Active dye anti-staining low-temperature soaping agent and method

A technology of reactive dyes and low-temperature soap, applied in the field of dyeing and finishing soaping technology, can solve the problems of high soaping temperature, poor anti-staining effect, low soaping efficiency, etc., to ensure chromaticity and color fastness, good synergy Synergistic effect, the effect of enhancing the anti-staining effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

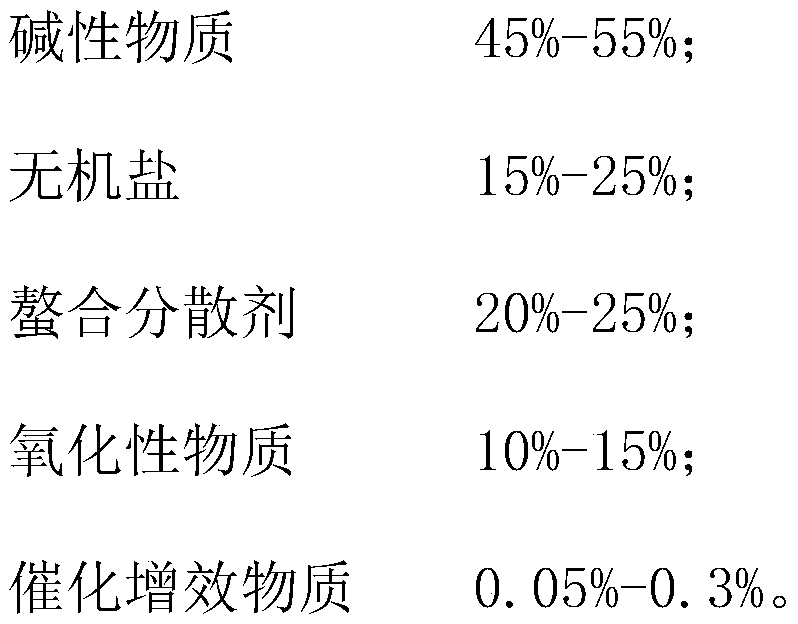

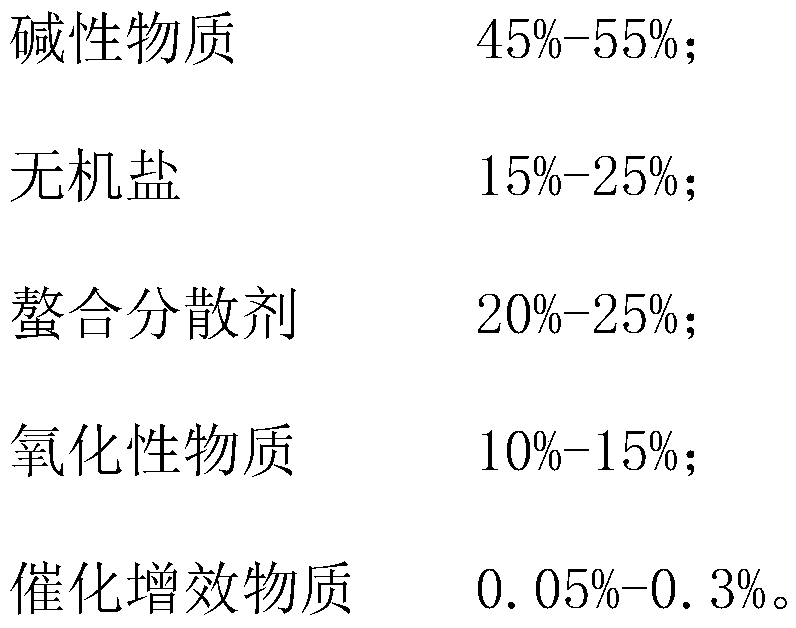

[0026] Configure the following components according to mass percentage: 450g of sodium carbonate; 200g of potassium chloride; 200g of sodium gluconate; In the feeder, stir and mix evenly at room temperature to prepare reactive dye anti-staining low-temperature soaping agent 1.

Embodiment 1-2

[0028] Configure the following components according to mass percentage: 450g of sodium carbonate; 200g of potassium chloride; 200g of sodium gluconate; 150g of sodium perborate; In the feeder, stir and mix evenly at room temperature to prepare reactive dye anti-staining low-temperature soaping agent 2.

Embodiment 1-3

[0030] Configure the following components according to mass percentage: 450g of sodium carbonate; 200g of potassium chloride; 200g of sodium gluconate; 150g of sodium perborate; In the feeder, stir and mix evenly at room temperature to prepare reactive dye anti-staining low-temperature soaping agent 3.

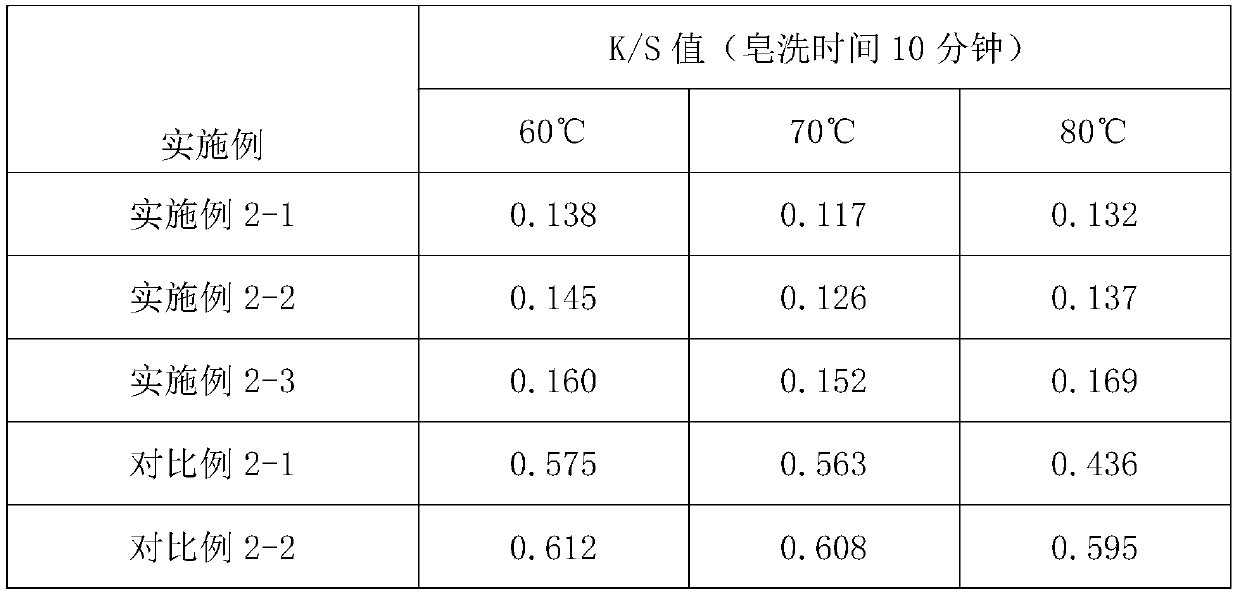

[0031] Anti-staining test

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com