Low-temperature reactive dye soaping agent as well as preparation method and application thereof

A technology of reactive dyes and low-temperature soap, applied in the directions of non-surface-active detergent compositions, inorganic non-surface-active detergent compositions, organic non-surface-active detergent compositions, etc. The number of times, anti-staining and de-floating can not be taken into account, etc., to achieve good working effect, good compounding effect, and ensure the effect of anti-staining effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

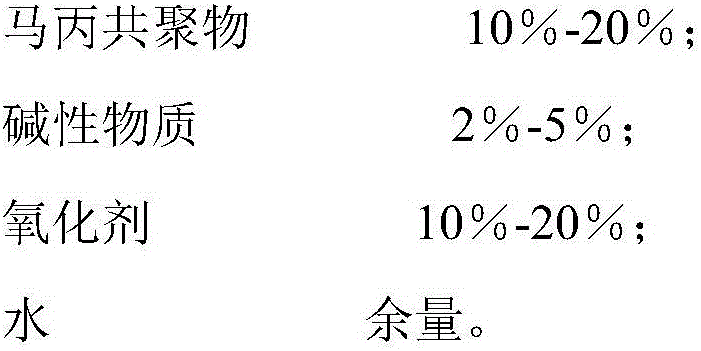

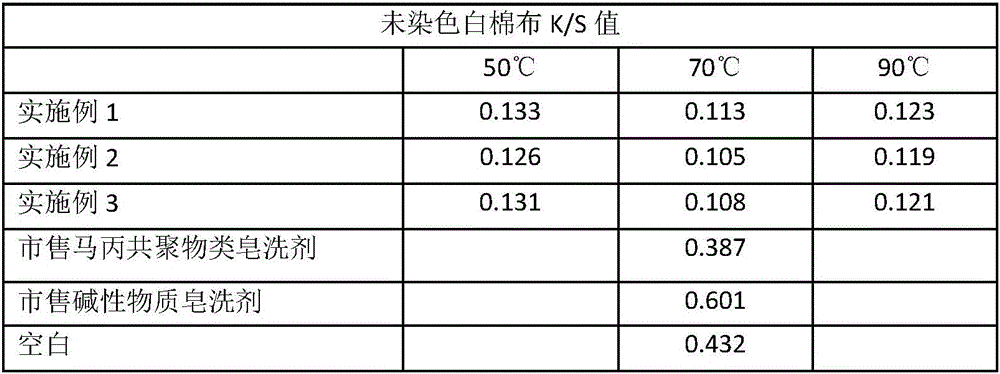

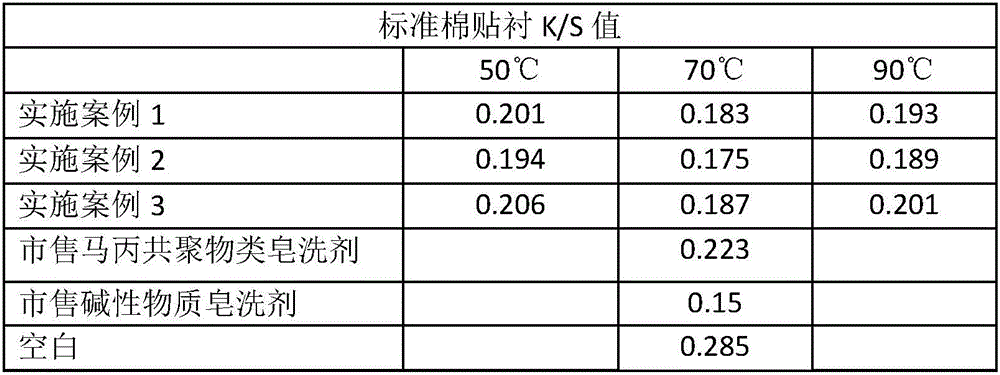

[0022] In the present embodiment, a kind of preparation method of reactive dye low-temperature soaping agent is provided, configure according to the following steps: step S1) configure the following components by mass percentage: horse-propylene copolymer 20%, sodium tripolyphosphate 5% , 10% sodium persulfate and the balance of water. Step S2) put 20% of the horse-propylene copolymer configured in step S1), 5% of sodium tripolyphosphate, and 10% of sodium persulfate into the reaction kettle, add the remaining water, fully stir and dissolve at room temperature, and obtain the new active Dye low temperature soaping agent.

Embodiment 2

[0024] In this embodiment, in this embodiment, a kind of preparation method of reactive dye low-temperature soaping agent is provided, configure according to the following steps: step S1) configure the following components by mass percentage: horse-propylene copolymer 15%, Soda ash 2%, sodium persulfate 15%, and the balance water. Step S2) Put 15% of the horse-propylene copolymer configured in step S1), 2% of soda ash, and 15% of sodium persulfate into the reactor, add the remaining water, fully stir and dissolve at room temperature, and obtain the novel reactive dye low-temperature soap lotion.

Embodiment 3

[0026] In this embodiment, in this embodiment, in this embodiment, a kind of preparation method of reactive dye low-temperature soaping agent is provided, configure according to the following steps: step S1) configure the following components by mass percentage: horse 15% of propylene copolymer, 5% of sodium metasilicate pentahydrate, 15% of sodium hypochlorite and the rest of water. Step S2) 15% of the horse-propylene copolymer configured in the step S1), 5% of sodium metasilicate pentahydrate, and 15% of sodium hypochlorite are added, and the rest of the water is added, fully stirred and dissolved at room temperature, and the novel reactive dye low-temperature soaping agent is obtained. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com