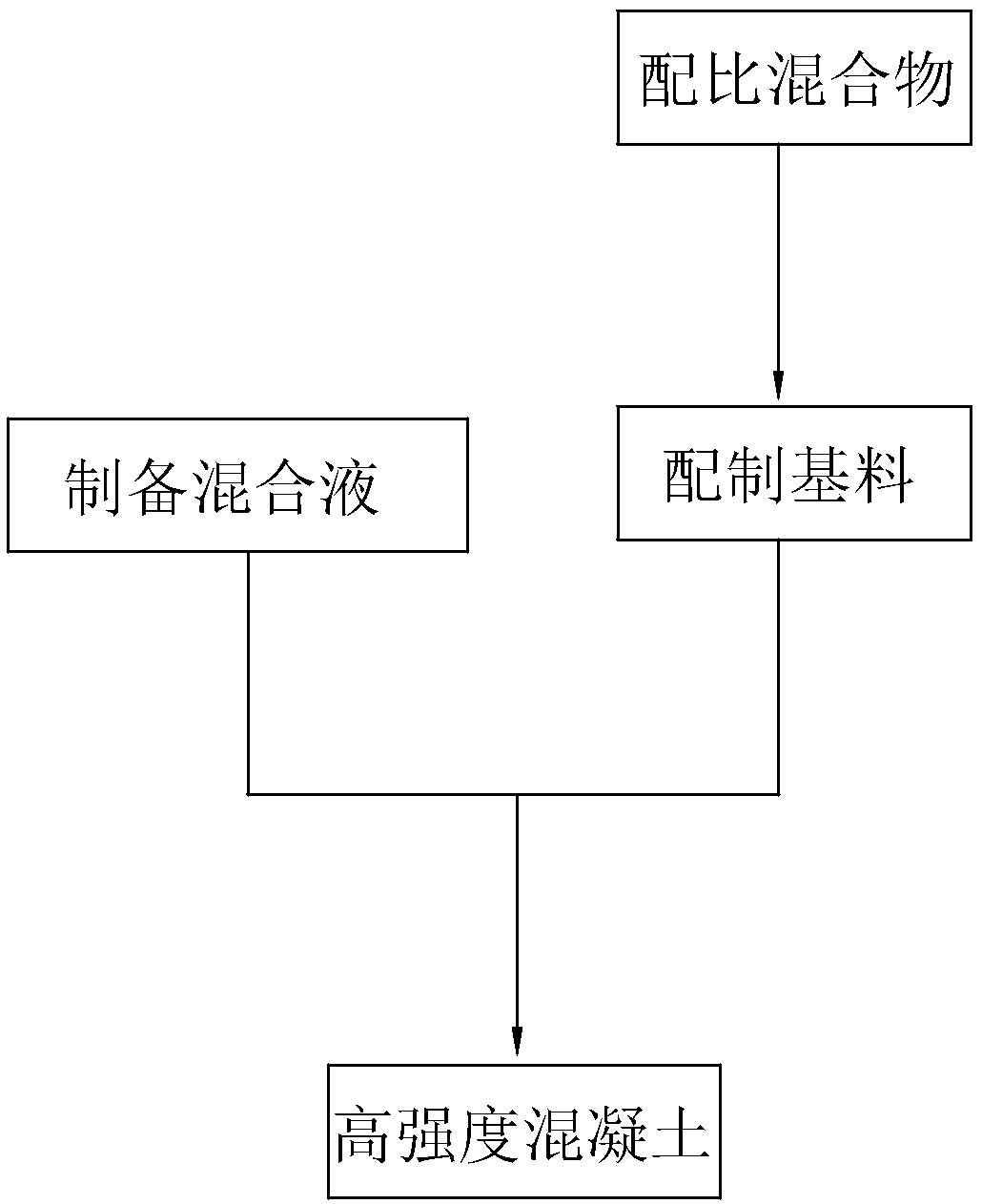

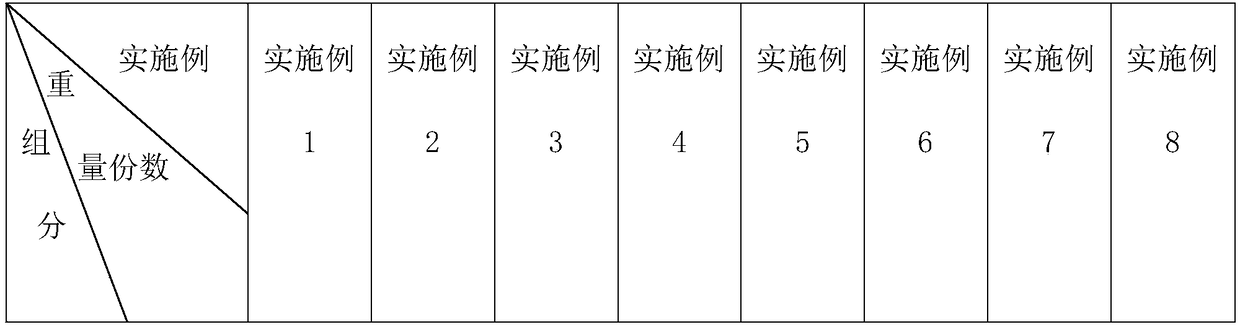

High-strength concrete and preparation process thereof

The invention discloses high-strength concrete and a preparation process thereof and relates to the technical field of concrete. The problem is solved that poor binding property of component raw materials in concrete causes lower overall structural strength. The high-strength concrete comprises, by weight, the following components: 190-210 parts of water, 330-350 parts of Portland cement, 480-520parts of medium sand, 720-790 parts of cobbles, 30-60 parts of rock wool, 50-80 parts of expanded perlite, 4-6 parts of a retarder, 2.5-3.5 parts of water reducing agent, 60-80 parts of ore powder, 45-55 parts of pulverized fuel ash and 18-26 parts of fiber filler. The high-strength concrete has higher compactness and thus has good structural strength.

Owner:上海兆捷实业发展有限公司

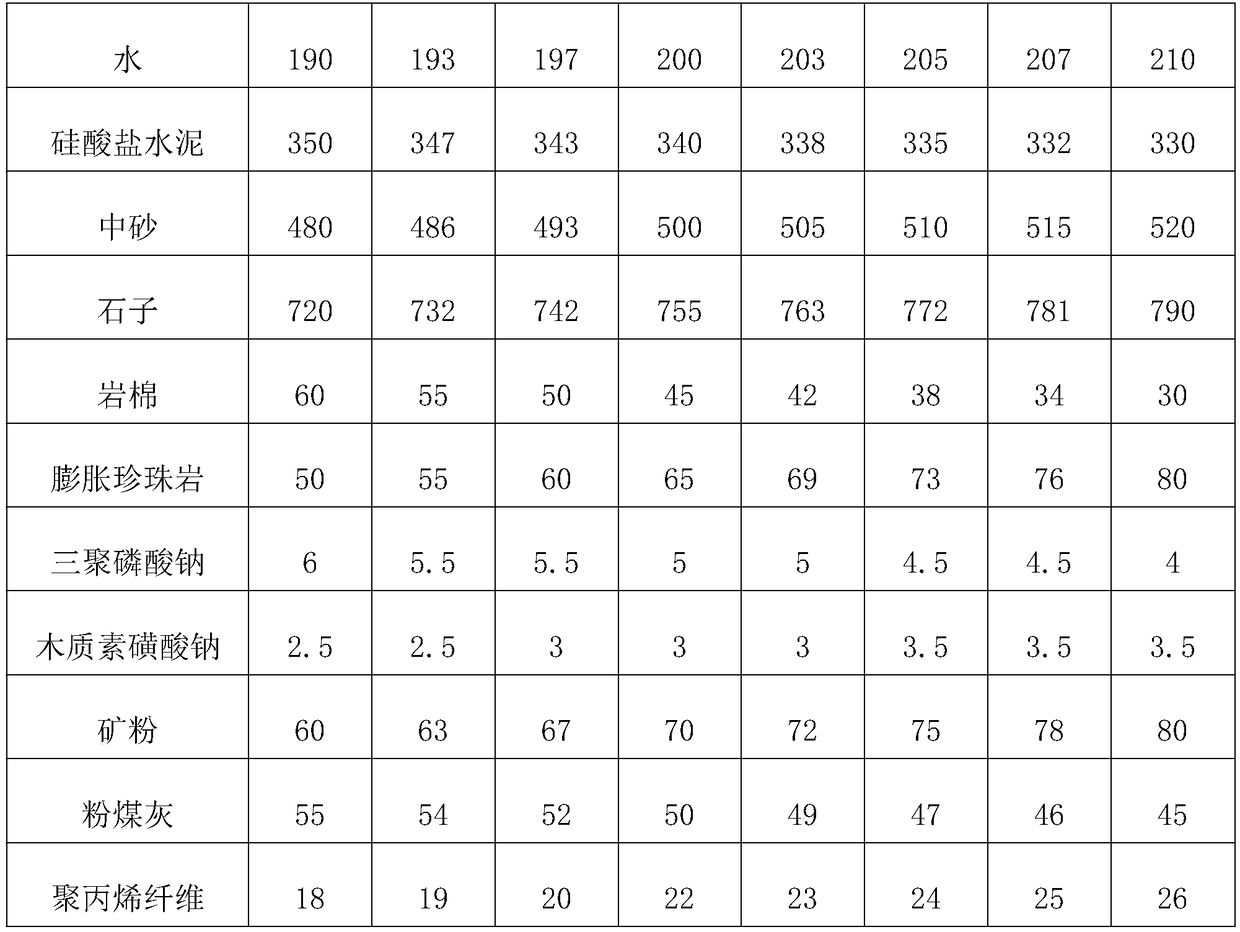

Oil base drilling cuttings cleaning agent and cleaning method thereof

InactiveCN107881025AGood degreasing effectHigh oil removal efficiencyInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsAlcoholSulfate

The invention belongs to the field of cleaning of oil base drilling cuttings, and particularly relates to an oil base drilling cuttings cleaning agent and a cleaning method thereof. The oil base drilling cuttings cleanings agent contains an epoxypropane or ethylene oxide nonionic surfactant, a sulfate or sulphosalt negative ion surfactant, short chain alcohol, sodium silicate, sodium salt except sodium silicate and water. The invention provides an oil base drilling cuttings cleaning agent which is high in oil removal efficiency, convenient in operation and low in cost and can be used repeatedly and a cleaning method thereof.

Owner:中海石油环保服务(天津)有限公司

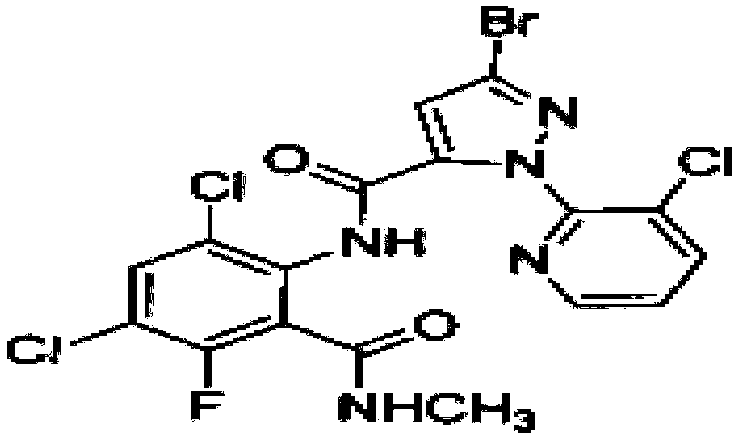

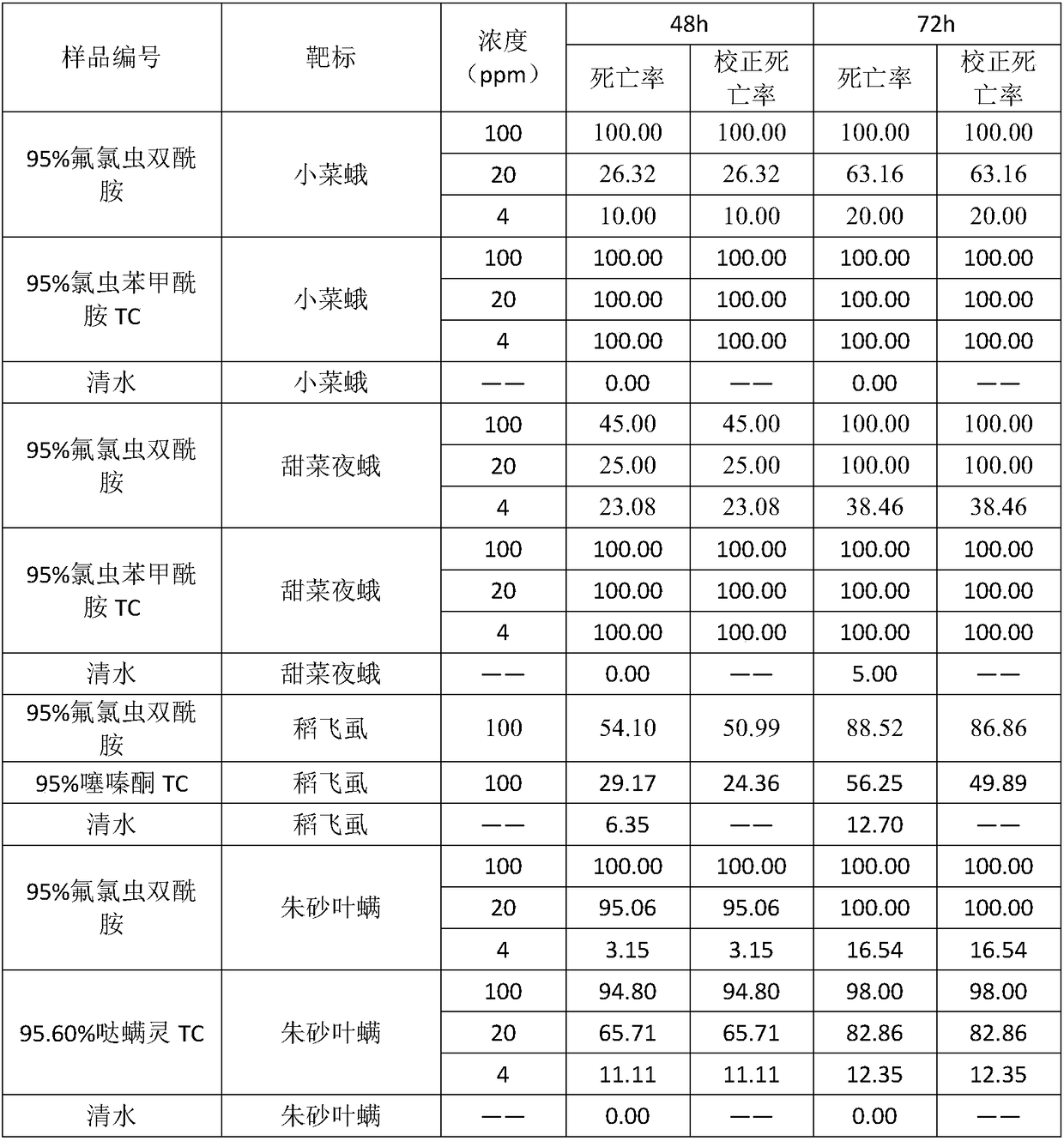

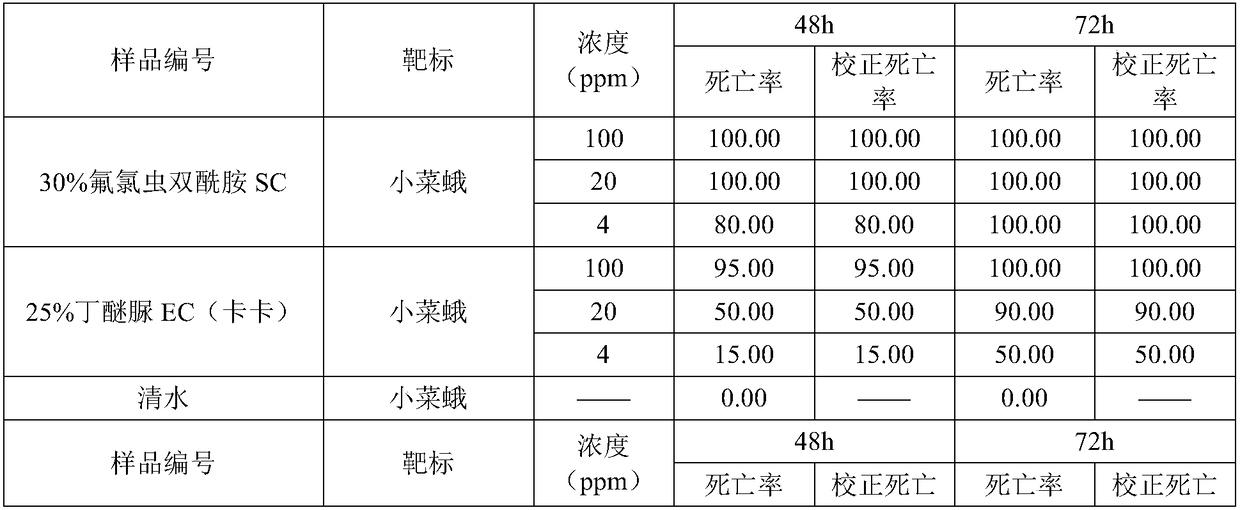

Fluchlobendiamide insecticide and application thereof

InactiveCN108605940ALong durationWith contact killBiocideOrganic chemistryChemical structureHomoptera

The invention provides a fluchlobendiamide insecticide and application thereof. The chemical structure is shown in the description. Fluchlobendiamide used as an active ingredient is applied in preparation of agricultural insecticides and can effectively prevent and control lepidoptera, homoptera and coleoptera pests. The fluchlobendiamide insecticide has the advantages that the insecticidal spectrum and antibacterial spectrum are wide, the insecticidal and antibacterial time is short, the lasting period is long, the synthesis process is simple, the cost is low, and the compounding effect is good.

Owner:HAILIR PESTICIDES & CHEM GRP

Water-borne polyurethane-urea dispersoid containing nonionic and anionic hydrophilic groups

The invention provides a water-borne polyurethane-urea dispersoid containing nonionic and anionic hydrophilic groups. The dispersoid is characterized in that: a resin main chain contains a nonionic hydrophilic component, and a side group contains an anionic hydrophilic group. The invention also provides a preparation method of the dispersoid. The water-borne polyurethane-urea dispersoid containing the nonionic-anionic hydrophilic groups can be applied to the fields of shoemaking adhesive, vacuum plastic and the like.

Owner:中科华宇(福建)科技发展有限公司

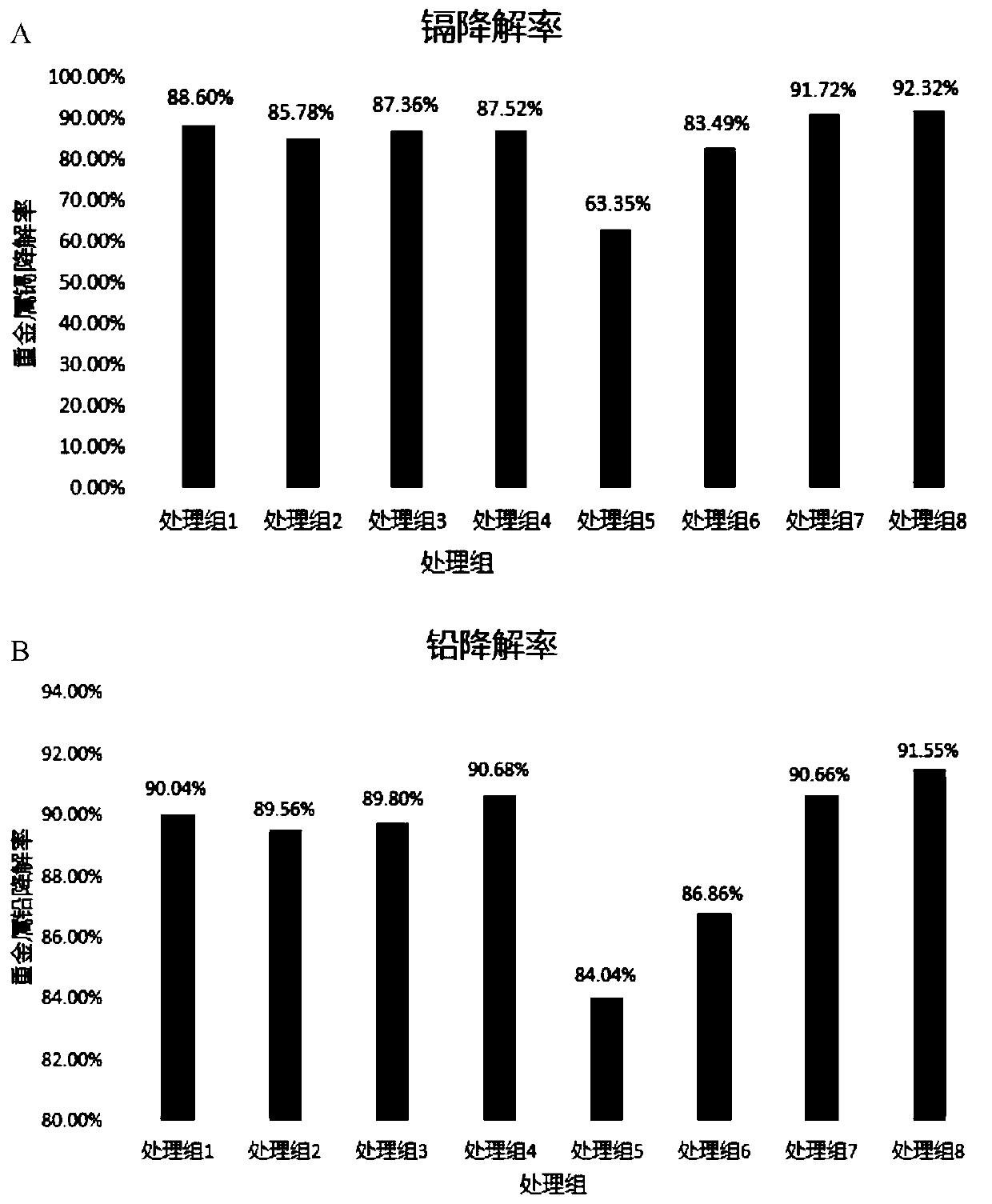

Composite bacterial agent, preparation method thereof and application in field of soil remediation

ActiveCN111423996AEasy to cleanStability is not affectedBacteriaContaminated soil reclamationSoil heavy metalsBacilli

The invention belongs to the technical field of soil heavy metal remediation, and specifically relates to a composite bacterial agent, a preparation method thereof and an application in the field of soil remediation. The invention provides 2 strains of bacillus tianshenli having soil heavy metal remediation effects, 1 strain of bacillus subtilis, and 1 strain of bacillus velezensis. The strains provided by the invention are obtained beneficial strains that efficiently adsorb soil heavy metals including cadmium and lead and are screened from materials such as soil, water samples and plants around an electroplating plant through technologies such as screening, purification and identification, safety tests are performed on the strains, fermentation conditions are studied, compound compatibility is performed, and after verification of potted and field experiments, the novel microecological preparation-soil heavy metal remediation bacteria agent is provided.

Owner:SHANDONG BEE LAN BIOTECHNOLOGY CO LTD +1

Processing technique for China-Hemp and paper straw mixed mat

ActiveCN104207561AGood hygroscopicityImprove antibacterial propertiesBed-coversWear resistantPulp and paper industry

The invention relates to a processing technique for mats and particularly relates to a processing technique for a China-Hemp and paper straw mixed mat. The processing technique comprises the following steps: cutting waterproof paper into sheets according to specifications of the mat, then wrapping straws with sheety waterproof paper so as to form ropy paper and then reeling to form wefts, and taking China-Hemp as warps for knitting, so as to obtain a mat main body; spraying water by using an atomizer of a pressing machine, heating, pressing polish and carrying out shrinking treatment on the mat main body, so as to obtain a semi-finished mat; soaking the semi-finished mat into a waterproof agent solution with a pH value of 4.5 to 6.5, and then placing the semi-finished mat into a drying oven for drying; arranging well cut lining cloth on peripheries of the dried semi-finished mat, wrapping the semi-finished mat by using the lining cloth, enabling the lining cloth to be symmetric on upper and lower surfaces of the mat, compacting, then carrying out edge covering treatment on the mat, and finally obtaining a finished mat. The mat prepared by using the processing technique provided by the invention are not only nice and cool, air-permeable, wear-resistant, sun-proof and has soft feel, but also has the advantages of bacteriostasis, uvio-resistance and the like, and is long in service life.

Owner:宁波黄古林工艺品有限公司

Paper starch adhesive and preparation method thereof

ActiveCN101967355ARaw materials are cheapWide range of usesNon-macromolecular adhesive additivesStarch derivtive adhesivesEpoxyHydrogen Sulfate

The invention discloses a paper starch adhesive and a preparation method thereof. The paper starch adhesive comprises the following components in part by weight: 100 parts of starch, 300 to 600 parts of water, 0.1 to 0.3 part of potassium hydrogen peroxymonosulfate, 5 to 10 parts of caustic soda, 1 to 5 parts of epoxy chloropropane, 0.5 to 1.5 parts of boric acid, 1 to 3 parts of sodium sulfite, 4 to 8 parts of light calcium carbonate and 2.5 to 5 parts of bridging agent. The preparation method comprises the following steps of: adding water into a reaction kettle, heating the water to 38 DEG C, adding the starch into the water, stirring the solution, adding potassium hydrogen peroxymonosulfate solution into the reaction kettle, and reacting the mixed solution for 20 minutes with stirring; diluting the caustic soda, then slowly adding the caustic soda into the reaction kettle twice, stirring the solution for about 20 minutes to form milk white or light yellow transparent colloid, then adding the boric acid, the bridging agent and the light calcium carbonate into the colloid, and stirring the mixture uniformly; and adding the epoxy chloropropane, sodium aliphatate and the sodium sulfite into the reaction kettle with stirring, and stirring the mixture uniformly to obtain the paper starch adhesive. The adhesive has the characteristics of stable viscosity, good adhesiveness, low comprehensive cost, good permeability and the like.

Owner:山东荣工建筑工程有限公司

Child moisturizing and chapping-preventing cream and preparation method thereof

ActiveCN103800270AExcellent moisturizing propertiesGood effectCosmetic preparationsToilet preparationsMedicineThickening agent

The invention relates to the field of daily chemicals, and in particular relates to child moisturizing and chapping-preventing cream and a preparation method thereof. The child moisturizing and chapping-preventing cream consists of the following components in percentage by weight: 5-15 percent of moisturizing agent, 0.5-5 percent of emulsifying agent, 3-15 percent of grease, 0.5-2 percent of stabilizing and thickening agent, 0.02-2.1 percent of additive, 0-1 percent of preservative and the balance of water. The child moisturizing and chapping-preventing cream is excellent in child skin moisturizing performance; polyol is matched with three emulsifying agents, so that the whole formula system is better in compounding property; a honey extract with excellent moisturizing performance is compounded with mild grease, so that the moisture preserving effect on the child skin is remarkable.

Owner:OPAL COSMETICS HUIZHOU

Popular searches

Strong acid and alkali resistance Improve stability Small particle size Improve hydrophilicity Improve hydrophilic ability Reduce total usage Good extreme pressure and anti-wear properties Improve extreme pressure and anti-wear performance Good thermo-oxidative stability Improve anti-corrosion performance

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com