Yellow liquid disperse dye and preparation method and application thereof

A liquid disperse dye, yellow technology, applied in dyeing, organic dyes, textiles and papermaking, etc., can solve the problems of easy precipitation and dyeing difficulty, and achieve the effects of excellent fastness, low price and low COD

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

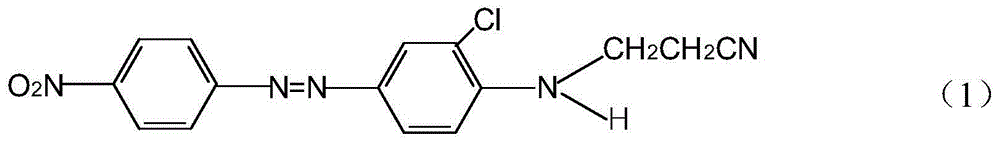

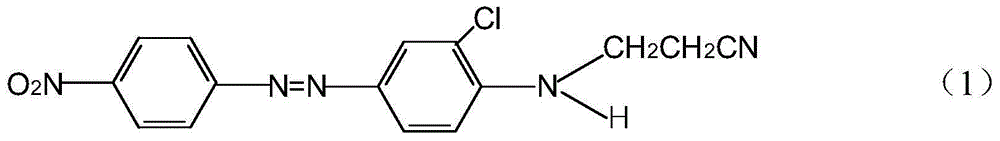

Image

Examples

preparation example Construction

[0037] The preparation method of yellow liquid disperse dye of the present invention may further comprise the steps:

[0038] The component A, additives and water are mixed in proportion with a sand mill or grinder to make a yellow liquid disperse dye;

[0039] Or add half of the water, component A and additives in proportion to mix with a sand mill or grinder, and then make up water in proportion to make a yellow liquid disperse dye.

Embodiment 1

[0045] Add 10 grams of component A shown in formula (1), 3.5 grams of diffusing agent CNF and 0.5 grams of Pingpinga O to 86 grams of water, grind and disperse with a sand mill to make a yellow liquid disperse dye.

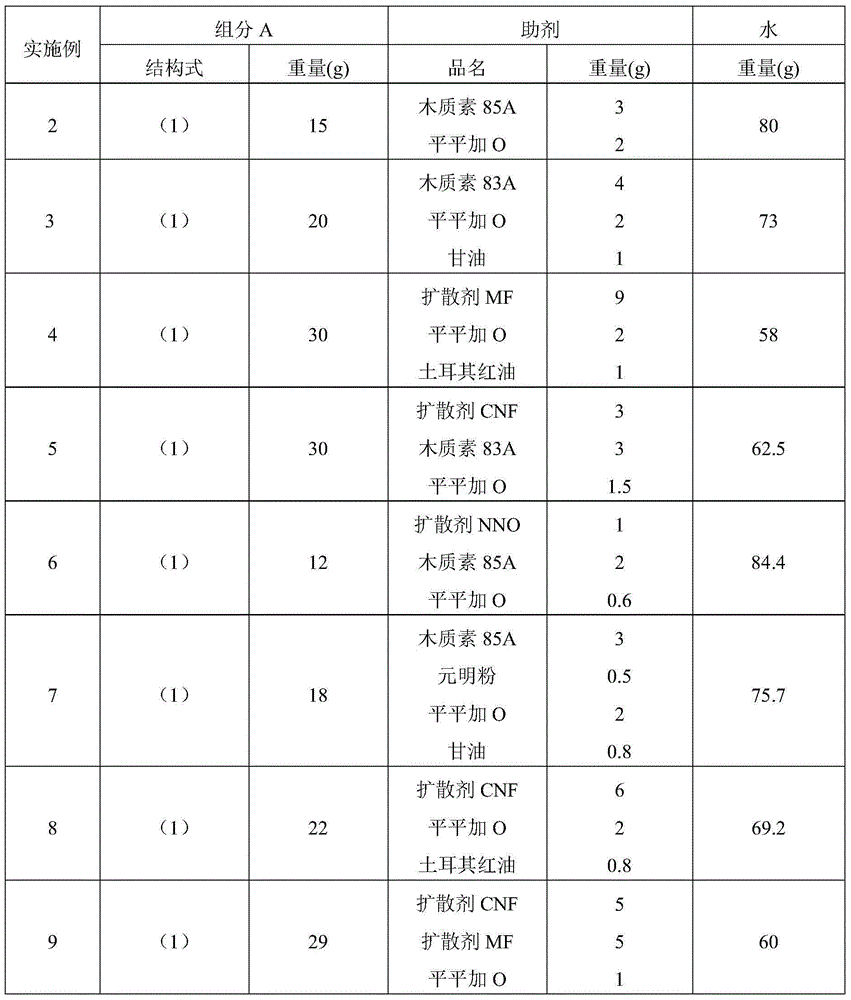

Embodiment 2-9

[0055] According to the composition recipe in Table 1, a yellow liquid disperse dye was made.

[0056] Table 1

[0057]

[0058] The performance test of the yellow liquid disperse dyes in Examples 2-9 was carried out by the same test method as in Example 1, and the specific data are shown in Table 2.

[0059] Table 2: Unit: Grade

[0060]

[0061] It can be seen from Table 2 that compared with Comparative Example 1-2, the yellow liquid disperse dyes of Examples 1-9 have prolonged precipitation time, which brings great convenience for transportation and use. And the yellow liquid disperse dye of embodiment 1-9 is compared with comparative example 1-2 and yellow powdery dye, dyed foot water chromaticity is light, COD is low, more environmental protection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com