Oil base drilling cuttings cleaning agent and cleaning method thereof

A technology for oil-based drilling cuttings and cleaning agent, which is applied in the directions of detergent compounding agent, detergent composition, chemical instrument and method, etc. Oil effect, enhanced emulsification and solubilization, reusable low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

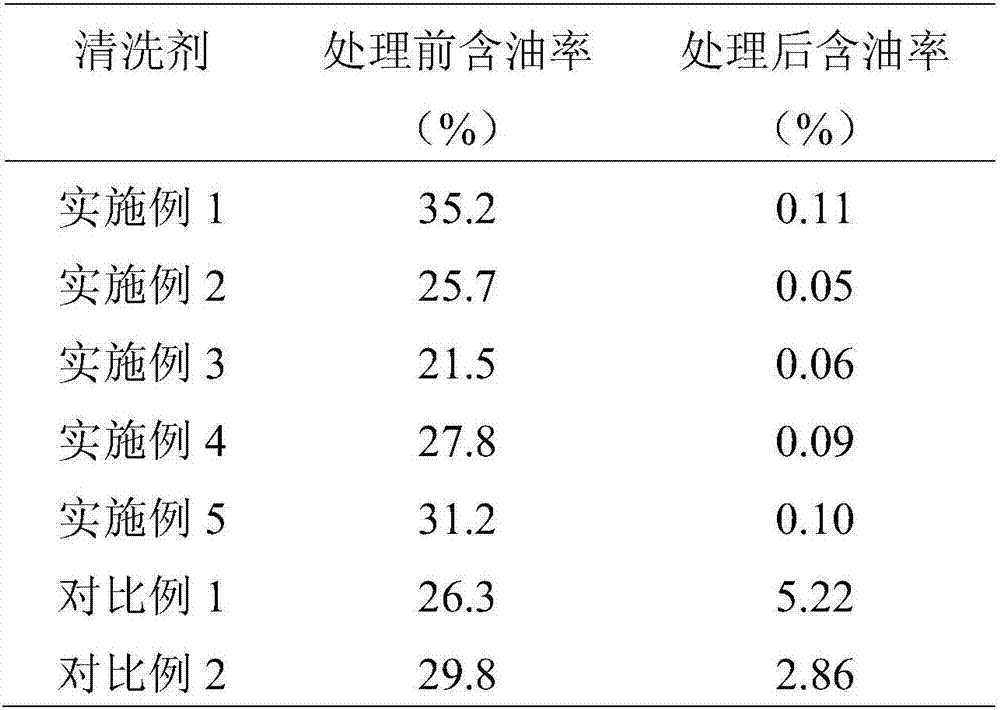

Examples

Embodiment 1

[0026] Add 1 part of sodium chloride and 1.75 parts of sodium silicate to 90 parts of water, stir until completely dissolved; then add 5 parts of n-butanol, stir until dissolved, then add 2 parts of sodium lauryl sulfate, stir until dissolved; finally Add 0.25 parts of polyethylene glycol p-isooctyl phenyl ether and stir until dissolved to obtain an oil-based drilling cuttings cleaning agent.

[0027] In a mixing tank equipped with a stirrer, add 20kg of oil-based drilling cuttings cleaning agent, and at a stirring speed of 200rpm, add 10kg of oil-based drilling cuttings, stir and mix for 20min, and centrifuge in a centrifuge (relative centrifugal force 800g, centrifugation time 5min) After separation, drill cuttings with low residual oil and oil-based cleaning agent containing base oil are obtained. The oil-based cleaning agent containing base oil can be recovered by means of demulsification separation (such as air flotation separation after adding a demulsifier) to recover...

Embodiment 2

[0029] Add 2 parts of sodium chloride and 2 parts of sodium silicate to 90.5 parts of water, stir until completely dissolved; then add 3 parts of ethanol, stir until dissolved, then add 2 parts of sodium dodecylbenzenesulfonate, stir until dissolved; finally Add 0.5 parts of Tween-80 and stir until dissolved to obtain an oil-based drilling cuttings cleaning agent.

[0030] In a stirring tank equipped with a stirrer, add 20kg of oil-based drilling cuttings cleaning agent, and at a stirring speed of 500rpm, add 40kg of oil-based drilling cuttings, stir and mix for 30min, and centrifuge in a centrifuge (relative centrifugal force 4000g, centrifugation time 5min) After separation, drill cuttings with low residual oil and oil-based cleaning agent containing base oil are obtained. The oil-based cleaning agent containing base oil can be recovered by means of demulsification separation (such as air flotation separation after adding a demulsifier) to recover the oil-based cleaning ag...

Embodiment 3

[0032] Add 1 part of sodium sulfate and 2 parts of sodium silicate to 93.7 parts of water, stir until completely dissolved; then add 2 parts of amyl alcohol, stir until dissolved, then add 1 part of sodium dodecylbenzenesulfonate, stir until dissolved; finally Add 0.3 parts of polyethylene glycol p-isooctyl phenyl ether and stir until dissolved to obtain an oil-based drilling cuttings cleaning agent.

[0033] In a mixing tank equipped with a stirrer, add 20kg of oil-based drilling cuttings cleaning agent, and at a stirring speed of 100rpm, add 5kg of oil-based drilling cuttings, stir and mix for 10 minutes, and centrifuge in a centrifuge (relative centrifugal force 400g, centrifugation time 20min) After separation, drill cuttings with low residual oil and oil-based cleaning agent containing base oil are obtained. The oil-based cleaning agent containing base oil can be recovered by means of demulsification separation (such as air flotation separation after adding a demulsifier)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com