Alkylbenzyl polyoxyethylene ether betaine surfactant and its preparation method and use

A technology of alkyl benzyl polyoxyethylene ether and surfactant, which is applied in the field of alkyl benzyl polyoxyethylene ether betaine surfactant and its preparation, and can solve the problem that does not involve alkyl benzyl polyoxyethylene ether beet Alkaline surfactants and other problems, to achieve excellent synergistic effect, low irritation, excellent antistatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 10

[0057] The preparation of embodiment 1 dodecyl benzyl trioxyethylene ether carboxylate betaine

[0058] Step 1: Weigh 0.1mol of trimethylamine hydrochloride into a 100ml three-neck flask, add 0.2mol of anhydrous aluminum trichloride to the reaction flask in batches under constant stirring at room temperature, and heat up to 80°C after the addition is complete. Continue the constant temperature reaction for 5 hours to obtain black N(CH 3 ) 3 HCl 2AlCl 3 ionic liquid.

[0059] Second step: get 6.4mol benzene and join in the 1000ml three-neck bottle that is equipped with reflux condenser, electric stirrer, constant pressure addition funnel, add 13g N(CH 3 ) 3 HCl 2AlCl 3 For ionic liquids, heat the system temperature to about 40°C, then add 0.8mol α-dodecene into the reaction system drop by drop with a constant pressure feeding funnel under constant stirring, and continue the constant temperature reaction for 5 hours after the completion of the reaction. Stand for stratific...

Embodiment 2

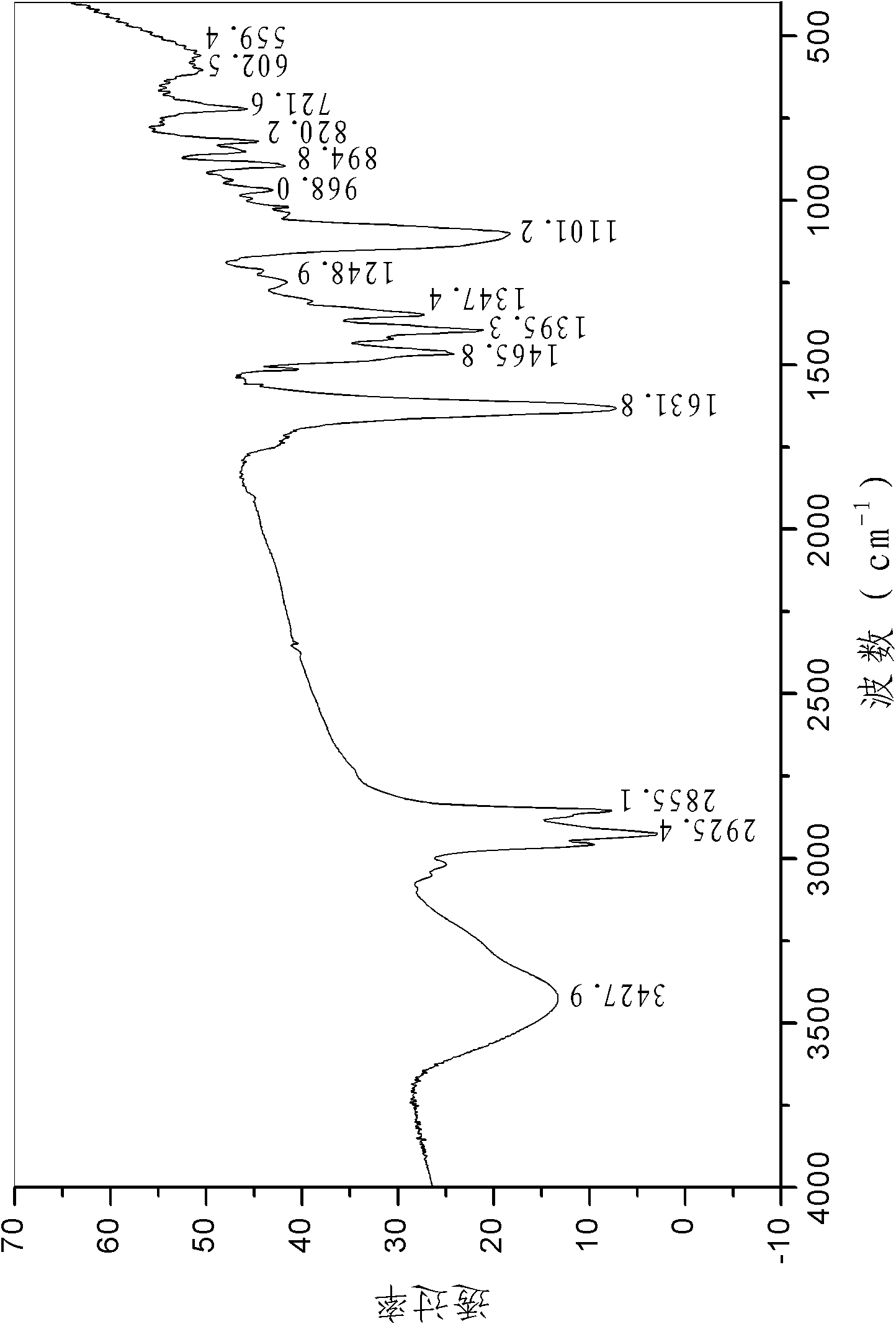

[0068] Technical scheme is basically the same as embodiment 1, just replaces alpha-dodecene with alpha-tetradecene in the second step, obtains tetradecylbenzene, and corresponding tetradecylbenzyl chloride replaces dodecylbenzyl chloride, ten Tetraalkylbenzyl trioxyethylene ether alcohol instead of dodecyl benzyl trioxyethylene ether alcohol, chlorinated tetradecyl benzyl trioxyethylene ether alcohol instead of chlorinated dodecyl benzyl trioxyethylene ether alcohol , tetradecyl benzyl trioxyethylene ether tertiary amine replaces dodecyl benzyl trioxyethylene ether tertiary amine, other conditions and operating methods are the same as in Example 1, and the product obtained is tetradecyl benzyl trioxyethylene ether Betaine vinyl ether carboxylate. Its IR spectrum is shown in Figure 4 .

Embodiment 3

[0070] Technical scheme is basically the same as embodiment 1, just replaces alpha-dodecene with alpha-hexadecene in the second step, obtains hexadecylbenzene, and corresponding hexadecylbenzyl chloride replaces dodecylbenzyl chloride, ten Hexaalkylbenzyl trioxyethylene ether alcohol instead of dodecyl benzyl trioxyethylene ether alcohol, chlorinated hexadecyl benzyl trioxyethylene ether alcohol instead of chlorinated dodecyl benzyl trioxyethylene ether alcohol , Cetyl benzyl trioxyethylene ether tertiary amine replaces dodecyl benzyl trioxyethylene ether tertiary amine, other conditions and operating methods are the same as in Example 1, and the product obtained is cetyl benzyl trioxyethylene Betaine vinyl ether carboxylate. intermediate of hexadecylbenzene 1 H-NMR spectrum see Figure 5 , the intermediate of cetyl benzyl trioxyethylene ether alcohol 1 H-NMR spectrum see Figure 6 , the intermediate of cetyl chloride benzyl trioxyethylene ether alcohol 1 H-NMR spectrum s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com