Composite urea-aluminum base grease composition and preparation method thereof

A lubricating grease composition and the technology of the composition are applied in the direction of lubricating composition, petroleum industry, etc., which can solve the problems of loss of composite aluminum-based grease, poor shear resistance, high temperature hardening of polyurea grease, etc., so as to enhance the thickening ability , Improve the effect of film formation and extreme pressure wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

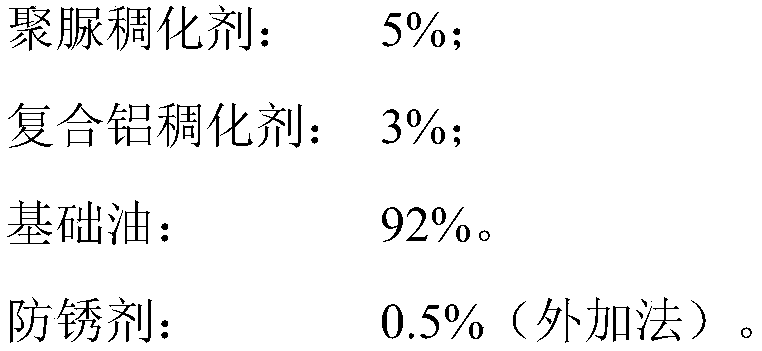

Embodiment 1

[0043]

[0044] Mix 350g of HVI 150BS and 30g of MDI and heat to 60°C, at the same time mix 15g of octylamine, 5g of o-phenylenediamine and 350g of HVI150BS and heat to 80°C, then mix and react the above two solutions for 30 minutes. Add 6g of benzoic acid and 14g of stearic acid into the mixing system, mix and heat to 80°C, then add 10g of aluminum isopropoxide trimer to carry out complex reaction, then raise the temperature of all materials to 180°C, and add 220g of HVI 150BS. When the temperature of the system was lowered to 70°C, 5 g of dodecenylsuccinic acid was added, and finally it was ground three times with a three-roll machine to form a fat. Performance see Table 1

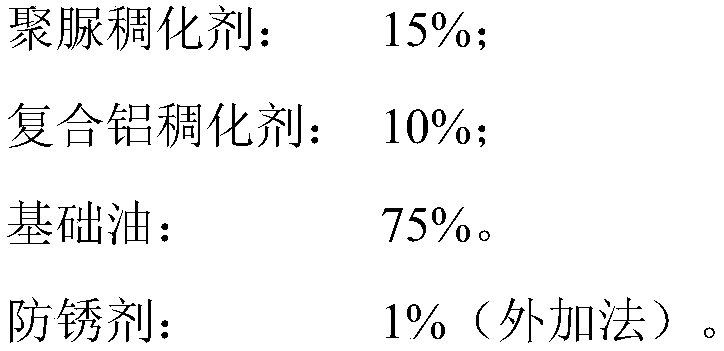

Embodiment 2

[0046]

[0047] Mix 420g of HVI 500SN and 70g of TDI and heat to 70°C. At the same time, mix 97g of hexadecylamine, 13g of ethylenediamine and 420g of HVI 500SN and heat to 90°C, then mix and react the above two solutions for 60 minutes. Add 24g of benzoic acid and 57g of stearic acid into the mixing system, mix and heat to 90°C, then add 39g of aluminum isopropoxide to carry out composite reaction, then raise the temperature of all materials to 200°C, and add 60g of HVI 500SN. When the temperature of the system was lowered to 80°C, 12 g of barium dinonylnaphthalenesulfonate was added, and finally it was ground three times with a three-roll machine to form a fat. Performance see table 1

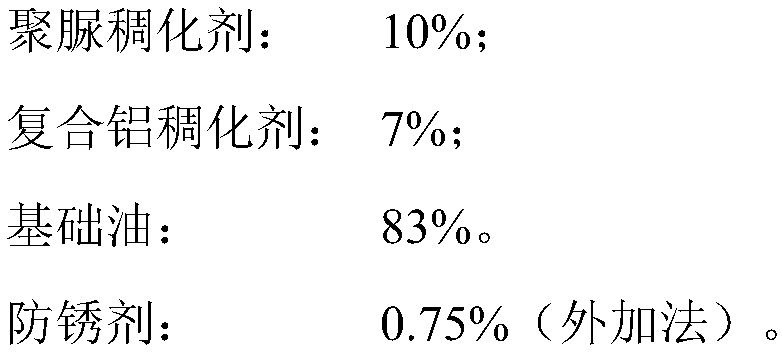

Embodiment 3

[0049]

[0050] Mix 630g of HVI 500SN and 55g of MDI and heat to 65°C. At the same time, mix 35g of aniline, 47g of octadecylamine, 43g of 1,4-cyclohexanediamine and 630g of HVI 150BS and heat to 85°C, then mix and react the above two solutions 45 minutes. Add 25g of benzoic acid and 59g of stearic acid into the mixing system, mix and heat to 85°C, then add 21g of aluminum isopropoxide trimer and 21g of aluminum isopropoxide to carry out composite reaction, and then raise the temperature of all materials to 190°C, Add HVI 500SN234g. When the temperature of the system was lowered to 75°C, 6.8 g of dodecenylsuccinic acid and 6.7 g of barium dinonylnaphthalene sulfonate were added, and finally it was ground three times with a three-roll machine to form a fat. Performance see table 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com