Lithium-based lubricating grease and preparation method thereof

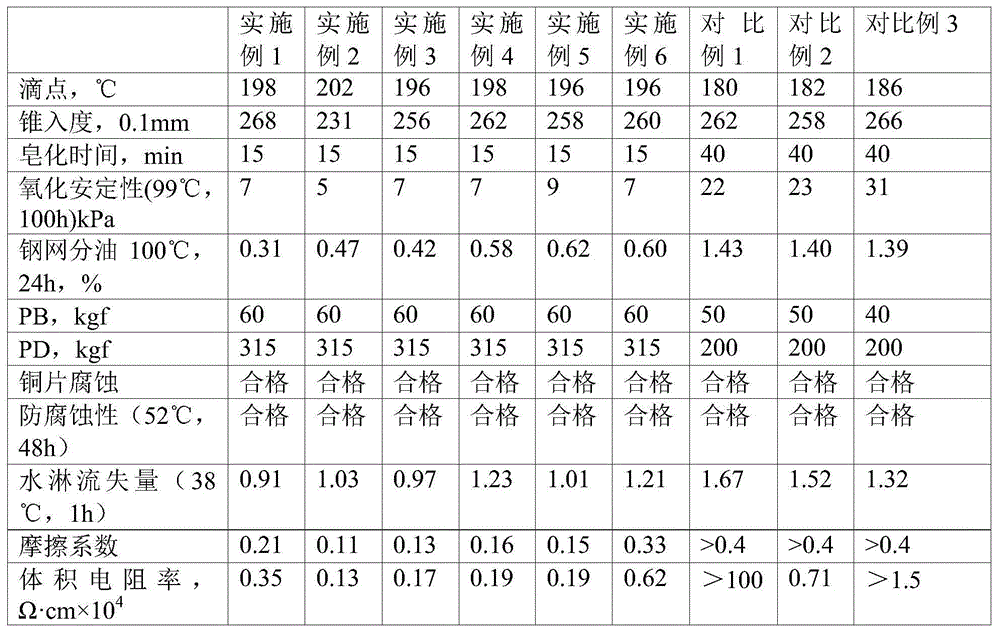

A technology of lithium-based lubricating grease and lubricating grease, applied in lubricating compositions, petroleum industry, thickeners, etc., can solve the problems of no related research on graphene application, poor anti-oxidation performance, poor anti-wear performance, etc., and achieve The effect of shortening saponification time, extremely mechanical stability, and improving extreme pressure and anti-wear properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] According to the second aspect of the present invention, the present invention provides a method for preparing lithium-based lubricating grease, the method comprising: uniformly mixing graphene, lithium-based thickener and part of base oil, and refining at a constant temperature of 180-230°C , cool, add the remaining base oil, and add necessary additives to get the finished product.

[0031] Wherein, the amount of graphene, lithium-based thickener and base oil is based on the weight of the obtained lubricating grease, including the following components: 65-95% lubricating base oil, 6-20% lithium-based thickener, 0.5-15% graphene; preferably 70-90% lubricating base oil, 8-18% lithium-based thickener, 1-12% graphene.

[0032] According to the present invention, said part of base oil: remaining base oil = 40-75: 25-60.

[0033] According to a third aspect of the present invention, the present invention provides a method for preparing lithium-based grease, the method compr...

Embodiment approach

[0041] According to a preferred embodiment of the present invention, the lithium base grease provided by the present invention can be prepared by the following method:

[0042] Add graphene, 40-75% base oil and polymeric acid into the fat-making kettle, stir and mix, heat up, when the temperature rises to 80-95°C, add lithium hydroxide aqueous solution for saponification reaction for 20-30min, After the saponification reaction is complete, continue to heat up to 190-220°C for high-temperature refining for 5-20 minutes; add the remaining base oil and cool down to 100-120°C, then add necessary additives and stir evenly; grind 2-3 times through a three-roller machine to form fat.

[0043] Compared with the lithium-based grease prepared by the preparation method provided by the second aspect, the lithium-based grease provided by the fourth aspect has better high temperature resistance, water resistance and adhesion, colloid stability and extreme pressure resistance. Abrasive.

[...

Embodiment 1

[0046] Preparation of graphene oxide:

[0047] Mix 1g of graphite flakes, 0.5g of sodium nitrate and 23ml of concentrated sulfuric acid in an ice bath, slowly add 3g of potassium permanganate while stirring, keep the temperature below 10°C and stir for 1h, then stir the mixture at 35°C for 0.5h, then add Dilute with 50ml of deionized water, a lot of heat is released during the process, keep the temperature below 100°C in an ice bath, after adding 50ml of water, stir the mixture for 0.5h, then add 200ml of deionized water for further dilution. Potassium permanganate was then reduced by adding 10 ml of a 30% by weight aqueous hydrogen peroxide solution. Finally, the mixture was washed and filtered with 5% hydrochloric acid (400ml) to remove metal ions. Then, the acid was removed with 0.5 L of deionized water, and dried at 60 °C for 24 h to obtain graphene oxide.

[0048] Preparation of graphene:

[0049] Add 0.1g of the graphene oxide prepared above to 100ml of water for ultr...

PUM

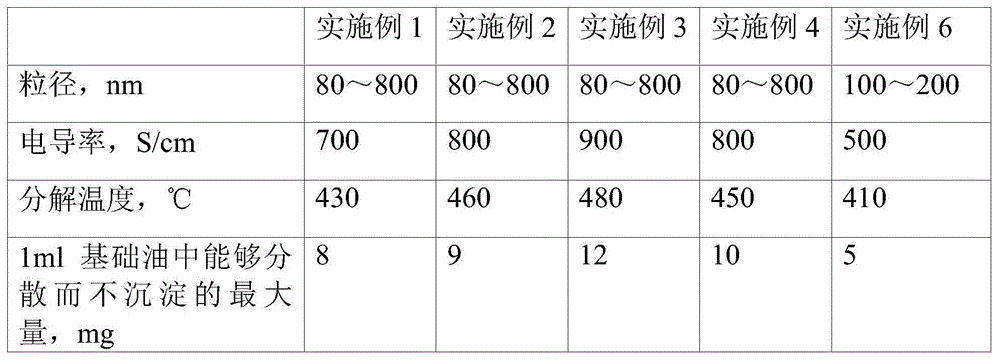

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com