Nonionic waterborne polyurethane dispersoid and preparation method thereof

A water-based polyurethane and dispersion technology, applied in the field of polyurethane materials, can solve the problems of poor acid and alkali resistance and poor electrolyte stability, and achieve the effects of high emulsion stability and strong acid and alkali resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

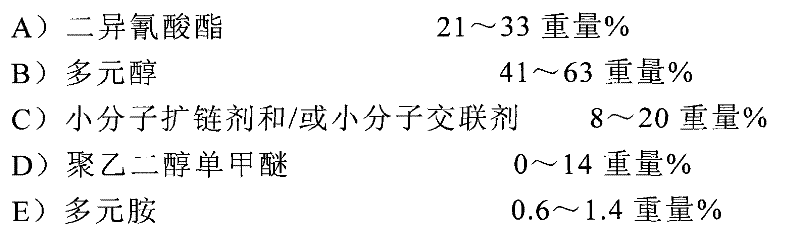

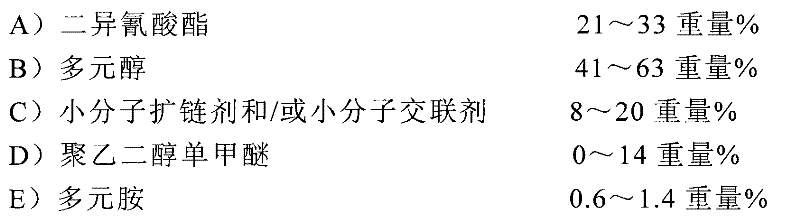

Method used

Image

Examples

Embodiment 1

[0027] Add 174 grams of polyethylene adipate diethylene glycol (molecular weight is about 2000), 48 grams of polyethylene oxide ether glycol (molecular weight is about 1500) into four-necked flask, and add 60 grams of methyl ethyl ketone , then pass dry nitrogen, start stirring and gradually raise the temperature to 55°C-70°C; after the solid is completely dissolved, add 164.8 grams of TDI dropwise at a faster speed, after the addition is completed, the temperature is raised to 85°C-100°C, and an appropriate amount of After the catalyst reacted for 1 to 2 hours, add 31.04 grams of 2,2-dimethylol propionic acid, continue the reaction for 30 to 45 minutes and then start to cool down; when the temperature drops to 70°C to 80°C, add 24.8 grams of Ethylene glycol chain extension; after reacting for 1 hour, add 52 grams of polyethylene glycol monomethyl ether (molecular weight is about 2800) and 11 grams of trimethylolpropane at the same time to continue chain extension (add at any t...

Embodiment 2

[0029] 108.8 grams of polyadipate-1,4-butylene glycol ester diol (molecular weight is about 3000), 15 grams of polypropylene oxide ether diol (molecular weight is about 2000) add four-necked flask, and add 180 grams Acetone, then feed dry nitrogen, start stirring and gradually warming up to 55 ℃ ~ 70 ℃; after the solid is completely dissolved, add 67.9 grams of TDI and MDI mixture dropwise at a faster speed (amount of substance 2: 1), add After completion, the temperature was raised to 80°C-95°C. After reacting for 1 to 2 hours, 13.4 grams of 2,2-dimethylolpropionic acid was added, and 20.1 grams of hydroquinone-bis(β-glycolic acid was added after continuing the reaction for 30 to 45 minutes. base) ether and a mixture of diethylene glycol for chain extension; after reacting for 1 hour, add 5 grams of trimethylolpropane to continue chain extension (in the chain extension process, add solvent at any time according to viscosity changes to reduce viscosity), and then react for 1 H...

Embodiment 3

[0031] 174 grams of polyethylene adipate glycol (molecular weight is about 2000), 48 grams of polyethylene oxide ether glycol (molecular weight is about 2000), MDI208.2 grams, 21.44 grams of 2,2-diol Add hydroxymethyl propionic acid and 24.8 grams of diethylene glycol together into a four-necked flask, and add 60 grams of acetone, then pass through dry nitrogen, start stirring and slowly raise the temperature to 85 ° C, add an appropriate amount of catalyst to react for 4 to 5 hours 4 grams of trimethylolpropane continue to extend the chain (in the process of chain extension, add solvent at any time according to the change of viscosity to reduce the viscosity), add 32 grams of polyethylene glycol monomethyl ether (molecular weight is about 3000) after reacting for 30 minutes, and react for another Hours began to cool down. When the temperature of the prepolymer drops to 10℃~25℃, use a high-shear disperser to add deionized water to disperse under the condition of rapid stirring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com