A kind of reactive dye anti-staining low-temperature soaping agent and soaping method

A technology of reactive dyes and low-temperature soap, applied in the field of dyeing and finishing soaping process, can solve the problems of high COD and total nitrogen, high chroma of soaping residue, low soaping efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

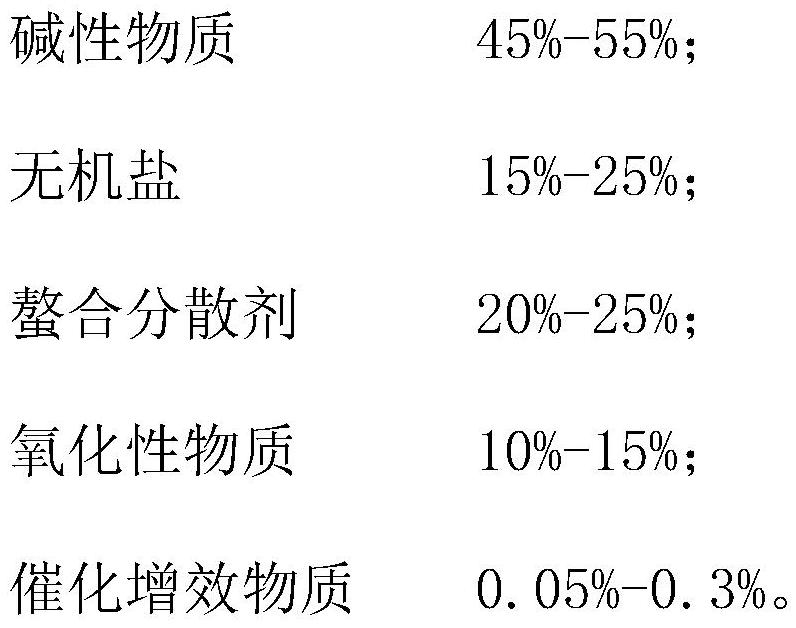

[0026] Percentage by mass arranged the following components: 450 g of sodium carbonate; 200 g of potassium chloride; 200 g of sodium gluconate; sodium perborate 150g, synergistic catalytic species EDTA chelating copper 2g, will be configured into a double helix cone material mixed the feeder, uniformly mixed at room temperature with stirring, to prepare a low temperature active anti-staining dye lotion soap 1.

Embodiment 1-2

[0028] Percentage by mass arranged the following components: 450 g of sodium carbonate; 200 g of potassium chloride; sodium 200 g of glucose; 150g sodium perborate; EDTA chelate manganese catalyst SYNERGIER 2g, will be configured into a double helix cone material mixed the feeder, uniformly mixed at room temperature with stirring, to prepare a low temperature active anti-staining dye soaping agent 2.

Embodiment 1-3

[0030] Percentage by mass arranged the following components: 450 g of sodium carbonate; 200 g of potassium chloride; sodium 200 g of glucose; 150g sodium perborate; EDTA chelated iron catalytic species synergistic 2g, will be configured into a double helix cone material mixed the feeder, uniformly mixed at room temperature with stirring, to prepare a low temperature active anti-staining dye soaping agent 3.

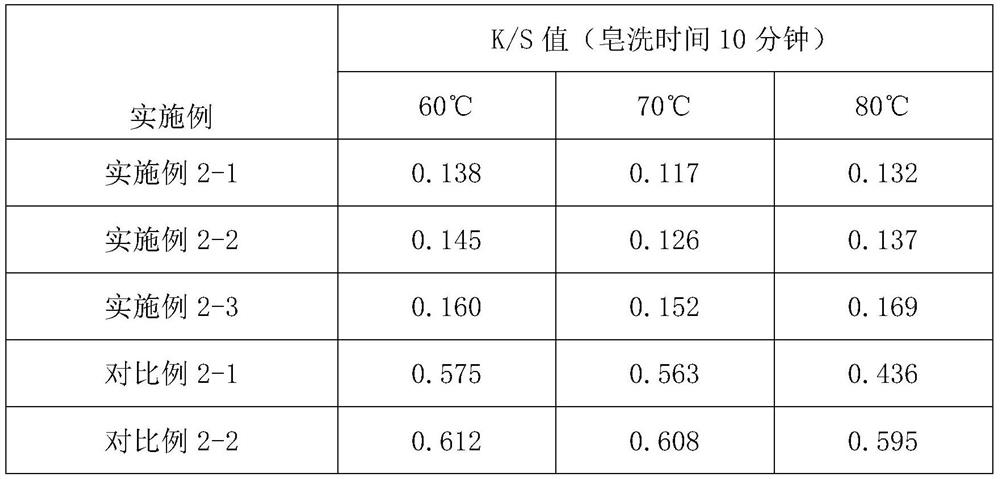

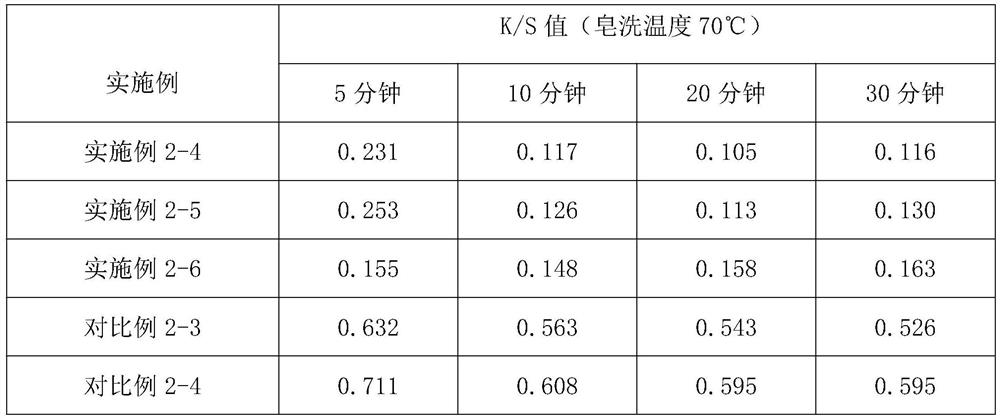

[0031] Anti-staining experiments

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com