Patents

Literature

172results about How to "Improve extreme pressure and anti-wear performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyurea grease composite

ActiveCN1657599AImprove extreme pressure and anti-wear performanceGood extreme pressure and anti-wear propertiesThickenersComposition BBase oil

Two lubricating polyurea-ester compositions with high stability and extreme-pressure antiwear performance contain proportionally basic oil, urea-based thickening agent, Ca-based thickening agent and extreme-pressure agent for composition A, or the composition A plus inorganic Ca salt for composition B.

Owner:CHINA PETROLEUM & CHEM CORP +1

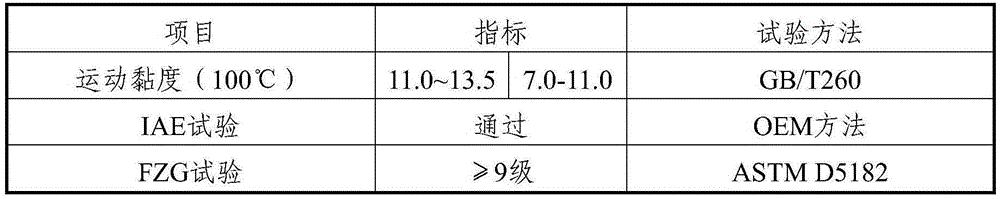

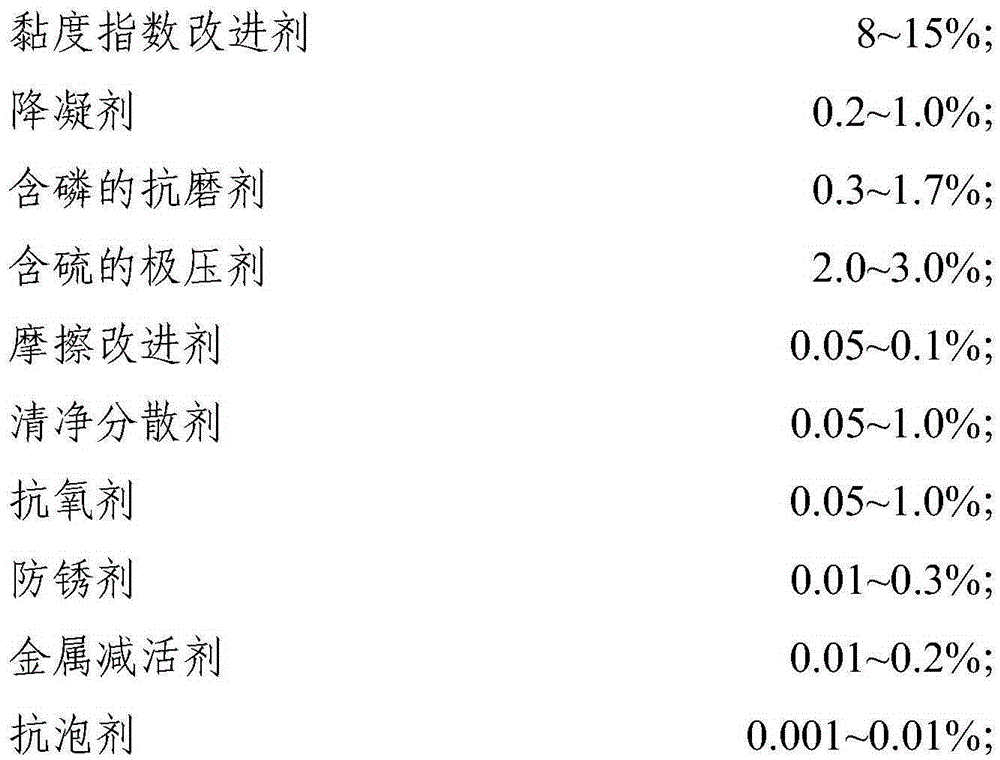

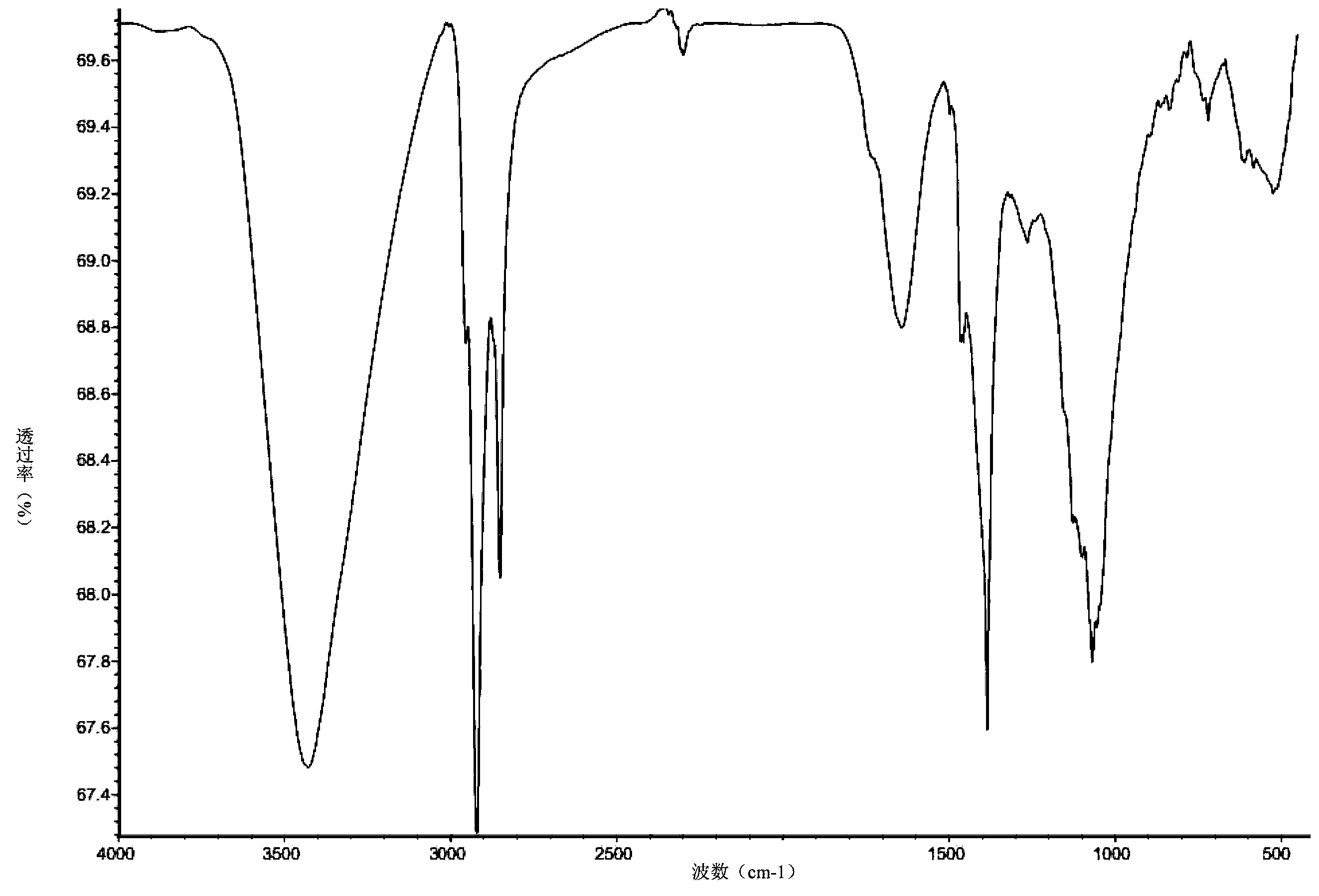

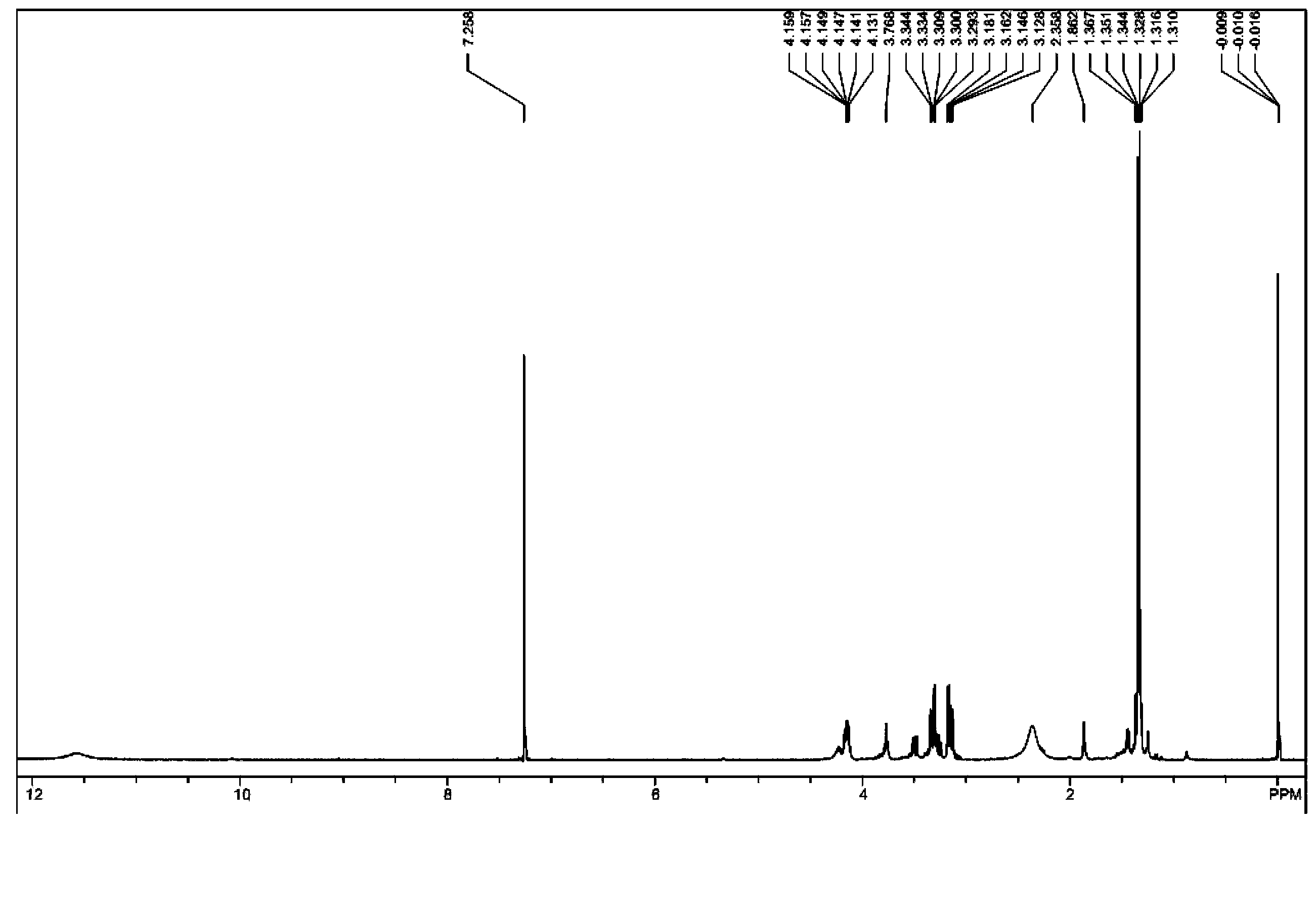

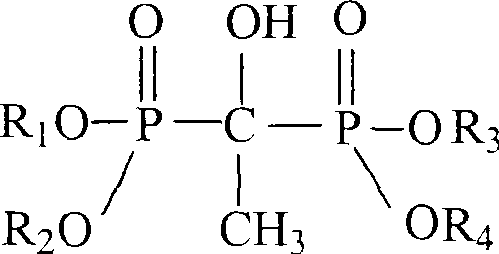

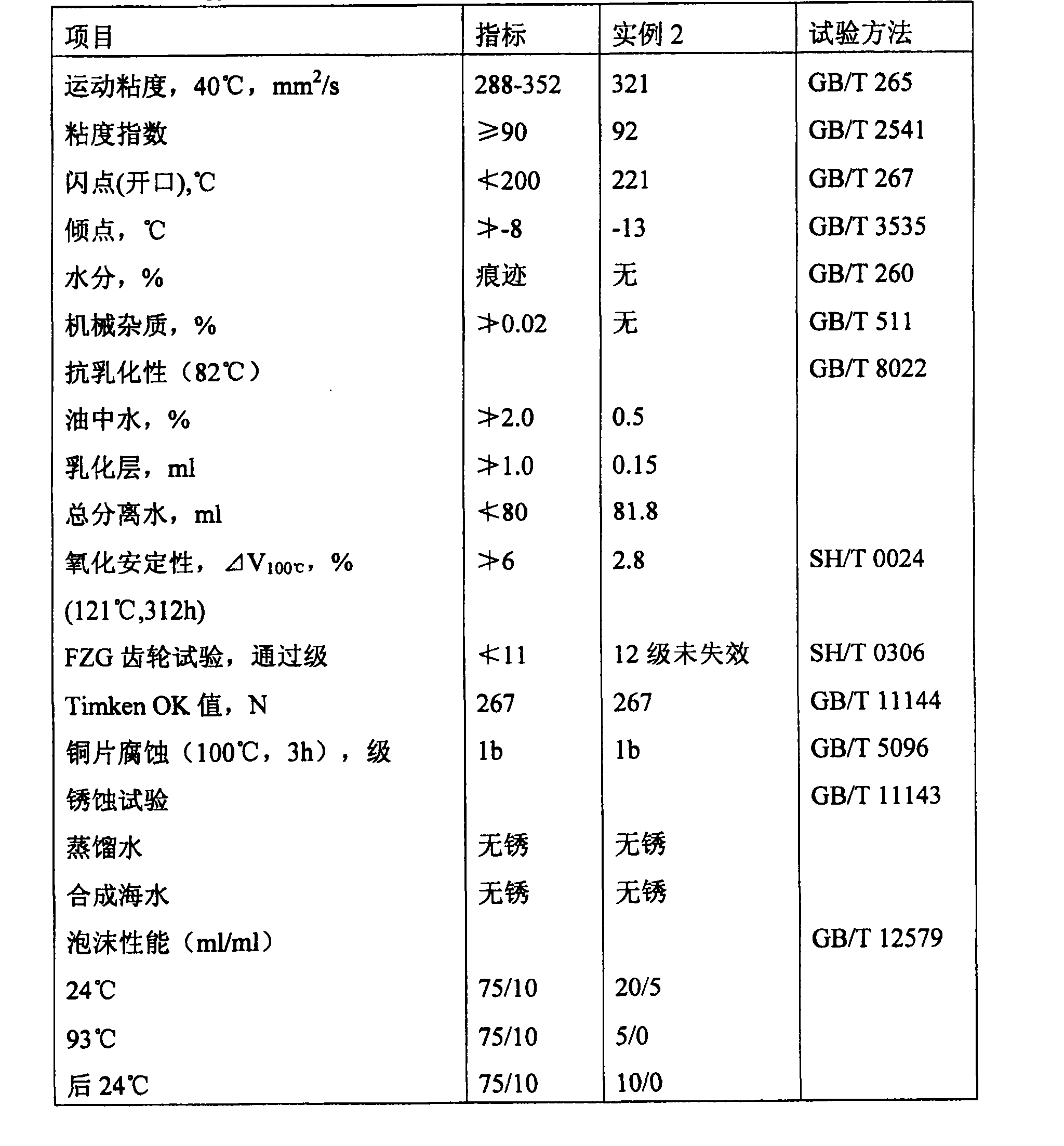

Combination of general gear oil

A universal oil composition for gear contains mineral lubricating oil or synthetic lubricating oil or their mixture, at least one viscosity index improver and / or pour depressor, at least one S-contained extreme-pressure agent, at least one P-contained antiwear agent, phosphate-type multi-effect agent, oil agent (1-hydroxyethylene-1, 1-biphosphonate), and at least one metallic deactivator and / or antirust agent.

Owner:CHINA PETROLEUM & CHEM CORP +1

Light cured dry film lubricant

InactiveCN102433201AHigh speedImprove extreme pressure and anti-wear performanceLubricant compositionPolymer scienceOligomer

The invention discloses a light cured dry film lubricant. The film forming substance of the light cured dry film lubricant consists, by weight percent, of 10 to 50% of solid lubricant, 0.2 to 5% of dispersant, 4 to 10% of antiwear additive, 2 to 6% of antioxidant, 0.5 to 2.5% of magnetic additive and 35-80% of coating film bonding matrix, wherein the bonding matrix consists of oligomer, reactive diluent, photo-initiator and auxiliary. The dry film lubricant disclosed by the invention can be cured under ultraviolet light at normal temperature, and is fast in being cured, environment-friendly, excellent in antiwear property and small in frictional surface scratch. The light cured dry film lubricant is applicable for the lubricating antiwear coating on oil-free lubrication components, and especially applicable for the lubricating antiwear coating on the surface of non-temperature-resistant base materials.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

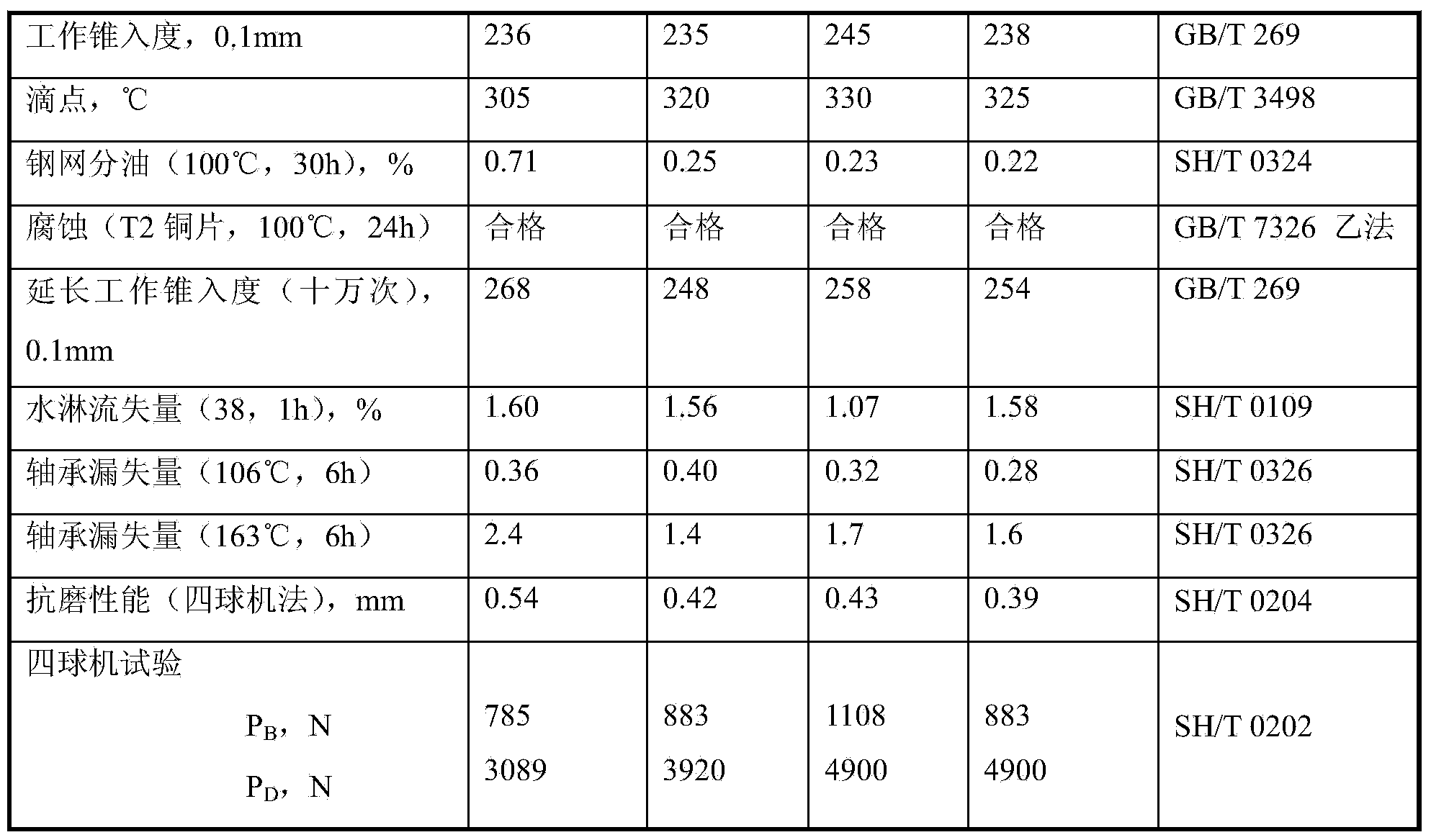

Lubricating grease for hubs of heavy trucks and preparation method for lubricating grease

ActiveCN102618368AStable structureImprove water resistanceLubricant compositionLithium soapHeat resistance

The invention discloses lubricating grease for hubs of heavy trucks. The lubricating grease consists of base oil, thickening agent and additive, the thickening agent is composite lithium soap thickener, and the additive consists of borate oiling agent, compound viscosity index improver, purification dispersant, amine-type antioxidant, sulfur-phosphorous-type antioxidant and sulfonate antirusting agent. The special lubricating grease for hubs of trucks which is obtained by means of circular shearing treatment is excellent in heat resistance, adhesion, mechanical stability, water resistance, extreme pressure abrasion resistance and the like, and can meet requirements on lubrication and protection for bearings of the hubs of the trucks under harsh conditions.

Owner:杭州得润宝油脂股份有限公司

Lubricating grease composition for heavy-loading roller press bearing and preparation method thereof

ActiveCN103275798AGood extreme pressure and anti-wear propertiesImprove the lubrication effectLubricant compositionLithiumAntioxidant

The invention provides a lubricating grease composition for a heavy-loading roller press bearing and a preparation method thereof. The composition has prominent extreme-pressure anti-wear property, lubricating property and water resistance. The lubricating grease composition contains the following ingredients: (a) complex lithium and calcium-based lubricating grease, (b) a tackifier, (c) an oiliness additive, (d) an extreme-pressure anti-wear agent, (e) an antioxidant and (f) a graphite additive.

Owner:SHANGHAI HITECRUN SPECIAL LUBRICATE SCI & TECH

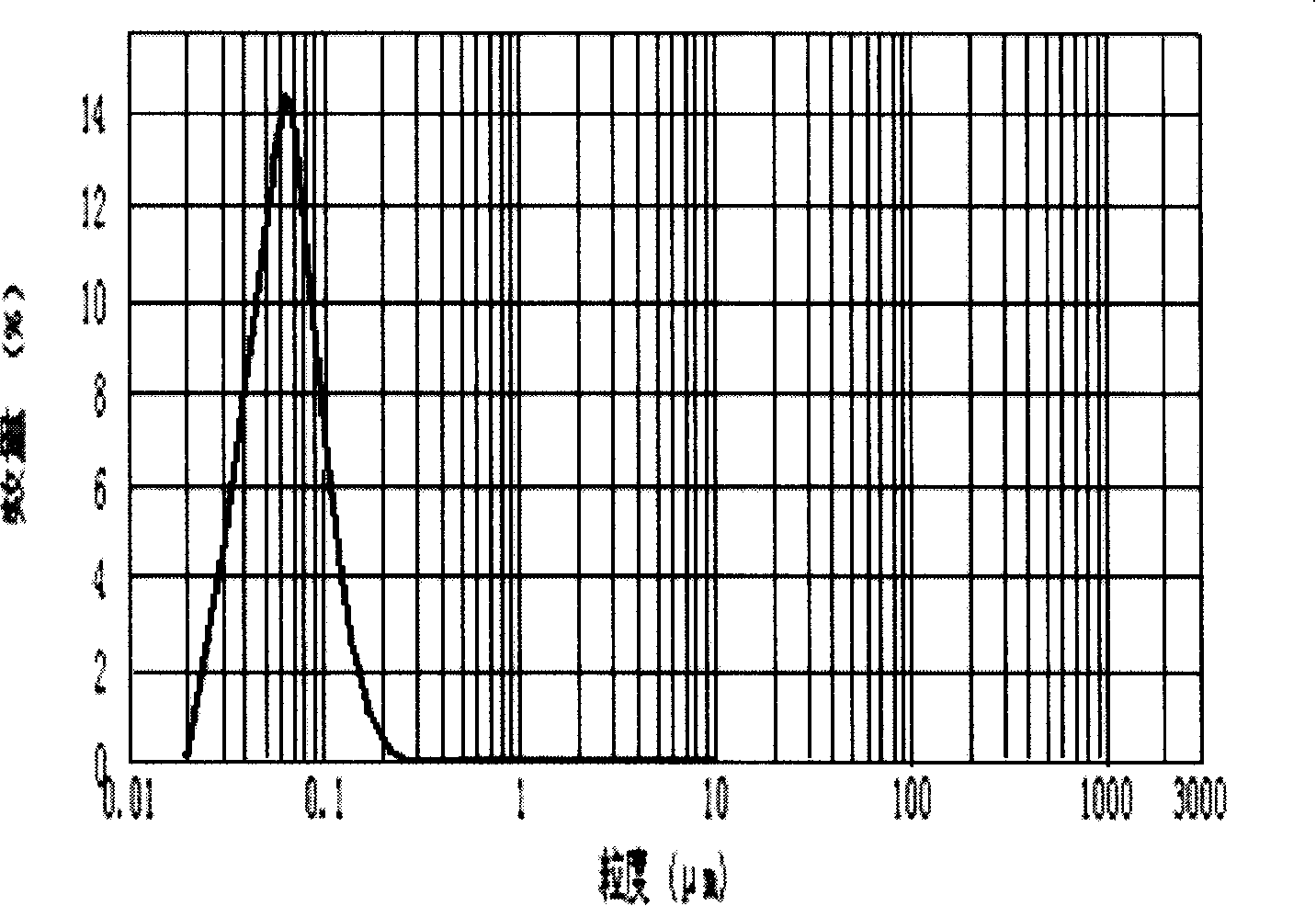

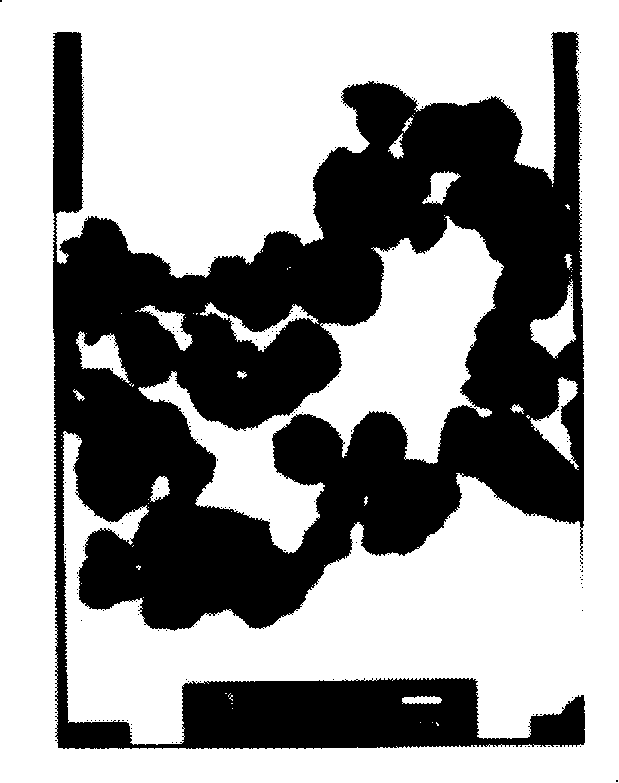

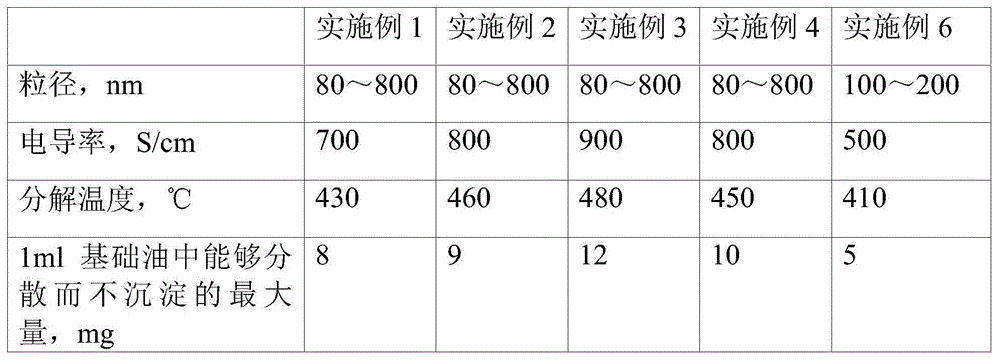

Nano core-shell type copper-nickel bimetal powder body and preparing method and application thereof

ActiveCN101209493AOvercome the disadvantage of easy oxidationMeet the requirement of transparent appearanceCoatingsThioureaConductive materials

The invention relates to a bimetal powder of copper and nickel and a preparation method thereof. The invention solves the defect of easy oxidation of the simple substance nanometer copper powder and improves the use effect of the ordinary copper nickel composite powder. Referring to the prior art, the invention firstly prepares a nanometer copper powder, the copper powder is stirred and dispersed homogeneously in the water, and suspension liquid of the copper powder is prepared; the suspension liquid of the copper powder is blended with the nickel sulfate solution comprising macromolecule protective agent and special copper coordination agent thiourea so as to cause a replacement reaction between nickel ion and the copper; surfaces of the ultrafine copper particles are partly or all coated with the nickel, thus forming the core-shell copper-nickel bimetal nanometer powder. The bimetal powder can be taken as lubricant, lubricating grease extreme pressure-antiwear additives, additives in powder metallurgy, or as porous materials, antibacterial materials, antifouling coatings, conductive materials, magnetic materials, self-lubricating materials, antifriction materials, diamond tools, and raw materials or additives of electrical carbon products.

Owner:HAILIAN INST OF LUBRICATING MATERIALS SHANGHAI

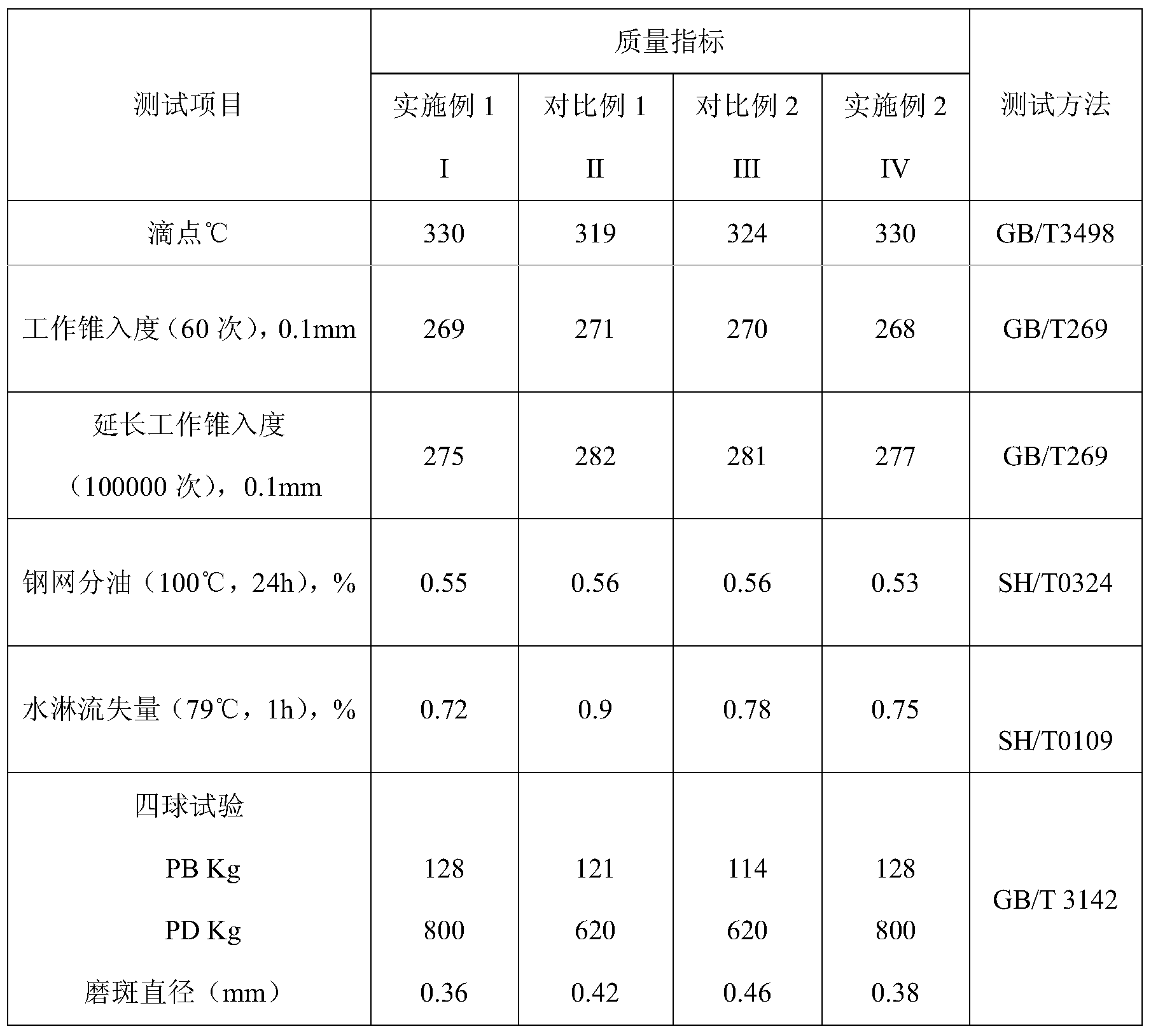

Preparation of high dropping point carbamido grease lubricant and obtained product

The invention provides a preparation process for high drop point ureido grease, wherein, the base oil, the solid additive powder, the organic amine and the diisocyanate are mixed between 50 DEG C and 100 DEG C to react, then added with the quench oil when the temperature rises between 160 DEG C and 220 DEG C and is then cooled to be taken out of a kettle. The grease obtained by the invention is taken as one hundred percent of total weight and comprises the following compositions: the weight of the base oil accounts for 70 to 90 percent, the ureido thickening agent produced by the reaction of the organic amine and the diisocyanate has a weight accounting for 5 to 25 percent, and the weight of the solid additive powder accounts for 0.1 to 10 percent. The grease obtained by the process has a drop point which is more than 330 DEG C and has good extreme pressure anti-abrasion performance as well as corrosion resistance performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Lithium-based lubricating grease and preparation method thereof

The invention discloses lithium-based lubricating grease and a preparation method thereof. The lithium-based lubricating grease is characterized by being prepared from the following components on the basis of the weight of the lubricating grease: 65-95% of lubricating base oil, 6-20% of lithium-based thickening agent and 0.5-15% of graphene. The lithium-based lubricating grease has excellent properties such as excellent high temperature resistance, water and adhesion resistance, colloidal stability, extreme pressure antiwear property, long lubricating service life, corrosion resistance and salt mist resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Lubricating grease for hub bearing of heavy load truck and preparation method thereof

InactiveCN103450978AEliminates tendency to overflowSlow dehydration stepThickenersThiocarbamateChemical industry

The invention relates to a lubricating grease and a preparation method thereof, particularly relates to a lubricating grease for a hub bearing of a heavy load truck and a preparation method thereof, and belongs to the technical field of a chemical industry. The lubricating grease is prepared from the following raw materials: (A) base oil which accounts for 60-85% of total weight of the lubricating grease, (B) a thickening agent, which is C12-C22 unitary organic acid which accounts for 7-12% of total weight of the lubricating grease, 0.5-3% of sebacic acid, 0.2-1% of boric acid, and 3-5% of lithium hydroxide oil solution, (C) an additive, which is thiocarbamate which accounts for 0.5-3% of total weight of the lubricating grease, 2-5% of sulfide olefin cottonseed oil, 2-4% of dialkyl dithiocarbamate salt, 0.5-2.5% of molybdenum dialkyl dithiophosphate, 0.3-2% of antirust agent and 0.3-1% of antioxidant. The lubricating grease has the beneficial effects that the production time is shortened; the lubricating grease is more controllable in process, stable in product quality, less in seepage loss of a high-temperature bearing, and prominent in extreme pressure property; lubricating protection can be better provided for hubs of the heavy load truck; the lubricating requirements of the hub bearing of the heavy load truck under various working conditions can be met; the grease exchange period of the hub bearing is prolonged.

Owner:JIANGSU LOPALTECH

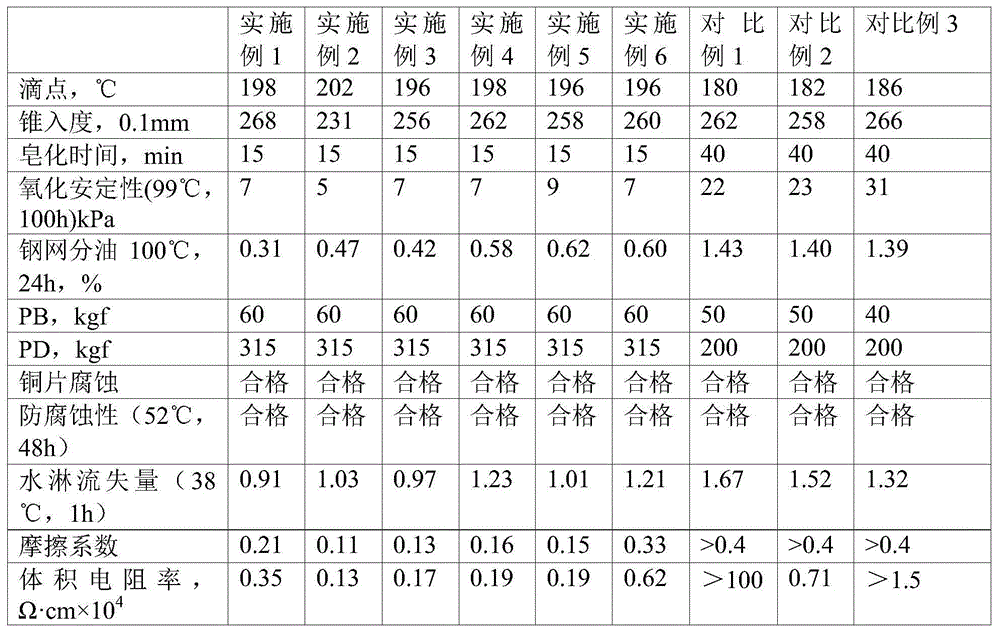

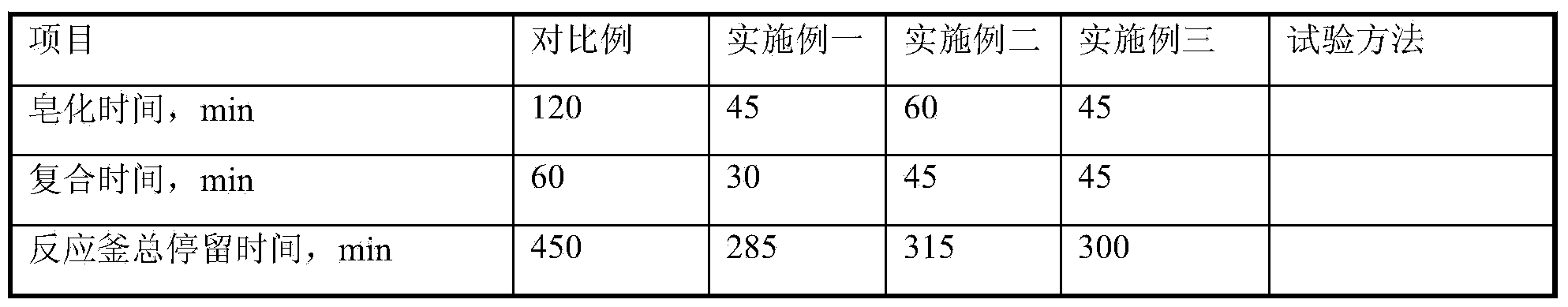

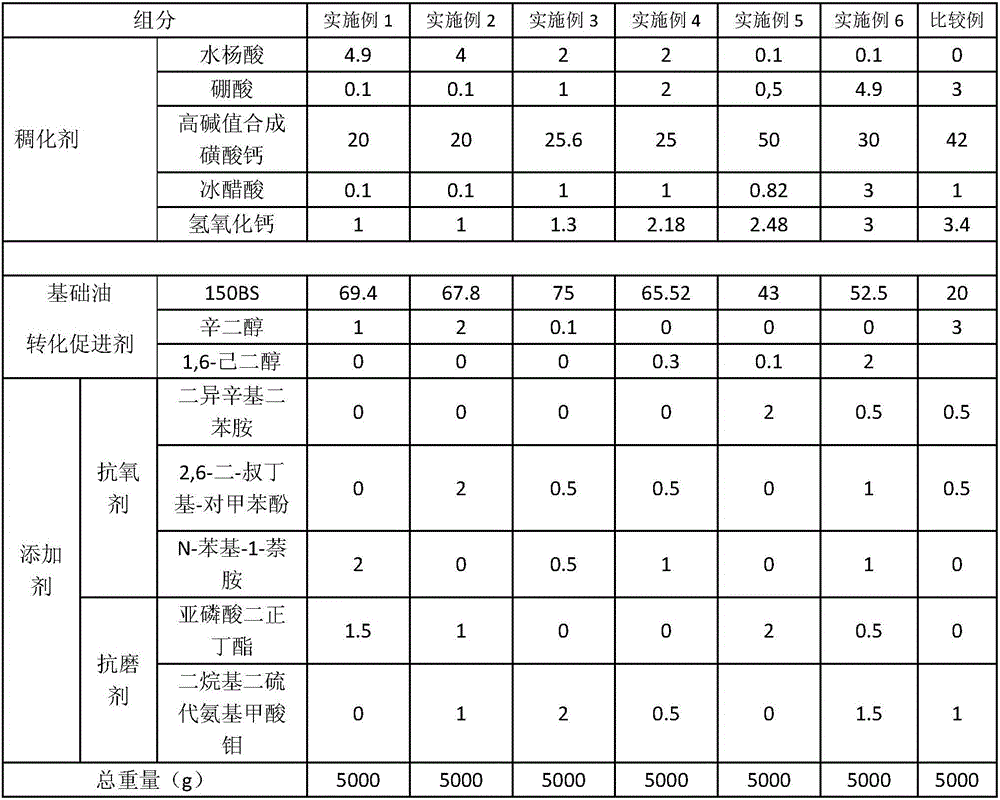

Modified composite calcium sulfonate based lubricating grease composition and preparation method

InactiveCN106497641AImproved long-term mechanical stabilityReduced surface hardeningLubricant compositionCalcium hydroxideAcetic acid

The invention relates to a modified composite calcium sulfonate based lubricating grease composition and a preparation method. The composition is prepared from, by weight, 20-50% of high-alkali-value synthesized calcium sulfonate, 45-75% of basic oil, 0.1-2% of conversion agent, 0.1-3% of glacial acetic acid, 1-3% of calcium hydroxide, 0.1-5% of composite acid and 1.0-4.0% of additive, wherein the total weight is 100%. The mechanical stability of a composite calcium sulfonate base is improved and especially a thickness change value of composite calcium sulfonate based lubricating grease in the storage process is decreased by improving the varieties and contents of the conversion agent and the complex additive required in the preparation process and a preparation process of the composition, and accordingly the mechanical stability performance of the composite calcium sulfonate based lubricating grease is improved. In addition, the high-temperature anti-oxidization properties of the composite calcium sulfonate based lubricating grease is improved and can meet the requirement for long service life of the lubricating grease in the using process to the great degree. In addition, the extreme-pressure anti-abrasion and anti-rust properties of the lubricating grease can be improved.

Owner:CHINA PETROLEUM & CHEM CORP

Environment-friendly steel wire drawing lubricating agent and production method thereof

The invention relates to the field of lubricating grease, in particular to an environment-friendly steel wire drawing lubricating agent and a production method thereof. The lubricating agent is prepared by blending the following components in percentage by weight: 5.0 to 10 percent of base oil, 15 to 24 percent of emulsifier, 5.0 to 8.0 percent of alkaline reserve agent, 9.4 to 18.8 percent of extreme pressure antiwear agent, 5.3 to 8.3 percent of water soluble antirust agent, 0.01 to 0.03 percent of coupling agent, 0.01 to 0.03 percent of defoaming agent, 0.01 to 0.03 percent of bacteriacideand 30.81 to 60.27 percent of distilled water. The total percentage of the components is 100 percent. Compared with the prior art, the components do not react with the steel wire substrates; the antirust performance, defoaming performance and biostability are high; the deterioration in storage and use is slow, and the service life is long; and environment pollution is avoided and waste liquid canbe treated easily.

Owner:辽宁海华科技股份有限公司

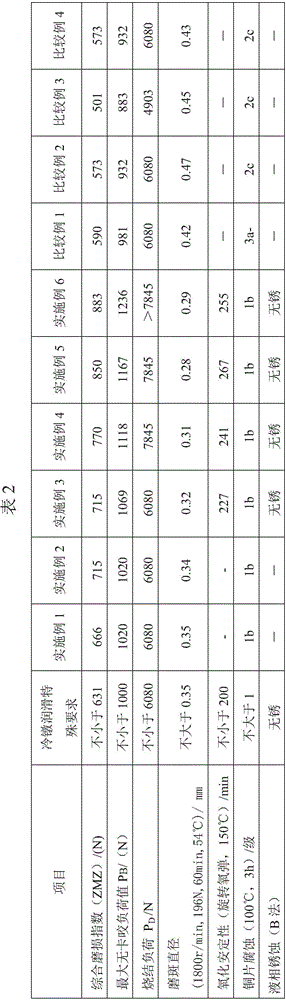

Hydraulic oil composition with high extreme pressure performance

ActiveCN102337175AImprove extreme pressure and anti-wear performanceLubricant compositionCarrying capacityIndustrial equipment

The invention provides a hydraulic oil composition with a high extreme pressure performance. The composition comprises base oil and an extreme pressure anti-wear agent accounting for 0.3-3% of the total weight of the composition, with the base oil composed of API I type oil and API II type oil in a weight ratio of 1:15-1:1.5. The hydraulic oil composition with a high extreme pressure performance in the invention, according to a test by the GB / T 3142 determination method for the load carrying capacity of lubricant (a four-ball method, under a test condition of 1760rpm), has a sintering load greater than or equal to 1236N, a maximum nonseizure load greater than or equal to 785N, and ZMZ greater than or equal to 295N. Compared with present products, the hydraulic oil composition of the invention has a high extreme pressure performance, and is suitable for various low, medium, high and even ultrahigh pressure hydraulic systems in engineering machineries and industrial equipment.

Owner:CHINA PETROLEUM & CHEM CORP

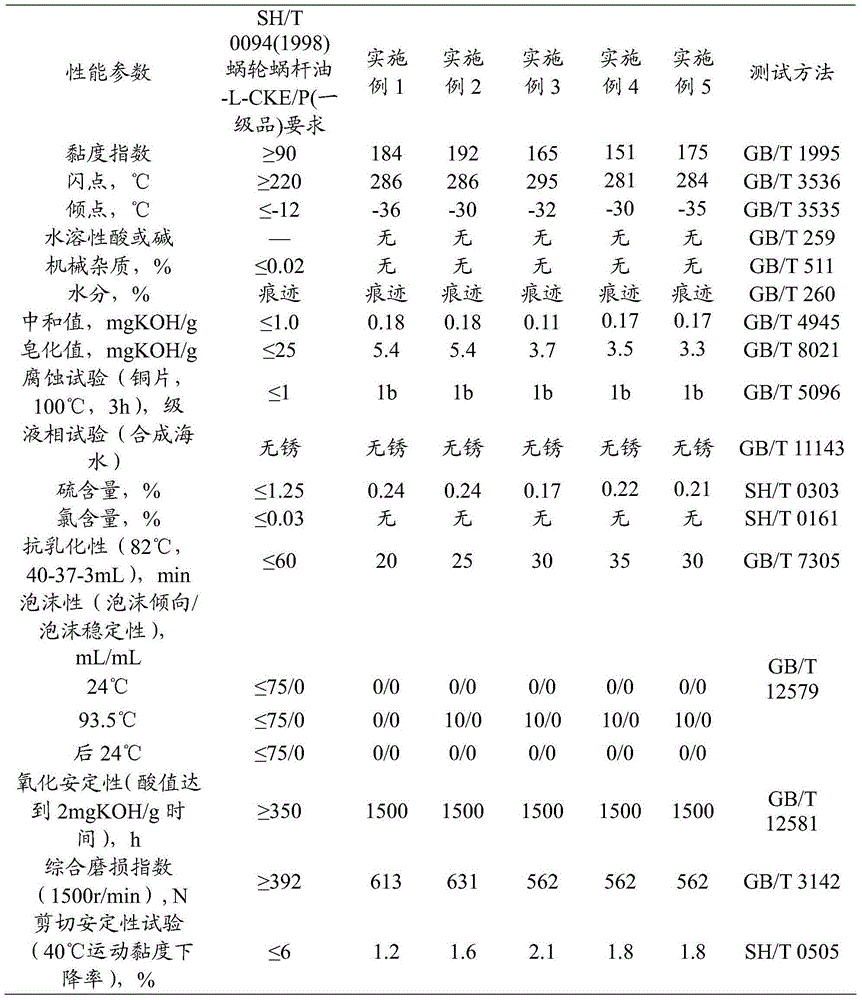

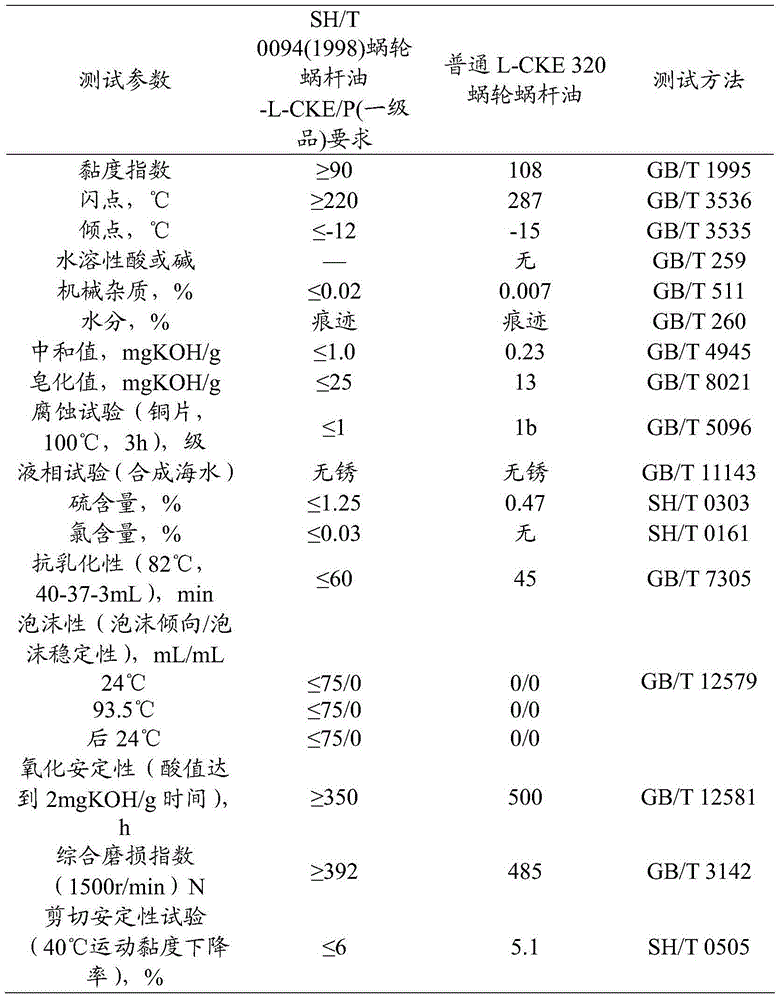

Worm wheel worm rod lubricating oil composition and preparation method thereof

ActiveCN104403741AImprove extreme pressure and anti-wear performanceImprove Oxidation StabilityLubricant compositionPolyolefinFoaming agent

The present invention provides a worm wheel worm rod lubricating oil composition and a preparation method thereof. The worm wheel worm rod lubricating oil composition comprises 45-75 wt% of poly[alpha]-olefin, 10-45 wt% of oil-soluble polyether, 0.1-5 wt% of an antioxidant, 0.01-0.5 wt% of a metal deactivator, 0.1-5 wt% of a corrosion inhibitor, 0.5-5 wt% of an extreme pressure anti-wear agent, and 0.0005-0.05 wt% of an anti-foaming agent. According to the present invention, the poly[alpha]-olefin and the oil-soluble polyether are adopted as the base oils, the antioxidant, the metal deactivator, the corrosion inhibitor, the extreme pressure anti-wear agent and the anti-foaming agent are adopted as the additives, and the contents of each component are controlled within the content range, such that the worm wheel worm rod lubricating oil composition has the good extreme pressure anti-wear property and the excellent oxidation stability; and the worm wheel worm rod lubricating oil composition further has characteristics of excellent corrosion resistance, excellent rust resistance, excellent shear stability, good oil-water separation property and good anti-foam property.

Owner:CHINA PETROLEUM & CHEM CORP

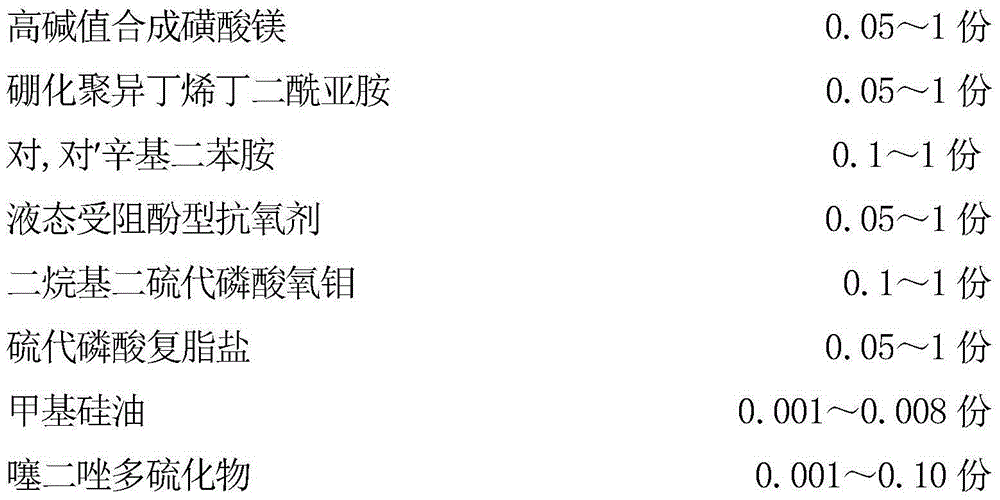

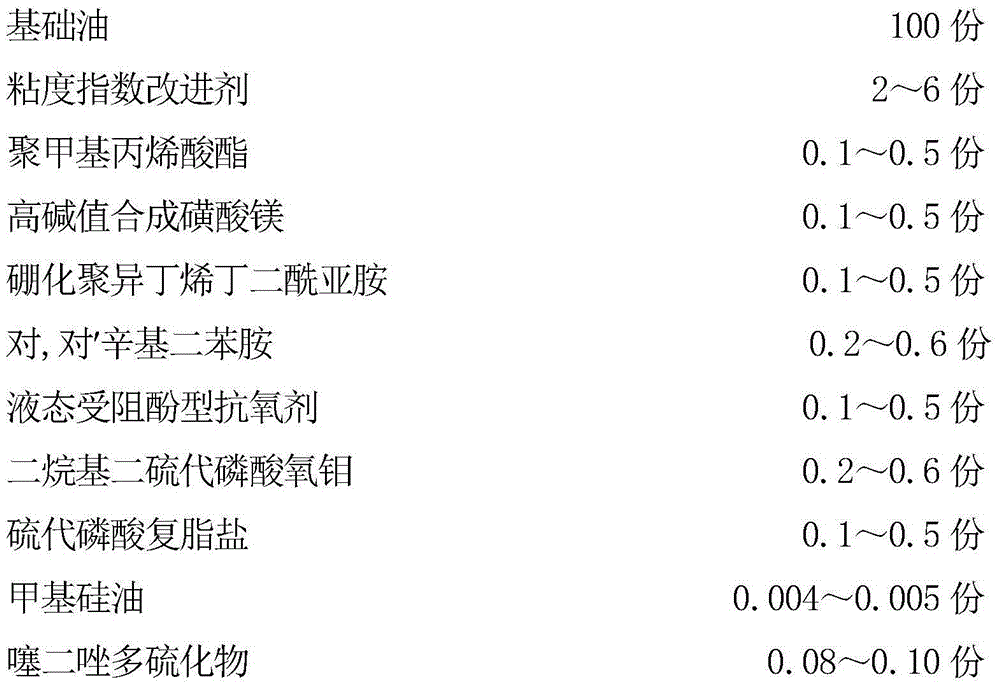

Special lubrication oil for heavy-load LNG (liquefied natural gas) engine

ActiveCN104804812AReduce dosageMeet low temperature performanceLubricant compositionLubricationLiquefied natural gas

The invention discloses special lubrication oil for a heavy-load LNG (liquefied natural gas) engine. The lubrication oil comprises base oil, a viscosity index improver, polymethacrylate, overbased compound magnesium sulfonate, borated polyisobutene succinimide, p,p'-octyldiphenylamine, a liquid hindered phenol type antioxidant, oxymolybdenum dialkydithiophosphate, thiophosphate complex ester, methyl silicone oil and thiadiazole polysulfide, wherein the viscosity index improver is prepared by mixing any of ethylene-propylene copolymers T604, T613, T614, T615 and T618 with a random copolymer of ethylene and alpha-olefin in the mass ratio of 1: 1-8:1. The lubrication oil has an excellent high-temperature detergent dispersing property, excellent high-temperature viscosity remaining capacity, acid neutralization capacity and attenuation resistance, the coking amount is small, the oil-change mileage of the engine is greatly increased, meanwhile, the low-temperature fluidity is good, the engine can work at a lower temperature, and the use requirement of the low-temperature heavy-load LNG engine can be met.

Owner:陕西通用润滑科技有限公司

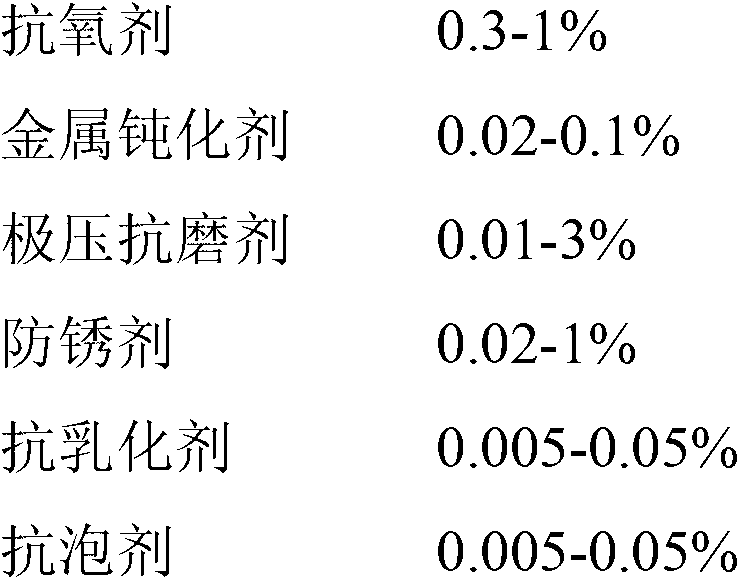

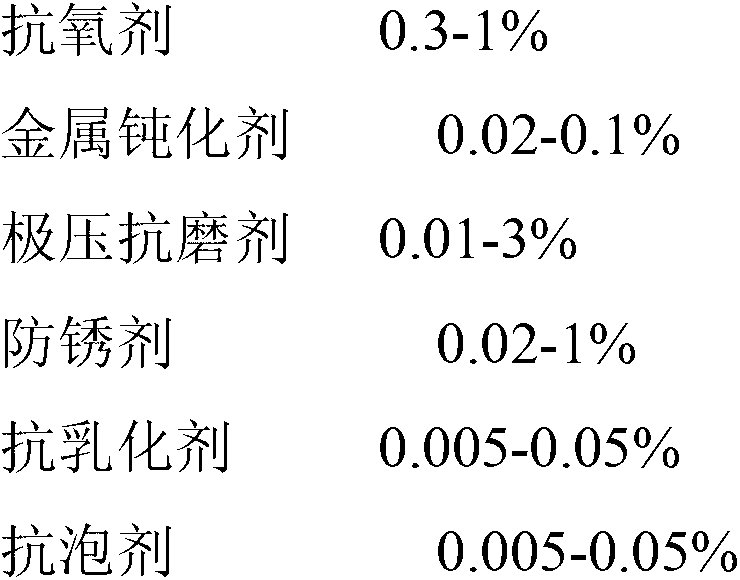

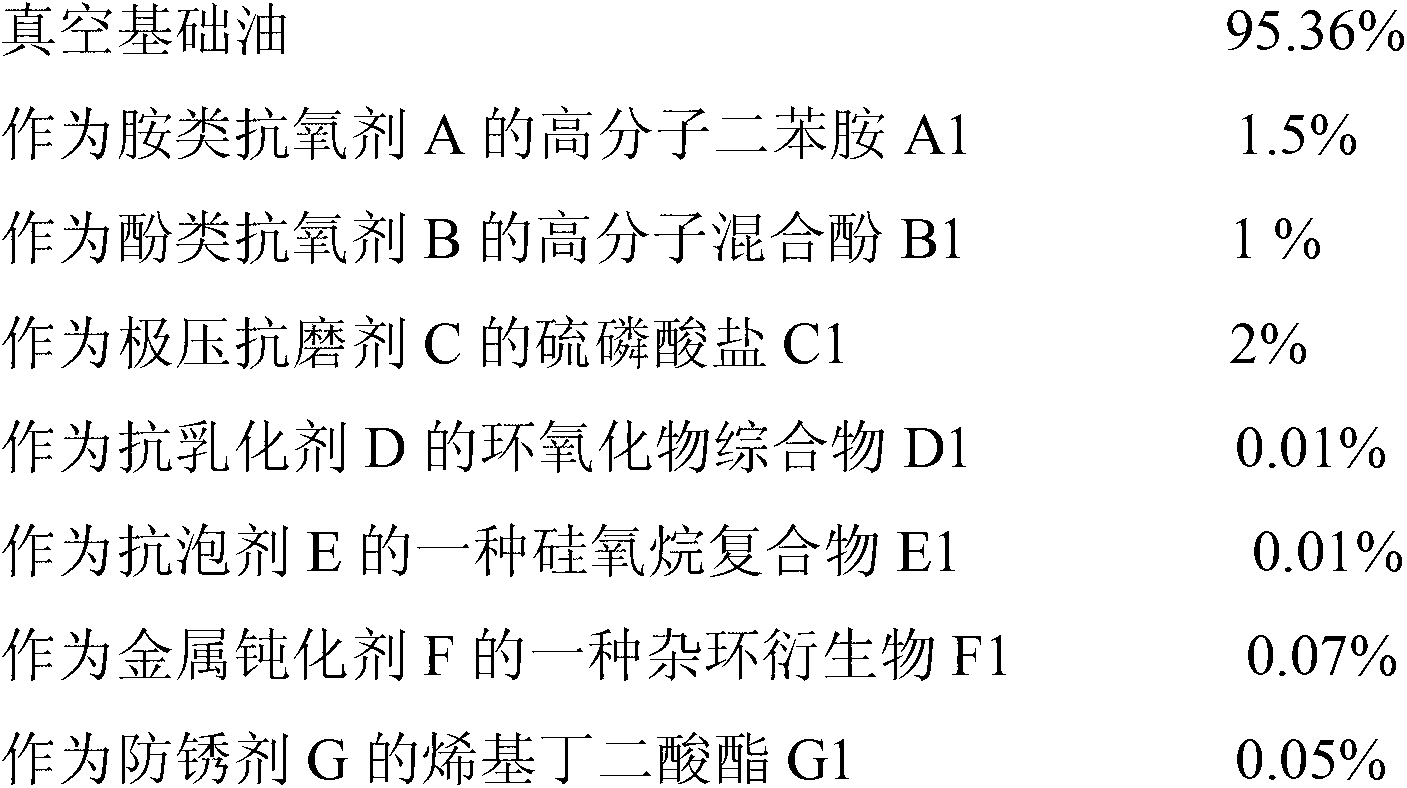

High-vacuum vacuum pump oil

InactiveCN103060065AGood antioxidant propertiesImprove extreme pressure and anti-wear performanceLubricant compositionChemistryPhenols

The invention discloses high-vacuum pump oil which is obtained by adding ash-free additive to compressed and distilled high-vacuum base oil. The high-vacuum pump oil comprises the following components in percentage by weight: 0.3%-1% of antioxidant, 0.02%-0.1% of metal passivator, 0.01%-3% of anti-wear reagent at extreme pressure, 0.02%-1% of antirust agent, 0.005%-0.05% of demulsifying compound and 0.05%-0.05% of anti-foaming agent, wherein the antioxidant comprises amine antioxidant and / or phenolic antioxidant; the amine antioxidant comprises high-polymer diphenylamine; the phenolic antioxidant comprises high-polymer mixed phenol. The high-vacuum pump oil disclosed by the invention has high-limit vacuum degree, and total limit pressure of 1*10<-4>kPa; and moreover, the vacuum oil is further provided with excellent oxidation resistance, high temperature resistance and anti-wear performance at extreme pressure without affecting the vacuum.

Owner:SUZHOU HUIFENG LUBRICANT

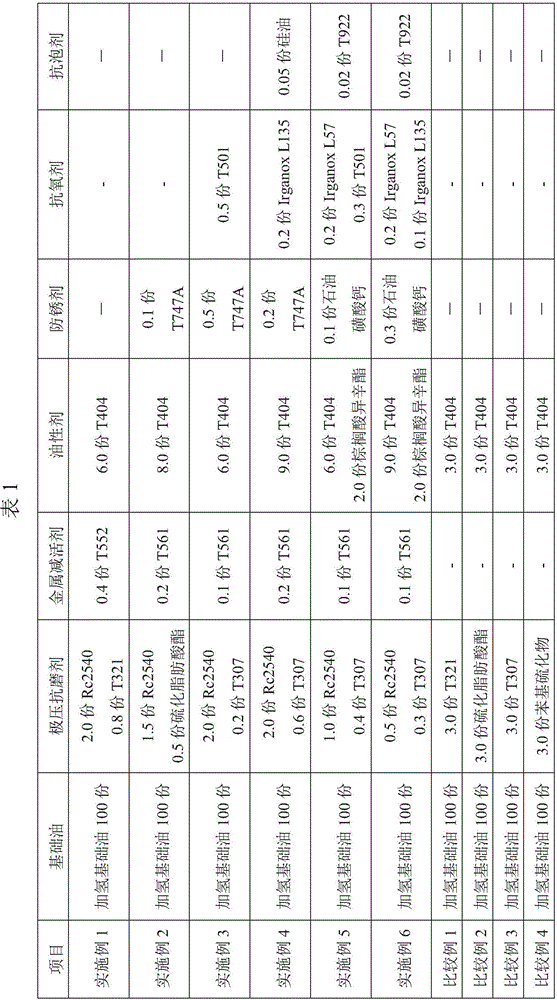

Cold heading oil composition and application thereof

ActiveCN106635285AImprove extreme pressure and anti-wear performanceAccelerated corrosionLubricant compositionGallingTriazole derivatives

The invention relates to a cold heading oil composition and an application thereof. The composition mainly solves the problems in the prior art that the extreme pressure anti-wear property and copper corrosion resistance of cold heading oil cannot satisfy usage requirements of partial cold heading equipment for lubrication unified oil supply for cold heading process and equipment, galling is generated on the surface of workpiece, or transmission gear shaft is corroded. The composition comprises the following components in parts by weight: a) 100 parts of mineral base oil; b) 0.1-5.0 parts of an anti-wear reagent at extreme pressure; c) 0.01-0.5 parts of a metal passivator; d) 1.0-15.0 parts of an oiliness agent; e) 0.005-0.5 parts of an anti-foaming agent. The anti-wear reagent at extreme pressure is a mixture of sulfurized olefin and at least one of sulfurized isobutylene, phenyl sulfide, sulfurized fatty acid ester or ammonium thiophsphonate. The metal passivator is selected from at least one of triazole derivatives or thiadiazole derivatives; the oiliness agent is a mixture of sulfurized plant oil and at least one selected from fatty acid ester or high-grade fatty alcohol. The technical scheme can better solve the problem, and is used for partial cold heading equipment for lubrication unified oil supply for cold heading process and equipment.

Owner:CHINA PETROLEUM & CHEM CORP

Gear machining minimum-quantity lubricating oil and preparation method and application thereof

InactiveCN102585983AGood lubricityGood extreme pressure and anti-wear propertiesLubricant compositionChemistryPetroleum

The invention belongs to the technical filed of lubricating oil and particularly relates to gear machining minimum-quantity lubricating oil and a preparation method and application thereof. The gear machining minimum-quantity lubricating oil is characterized by being prepared by the following raw materials by weight: 30-40% of compound synthetic ester, 20-30% of bright stock, 10-12% of compound phosphate, 10-12% of chlorinated paraffin, 8-10% of vulcanized animal oil, 2-3% of petroleum calcium sulfonate with a high alkali value, 2-3% of ricinoleic acid and 1-2% of dispersing agents. The compound synthetic ester adopts mixture formed by any two or more than two of dioctadecyl adipate, pentaerythritol ester, trimethylolpropane trioleate, dimethyl phthalate and diethyl phthalate. The compound phosphate adopts mixture formed by any two or more than two of dibutyl phosphate, o-tolyl phosphate and triphenyl thiophosphate. Compared with the prior art, the gear machining minimum-quantity lubricating oil has good lubricity and extreme pressure and anti-wear property.

Owner:阜宁县特种油品有限公司

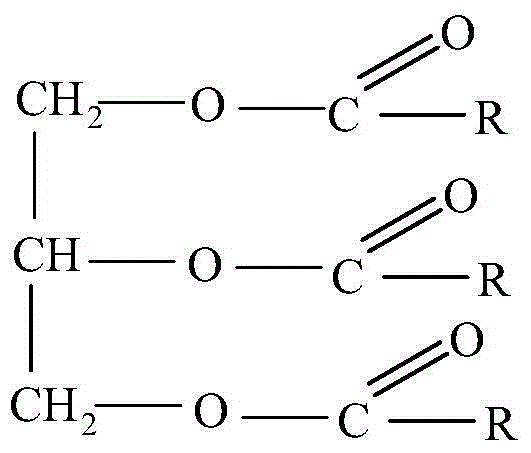

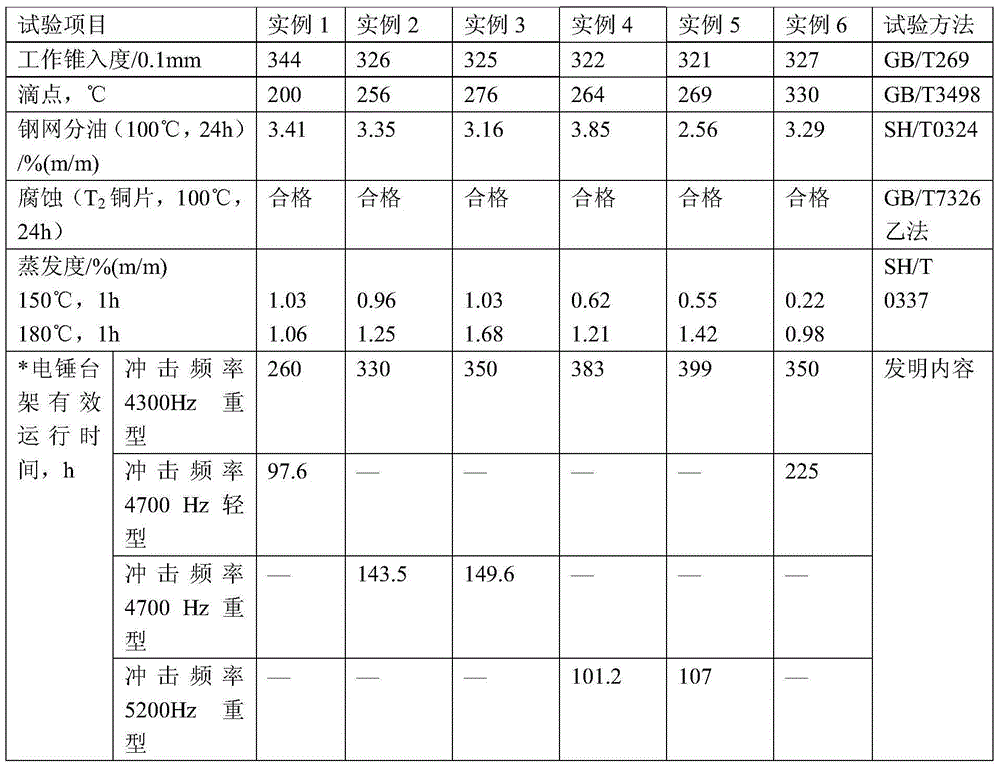

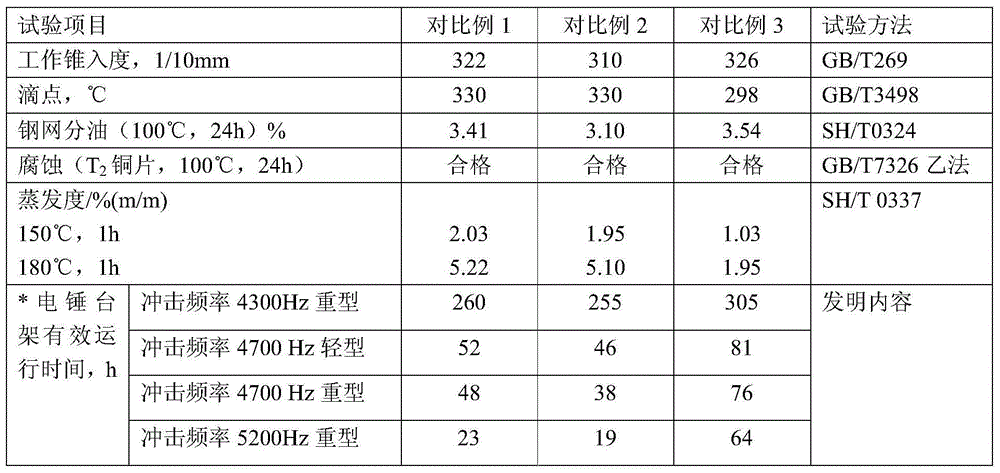

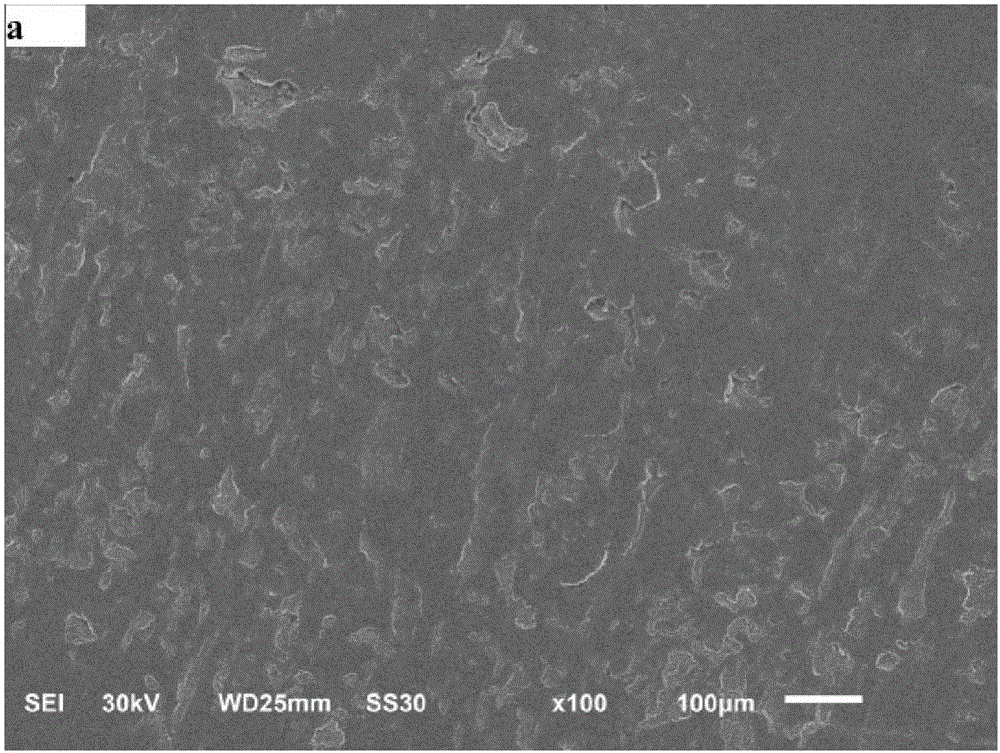

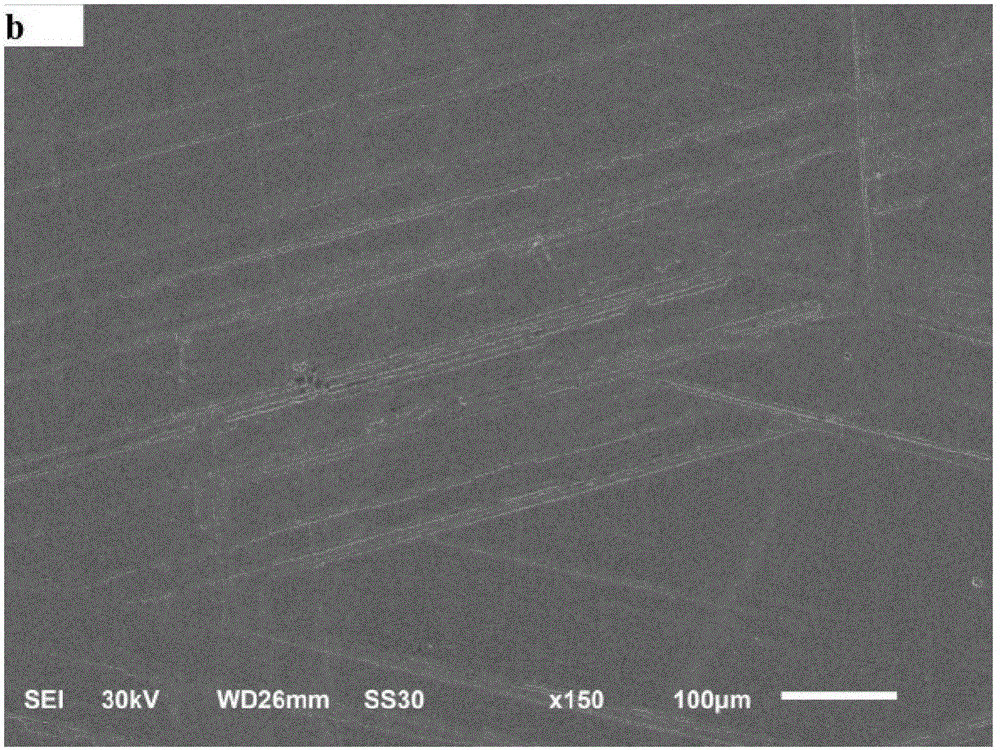

A lubricating grease composition used for cylinders of electric tools and a preparing method thereof

ActiveCN105586121ALow evaporation loss performanceImprove extreme pressure and anti-wear performanceAdditivesBase-materialsLithium soapAntioxidant

A lubricating grease composition used for cylinders of electric tools is provided. The composition comprises base oil, a thickening agent and functional additives, wherein the base oil is one of or a mixture of at least two substances selected from HVI hydrogenated base oil, metallocene PAO, trimethylolpropane trioleate, alkyl silicone oil or methylphenyl silicone oil, the thickening agent is one of or a mixture of at least two substances selected from lithium soap, composite aluminum soap or polyurea, the functional additives are an extreme pressure antiwear agent, an antioxidant or a rubber compatibility modifier or a mixture thereof, the extreme pressure antiwear agent comprises an organic molybdenum salt and a heavy-load diesel engine oil complexing agent, and the rubber compatibility modifier is dimethyl silicone oil or / and alkyl silicone oil. The lubricating grease prepared with the composition is excellent in impact load resistance, free of loss at high temperature, long in service lifetime and low in high-temperature evaporation loss and can be widely used for cylinders of various electric hammers and electric picks.

Owner:杭州得润宝油脂股份有限公司

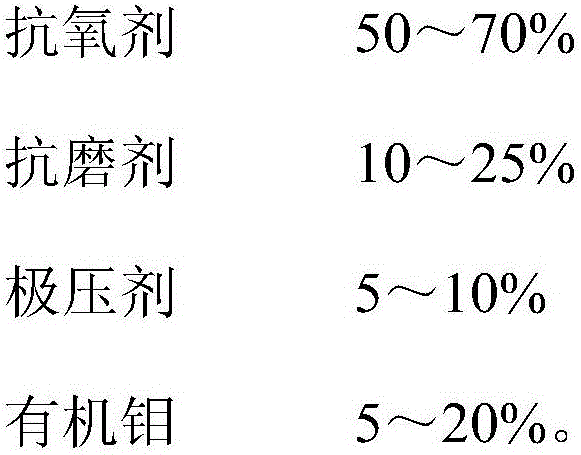

Anti-pitting self-repairing gear grease

ActiveCN105733787AExtend the lifespanPrevent oxidation failureLubricant compositionAntioxidantEngineering

The invention relates to anti-pitting self-repairing gear grease. The anti-pitting self-repairing gear grease comprises, by weight, 92-97% of a gear grease body and 3-8% of a self-repairing addition agent. According to calculation of the total mass of 100%, the self-repairing addition agent comprises, by weight, 50-70% of antioxidant, 10-25% of an anti-wear agent, 5-10% of an extreme pressure agent and 5-20% of organic molybdenum. The anti-pitting self-repairing gear grease has excellent antioxygen performance and extreme pressure wear resisting performance at different temperatures, can effectively prevent the surface of a gear from generating pitting, and can have a function of repairing the worn surface of the gear to a certain degree, so that the service life of the gear is prolonged.

Owner:东莞太平洋博高润滑油有限公司

Low-viscosity manual transmission oil composition with extreme pressure and anti-wear behaviors, and application thereof

InactiveCN106609170AImprove performanceSimple ingredientsAdditivesBase-materialsViscosity gradeMetal

The invention relates to a low-viscosity manual transmission oil composition with extreme pressure and anti-wear behaviors. The composition comprises, by weight, 100 parts of manual transmission oil with a viscosity grade of 75 W / 80 or 75 W / 85 and 2 to 5 parts of sulfurized olefin. The manual transmission oil composition provided by the invention has excellent performance and a wide application scope, can greatly improve the extreme pressure and anti-wear behaviors of low-viscosity manual transmission oil for passenger cars, meets the special requirement of clients for the extreme pressure and anti-wear behaviors of low-viscosity manual transmission oil, and is good in stability and low in metal corrosivity. Moreover, the manual transmission oil composition provided by the invention is simple in composition, uses easily available raw materials, is easy to prepare and has good large-scale application prospects.

Owner:CHINA PETROLEUM & CHEM CORP

Excellent carbamido lubricating grease composition with shear stability and preparation method thereof

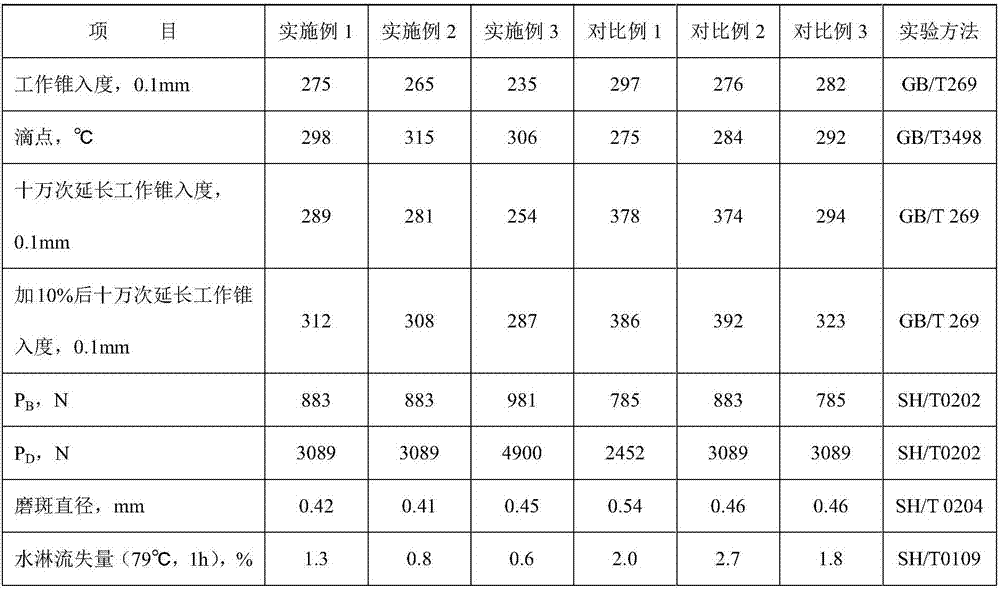

The invention discloses an excellent carbamido lubricating grease composition with shear stability and a preparation method of the carbamido lubricating grease composition. The carbamido lubricating grease provided by the invention comprises: (a) base oil, (b) a carbamido thickening agent, and (c) a surfactant, wherein the carbamido thickening agent is generated by a reaction of two or more kinds of diisocyanates, mono-aromatic amine and fatty amine; and borate oil, an extreme pressure antiwear agent containing sulfur, an antioxidant, an antirusting agent and the like are added to improve various performances of the carbamido lubricating grease. The carbamido lubricating grease prepared by the preparation method provided by the invention has good mechanical stability, water-resistance, heat resistance, extreme pressure abrasion resistance, pumping performance and the like, can be applied to the lubrication and the protection of a turret, a crystallizer, a segment roller bed, a withdrawal and straightening unit, a pendulum shear and a conveying roller of metallurgy continuous casting equipment, and is also applied to the lubrication of a tandem mill, bearings of friction parts of high-temperature heavy-duty equipment and the like.

Owner:杭州得润宝油脂股份有限公司

Modified vegetable oil

ActiveCN101407746AImprove Oxidation StabilityImprove extreme pressure and anti-wear performanceFatty acid chemical modificationChemistryOxidation stability

The invention provides modified vegetable oil which is obtained by the following method: mixing alcohol and tetrabutyl titanate with the vegetable oil; carrying out reaction at the temperature of 20 to 80 DEG C; after the reaction, separating the remnant alcohol to obtain the modified vegetable oil. Compared with the unmodified one, the modified vegetable oil greatly improves oxidation stability and extreme pressure anti-wear, and broadens the application prospect of the vegetable oils in various fields.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composite urea-aluminum base grease composition and preparation method thereof

InactiveCN108841430AImprove water resistanceEnhanced pumpabilityLubricant compositionFiberBenzoic acid

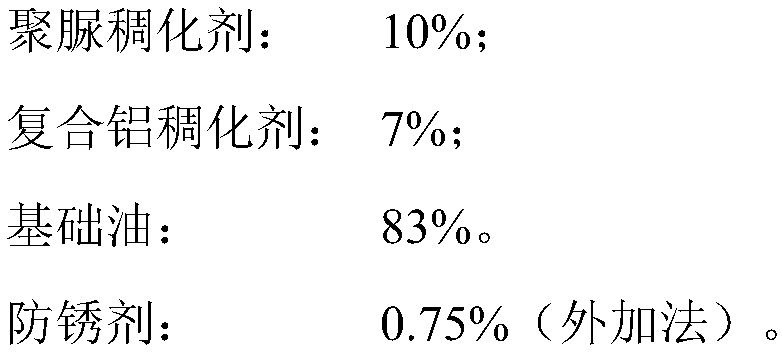

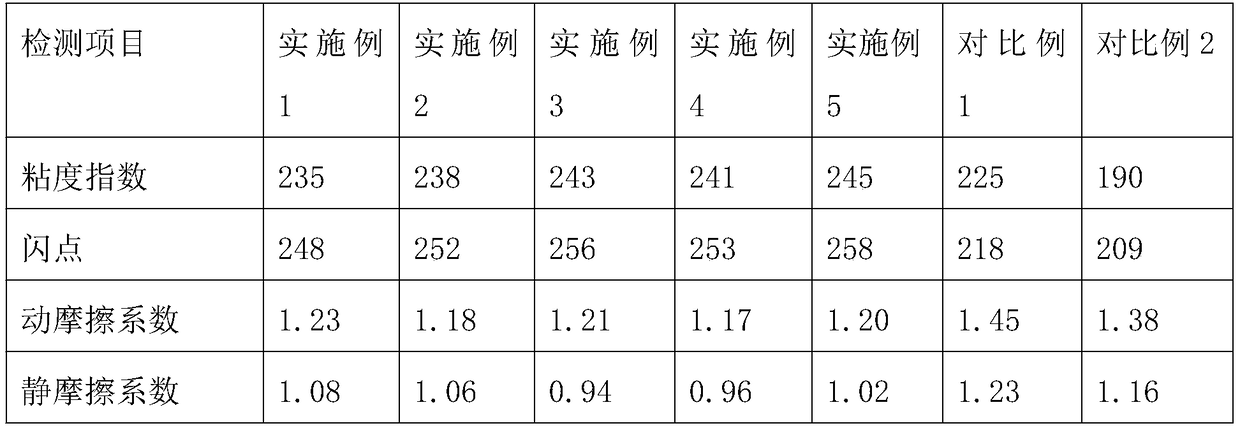

The invention aims to provide a composite urea-aluminum base grease composition and a preparation method thereof. The composite urea-aluminum base grease composition comprises the following components: 5-15% of a polyurea thickening agent, 3-10% of a composite aluminum thickening agent, 75-92% of base oil and 0.5-1% of an additional antirust agent, wherein organic amine and isocyanate react to prepare the polyurea thickening agent, benzoic acid, stearic acid and organic aluminum react to prepare composite aluminum soap, then a composite reaction is carried out, the temperature is raised, the antirust agent is added after cooling, and then the composite aluminum soap is ground into grease. In addition to the good water resistance and pumping performance common to polyurea and composite aluminum-based lubricating grease, the composite urea-aluminum base grease which is prepared according to the method provided in the invention and relies on composite penetration of thickening agent fibers can enhance thickening capability and adhesion to metals, and improve film forming property and extreme pressure wear resistance, and has good colloid stability at a high temperature. The compositeurea-aluminum base grease composition is suitable for use under harsh conditions with high temperature, heavy load, humidity, and the like.

Owner:CHINA PETROLEUM & CHEM CORP

Lubricating oil for mechanical equipment and preparation method thereof

InactiveCN108822934AHigh viscosityImprove the lubrication effectLubricant compositionAntioxidantMechanical equipment

The invention discloses lubricating oil for mechanical equipment and a preparation method thereof, and relates to the field of lubricating oil. The lubricating oil for the mechanical equipment comprises the following raw materials in parts by weight: 30-40 parts of polyalphaolefin, 15-20 parts of fluorosilicone oil, 1.5-4 parts of pentaerythritol ester, 2-5 parts of modified nanodiamond, 1-3 partsof castor oil, 3-6 parts of grapheme, 1-3 parts of molybdenum disulfide, 0.4-0.8 part of Tween, 0.5-1.2 parts of sorbitol monooleate, 0.2-0.6 part of an antioxidant, 0.4-0.8 part of a demulsifying agent and 0.7-1.5 parts of a viscosity index improver. Through cooperation of the raw materials, the lubricating oil has good viscosity, lubricity and antioxidation; the lubricating oil forms a curing protection layer on the surface of the mechanical equipment; meanwhile, the lubricating oil has good wear resistance and durability.

Owner:合肥博创机械制造有限公司

Borate anti-abrasion extreme pressure additive and preparing method thereof

ActiveCN102627996AImprove thermal stabilityGood anti-wear extreme pressure performanceAdditivesPolymer sciencePotassium hydroxide

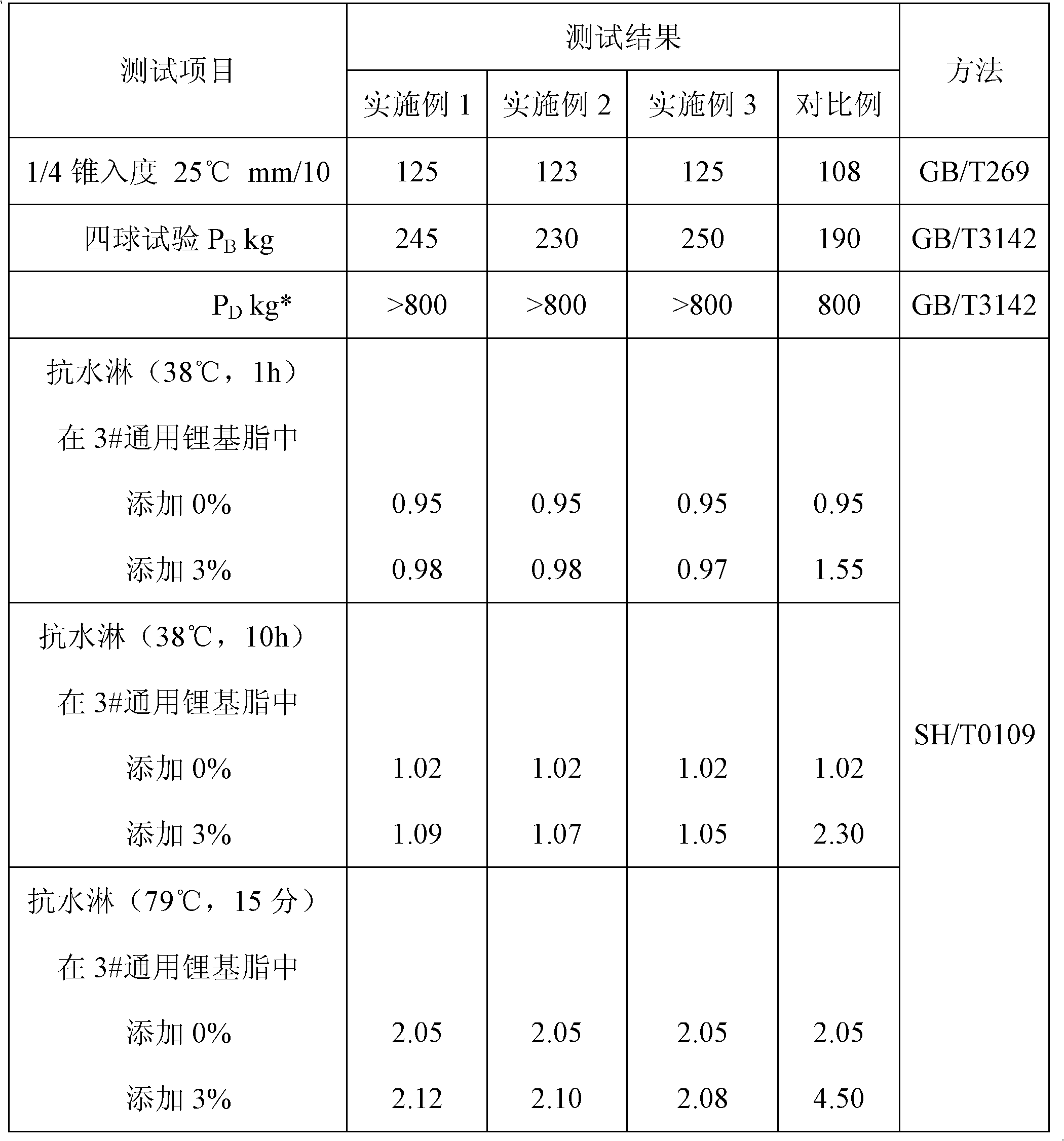

The invention relates to a borate anti-abrasion extreme pressure additive, which comprises by weight percentage: 50-90% of polyborates, 5-50% of synthetized basic oil and 0.1-8% of dispersing agents. The polyborates are prepared by the following procedures: (1) leading potassium hydroxide and boracic acid to react for more than 10min at the temperature of 60-95 DEG C; (2) heating the reaction mixture obtained in step (1) to react for more than 10min at the temperature of 100-150 DEG C; (3) heating the reaction mixture obtained in step (2) to temperature of 190-250 DEG C to react for more than 20min, and cooling to obtain the polyborates. The using amount of the borate anti-abrasion extreme pressure additive in lubricating grease by weight percentage is 0.5-10%. A preparing process of the borate anti-abrasion extreme pressure additive is simple, and the borate anti-abrasion extreme pressure additive has excellent water-resisting performance and anti-abrasion extreme pressure performance.

Owner:杭州得润宝油脂股份有限公司

Lubricating grease with long service life, extreme pressure and high-temperature resistance and preparation method thereof

InactiveCN107955677AImprove extreme pressure performanceMeet lubrication needsLubricant compositionPolyesterAntioxidant

The invention discloses lubricating grease with long service life, extreme pressure and high-temperature resistance and a preparation method thereof. The lubricating grease comprises the following components in percentages by weight: 8.1 to 18.6% of a thickening agent, 0.3 to 0.7% of fatty alcohol, 2 to 10% of dibasic acid polyester, 0.3 to 1.5% of an antioxidant, 0.3 to 1.0% of a metal deactivator and 2 to 5% of an extreme-pressure antiwear agent, with the balance being base oil. The invention has the following advantages: the lubricating grease has excellent high-temperature resistance, shear stability and extreme-pressure wear resistance and good storage stability, adhesiveness and low-temperature fluidity; the requirement of a bearing for lubricating under various working conditions ofhigh temperature, high speed, heavy load and even impulse load can be met; a grease exchange period can be prolonged; meanwhile, the preparation process for the lubricating grease is simple, and facilitates large-scale industrial production.

Owner:JIANGSU LOPALTECH

Ceramic alloy lubricating oil special for dredging workboat engine and preparation method thereof

InactiveCN101967419AImprove extreme pressure and anti-wear performanceImprove the lubrication effectAdditivesLubricationHigh energy

The invention relates to ceramic alloy lubricating oil special for a dredging workboat engine, which consists of the following components in percentage by weight: 1 to 6 percent of ceramic alloy coupling agent, 75 to 85 percent of base oil, 0.1 to 0.5 percent of pour point depressant, 7 to 13 percent of viscosity index improver, 4 to 7 percent of complexing agent and 200 to 400ppm of non-silicon anti-foaming agent. In addition, the invention also discloses a preparation method thereof. The ceramic alloy lubricating oil forms a ceramic alloy material layer on the metal friction surface in a high-energy mechanical alloying ceramic alloy coupling mode, improves extreme pressure abrasive resistance of the lubricating oil, and has excellent functions of lubrication, protection, energy conservation and emission reduction, and the oil-saving rate of 3 to 8 percent.

Owner:TIANJIN SURE ENERGY LUBRICATION TECH

Preparation method of high shear stability lithium grease

InactiveCN101619260AOvercoming the defects of uneven growthImprove shear stabilityAdditivesBase-materialsLithiumMechanical equipment

The invention discloses a preparation method of high shear stability lithium grease, comprising the following steps: saponifying, heating to dehydrate, refining at high temperature, quenching sharply to mix, standing, mixing into grease, shearing, homogenizing, re-shearing and deaerating. The preparation method of high shear stability lithium grease adds the steps of standing and recutting and overcomes the defect of uneven growth of soap fibers in the traditional lithium grease production technology, and the length of the soap fibers has a proper proportion, therefore, a three-dimensional cavity formed by the soap fibers can absorb a large amount of base oil, and an orienting arrayed crystal fiber structure is formed. When the good colloid stability of the lithium grease is ensured, the lithium grease has prominent high shear stability, the penetration change rate of 100 thousand time extended work is less than 8 percent, a bearing grease exchanging period can be extended above 2000 hours / time from 500 hours / time generally, and the service life of mechanical equipment can be prolonged by 4-5 times.

Owner:安徽中天石化股份有限公司

Hydroxy-containing thiadiazole derivative, and preparation method and application thereof

ActiveCN103695078AImprove adsorption capacityImprove extreme pressure and anti-wear performanceOrganic chemistryAdditivesChemistryCarbon chain

The invention provides a hydroxy-containing thiadiazole derivative. The hydroxy-containing thiadiazole derivative has a structural formula shown in the specification, R in the structural formula is also shown in the specification, and R1 and R2 in the formula of R are respectively independently selected from C1-C30 straight-chain or branched-chain or C3-C30 cycloalkyl groups. The introduction of a hydroxy-containing oil-soluble carbon chain into the hydroxy-containing thiadiazole derivative makes the hydroxy-containing thiadiazole derivative well compatible with grease, and the hydroxy group can be effectively adsorbed by the surface of a metal, and can enhance the extreme pressure wear resistance.

Owner:CHINA PETROLEUM & CHEM CORP

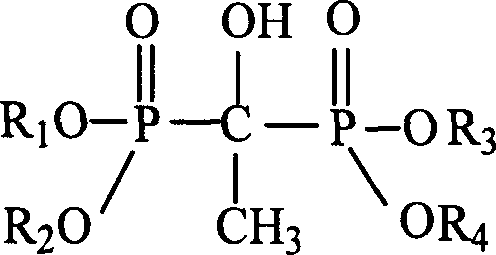

Combination of general gear oil

A universal oil composition for gear contains mineral lubricating oil or synthetic lubricating oil or their mixture, at least one viscosity index improver and / or pour depressor, at least one S-contained extreme-pressure agent, at least one P-contained antiwear agent, phosphate-type multi-effect agent, oil agent (1-hydroxyethylene-1, 1-biphosphonate), and at least one metallic deactivator and / or antirust agent.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com