Patents

Literature

33results about How to "Shorten saponification time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

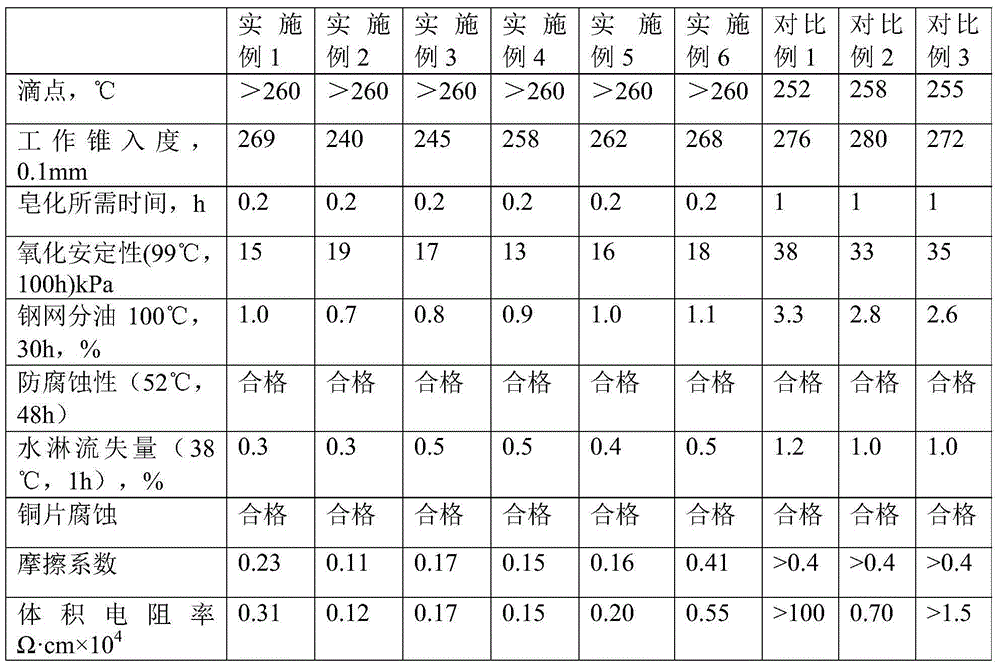

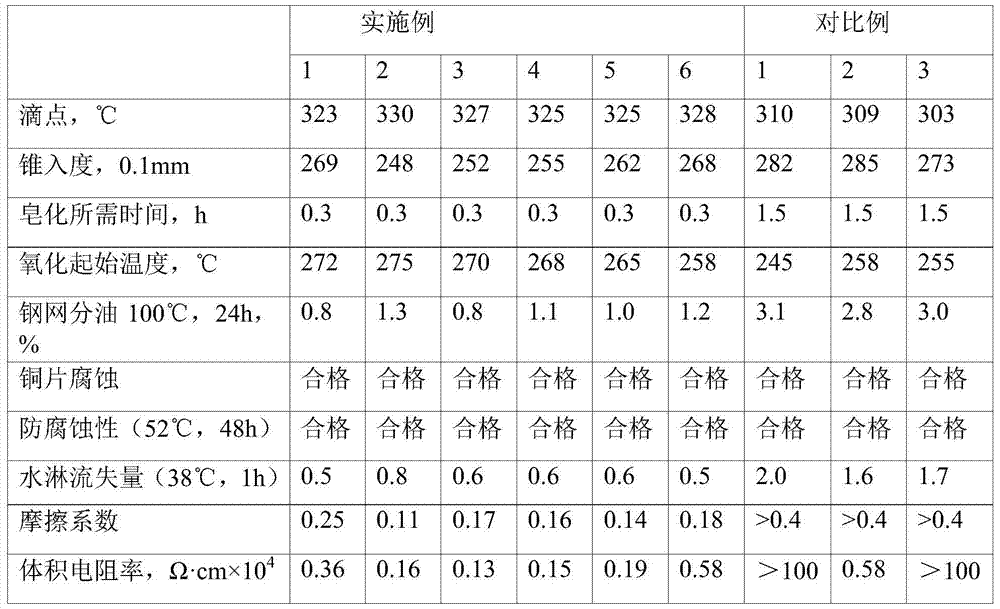

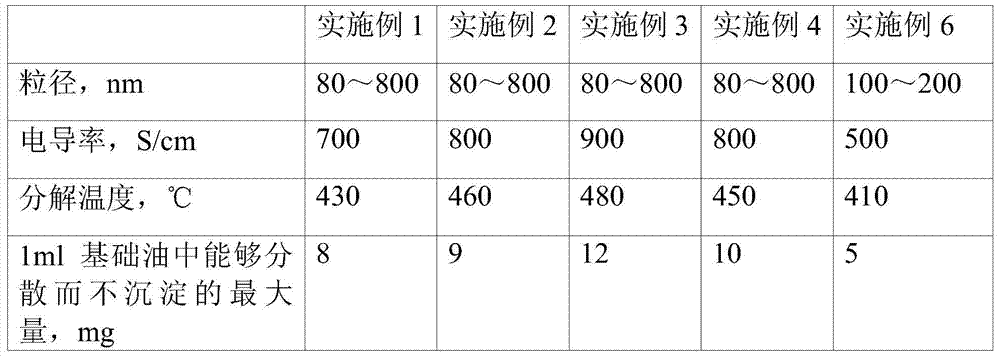

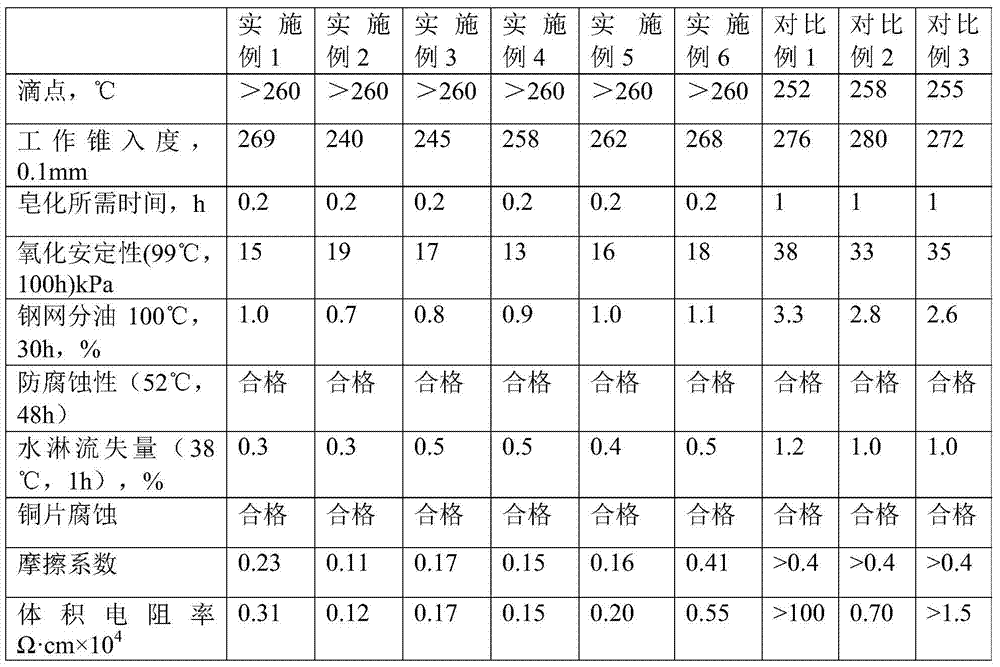

Lithium-based lubricating grease and preparation method thereof

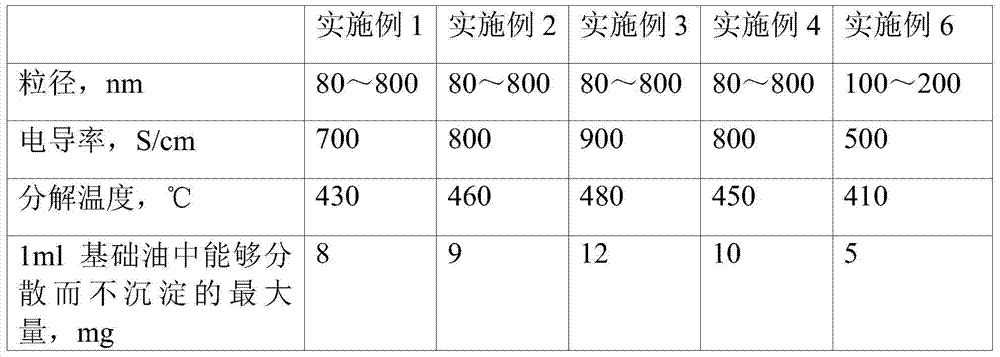

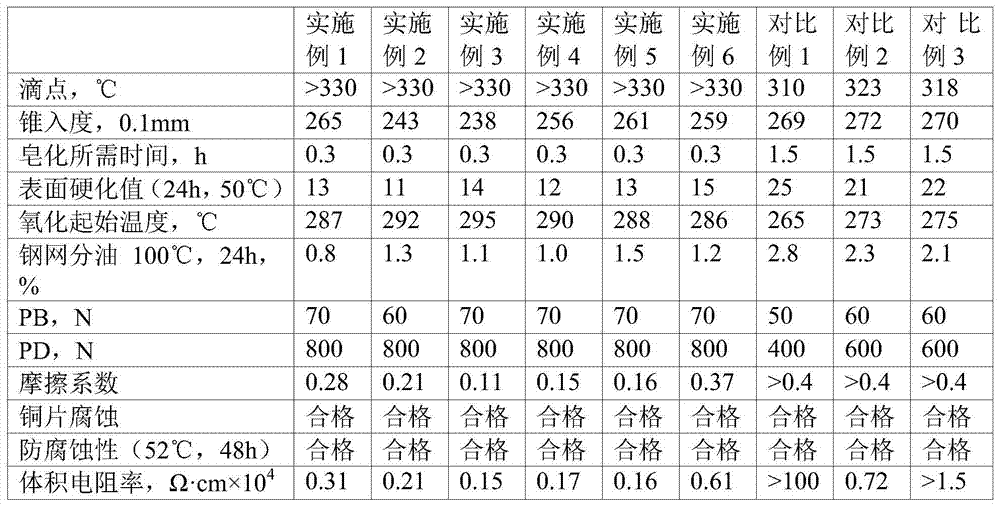

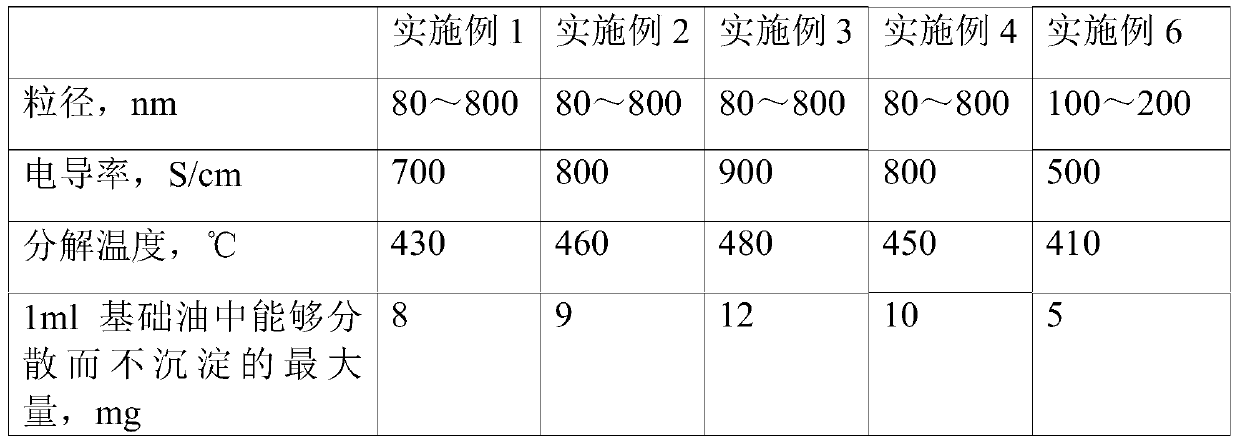

The invention discloses lithium-based lubricating grease and a preparation method thereof. The lithium-based lubricating grease is characterized by being prepared from the following components on the basis of the weight of the lubricating grease: 65-95% of lubricating base oil, 6-20% of lithium-based thickening agent and 0.5-15% of graphene. The lithium-based lubricating grease has excellent properties such as excellent high temperature resistance, water and adhesion resistance, colloidal stability, extreme pressure antiwear property, long lubricating service life, corrosion resistance and salt mist resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

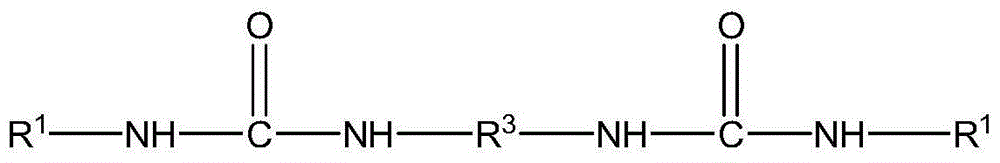

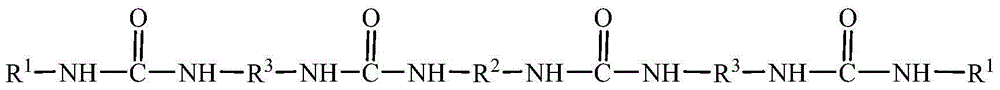

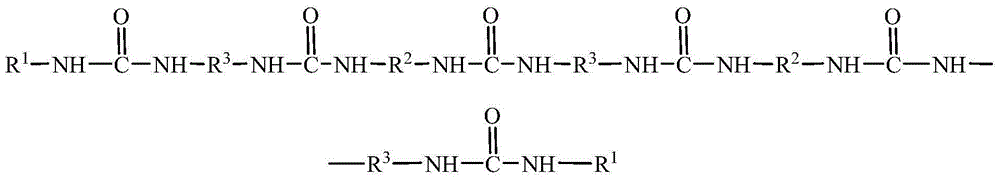

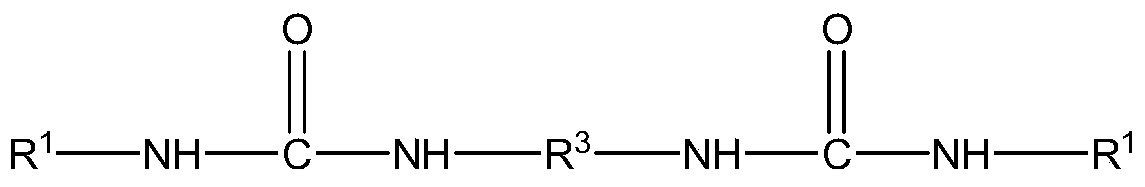

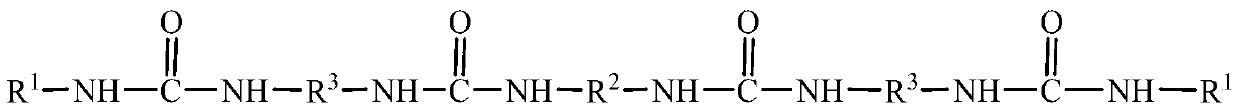

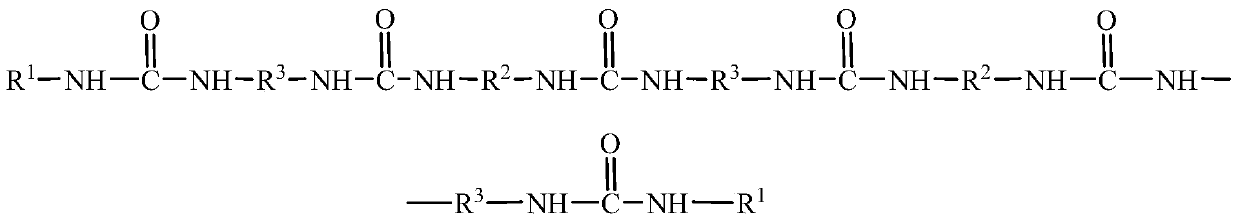

Polyurea lubricating grease and preparation method thereof

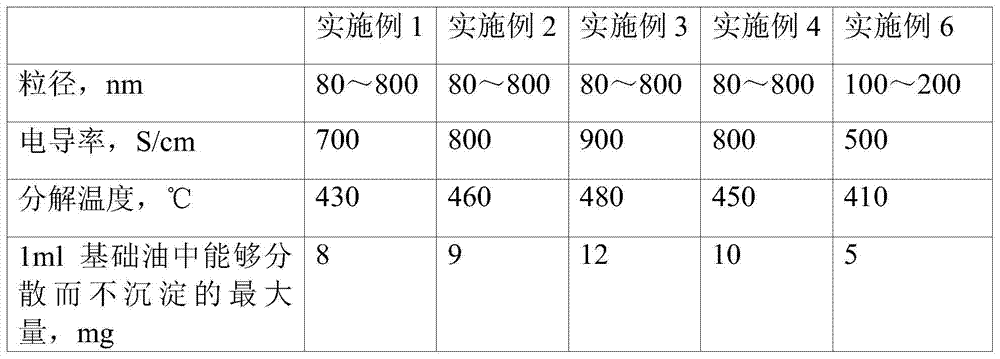

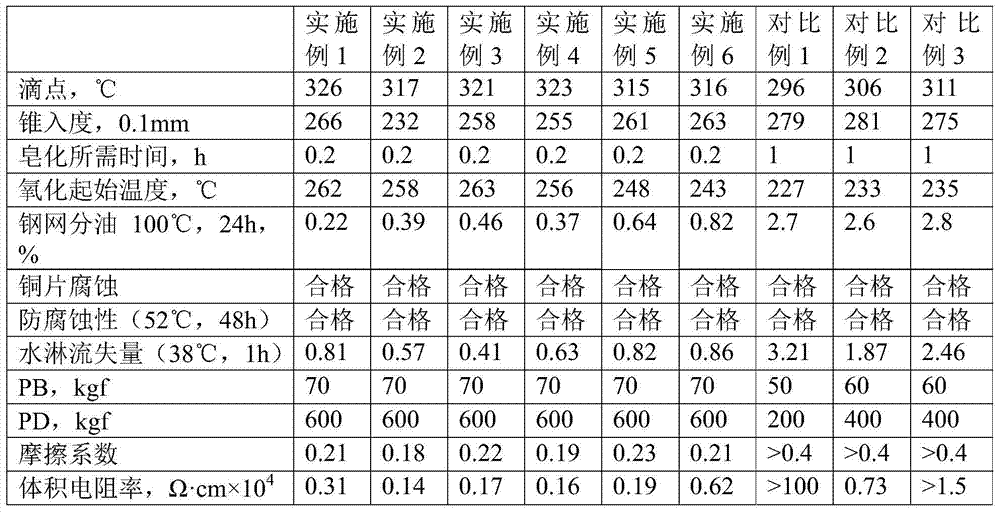

ActiveCN104560265AImprove high temperature performanceGood extreme pressure and anti-wear propertiesThickenersBase oilPolyurea

The invention discloses polyurea lubricating grease, which is characterized in that based on the weight of the lubricating grease, the lubricating grease comprises the following components: 0.2-15% of grapheme, 4-30% of a polyurea compound, 65-95% of base oil and 0.5-15% of an additive. The invention also discloses a preparation method of the polyurea lubricating grease and the prepared polyurea lubricating grease. The polyurea lubricating grease disclosed by the invention not only has excellent corrosion resistance and salt fog resistance, but also has the properties such as excellent heat temperature resistance, water resistance, adhesivity, colloid stability and extreme pressure antiwear property, and has a long service life. The polyurea lubricating grease disclosed by the invention is simple in preparation process, environmental friendly, low in cost and stable in product quality.

Owner:CHINA PETROLEUM & CHEM CORP +2

Composite sodium-based lubricating grease and preparation method thereof

ActiveCN104560315AImprove antioxidant capacityImprove high drop pointThickenersSalt resistanceGraphene

The invention discloses composite sodium-based lubricating grease and a preparation method thereof. By the weight of the lubricating grease, the compound sodium-based lubricating grease comprises the following components: 65-95% of lubricating base oil, 5-30% of a composite sodium-based thickener and 0.2-15% of graphene. The composite sodium-based lubricating grease disclosed by the invention has excellent properties such as high temperature resistance, water resistance, adhesivity, colloid stability, extreme pressure antiwear property, long lubricating life, corrosion resistance and salt fog resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Complex aluminum-base lubricating grease and preparation method thereof

ActiveCN104560314AImprove antioxidant capacityImprove high drop pointLubricant compositionSalt resistanceGraphene

The invention discloses complex aluminum-base lubricating grease and a preparation method thereof. On a lubricating grease weight basis, the complex aluminum-base lubricating grease comprises the following components: 65-95 percent of lubricating base oil, 5-30 percent of complex aluminum-base thickening agent and 0.2-15 percent of graphene. The complex aluminum-base lubricating grease provided by the invention has excellent properties such as high-temperature resistance, water resistance, adhesivity, colloid stability, extreme pressure wearability, lubricating life, corrosion resistance and salt fog resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation process of resin with starch base high water absorbency

InactiveCN1560099AShorten the synthesis processShorten the compositing timeAcrylonitrileSaponification

The invention is a starch-based high water absorptivity resin preparing method, using starch, acrylic nitricle (AN), and 2-acrylamide-2-methyl prophyl sulfonic acid (AMPS) as raw materials, adopting [Mn(H2P2O7)3]3- as initiator, making graft polymerization and saponification, and fast synthesizing starch-based high water absorptivity resin. It makes graft copolymerization on starch and two kinds of monomer raw materials, making them form multielement compound, the initiator is cheap and the modified process can omit medium washing step and AMPS group is added to be able to obviously shorten the synthesis process and time of the final product, reduce production cost and simultaneously also be able to improve the water-absorbing performance of the final product.

Owner:JIANGNAN UNIV

Composite barium-based lubricating grease composition and preparation method thereof

The invention discloses a composite barium-based lubricating grease composition and a preparation method thereof. By taking the weight of the lubricating grease as a benchmark, the composite barium-based lubricating grease composition comprises the following components: 65-95% of lubricating base oil, 5-30% of a composite barium-based thickening agent and 0.2-15% of graphene. The composite barium-based lubricating grease has excellent high temperature resistance, water resistance, adhesion, colloidal stability, extreme pressure antiwear property, anti-corrosion property, salt and spray resistance and the like and long lubricating life.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of complex lithium calcium base grease and preparation method thereof

The invention discloses a composite lithium calcium base lubricating grease and a preparation method thereof. Based on the grease weight, the lithium-calcium complex grease includes the following components: 65-95% lubricating base oil, 5-30% lithium-calcium complex thickener, and 0.2-15% graphene. The complex lithium-calcium-based lubricating grease of the invention has excellent performances such as high temperature resistance, water resistance, adhesion, colloid stability, extreme pressure and wear resistance, lubrication life, corrosion resistance and salt spray resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

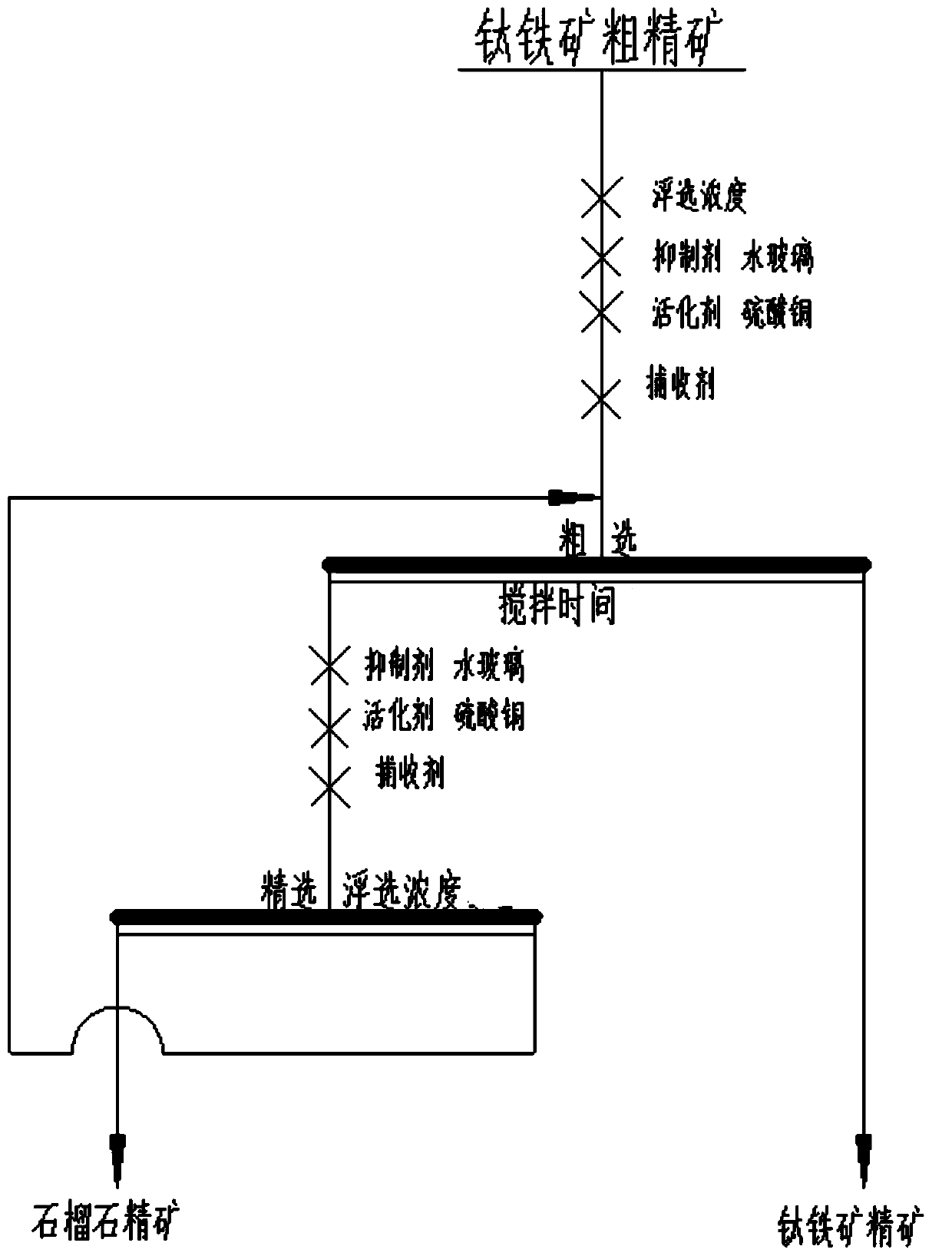

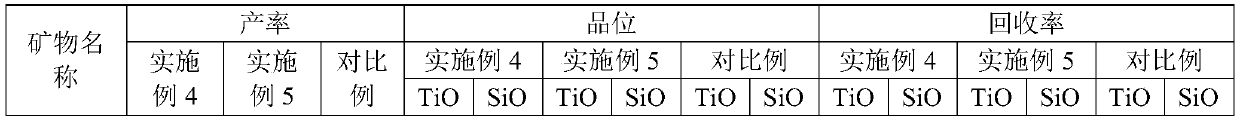

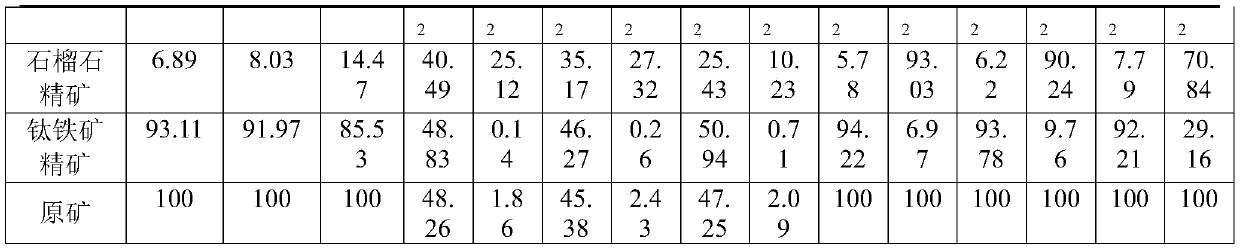

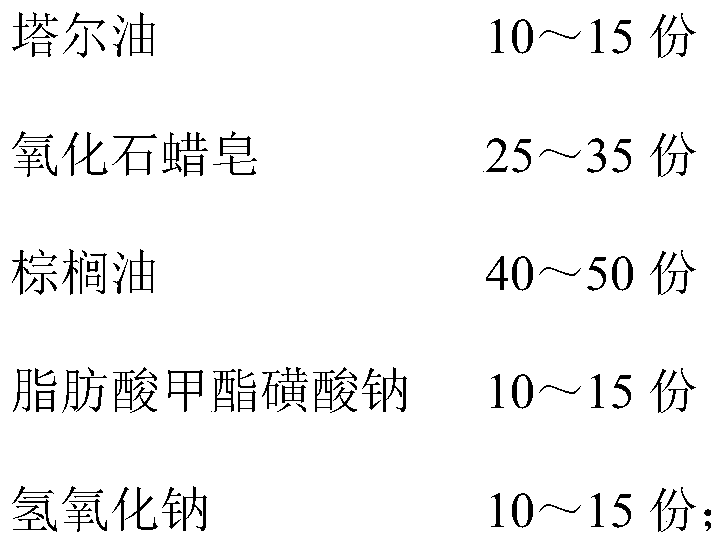

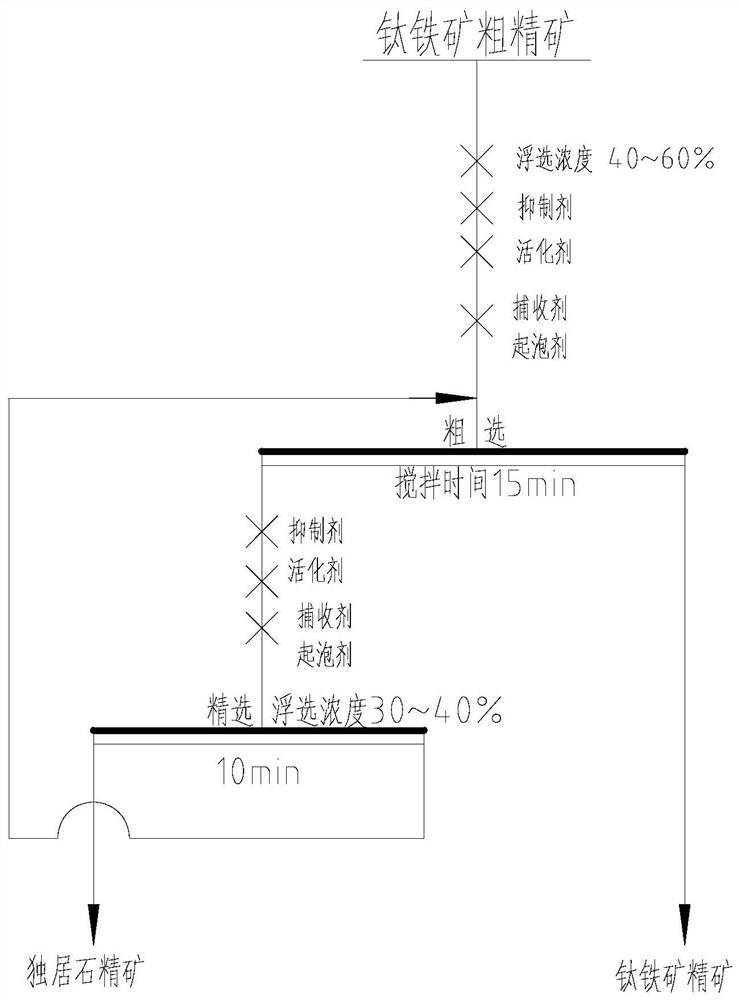

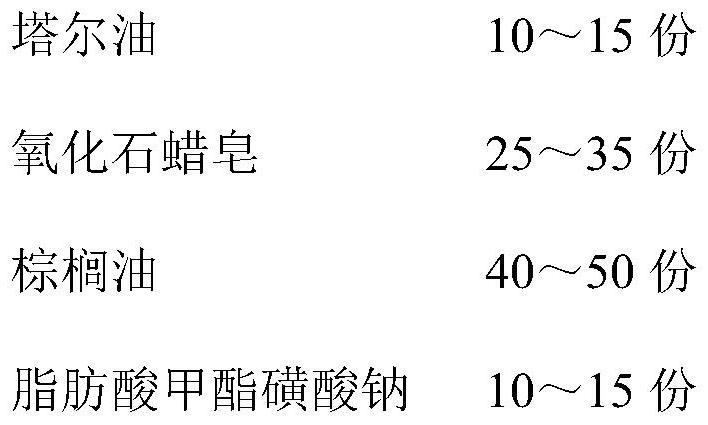

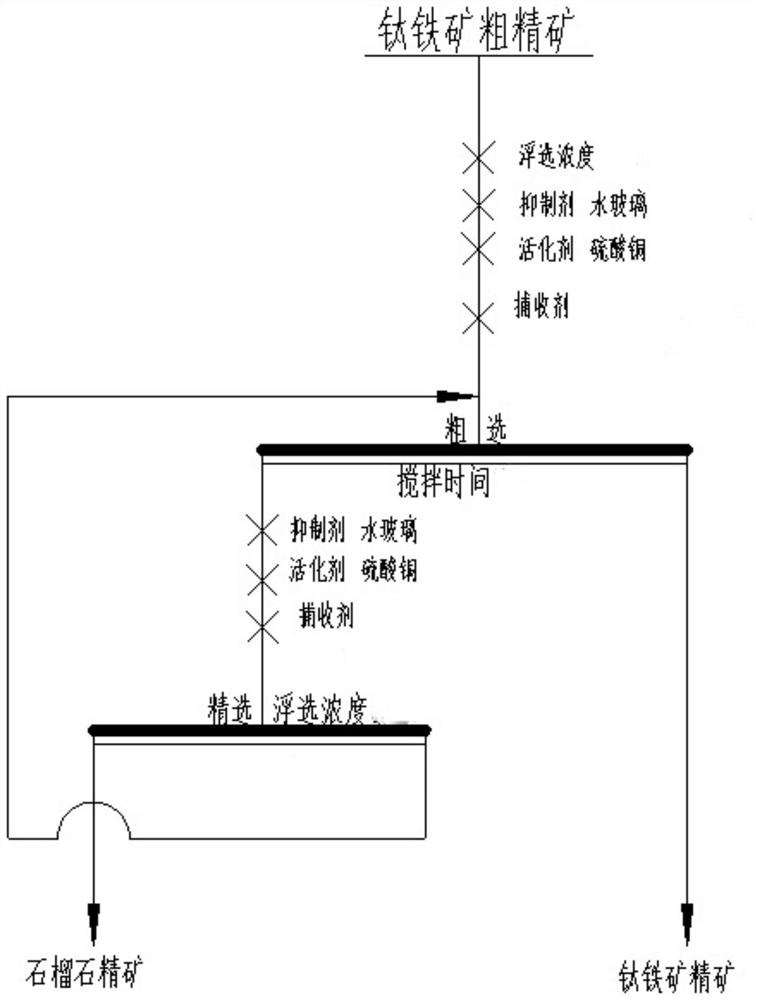

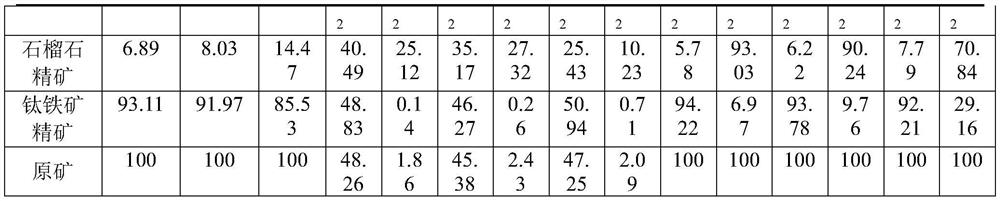

Collecting agent for separating garnet and ilmenite and flotation process of collecting agent

The invention provides a collecting agent for separating garnet and ilmenite and a flotation process of the collecting agent. The collecting agent is composed of the following raw materials in parts by weight: 10-15 parts of tall oil, 25-35 parts of oxidized paraffin soap, 40-50 parts of palm oil, 10-15 parts of sodium fatty acid methyl ester sulfonate and 10-15 parts of sodium hydroxide. The collecting agent provided by the invention is used for flotation of garnet and ilmenite; high selectivity and collecting performance are realized; the collecting effect is improved, the collecting dosageis reduced, the stability is good, the flotation speed is high, the grade of garnet is comprehensively improved, the impurity content in a concentrate product is reduced, the operation recovery rate of garnet concentrate is increased by 10-20%, the grade of garnet is increased by 10-20%, and good economic benefits are achieved.

Owner:HAINAN WENSHENG HIGH TECH MATERIALS +3

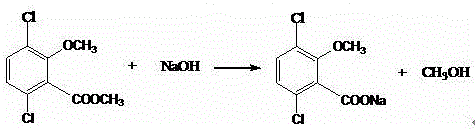

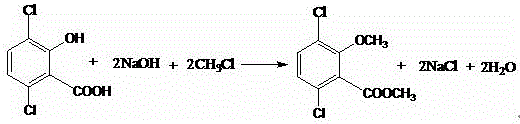

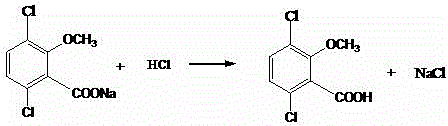

Process of preparing dicamba by 3, 6-dichlorosalicylic acid

InactiveCN105906503AHigh yieldIncrease profitPreparation from carboxylic acid saltsOrganic compound preparationWastewaterSaponification

The invention relates to a process of preparing dicamba by 3, 6-dichlorosalicylic acid, and belongs to the technical field of herbicide dicamba preparation processes. The process includes the steps of methylation reaction, saponification, methanol recovery, acidizing reaction and the like. By means of saponification with specific process parameters, efficiency can be greatly improved, saponification time is shortened, wastewater quantity is remarkably reduced, and equipment utilization rate is increased.

Owner:SICHUAN FOURSTAR BIOTECH RANDD CORP

A kind of lithium composite grease and preparation method thereof

ActiveCN104560264BGood colloidal stabilityGood mechanical stabilityThickenersPhysical chemistryBase oil

The invention discloses a composite lithium base grease and a preparation method thereof. Based on the weight of the grease, the lithium complex grease includes the following components: 65-95% lubricating base oil, 6-20% lithium complex thickener, and 0.5-15% graphene. The complex lithium-based grease of the present invention has excellent high temperature resistance, water resistance and adhesion, colloidal stability, extreme pressure and wear resistance, lubricating life, corrosion resistance and salt spray resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of polyurea lubricating grease and preparation method thereof

ActiveCN104560265BImprove high temperature performanceGood extreme pressure and anti-wear propertiesThickenersPolymer scienceBase oil

The invention discloses a polyurea grease, which is characterized in that, based on the weight of the grease, it comprises the following components: 0.2-15% by weight of graphene; 4-30% by weight of polyurea compound; 65-95% by weight % of base oil and 0.5‑15% by weight of additives. The invention also discloses a preparation method of the polyurea grease and the prepared polyurea grease. The polyurea grease of the present invention not only has excellent corrosion resistance and salt spray resistance, but also has excellent properties such as high temperature resistance, water resistance, adhesion, colloid stability, extreme pressure and anti-wear properties, and Long lubrication life. The preparation process of the lubricating grease of the invention is simple, environment-friendly, low in cost and stable in product quality.

Owner:CHINA PETROLEUM & CHEM CORP +2

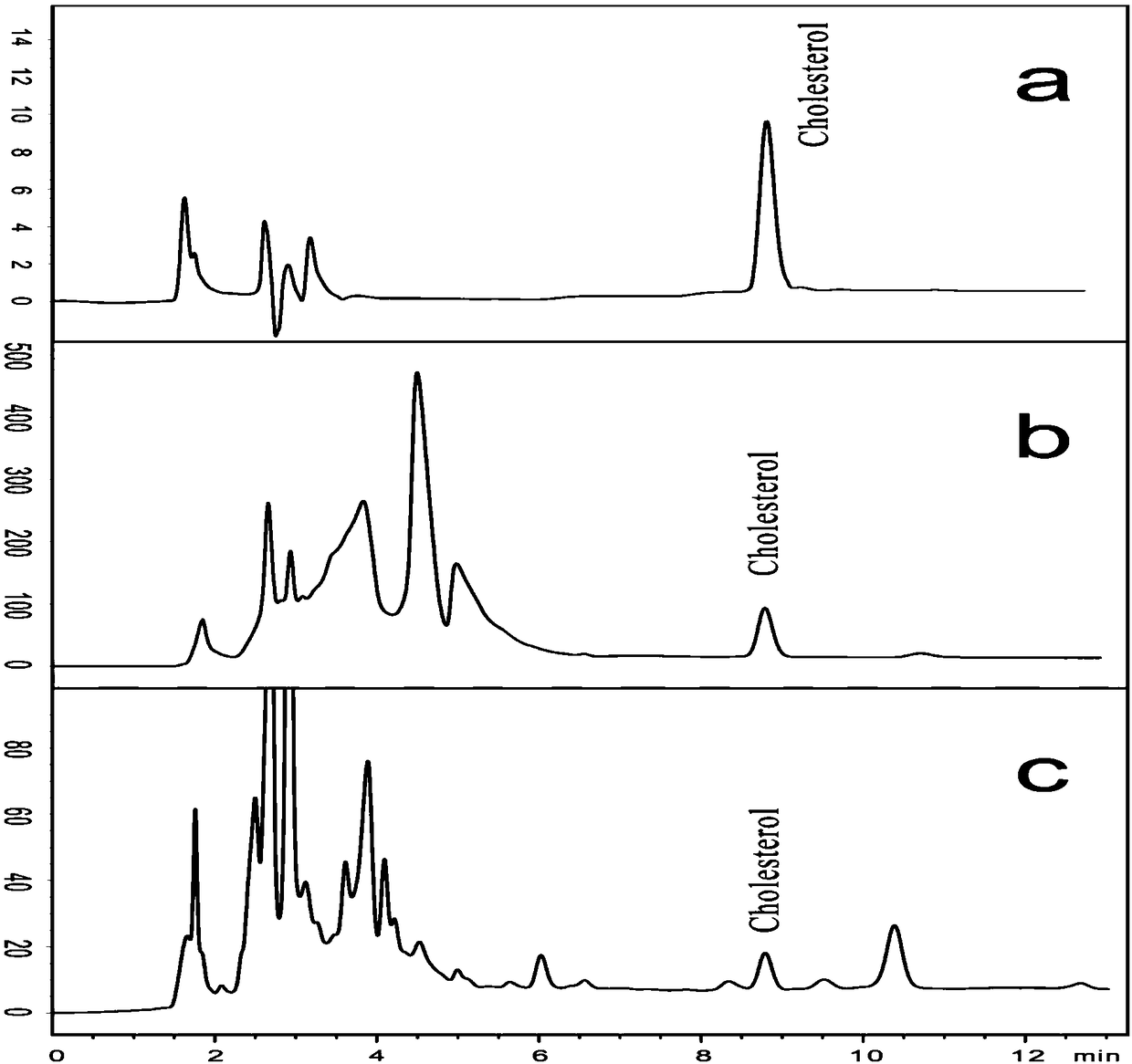

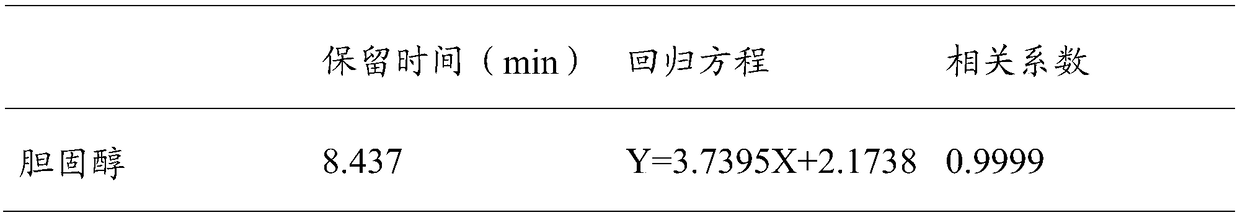

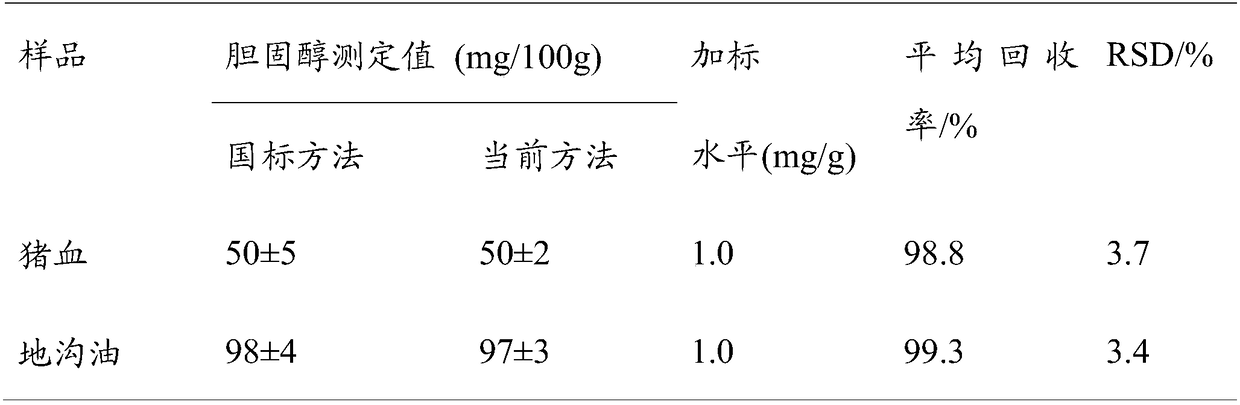

Polystyrene-diethyl benzene heating-free solid phase saponification extraction column and preparation method and applications thereof

InactiveCN108939614AEasy to useEasy to prepareComponent separationSolid sorbent liquid separationDiethyl benzenePolystyrene

The invention discloses a polystyrene-diethyl benzene heating-free solid phase saponification extraction column and a preparation method and applications thereof. The extraction column comprises a hollow column. An outlet screen plate, a polystyrene-diethyl benzene particle filled layer, an isolation screen plate, and a KOH powder filled layer are arranged in the hollow column from bottom to top in sequence. The prepared extraction column can be used to preprocess lipid containing liquid. Compared with the prior art, the preparation method is simple, the saponification is obviously reduced, the steps of heating and solid phase extraction are eliminated, a large amount of time is saved, and the detection sensitivity and the work efficiency are improved.

Owner:NORTHWEST UNIV

Continuous lutein extract saponifying process

The invention discloses a continuous lutein extract saponifying process, and belongs to the technical field of natural plant extracts. The continuous lutein extract saponifying process comprises the following steps: adding a part of a lutein extract and a part of an alcoholic-alkaline solution into saponifying equipment, heating, mixing, and presaponifying to obtain a saponified lutein extract mixture I; continuously adding the lutein extract and the alcoholic-alkaline solution into the saponified lutein extract mixture I, heating, mixing, continuously feeding and continuously discharging at the same time to achieve rapid continuous saponification of the lutein extract so as to obtain saponified lutein liquid. In a way of continuous feeding, forcible mixing and circulating saponification, the rapid saponification of the lutein extract is achieved, the saponifying time is greatly shortened, the heated loss of the extract is reduced, and the final lutein crystal yield of a product is increased.

Owner:CHENGUANG BIOTECH GRP CO LTD

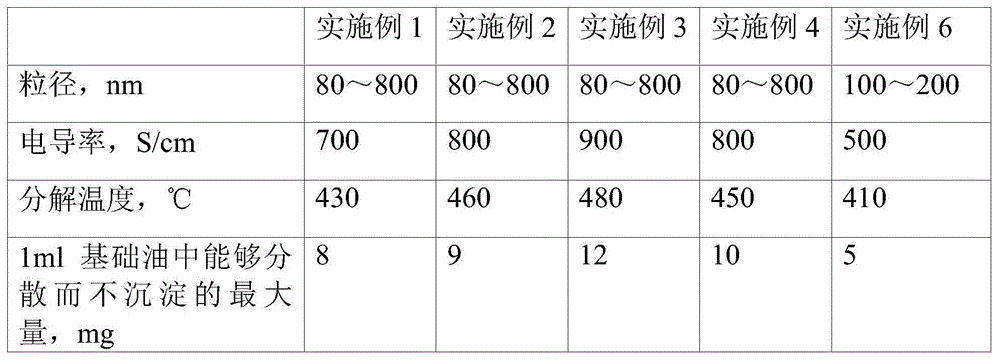

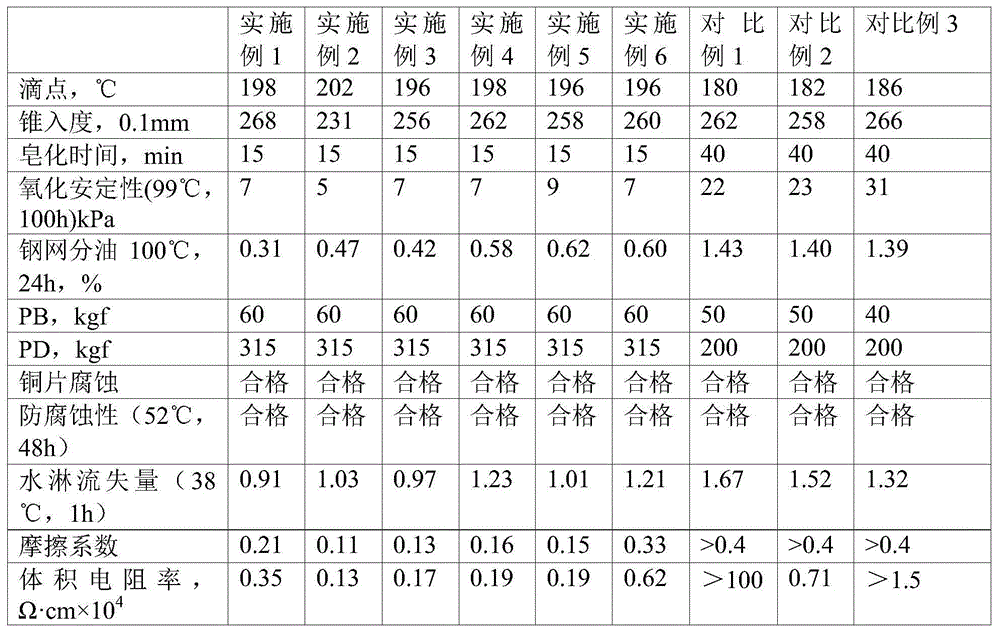

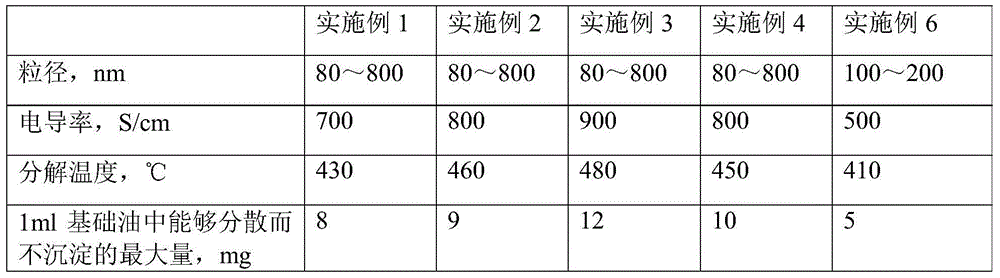

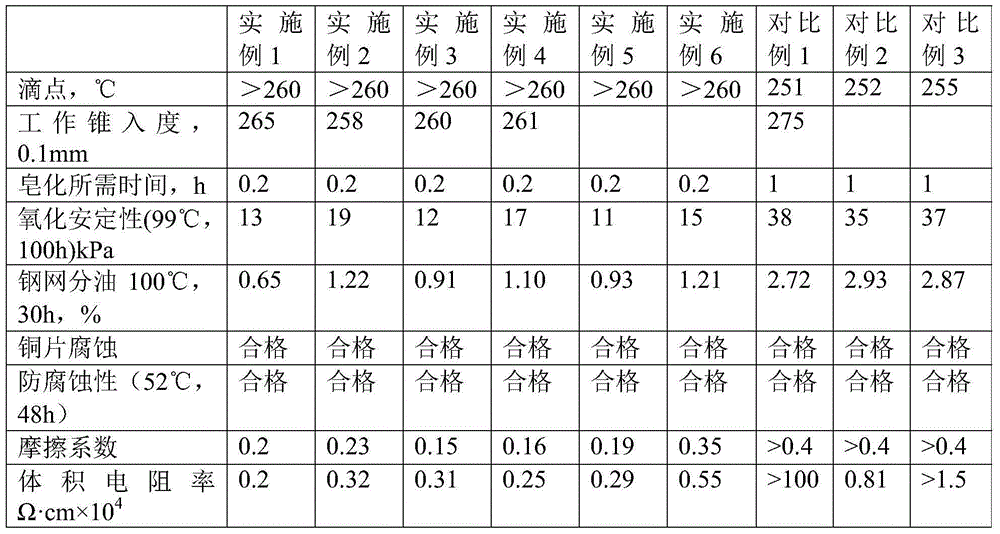

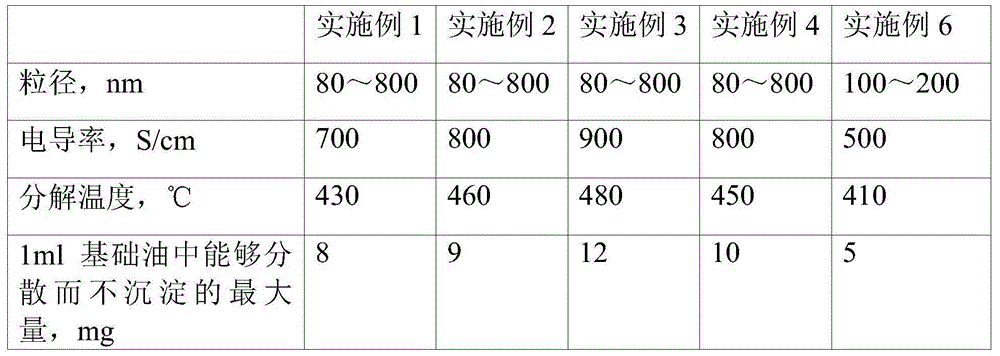

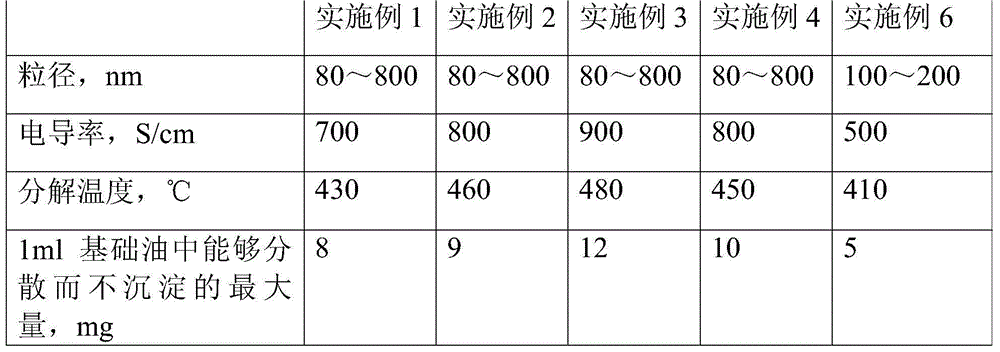

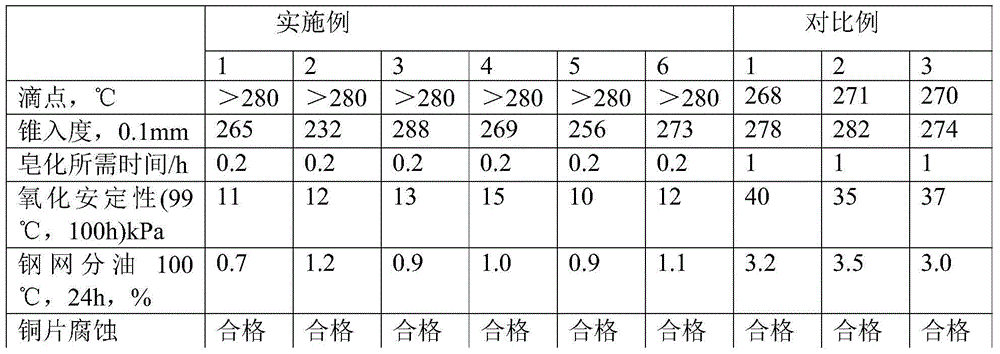

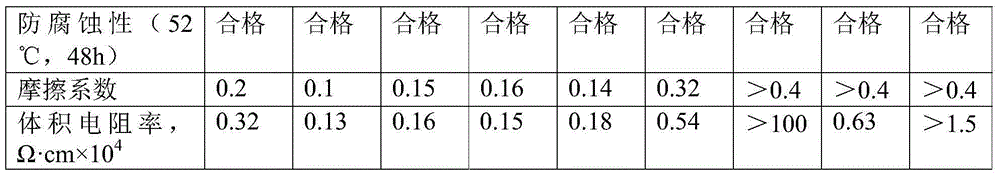

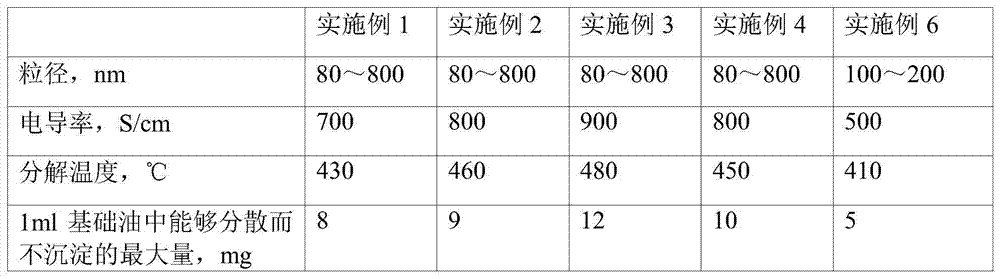

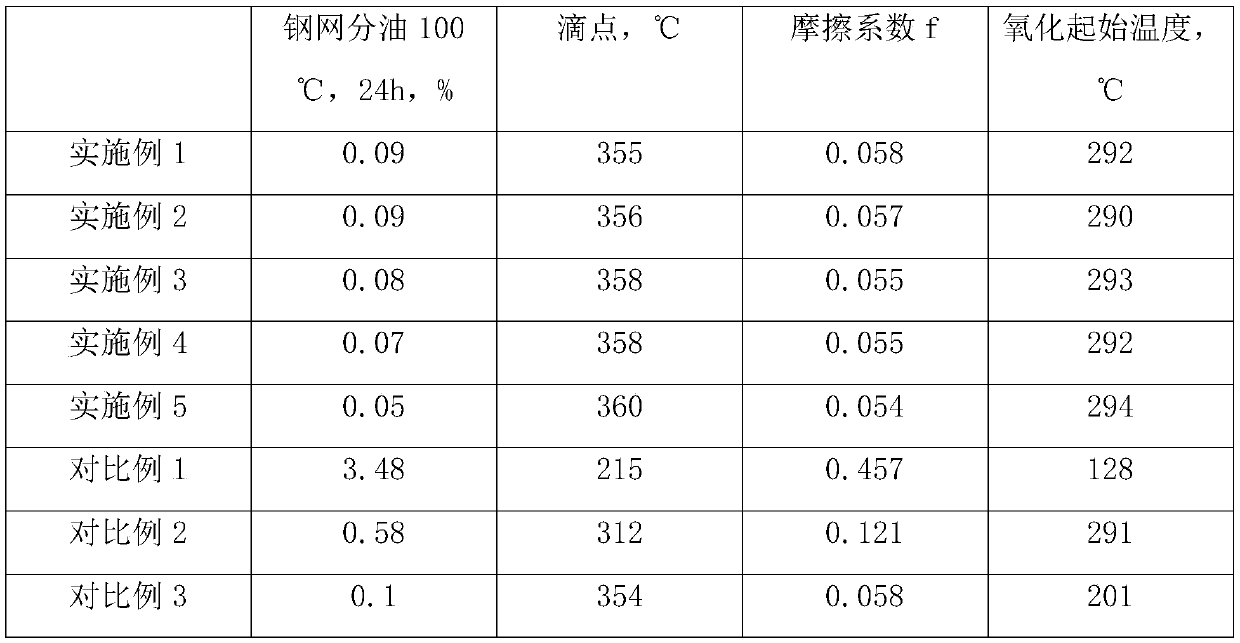

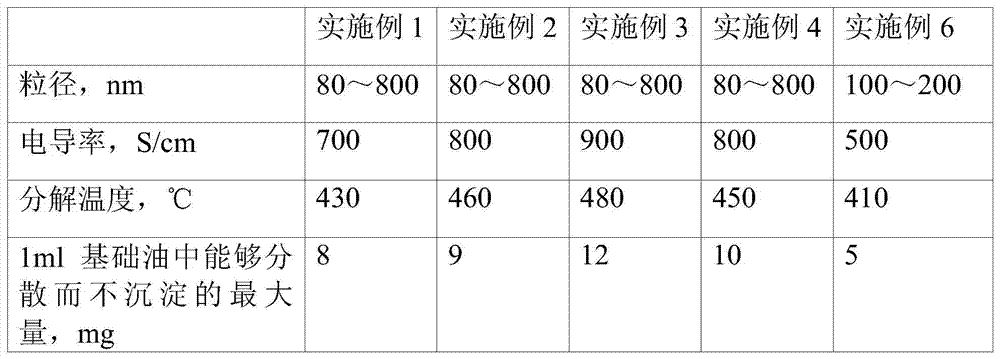

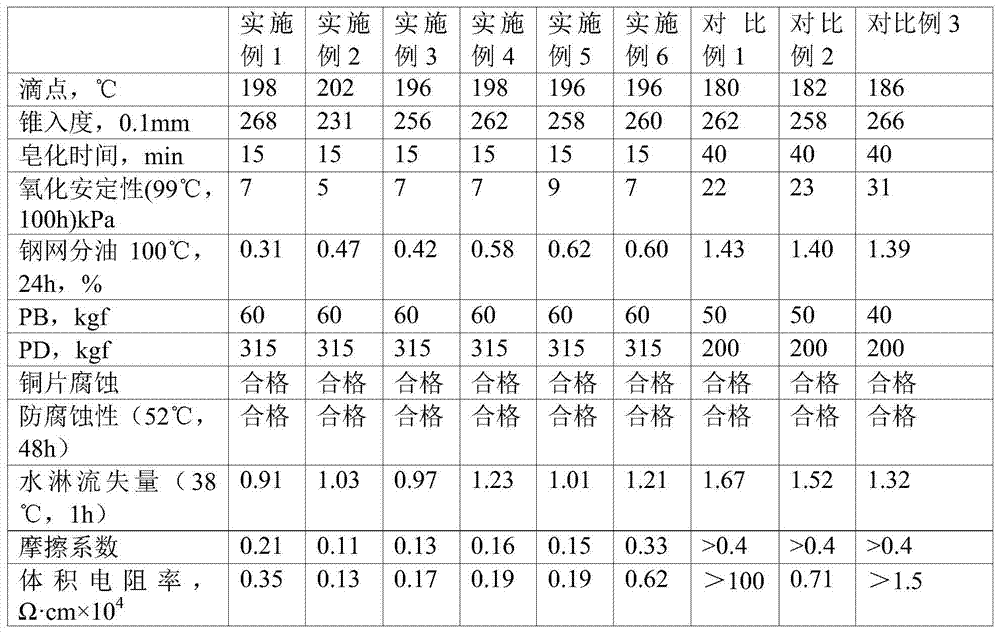

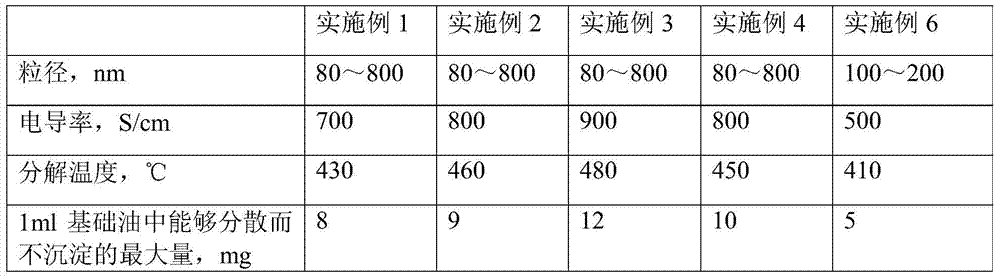

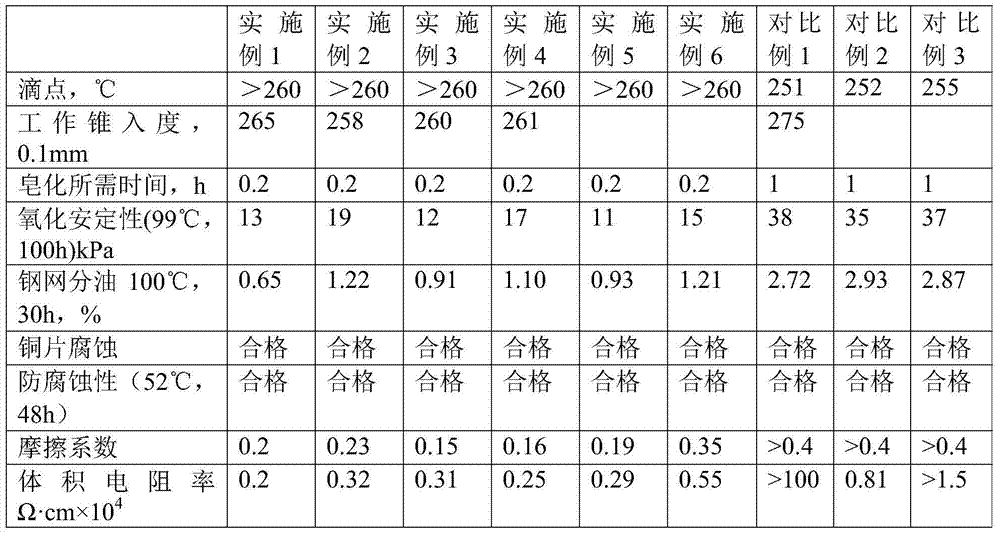

Preparation method of graphene composite lubricating grease

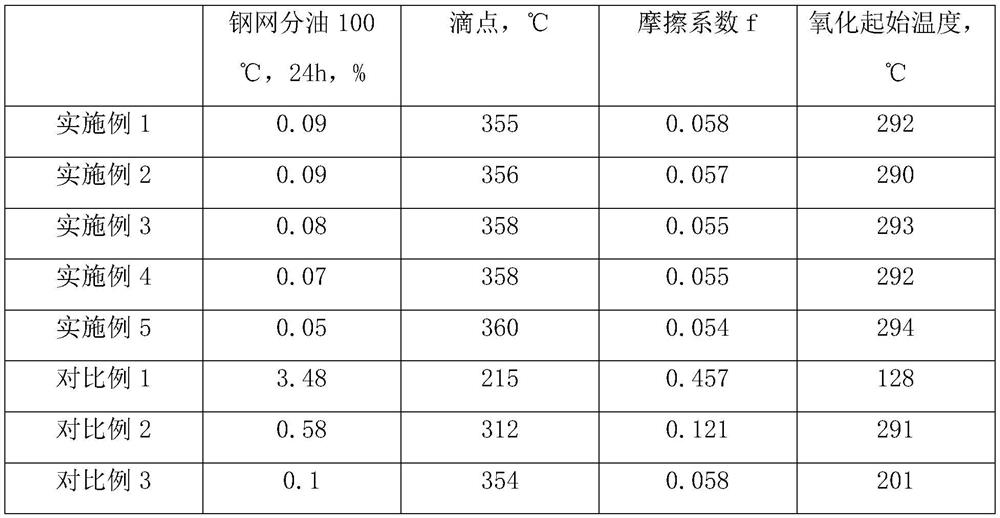

ActiveCN111471510ADrop point highGood colloidal stabilityLubricant compositionCalcium hydroxideLithium hydroxide

The invention provides a graphene composite lubricating grease and a preparation method thereof. Base oil, graphene, a high-molecular acid, calcium hydroxide, a low-molecular acid, and lithium hydroxide are used as raw materials, and after two times of saponification, the lubricating grease is prepared. The base oil and graphene are uniformly fed in two times, and the lubricating grease has advantages of good colloid stability, high dropping point, excellent friction reducing performance and excellent oxidation resistance.

Owner:贵州中时烯材科技有限公司

Preparation process of resin with starch base high water absorbency

InactiveCN1243776CShorten the synthesis processShorten the compositing timeAcrylonitrileSaponification

The invention is a starch-based high water absorptivity resin preparing method, using starch, acrylic nitricle (AN), and 2-acrylamide-2-methyl prophyl sulfonic acid (AMPS) as raw materials, adopting [Mn(H2P2O7)3]3- as initiator, making graft polymerization and saponification, and fast synthesizing starch-based high water absorptivity resin. It makes graft copolymerization on starch and two kinds of monomer raw materials, making them form multielement compound, the initiator is cheap and the modified process can omit medium washing step and AMPS group is added to be able to obviously shorten the synthesis process and time of the final product, reduce production cost and simultaneously also be able to improve the water-absorbing performance of the final product.

Owner:JIANGNAN UNIV

A kind of lithium-based grease and preparation method thereof

ActiveCN104560289BGood colloidal stabilityGood mechanical stabilityThickenersPhysical chemistryBase oil

The invention discloses a lithium-based lubricating grease and a preparation method thereof, which is characterized in that, based on the weight of the lubricating grease, it comprises the following components: 65-95% lubricating base oil, 6-20% lithium-based thickener , 0.5‑15% graphene. The lithium-based lubricating grease of the invention has excellent properties such as high temperature resistance, water resistance, adhesion, colloid stability, extreme pressure and wear resistance, lubrication life, corrosion resistance and salt spray resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

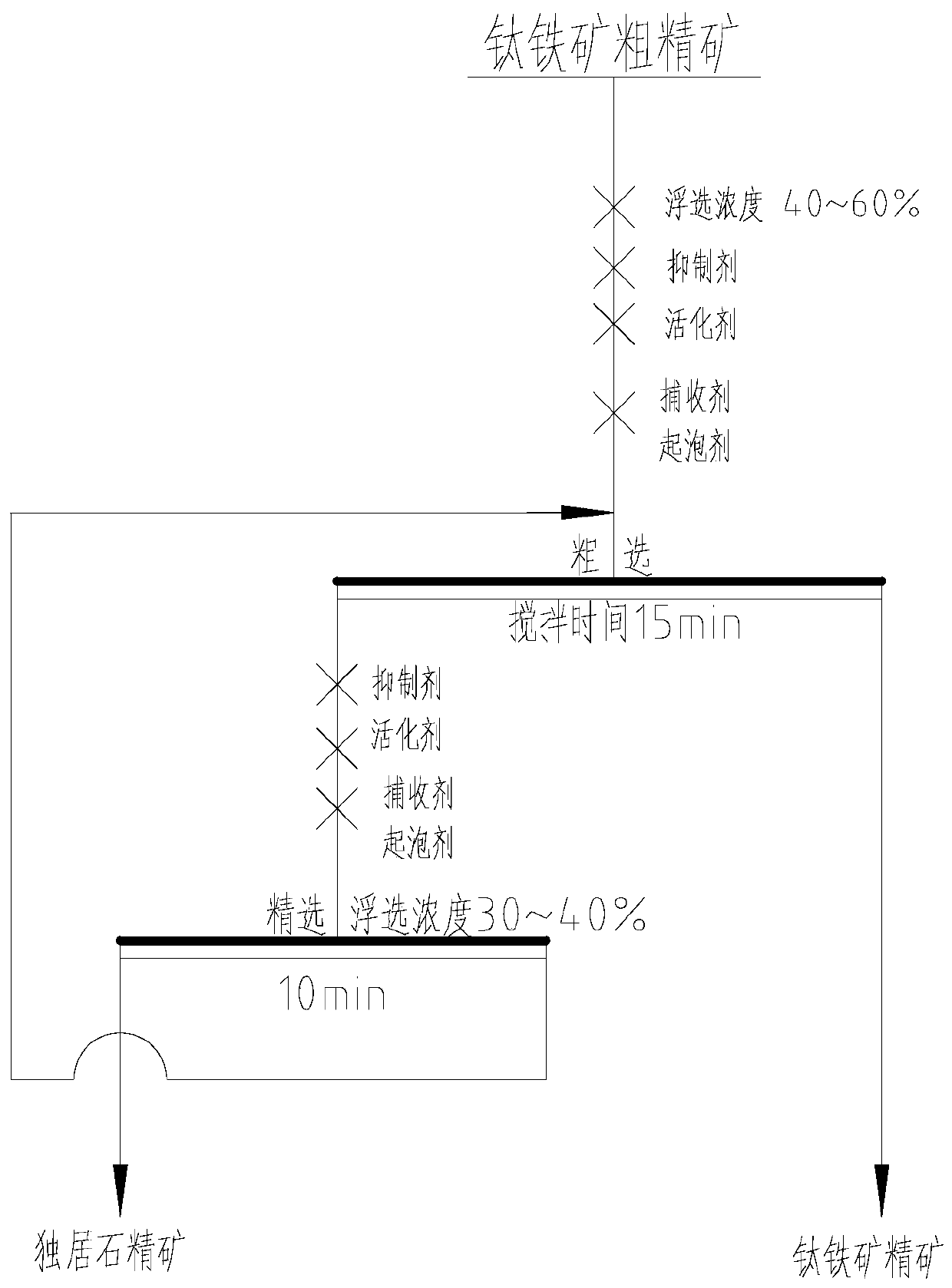

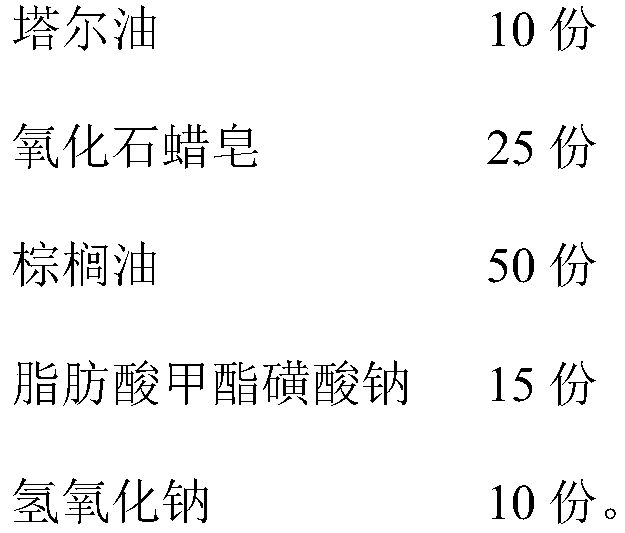

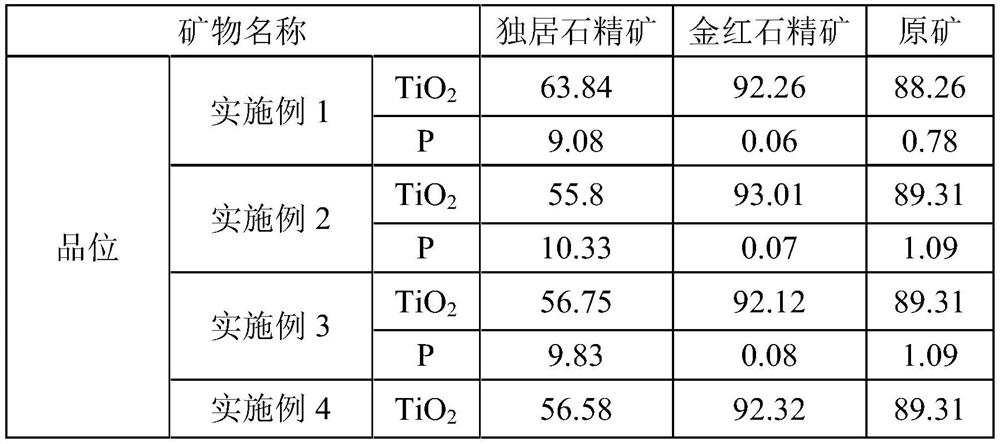

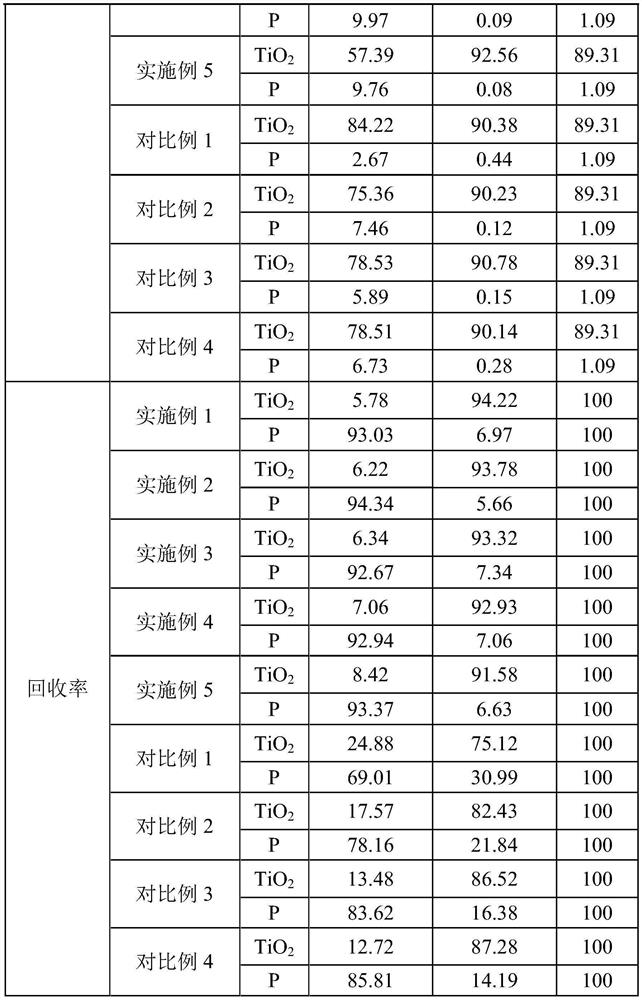

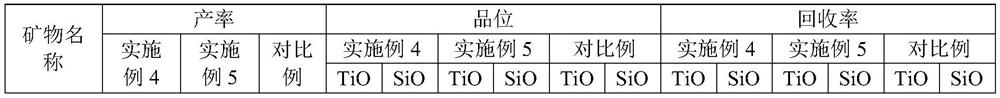

Collecting agent for sorting monazite and ilmenite and using method of collecting agent

ActiveCN111515029AShorten saponification timeReduce generation costFlotationMechanical material recoverySulfonateIlmenite

The invention provides a collecting agent for sorting monazite and ilmenite and a using method of the collecting agent. The collecting agent comprises 10-15 parts of tall oil, 25-35 parts of oxidizedparaffin soap, 40-50 parts of palm oil, 10-15 parts of fatty acid methyl ester sodium sulfonate and 10-15 parts of sodium hydroxide. The preparation method comprises the following steps: carrying outmicrowave pretreatment on tall oil, oxidized paraffin soap, palm oil and sodium fatty acid methyl ester sulfonate, and then mixing and stirring at 70-85 DEG C; and adding sodium hydroxide, and mixingunder the condition of 85-100 DEG C to obtain the collecting agent. A novel microwave pre-activation pretreatment mode is adopted on equipment, a direct reaction kettle reaction is replaced, the saponification time is shortened, the production cost is reduced, and the collecting effect is better. The collecting agent is used; the comprehensive grade P of monazite concentrate can be increased to 10.29% or above, the operation recovery rate P is increased to 88.03% or above, the comprehensive grade TiO2 of ilmenite is increased to 50.00% or above, the operation recovery rate TiO2 is increased to96.22% or above, and good economic benefits are achieved.

Owner:盛和资源(连云港)新材料科技有限公司 +3

A method for extracting lutein from marigold

ActiveCN109053517BAvoid the disadvantages of high toxicityHigh purityOrganic chemistryLuteinPotassium hydroxide

The invention belongs to the field of plant purification, and provides a method for extracting lutein from marigolds. The method includes the following steps: (1) adding dry marigold powder and organic solvents into an extraction container for stirring and extracting; (2) filtering the mixture in the extraction container, collecting filtrate, and subjecting the filtrate to decompressed concentration to obtain a lutein ointment; (3) adding a potassium hydroxide ethanol solution and high-temperature alkaline lipases into the lutein ointment, and after stirring and dissolving, transferring the lutein ointment into a reactor for saponification; (4) standing saponification liquid at a low temperature to precipitate out lutein crystals, performing filtration, washing filter cakes by distilled water, and drying the filter cakes to obtain the high-purity lutein crystals, wherein the purity of the lutein in the final products ranges from 70% to 90%. The method has the advantages that the problems of complicated extraction process, high solvent toxicity and low product purity of existing lutein are solved; the method has a simple process, high operability and high product purity, and is suitable for industrial mass production.

Owner:CHAMBROAD CHEM IND RES INST CO LTD

A kind of composite aluminum base lubricating grease and preparation method thereof

ActiveCN104560314BImprove antioxidant capacityImprove high drop pointLubricant compositionMetallurgyPhysical chemistry

The invention discloses a composite aluminum-based lubricating grease and a preparation method thereof. Based on the grease weight, the composite aluminum-based grease includes the following components: 65-95% lubricating base oil, 5-30% composite aluminum-based thickener, and 0.2-15% graphene. The composite aluminum-based lubricating grease of the invention has excellent properties such as high temperature resistance, water resistance, adhesion, colloid stability, extreme pressure and wear resistance, lubrication life, corrosion resistance and salt spray resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of preparation method of graphene composite lubricating grease

ActiveCN111471510BDrop point highGood colloidal stabilityLubricant compositionCalcium hydroxideLithium hydroxide

The invention provides a graphene composite lubricating grease and a preparation method thereof. The invention uses base oil, graphene, high molecular acid, calcium hydroxide, low molecular acid, lithium hydroxide, etc. as raw materials, and undergoes two saponification reactions. A lubricating grease is obtained, the base oil and the graphene are equally divided into two feeds, and the product has good colloidal stability, high dropping point, excellent anti-friction performance and anti-oxidation performance.

Owner:贵州中时烯材科技有限公司

Production process of octacosanol

ActiveCN103232320BReduce dosageReduce demandOxygen-containing compound preparationOrganic compound preparationWaxBran

The invention discloses a production technology of octacosanol. Raw bran wax is sequentially subjected to saponifying, cleaning, dehydrating, drying, smashing, extracting, filtering and desolventizing to obtain fatty alcohol, and vacuum rectification is carried out to obtain the octacosanol. By adopting the production technology of octacosanol, reaction can be sped up, production efficiency is improved, and yield and content of the octacosanol are also increased.

Owner:HUZHOU SIFENG PLANT EXTRACT

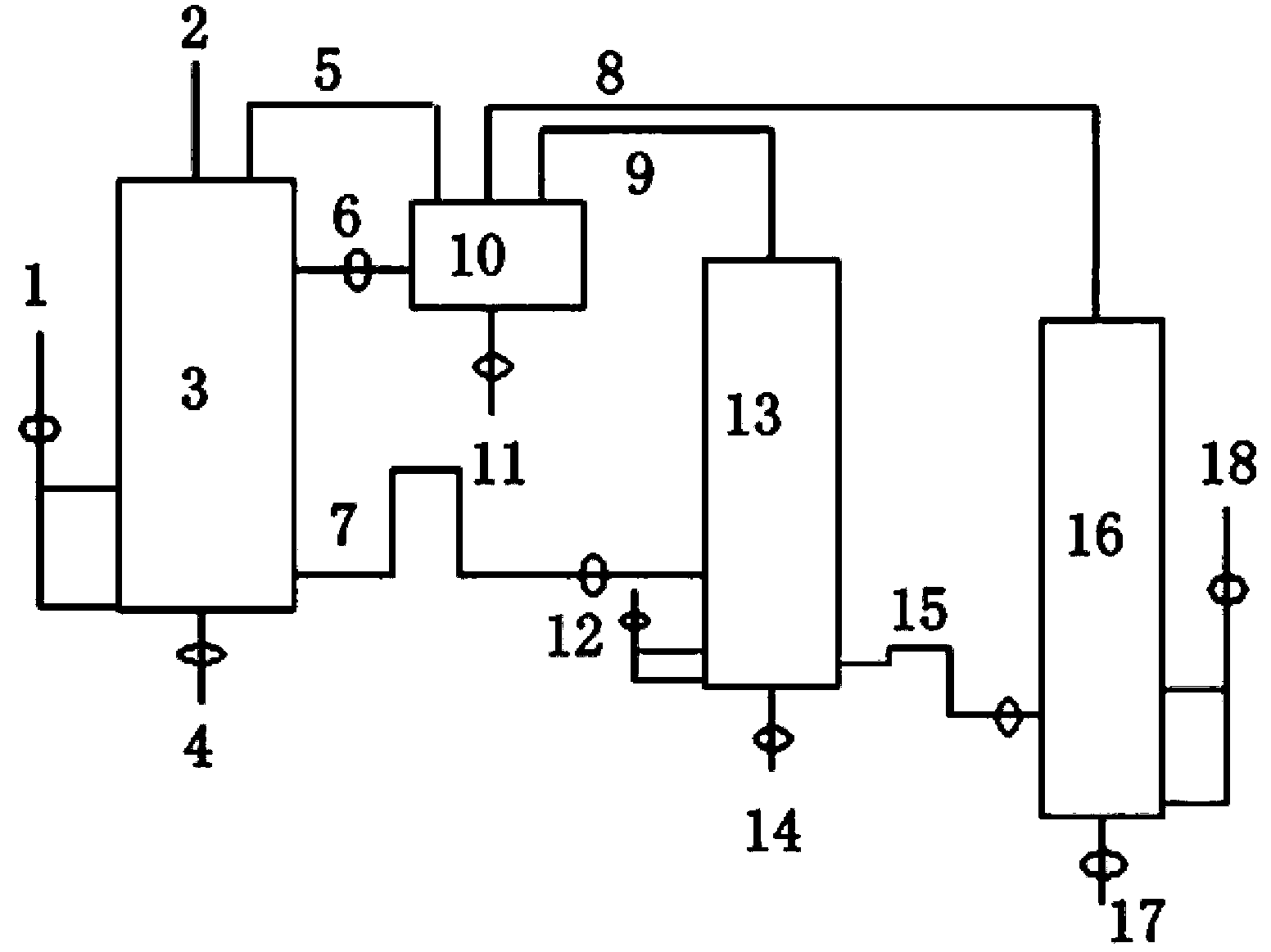

A kind of collector for separating monazite and ilmenite and using method thereof

ActiveCN111515029BShorten saponification timeReduce generation costFlotationMechanical material recoverySulfonatePretreatment method

The invention provides a collector for sorting monazite and ilmenite and its use method. The collector includes 10-15 parts of tall oil, 25-35 parts of oxidized paraffin soap, and 40-50 parts of palm oil. 10-15 parts of sodium fatty acid methyl ester sulfonate, 10-15 parts of sodium hydroxide; microwave pretreatment of tall oil, oxidized paraffin soap, palm oil and sodium fatty acid methyl ester sulfonate, and then 70-85 ℃ Mix and stir; then add sodium hydroxide and mix at 85-100°C to obtain the collector. The invention adopts a novel microwave pre-activated pretreatment method on the equipment, which replaces the direct reactor reaction, reduces the saponification time, reduces the production cost, and has better harvesting effect. Using the collector of the present invention can improve the comprehensive grade P of monazite concentrate to more than 10.29%, the operational recovery rate P can be raised to more than 88.03%, and the comprehensive grade P of ilmenite ore TiO 2 Increase to more than 50.00%, operating recovery rate TiO 2 Increase to more than 96.22%, has very good economic benefits.

Owner:盛和资源(连云港)新材料科技有限公司 +3

A kind of complex calcium base lubricating grease and preparation method thereof

The invention discloses a composite calcium-based lubricating grease and a preparation method thereof. Based on the grease weight, the complex calcium-based grease includes the following components: 65-95% lubricating base oil, 6-20% complex calcium-based thickener, and 0.2-15% graphene. The composite calcium-based lubricating grease of the invention has excellent properties such as high temperature resistance, water resistance, adhesion, colloid stability, extreme pressure and wear resistance, lubrication life, corrosion resistance and salt spray resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

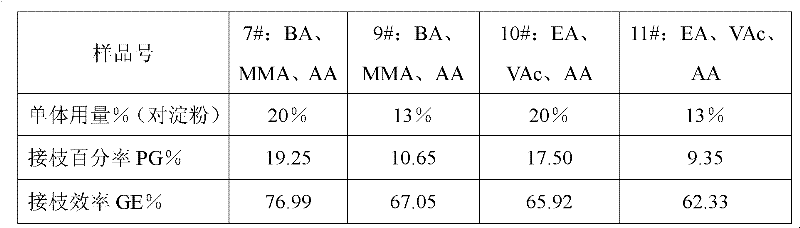

Method for preparing grafted modified starch

InactiveCN101948557BImprove use valueImprove performanceFibre treatmentEcological environmentCarvacryl acetate

The invention relates to a method for preparing grafted modified starch. The method comprises the following steps of: (1) preparing starch milk from the common starch and then performing acidification for 1.5 to 2.5 hours; (2) introducing nitrogen into the acidified starch milk to remove oxygen from a system and then adding dihydrogen manganese pyrophosphate and grafted monomers of acrylic acid, methyl acrylate, ethyl acrylate and vinyl acetate sequentially to perform a graft copolymerization reaction; (3) adding sodium hydroxide and sodium hypochlorite into the starch copolymer to perform saponification aftertreatment; and (4) neutralizing by adding sulfuric acid until the pH value is 6 and 8, and then performing dehydration, drying, pulverization, sieving, packaging and metering to obtain the grafted modified starch finished product. The method has the advantages that: the properties of the grafted modified starch are stable; the process operation is simple; and chemicals used in the modifying process have low price and convenient and readily available source. The grafted modified starch product has the advantages of meeting a starching requirement, effectively reducing the costof sizing agents and reducing pollution of PVA to ecological environment, along with excellent properties, stable quality and lower price.

Owner:TIANJIN TIANFUTONG BIOTECH DEV

A kind of anhydrous calcium base lubricating grease and preparation method thereof

ActiveCN104560267BImprove extreme pressure and anti-wear performanceEnhanced ability to cure base oilsThickenersHeat resistanceGraphene

The invention discloses an anhydrous calcium-based lubricating grease and a preparation method thereof. Based on the grease weight, the anhydrous calcium-based grease includes the following components: 60-90% lubricating base oil, 5-30% anhydrous calcium-based thickener, and 0.2-15% graphene. The anhydrous calcium-based lubricating grease of the present invention has excellent properties such as high temperature resistance, water resistance, adhesion, colloid stability, extreme pressure and wear resistance, lubrication life, corrosion resistance and salt spray resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

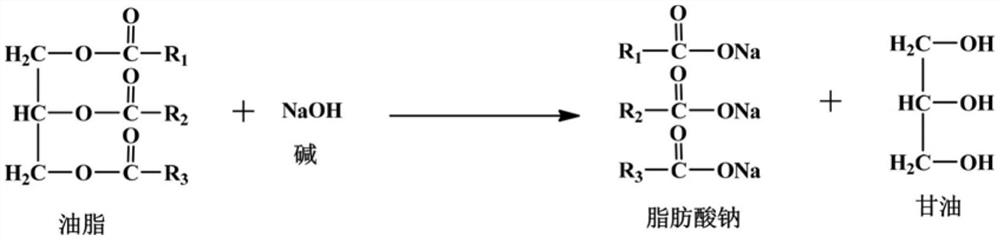

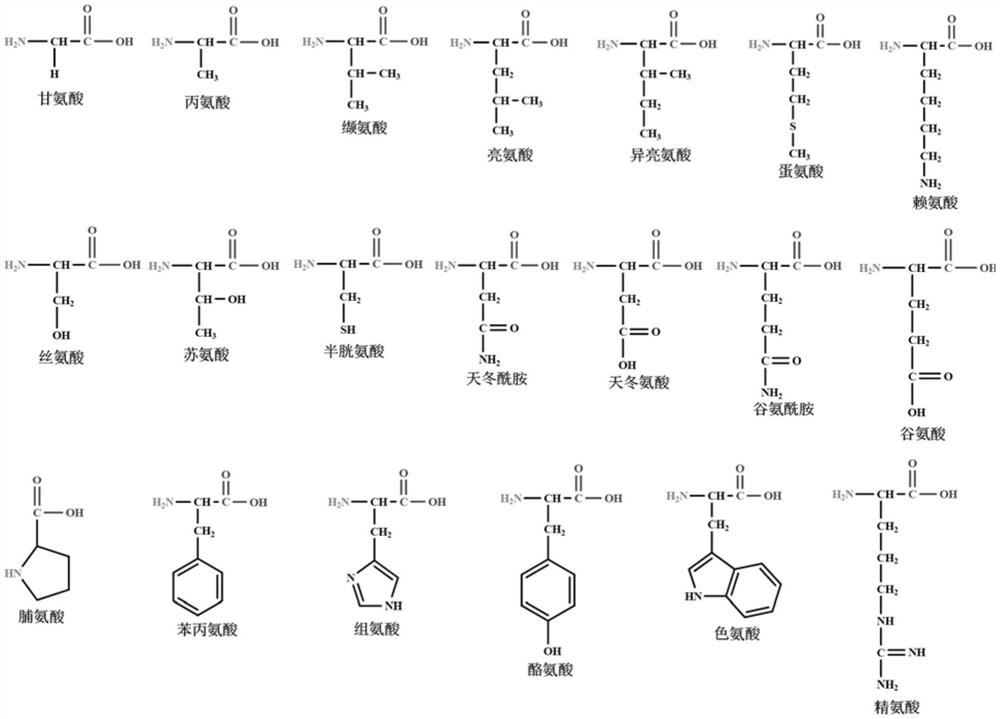

A kind of handmade soap with shortened saponification time and preparation method thereof

ActiveCN110257194BWide variety of sourcesAlkaline adjustableSkin careAlkali/ammonium soap compositionsLithium hydroxidePotassium hydroxide

The invention relates to the field of handmade soap, and particularly relates to handmade soap with a shortened saponification time and a preparation method thereof. The handmade soap is prepared by the following steps: proportioning base oil, an amino acid salt and distilled water according to a certain ratio, carrying out mixing, then carrying out a saponification reaction, and after the saponification is mature, adding a certain proportion of additives to prepare the handmade soap. The handmade soap comprises the following components in percentage by weight: 60%-75% of the base oil, 5%-20% of the amino acid salt, 10%-20% of distilled water and 0.5%-5% of the additives. According to the scheme, the amino acid salt is used for replacing a conventional strong base for a saponification process of grease, and the used amino acid salt can be directly purchased in the market, and can also be prepared by separately carrying out reactions on amino acid with lithium hydroxide, sodium hydroxide and potassium hydroxide. The material source is wide, alkalinity is adjustable, and biocompatibility is good.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

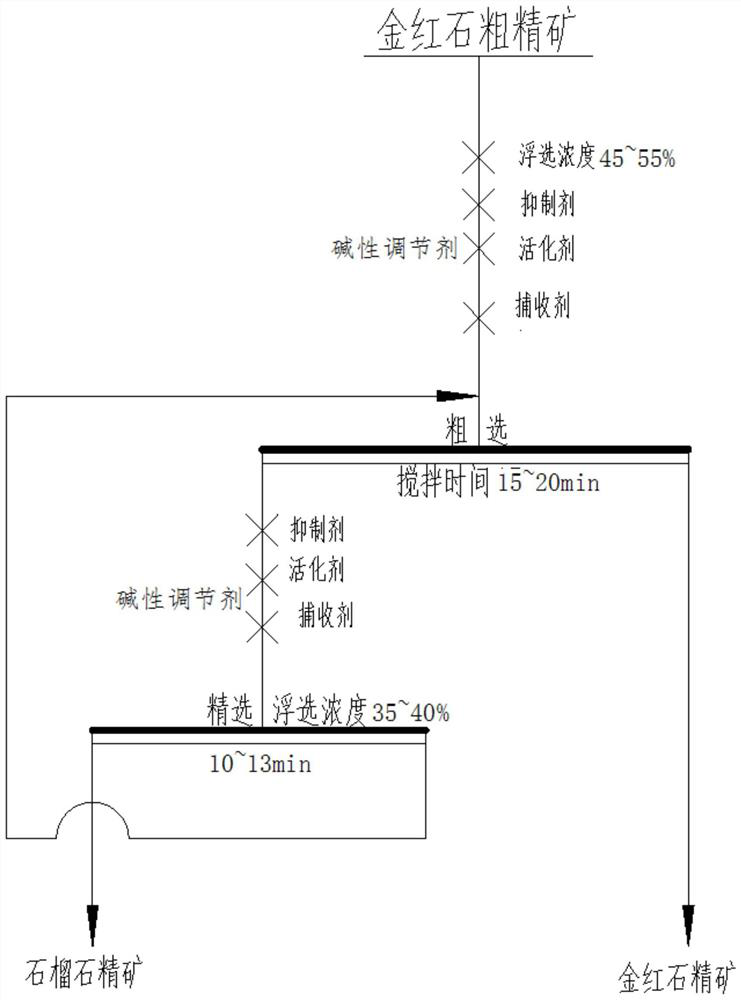

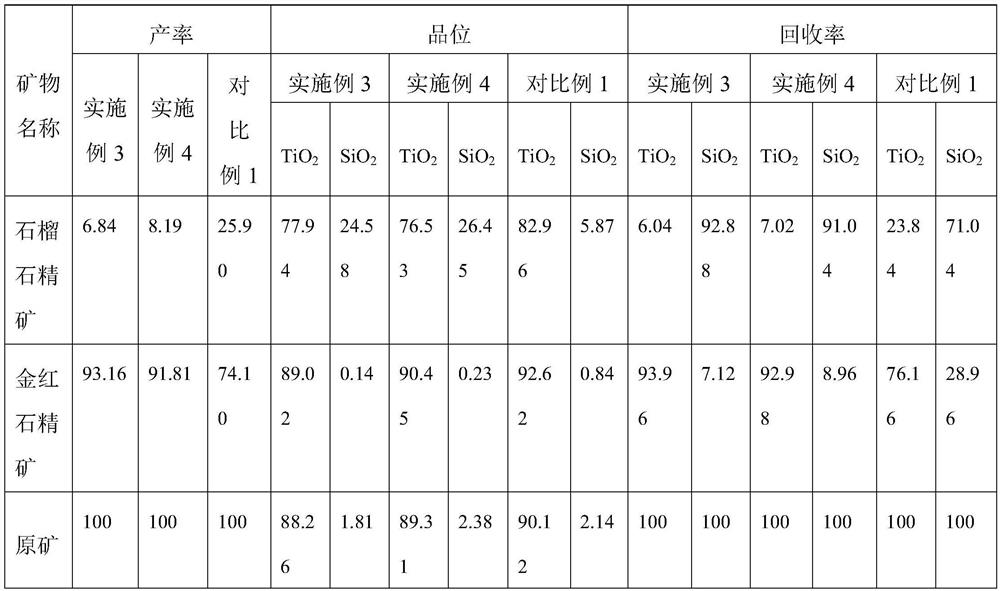

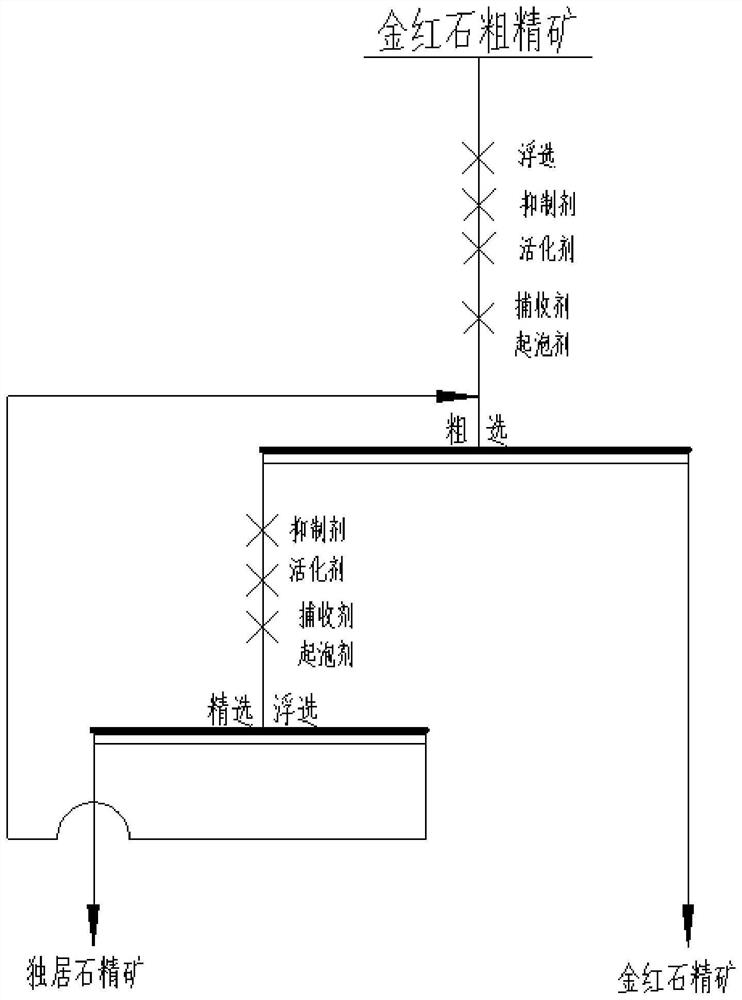

A beneficiation process for separating garnet and rutile based on composite flotation agents

The invention provides a mineral processing process for sorting garnet and rutile based on composite flotation reagents, comprising the steps of: (1) preparing a composite garnet collector: including 20-25 parts of tall oil and 30-35 parts of oxidized paraffin wax soap , 20-30 parts of palm oil and 12-18 parts of sodium fatty acid methyl ester sulfonate; saponification reaction after microwave pre-activation; It is water glass, the activator is copper sulfate, the flotation concentration is 45-55%, and the garnet rough concentrate and rutile concentrate are obtained; (3) selection flotation: the dosage of garnet composite collector is 85-95 / t , the inhibitor is water glass, the activator is copper sulfate, the flotation concentration is 35-40%, and the garnet concentrate and rutile medium ore are obtained. The invention realizes the positive flotation separation of garnet and rutile, simultaneously improves the grade and recovery rate of rutile concentrate and garnet concentrate, and has simpler process steps.

Owner:HAINAN WENSHENG HIGH TECH MATERIALS +3

A kind of beneficiation process and application of using composite collector to separate monazite and rutile

ActiveCN111515030BEfficient sortingImprove qualityFlotationProcess efficiency improvementFoaming agentMonazite

The present invention provides a kind of ore dressing process and application of using composite collector to separate monazite and rutile, said ore beneficiation process includes the following steps: (1) by weight, 10 to 15 parts of tall oil, 25 parts of oxidized paraffin wax soap ~35 parts, palm oil 40~50 parts, sodium fatty acid methyl ester sulfonate 10~15 parts, microwave preactivation 5~10min; Saponification for 1.5 to 2.5 hours to obtain the target collector; (2) Take the rutile crude concentrate raw material, add the above-mentioned collector, inhibitor, activator, and foaming agent, and perform the first flotation to obtain monazite Coarse concentrate and tailings; (3) add monazite coarse concentrate to the above-mentioned collector, inhibitor, activator, foaming agent, and carry out the second flotation to obtain monazite concentrate and tailings, the tailings The mine is rutile concentrate. The beneficiation process of the invention effectively separates the rutile rough concentrate to obtain monazite concentrate products and rutile concentrate products with high quality and is environmentally friendly.

Owner:盛和资源(连云港)新材料科技有限公司 +3

A kind of composite sodium base lubricating grease and preparation method thereof

ActiveCN104560315BImprove antioxidant capacityImprove high drop pointThickenersHeat resistanceGraphene

The invention discloses a composite sodium-based lubricating grease and a preparation method thereof. Based on the grease weight, the complex sodium-based grease includes the following components: 65-95% lubricating base oil, 5-30% complex sodium-based thickener, and 0.2-15% graphene. The composite sodium-based lubricating grease of the present invention has excellent properties such as high temperature resistance, water resistance, adhesion, colloid stability, extreme pressure and wear resistance, lubrication life, corrosion resistance and salt spray resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

A collector and flotation process for sorting garnet and ilmenite

The invention provides a collector for sorting garnet and ilmenite and a flotation process thereof. The collector includes the following raw materials in parts by weight: 10-15 parts of tall oil, 25-35 parts of oxidized paraffin wax soap, 40-50 parts of palm oil, 10-15 parts of sodium fatty acid methyl ester sulfonate, 10-15 parts of sodium hydroxide, the collector of the present invention carries out the flotation of garnet and ilmenite, and has strong selectivity and Harvesting performance, improving the harvesting effect, reducing the amount of harvesting, good stability, fast flotation speed, comprehensively improving the grade of garnet, reducing the impurity content in concentrate products, and recovering garnet concentrate The yield has increased by 10-20%, and the grade of garnet has increased by 10-20%, which has good economic benefits.

Owner:HAINAN WENSHENG HIGH TECH MATERIALS +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com