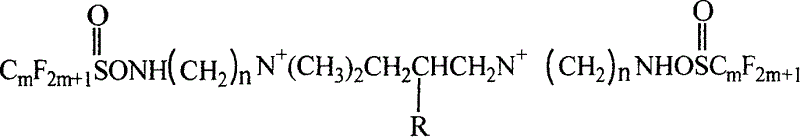

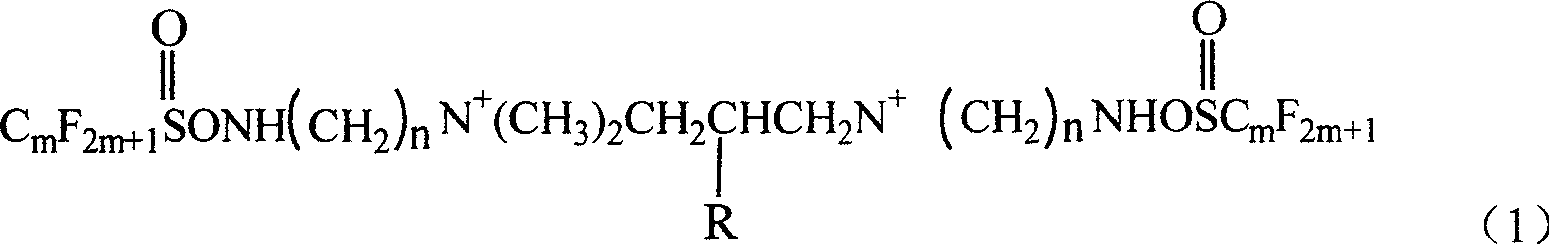

Fluorine-carbon sufactant and preparing method

A fluorocarbon surface, gemini technology, applied in chemical instruments and methods, dissolution, chemical/physical processes, etc., can solve the problems of few reports of amphoteric gemini surfactants, no industrial value, harsh synthesis conditions, etc. Excellent detergency, strong foaming power, good color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

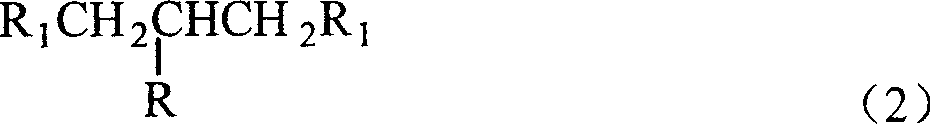

Method used

Image

Examples

Embodiment 1

[0038] Weigh 15.06g (0.03mol) of perfluorooctanesulfonyl fluoride and dissolve it in 50mL of isopropyl ether to make a solution, and dissolve 15.06g (0.03mol) of N,N-dimethyl-1,3-propanediamine in Prepare a solution in 25mL isopropyl ether, slowly add the latter solution dropwise to the former solution at low temperature (about 20°C), and stir at constant temperature. The dropping process is about 0.5h. ℃, reflux and stir for 3 hours, the hydrogen fluoride gas generated by the reaction is absorbed with sodium hydroxide solution, and the reaction is completed and cooled. After cooling, the reaction mixture was washed successively with water, 0.5% hydrochloric acid aqueous solution, saturated brine and dried over anhydrous magnesium sulfate. After removal of the solvent, distillation under reduced pressure gave N-[(dimethylamino)-alkyl]perfluorooctanesulfonamide as a light yellow solid product.

[0039] Weigh 17.52g (0.03mol) of N-[3-(dimethylamino)-propyl] perfluorooctane sulf...

Embodiment 2

[0041] The preparation of the intermediate N-[(dimethylamino)-alkyl]perfluorooctanesulfonamide is the same as above.

[0042] Weigh 23.36g (0.04mol) of N-[3-(dimethylamino)-propyl] perfluorooctane sulfonamide, join in the 250ml four-neck flask with rotor, thermometer, condensing device, with 70ml without Water ethanol is the quaternization solvent, add 3.20g (0.08mol) of NaOH, start the magnetic stirring device and connect the condensed water, stir and react for 30min, heat the constant temperature water bath to 80°C, slowly drop in the sulfonic acid containing sulfonic acid with the dropping funnel Lactone dichloropropane 16.10g (ie 0.02mol), sultone dichloropropane ethanol solution with a weight concentration of 20%, was added dropwise within 1 hour, and the reaction was continued at 80°C for 6 hours. After the reaction was completed, ethanol was distilled off to obtain a yellow solid product, a novel gemini-type fluorocarbon surfactant NGFPA: N, N, N', N'-tetramethyl-N, N'-...

Embodiment 3

[0044] The preparation of the intermediate N-[(dimethylamino)-alkyl]perfluorooctanesulfonamide is the same as above.

[0045]Weigh 23.36g (0.04mol) of N-[3-(dimethylamino)-propyl]perfluorooctane sulfonamide, join in the 250ml four-neck flask with rotor, thermometer, condensing device, with 50ml without Water ethanol is the quaternization solvent, add 3.20g (0.08mol) of NaOH, start the magnetic stirring device and connect the condensed water, stir and react for 30min, heat the constant temperature water bath to 80°C, slowly drop in the sulfuric acid lactone with the dropping funnel 17.70 g (0.015 mol) of dichloropropane, 20% ethanol solution of sulfuric acid lactone dichloropropane with a weight concentration of 20%, was added dropwise within 1 hour, and kept at 80° C. for 8 hours of continuous reaction. After the reaction was completed, ethanol was distilled off to obtain a yellow solid product as a novel gemini-type fluorocarbon surfactant: N, N, N', N'-tetramethyl-N, N'-bis[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com