Admixture of disperse dyes

A technology of disperse dyes and mixtures, applied in organic dyes, dyeing methods, textiles and papermaking, etc., can solve the problems that application properties such as lifting force and color fastness cannot fully meet the needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

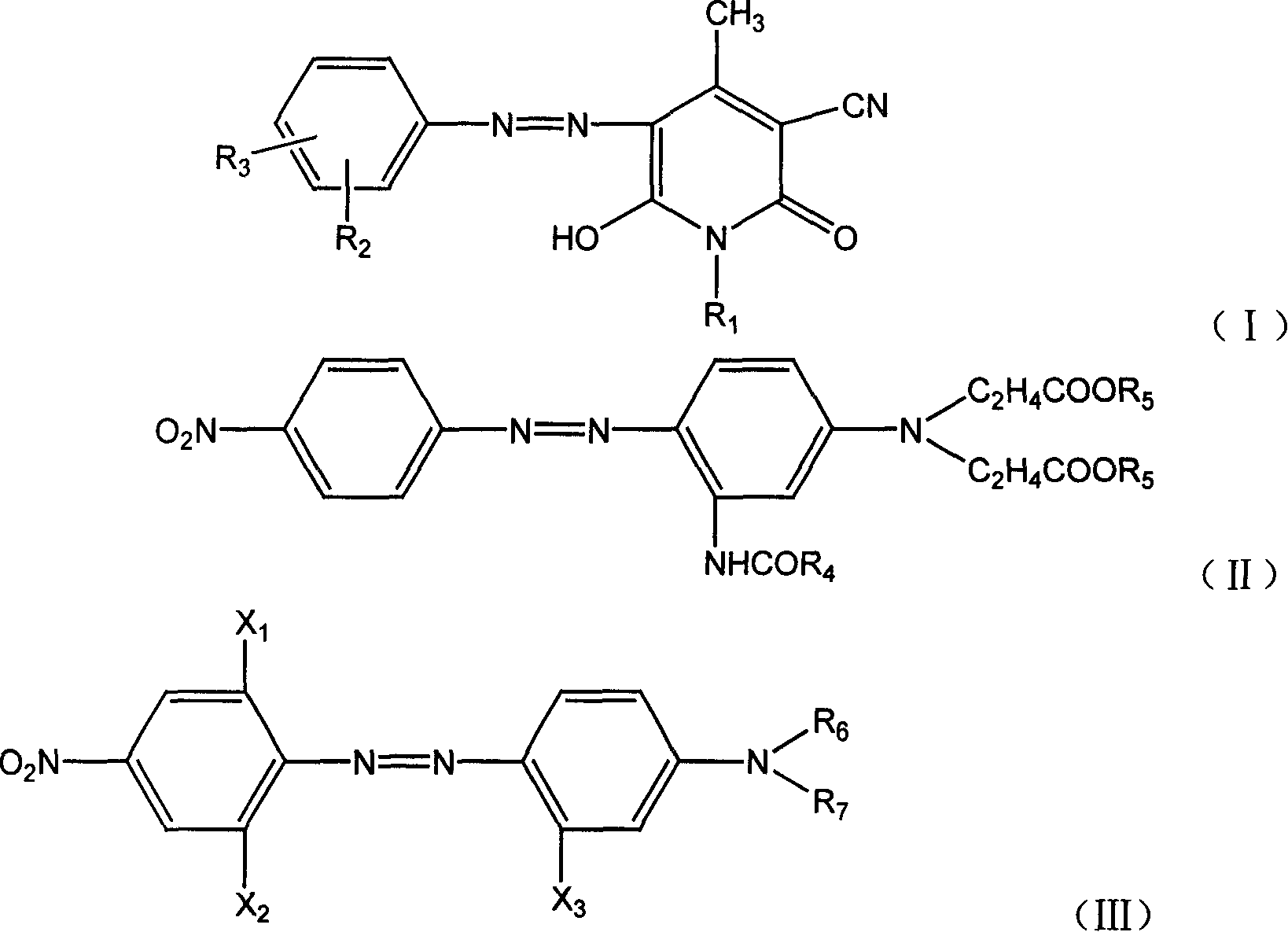

Method used

Image

Examples

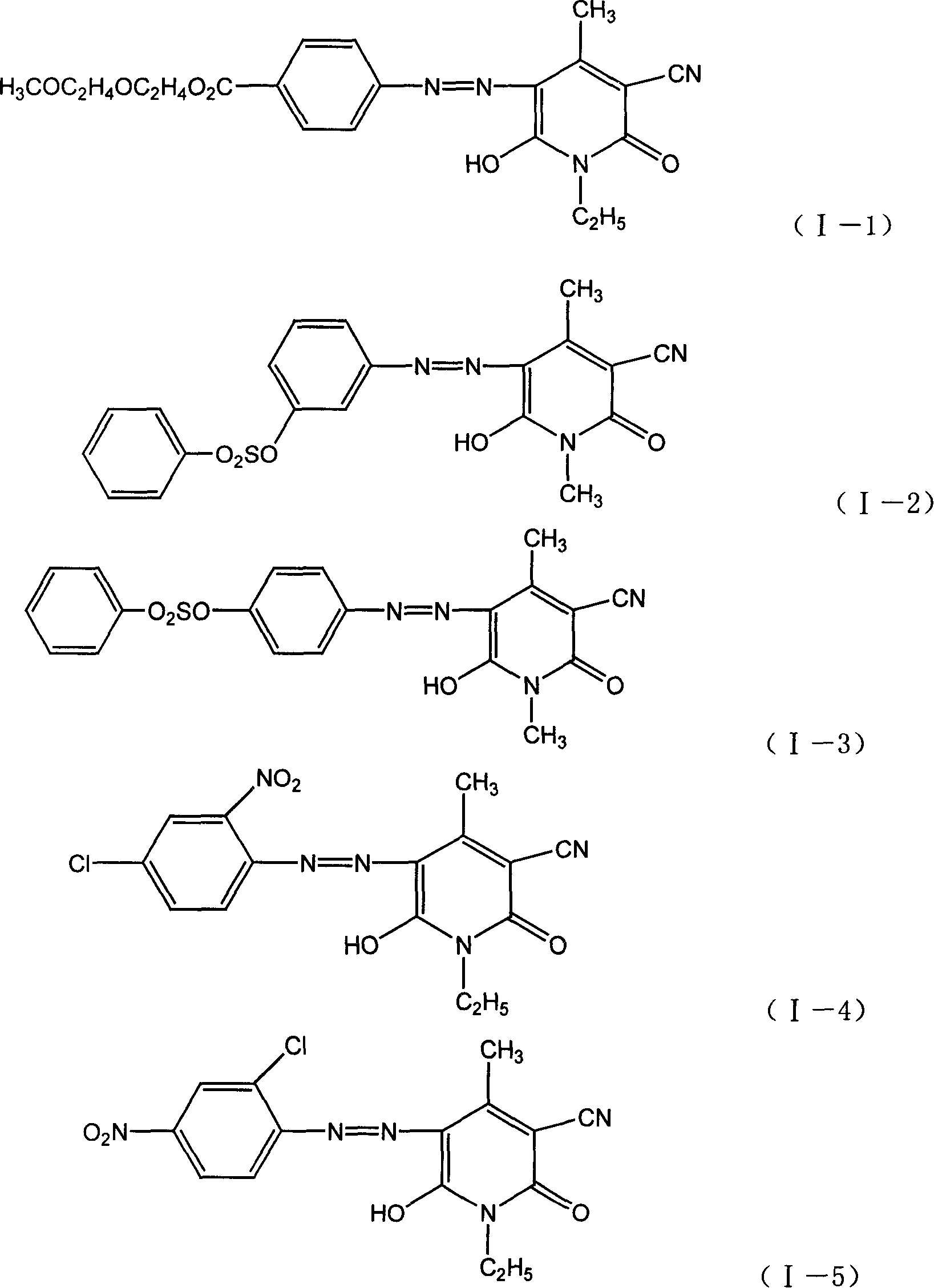

Embodiment 1

[0028] With the dyestuff A of 70.2 gram formula (I-1), the dyestuff A of 15.3 gram formula (I-2), the dyestuff B of 8.9 gram formula (II-1), the dyestuff C of 5.6 gram formula (III-1), 195 gram of sodium lignosulfonate, after adding water to blend, grind and disperse with a grinder, and spray dry to obtain the finished dye, which can provide the orange color with excellent fastness properties of the fabric.

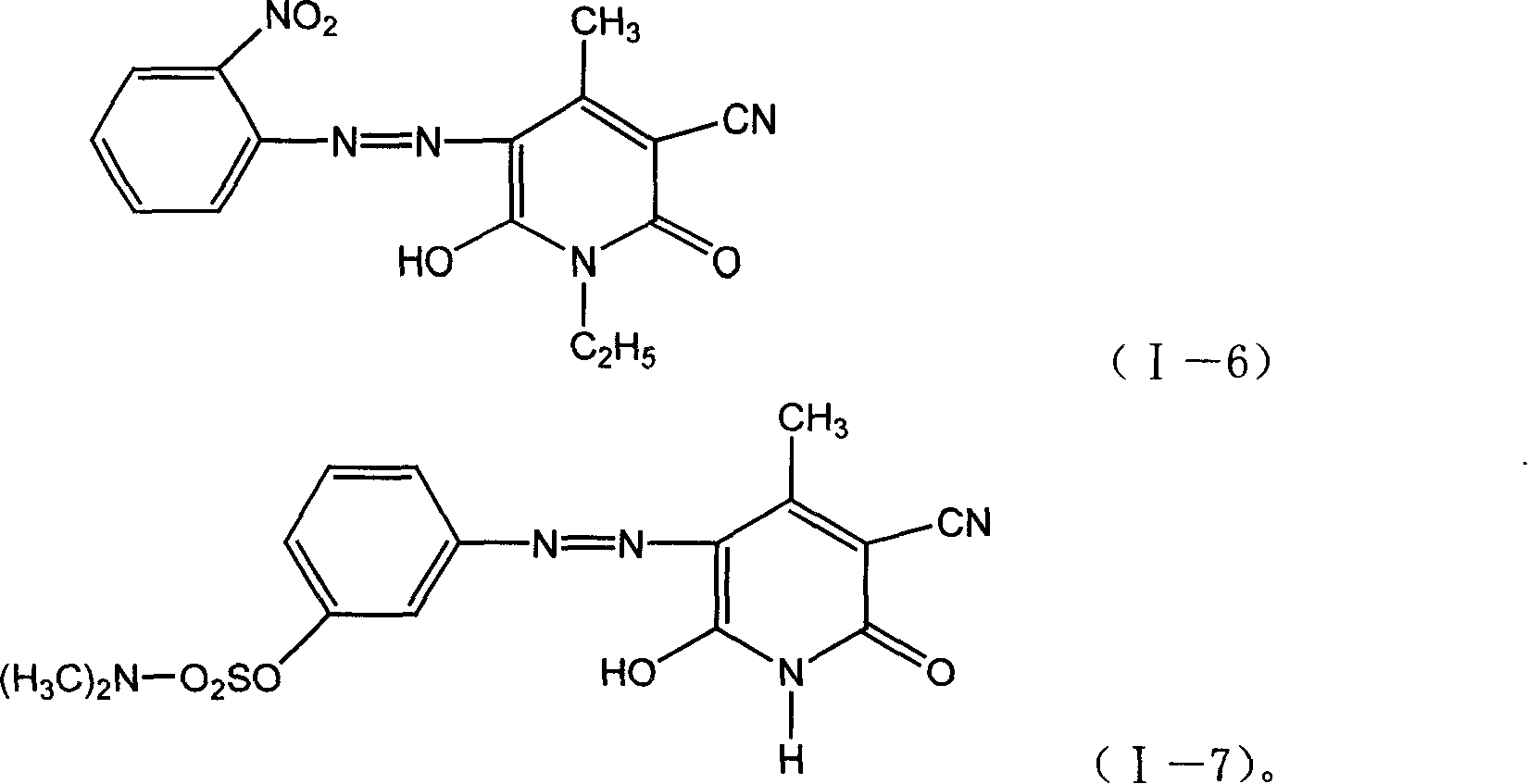

[0029]

[0030]

Embodiment 2~10

[0032] According to the preparation method shown in Example 1, dye A, dye B and dye C are blended according to the metering data in Table 1 for the dye mixture.

[0033] Example

Embodiment 11~18

[0035] According to the preparation method of Example 1, the structures of dye A, dye B, and dye C defined by each substituent are as shown in Table 2, and the dye mixture is mixed with dye A, dye B, The dye C is blended to obtain the finished dye.

[0036] Table 2

[0037]

[0038] Example name

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com