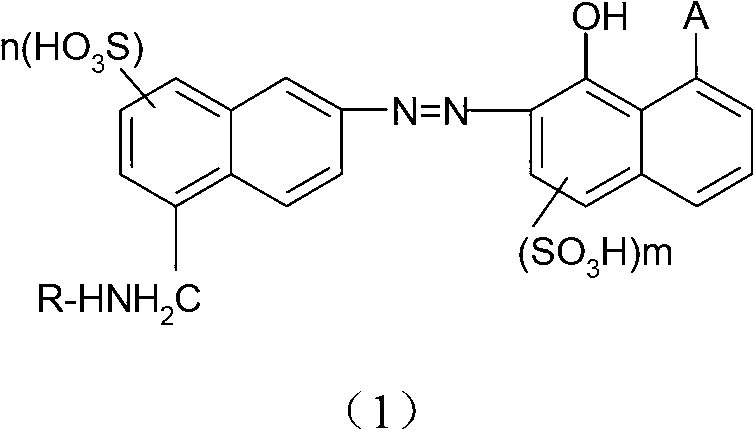

Red reactive dye and preparation as well as use thereof

A reactive dye and dye technology, applied in the field of dyes, to achieve the effects of good wet fastness performance, good fastness performance, and good deepening performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

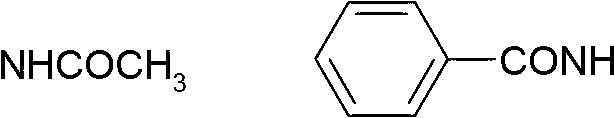

[0032] A. Add 25.2 parts of 2-amino-5-methylaminonaphthalenesulfonic acid to 300 parts of water for one hour, and then add 24 parts of 30% hydrochloric acid and stir for 30 minutes, add ice to cool to 0°C, and mix 7.2 parts of sub Sodium nitrate is added as a solution, and the diazotization reaction is completed in one hour after the addition is complete.

[0033] B. Then add 40.5 parts of 1 naphthol 8-acetamido-3.6 disulfonic acid. Make a solution with 200 parts of water and add it to A in 40 minutes. After adding baking soda, adjust the pH of the material to 5-6. React at T=5-10℃ and pH=5-6 for five hours to complete the coupling reaction. .

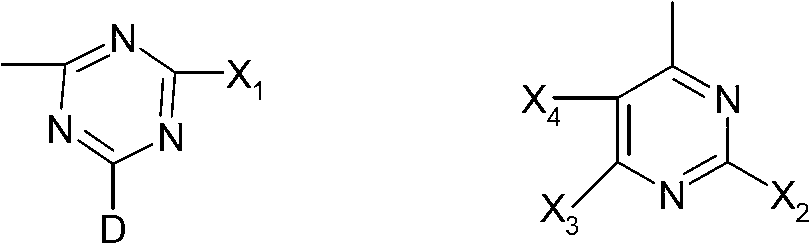

[0034] C. Add 28 parts of neutral solution of p-(β-vinylsulfone sulfate) aniline to 18.5 parts of cyanuric chloride ice water slurry, adjust pH=3.0 with baking soda, react for 4h, complete one condensation reaction.

[0035] D. Add the neutral solution of C to B, adjust the pH to 7-8 with sodium hydroxide solution, then slowly raise the te...

Embodiment 2-14

[0038] According to the preparation method of Example 1, according to the definition of each group in the preceding text, the following dyes in accordance with general formula (1) can also be obtained. These dyes can dye hydroxyl-containing or nitrogen-containing fibers into red shades and all have good overall fastness properties.

[0039]

[0040]

[0041]

Embodiment 15

[0043] A. Add 25.2 parts of 2-amino-5-methylaminonaphthalenesulfonic acid to 300 parts of water for one hour, and then add 24 parts of 30% hydrochloric acid and stir for 30 minutes, add ice to cool to 0°C, and mix 7.2 parts of sub Sodium nitrate is added as a solution, and the diazotization reaction is completed in one hour after the addition is complete.

[0044] B. Then add 40.5 parts of 1 naphthol 8-acetamido-3.6 disulfonic acid. Make a solution with 200 parts of water and add it to A in 40 minutes. After adding baking soda, adjust the pH of the material to 5-6. React at T=5-10℃ and pH=5-6 for five hours to complete the coupling reaction. .

[0045] C. Add 14 parts of cyanuric fluoride to B in 30 minutes under the conditions of T=0°C and pH=5-7, and complete the reaction for 30 minutes.

[0046] D. Add 2-sulfate group 2'-amino divinyl sulfone to C, adjust pH=6-8, then slowly raise the temperature to 20-30°C, react for 3h under this condition, and obtain the general formula ( 1)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com