Preparation method of de-filtration plugging agent for water-base drilling fluids

A technology for water-based drilling fluid and filtration reduction, which is applied in drilling compositions, chemical instruments and methods, etc., and can solve problems such as large differences in the performance of plugging agents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 15Kg styrene after refining, 5Kg methyl acrylate and 5Kg butyl acrylate are transferred in the reactor of belt reflux condensation and shear emulsification device, then add the aqueous solution of allyl ether sulfonate (wherein Contains 5Kg allyl ether sulfonate and 110Kg deionized water), after bubbling nitrogen gas for deoxygenation, shear emulsification at a speed of 3000r / min for 15min under normal temperature conditions, and continuously bubbling high-purity nitrogen gas for deoxygenation conditions Next, start the agitator, control its stirring speed at 300r / min, and start the reflux condensation and heating device. When the inside of the reaction kettle reaches 75°C, add a deionized aqueous solution of ammonium persulfate (including 0.6Kg of ammonium persulfate and 30Kg of deionized water) dropwise into the kettle, and after passing nitrogen for 6 hours, the water-based drilling solution of the present invention is obtained. Fluid loss plugging agent I for liquid...

Embodiment 2

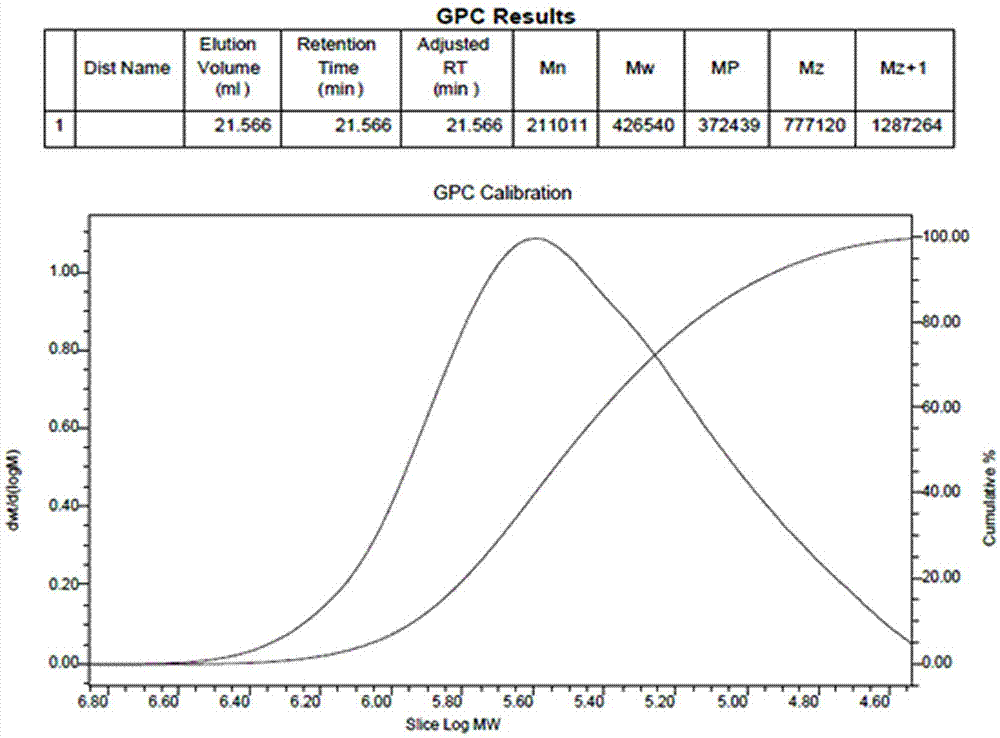

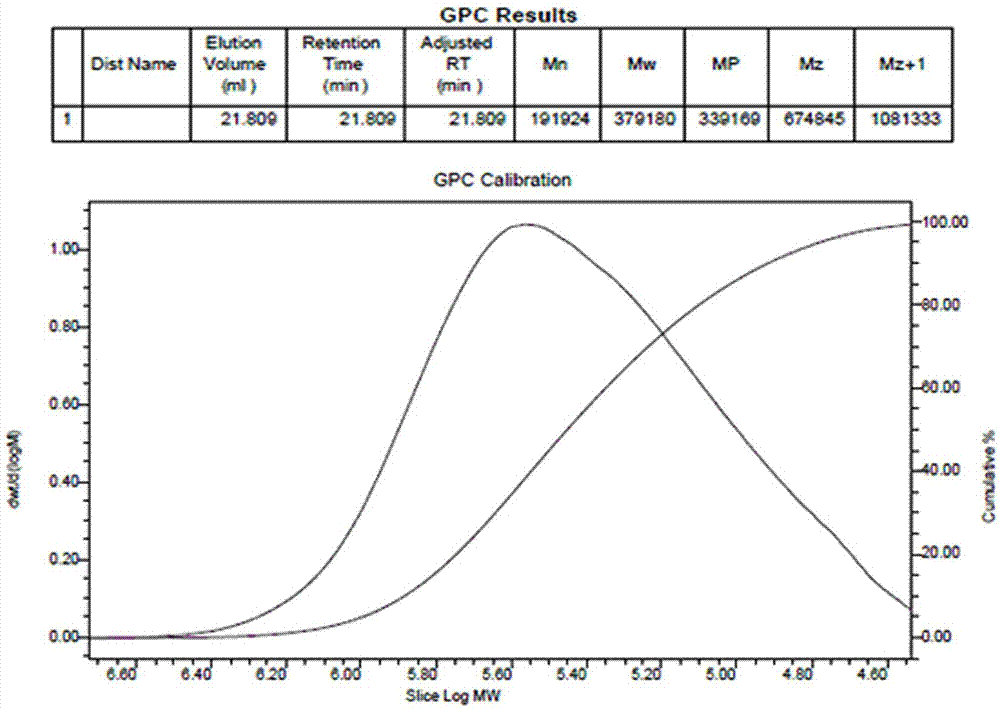

[0027] Transfer the refined 15Kg of divinylbenzene, 5Kg of ethyl acrylate, and 6Kg of propyl acrylate to a reaction kettle with reflux condensation and shear emulsification devices, and then add an aqueous solution of acrylamide alkylsulfonate to the reaction kettle (Contains 6.5Kg of acrylamide alkyl sulfonate and 130Kg of deionized water), after bubbling with nitrogen gas to remove oxygen, shear and emulsify at a speed of 5000r / min for 10min at room temperature, and continue bubbling with high-purity nitrogen gas Under the condition of deoxygenation, start the stirrer, control its stirring speed at 400r / min, start the reflux condensation and heating device. When the inside of the reaction kettle reaches 80°C, add a deionized aqueous solution of potassium persulfate (including 0.6Kg of potassium persulfate and 25Kg of deionized water) dropwise into the kettle. Fluid loss plugging agent II for liquid use, hereinafter referred to as fluid loss plugging agent II. The molecular ...

Embodiment 3

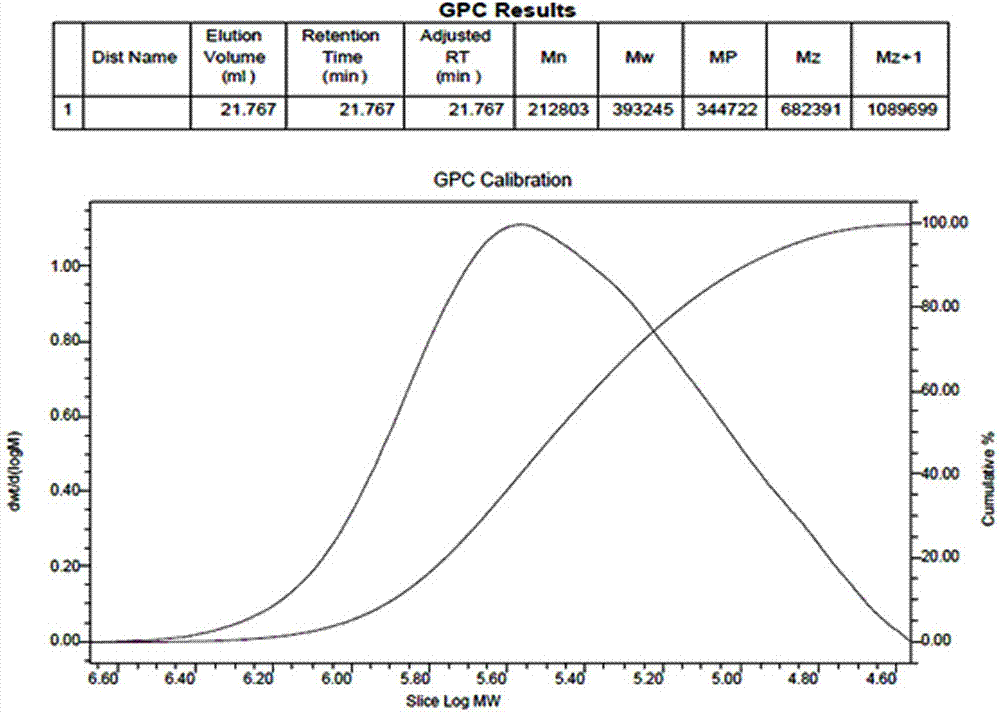

[0030] 15Kg divinylbenzene after refining and 12.5Kg butyl acrylate are transferred in the reactor of band reflux condensation and shear emulsification device, then add the aqueous solution of acrylamide alkyl sulfonate (which contains 6Kg Alkyl propyl succinate sulfonate and 120Kg deionized water), after nitrogen bubbling for deoxygenation, shear emulsification at a speed of 5000r / min for 15min at room temperature, and continuous bubbling of high-purity nitrogen for deoxygenation Under the condition, start the agitator, control its stirring speed at 500r / min, and start the reflux condensation heating device. When the inside of the reaction kettle reaches 85°C, add a deionized aqueous solution of potassium persulfate-potassium bisulfite (including 0.6Kg of potassium persulfate-potassium bisulfite and 20Kg of deionized water) dropwise into the kettle, and let the nitrogen flow to keep the reaction After 7 hours, the fluid loss plugging agent for water-based drilling fluid of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com