Preparation method of graphene composite lubricating grease

A graphene composite and graphene technology, applied in the field of lubricating grease, can solve the problems of poor uniformity of lubricating grease, poor oxidation resistance, poor dispersion uniformity, etc., and achieve excellent anti-friction performance and anti-oxidation performance, and good colloidal stability , The effect of high dropping point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

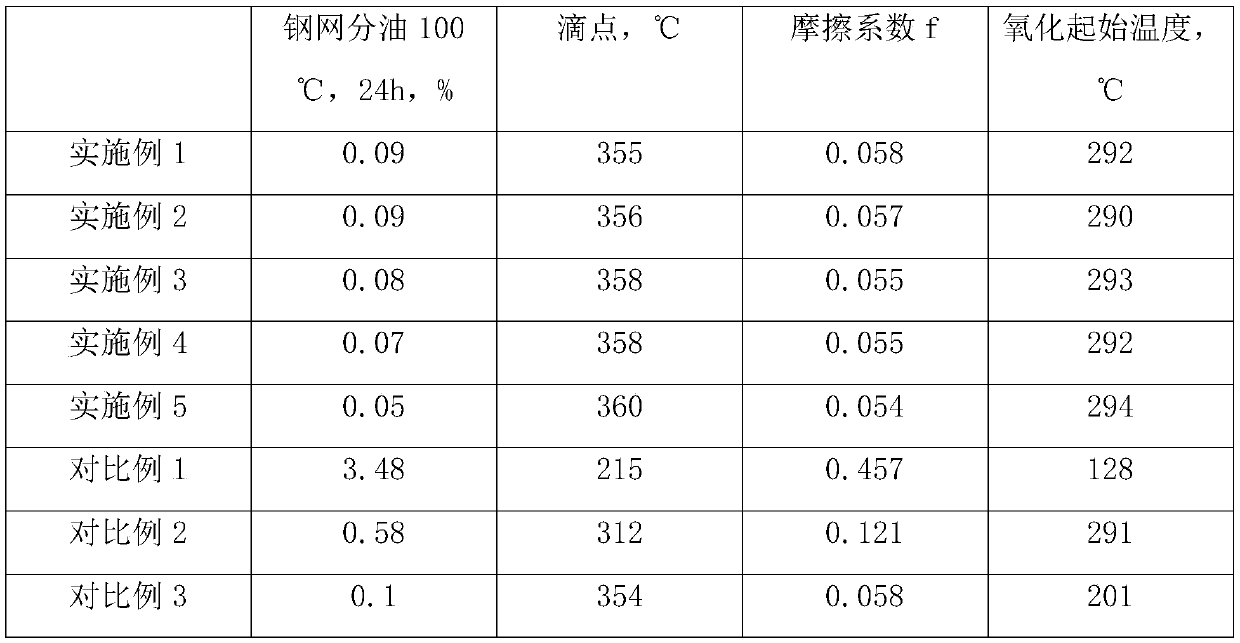

Examples

Embodiment 1

[0031] A preparation method of graphene composite lubricating grease, first mix and heat the first part of graphene, the first part of base oil, and high molecular acid, add the suspension of calcium hydroxide and water, carry out the first saponification reaction, and then add low molecular weight acid and lithium hydroxide for the second saponification reaction, refining, adding the second part of base oil, cooling, adding the second part of modified graphene, stirring evenly, and grinding into fat, that is, the above-mentioned a kind of graphite Graphene compound grease; Wherein, the modified treatment method of the second part of graphene is as follows: the second part of graphene, epoxy resin, vinyltriethoxysilane, organic solvent is added in the ball mill tank, and the first ball mill treatment , and then add antioxidants, the second ball milling treatment, dropwise adding calcium borate suspension, the third ball milling treatment, post-processing.

[0032] The base oil...

Embodiment 2

[0045] A preparation method of graphene composite lubricating grease, first mix and heat the first part of graphene, the first part of base oil, and high molecular acid, add the suspension of calcium hydroxide and water, carry out the first saponification reaction, and then add low molecular weight acid and lithium hydroxide for the second saponification reaction, refining, adding the second part of base oil, cooling, adding the second part of modified graphene, stirring evenly, and grinding into fat, that is, the above-mentioned a kind of graphite Graphene compound grease; Wherein, the modified treatment method of the second part of graphene is as follows: the second part of graphene, epoxy resin, vinyltriethoxysilane, organic solvent is added in the ball mill tank, and the first ball mill treatment , and then add antioxidants, the second ball milling treatment, dropwise adding calcium borate suspension, the third ball milling treatment, post-processing.

[0046] The base oil...

Embodiment 3

[0059] A preparation method of graphene composite lubricating grease, first mix and heat the first part of graphene, the first part of base oil, and high molecular acid, add the suspension of calcium hydroxide and water, carry out the first saponification reaction, and then add low molecular weight acid and lithium hydroxide for the second saponification reaction, refining, adding the second part of base oil, cooling, adding the second part of modified graphene, stirring evenly, and grinding into fat, that is, the above-mentioned a kind of graphite Graphene compound grease; Wherein, the modified treatment method of the second part of graphene is as follows: the second part of graphene, epoxy resin, vinyltriethoxysilane, organic solvent is added in the ball mill tank, and the first ball mill treatment , and then add antioxidants, the second ball milling treatment, dropwise adding calcium borate suspension, the third ball milling treatment, post-processing.

[0060] The base oil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com