Lubricating oil for mechanical equipment and preparation method thereof

A technology of mechanical equipment and lubricating oil, applied in the field of lubricating oil, can solve the problems of lubricating oil performance and viscosity reduction, affecting lubricating oil lubrication effect, poor wear resistance of lubricating oil, etc., and achieve excellent lubricity and excellent oxidation stability , the effect of good viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

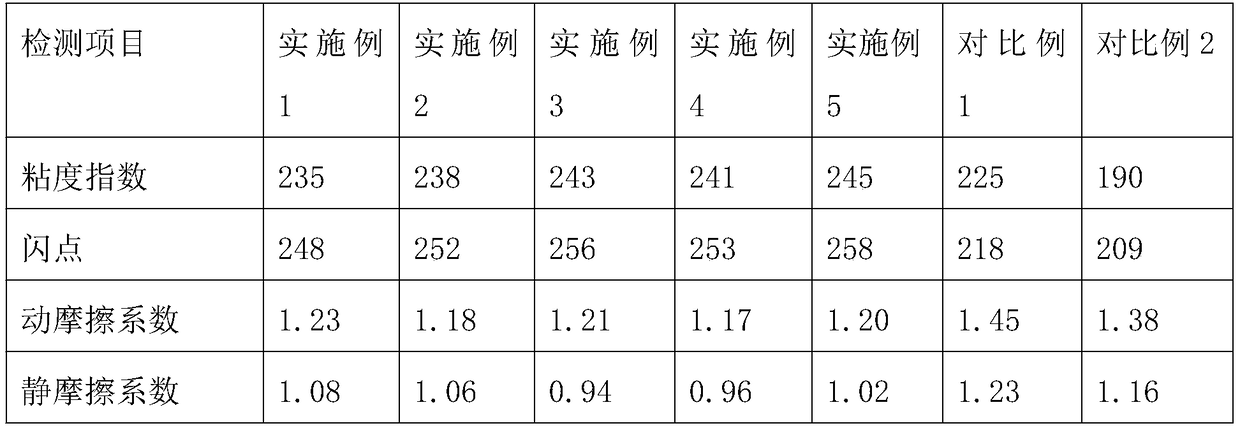

Examples

Embodiment 1

[0032] A lubricating oil for mechanical equipment, comprising the following raw materials in parts by weight:

[0033] 30 parts of polyalphaolefin, 15 parts of fluorosilicone oil, 1.5 parts of pentaerythritol ester, 2 parts of modified nano-diamond, 1 part of castor oil, 3 parts of graphene, 1 part of molybdenum disulfide, 0.4 part of Tween, sorbitol mono-oil 0.5 parts of esters, 0.2 parts of antioxidants, 0.4 parts of anti-emulsifiers and 0.7 parts of viscosity index improvers.

[0034] The preparation method of modified nano-diamond is as follows:

[0035] (a) Add nano-diamonds into the mixed solution of concentrated nitric acid and concentrated sulfuric acid, stir and mix evenly, heat up to 85-90 degrees Celsius, and react at a constant temperature for 2 hours at a speed of 300 rpm, filter, and use ammonia water and deionized water respectively Wash with water 3 times;

[0036] (b) Add the product of step (1) into 15% hydrofluoric acid solution, stir and mix evenly, heat ...

Embodiment 2

[0048] A lubricating oil for mechanical equipment, comprising the following raw materials in parts by weight:

[0049] 40 parts of polyalphaolefin, 20 parts of fluorosilicone oil, 4 parts of pentaerythritol ester, 5 parts of modified nano-diamond, 3 parts of castor oil, 6 parts of graphene, 3 parts of molybdenum disulfide, 0.8 parts of Tween, sorbitol mono-oil 1.2 parts of acid ester, 0.6 parts of antioxidant, 0.8 parts of anti-emulsifier and 1.5 parts of viscosity index improver.

[0050] The preparation method of modified nano-diamond is as follows:

[0051] (a) Add nano-diamonds in the mixed solution of concentrated nitric acid and concentrated sulfuric acid, stir and mix evenly, heat up to 90 degrees Celsius, speed of 400 rpm, after constant temperature reaction for 3 hours, filter, wash with ammonia water and deionized water for 3 hours respectively Second-rate;

[0052] (b) Add the product of step (1) into 15% hydrofluoric acid solution, stir and mix evenly, heat up to...

Embodiment 3

[0064] A lubricating oil for mechanical equipment, comprising the following raw materials in parts by weight:

[0065] 33 parts of polyalphaolefin, 17 parts of fluorosilicone oil, 2.5 parts of pentaerythritol ester, 3 parts of modified nano-diamond, 1.5 parts of castor oil, 4 parts of graphene, 1.5 parts of molybdenum disulfide, 0.5 parts of Tween, sorbitol mono-oil 0.7 part of acid ester, 0.3 part of antioxidant, 0.5 part of anti-emulsifier and 1 part of viscosity index improver.

[0066] The preparation method of modified nano-diamond is as follows:

[0067] (a) Add nano-diamonds to the mixed solution of concentrated nitric acid and concentrated sulfuric acid, stir and mix evenly, heat up to 85-90 degrees Celsius, and react at a constant temperature for 2.4 hours at a speed of 320 rpm, filter, and use ammonia water and deionized water respectively Wash with water 3 times;

[0068] (b) Add the product of step (1) into 15% hydrofluoric acid solution, stir and mix evenly, rai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com