Patents

Literature

57results about How to "Give full play to excellent performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

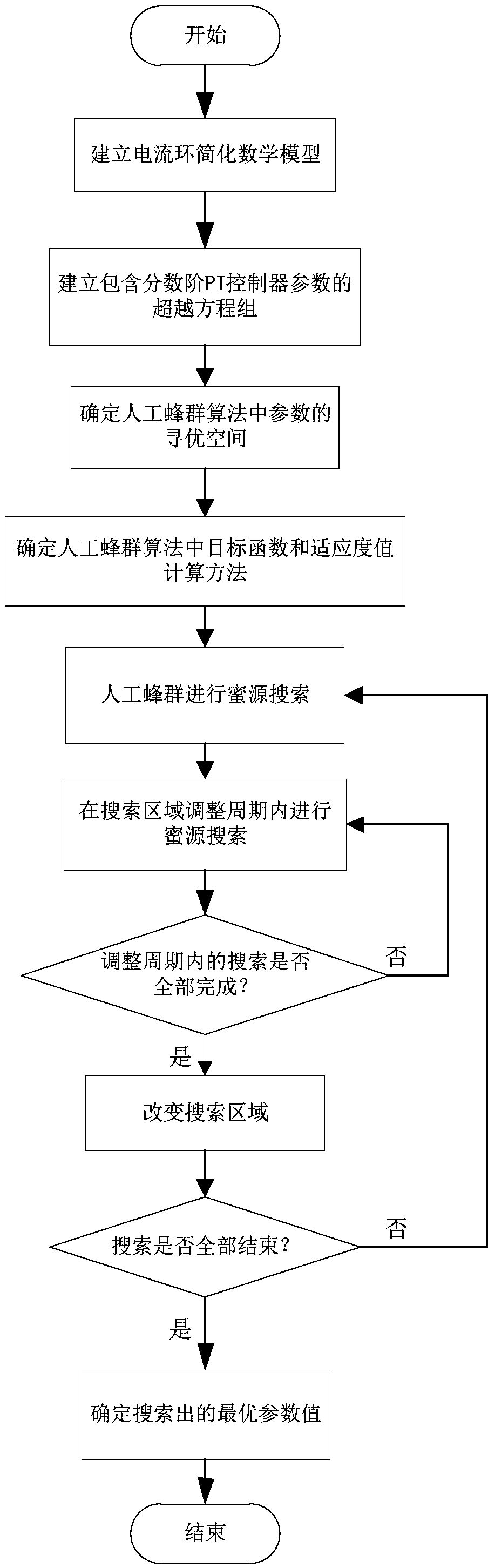

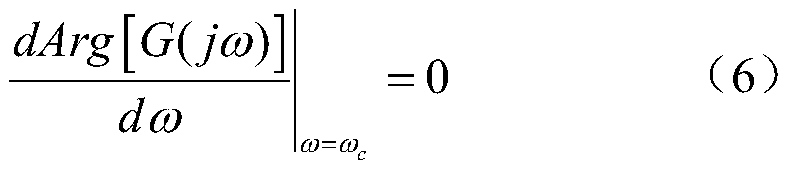

Parameter setting method for fractional order PI controller of servo motor

ActiveCN105511259AGive full play to excellent performanceImprove efficiencyControllers with particular characteristicsComputer scienceObject function

The invention relates to the technical field of intelligent control and specifically relates to a parameter setting method for the fractional order PI controller of a servo motor. the parameter setting method comprises the steps of S1, establishing a transcendental equation system containing three unknown parameters Krho, Ki and lambda of a fractional order PI controller; 2, determining an optimal interval for the above three unknown parameters Krho, Ki and lambda based on the artificial bee colony algorithm; 3, determining a target function of an artificial bee colony and a fitness value calculation method; 4, searching the optimal values of the above three unknown parameters Krho, Ki and lambda based on the search strategy-improved artificial bee colony algorithm. According to the technical scheme of the invention, the requirements of a servo control system on the quick response performance and the high-precision trajectory tracking performance can be met.

Owner:SHANDONG UNIV OF SCI & TECH

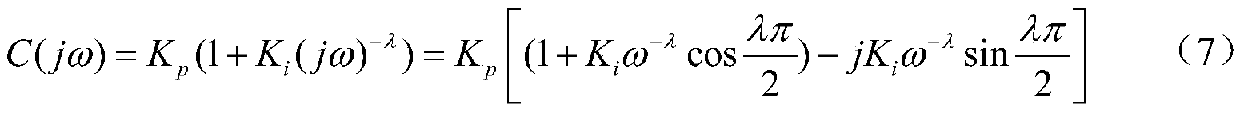

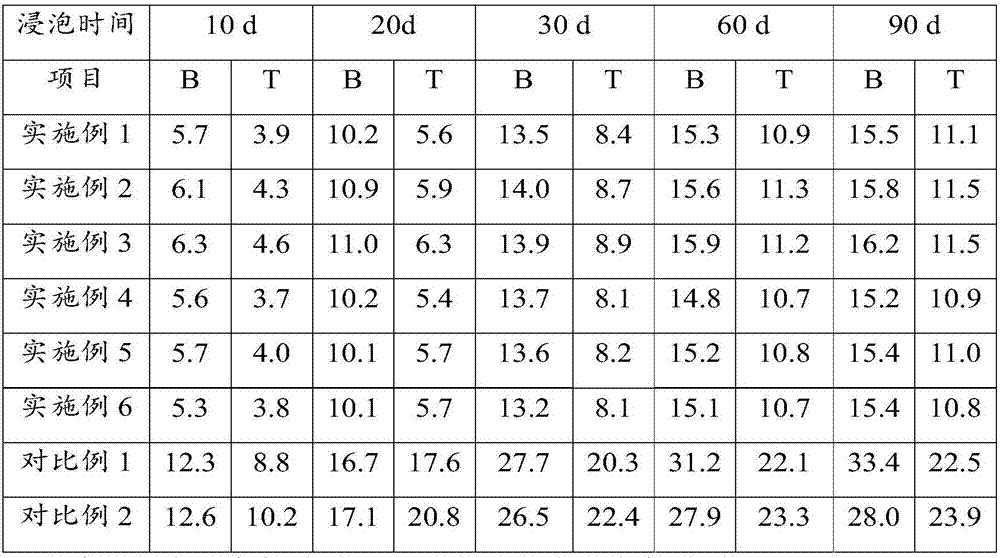

Basalt fiber and glass fiber mixed reinforced resin, as well as preparation method and application thereof

The invention provides basalt fiber and glass fiber mixed reinforced resin, as well as a preparation method and application thereof, and relates to the technical field of composite materials. The preparation method comprises the following steps: adding a coupling agent into a graphene oxide solution to treat mixed fiber consisting of basalt fiber and glass fiber, and carrying out the low temperature plasma process to obtain a modified reinforced material; preparing the basalt fiber and glass fiber mixed reinforced resin from the modified reinforced material and nano-zirconia-blended thermosetting resin through a curing molding process. The preparation method is simple in process; a fiber reinforcing body and resin are both subjected to certain modification treatment, so that the reinforced resin is extremely high in consistency; meanwhile, with the excellent characteristics of the basalt fiber and the glass fiber, the reinforced resin is high in mechanical property and corrosion resistance, can be applied to the field of building materials, and has a good development and application prospect.

Owner:SICHUAN AEROSPACE WU YUAN COMPOSITE

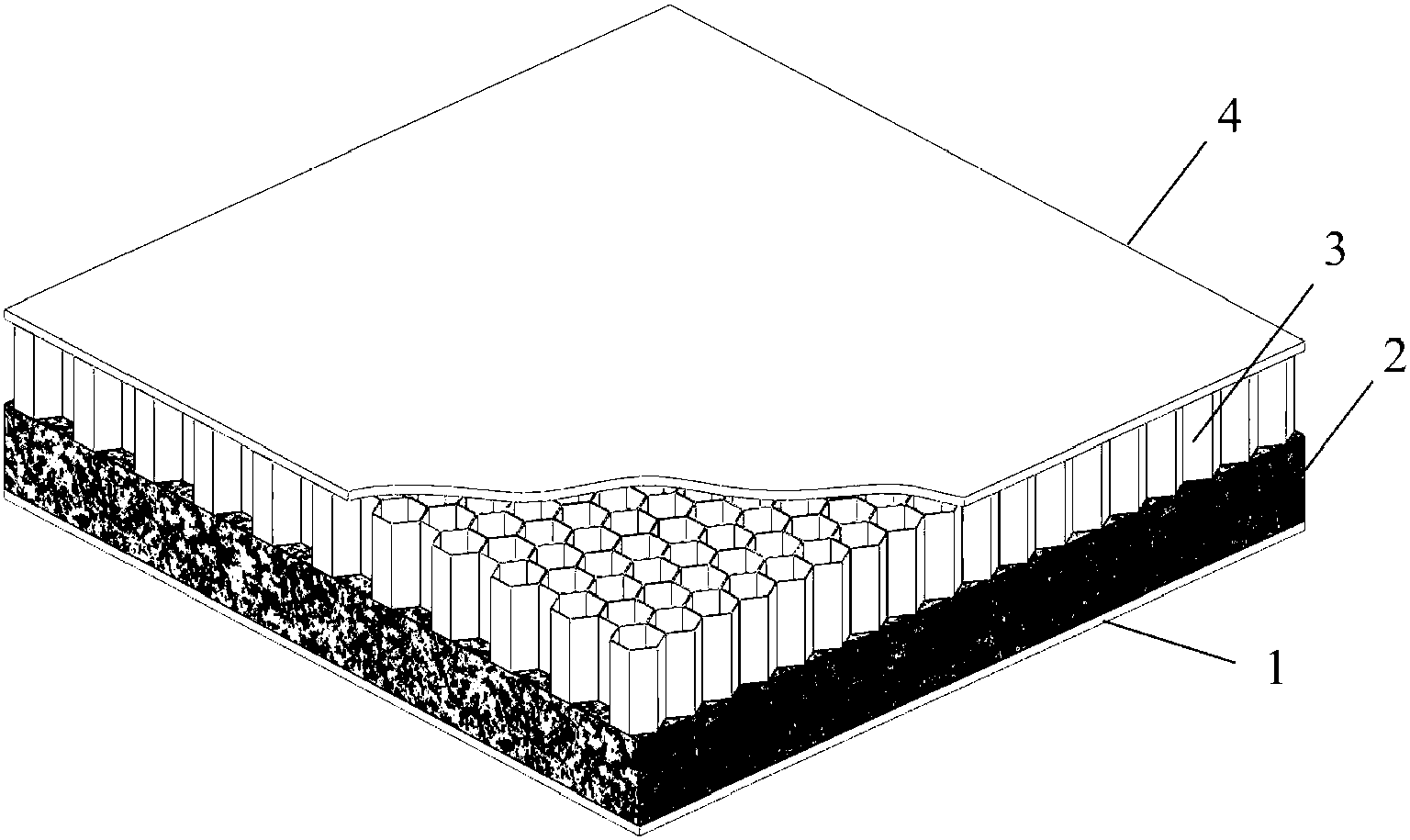

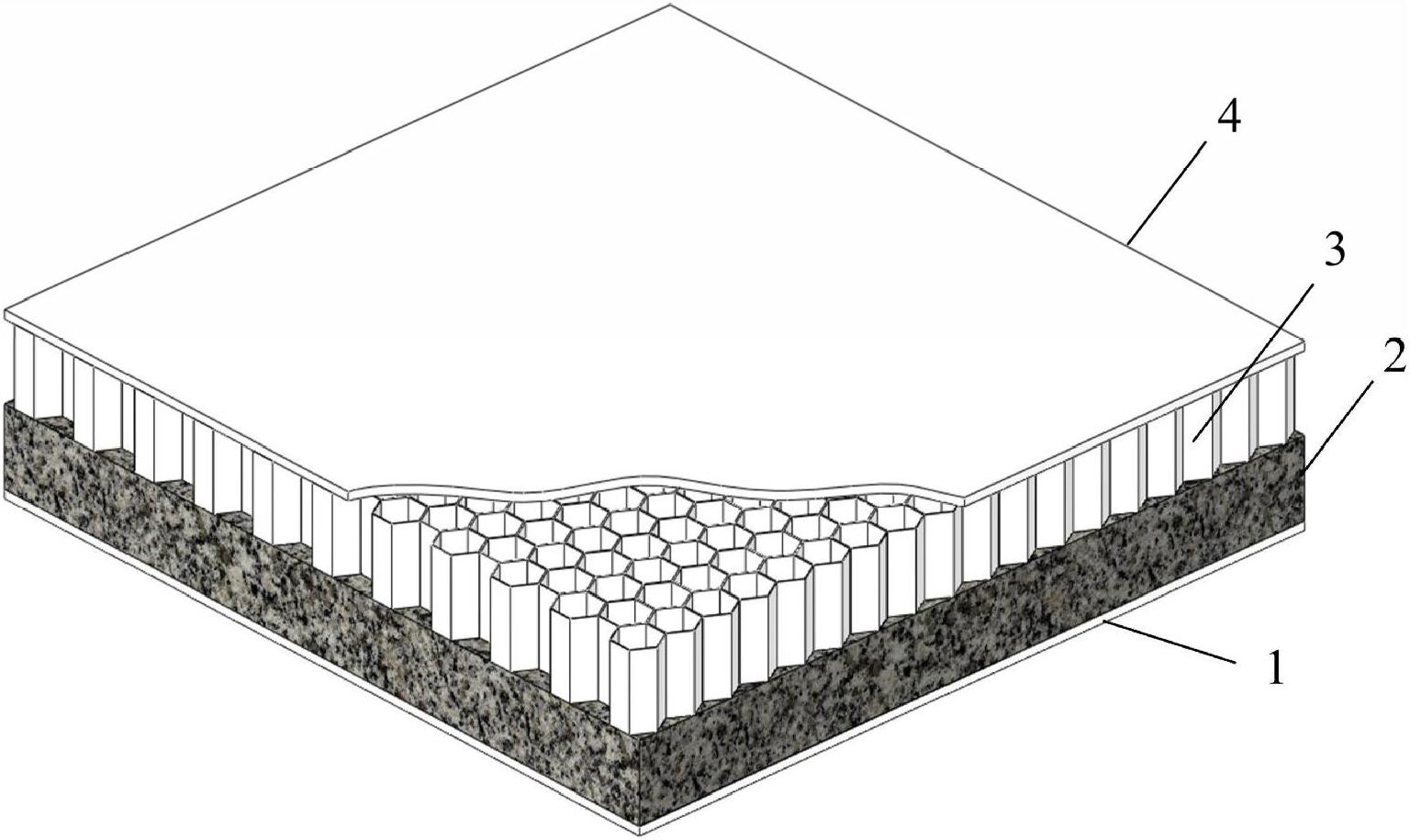

Light multifunctional composite structure

InactiveCN102700181AReduce weightGive full play to excellent performanceMetal layered productsMetallurgyAluminum honeycomb

The invention discloses a light multifunctional composite structure. The composite structure comprises a first outer surface plate, a second surface plate, a metal foam sandwich layer and a honeycomb sandwich layer, wherein the metal foam sandwich layer and the honeycomb sandwich layer are arranged between the first outer surface plate and the second surface plate, and the honeycomb sandwich layer is hexagonal aluminum honeycombs or square aluminum honeycombs. According to the sandwich structure through the composition of metal foams with the hexagonal aluminum honeycombs or the square aluminum honeycombs, the weight can be obviously reduced, and a plurality of functions such as load bearing, sound absorption, sound and heat insulation and shock resistance are provided.

Owner:XI AN JIAOTONG UNIV

Method for producing ramie high grade folded yarn

The method provides a method for producing a ramie high grade folded yarn. The method is characterized by the following steps: blending ramie fiber and water-soluble vinylon to produce a blended yarn with higher courts; folding the obtained blended yarn, removing viylon, washing and drying the obtained blended yarn to produce the ramie high grade folded yarn. By adopting the method, the ramie high grade folded yarn with fineness over 100Nm / 2 can be produced, thereby realizing development of type diversification, thinness and high quality of the ramie high grade folded yarn.

Owner:DONGHUA UNIV

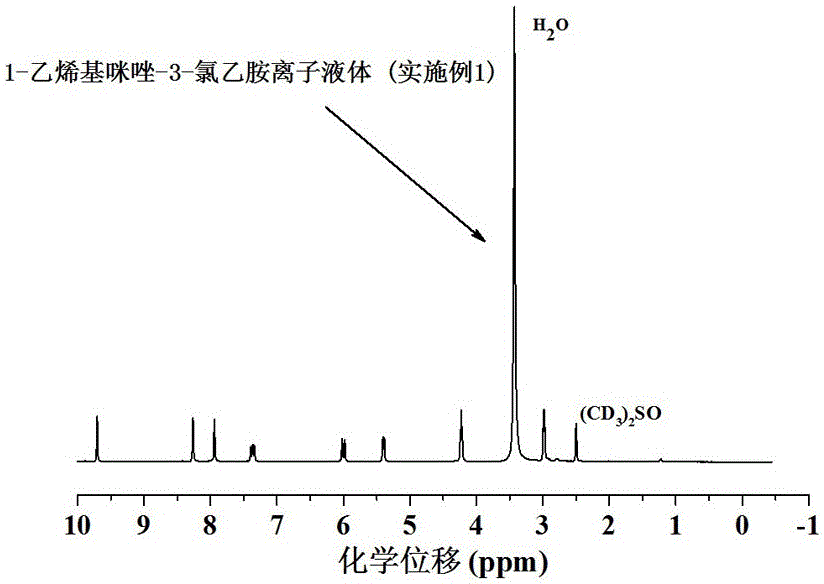

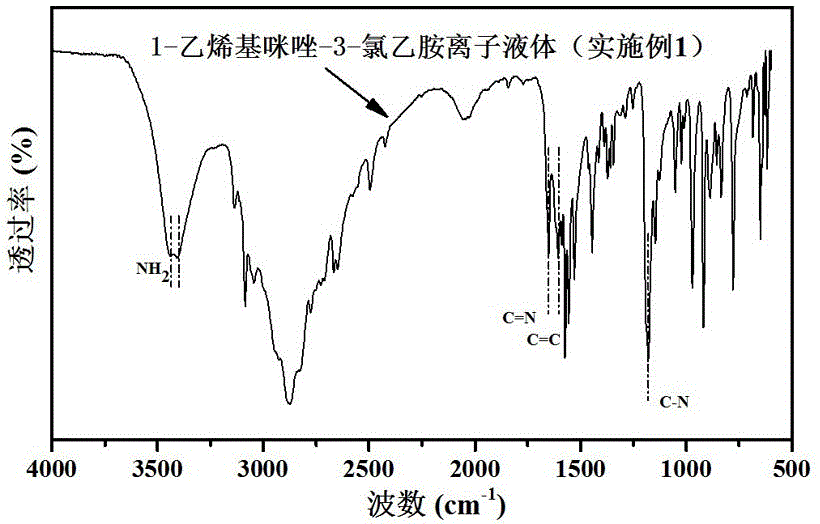

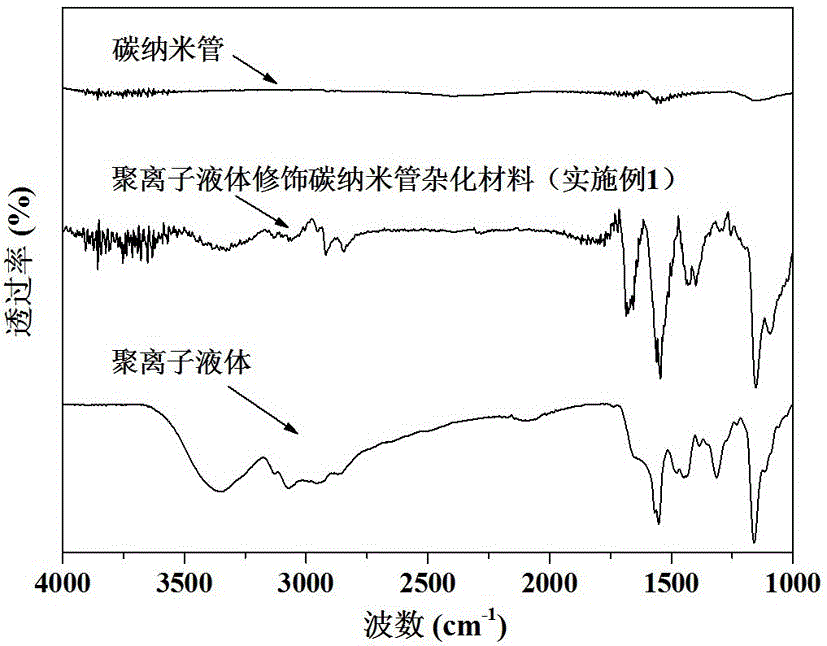

Polyion liquid-modified carbon nano-tube hybrid material and preparation method thereof

The invention discloses a polyion liquid-modified carbon nano-tube hybrid material and a preparation method thereof. The preparation method comprises the following steps: under the protection of nitrogen, mixing and heating vinyl N-heterocycle and 2-chloroethylamine hydrochloride; performing Menshutkin reaction to obtain an ionic liquid hydrochloride; neutralizing to obtain ion liquid monomers; reacting a certain ratio of monomers and a metal salt under a heating condition to obtain an ion liquid which contains an amino end group and a transition metal; dissolving obtained ion liquid in water, adding a fixed amount of carbon nano-tubes, performing ultrasonic dispersing, adding an initiator to perform surface-initiated polymerization, and filtering and drying a product to obtain the polyion liquid-modified carbon nano-tube hybrid material. According to the polyion liquid-modified carbon nano-tube hybrid material and the preparation method thereof, the hybrid material is prepared by coating the carbon nano-tubes with polyion liquid; the hybrid material has toughening and catalyzing functions; the preparation method has the characteristics of simple process and easiness in control.

Owner:SUZHOU UNIV

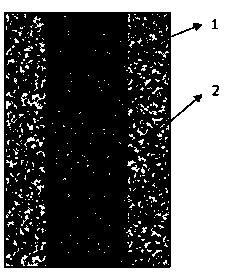

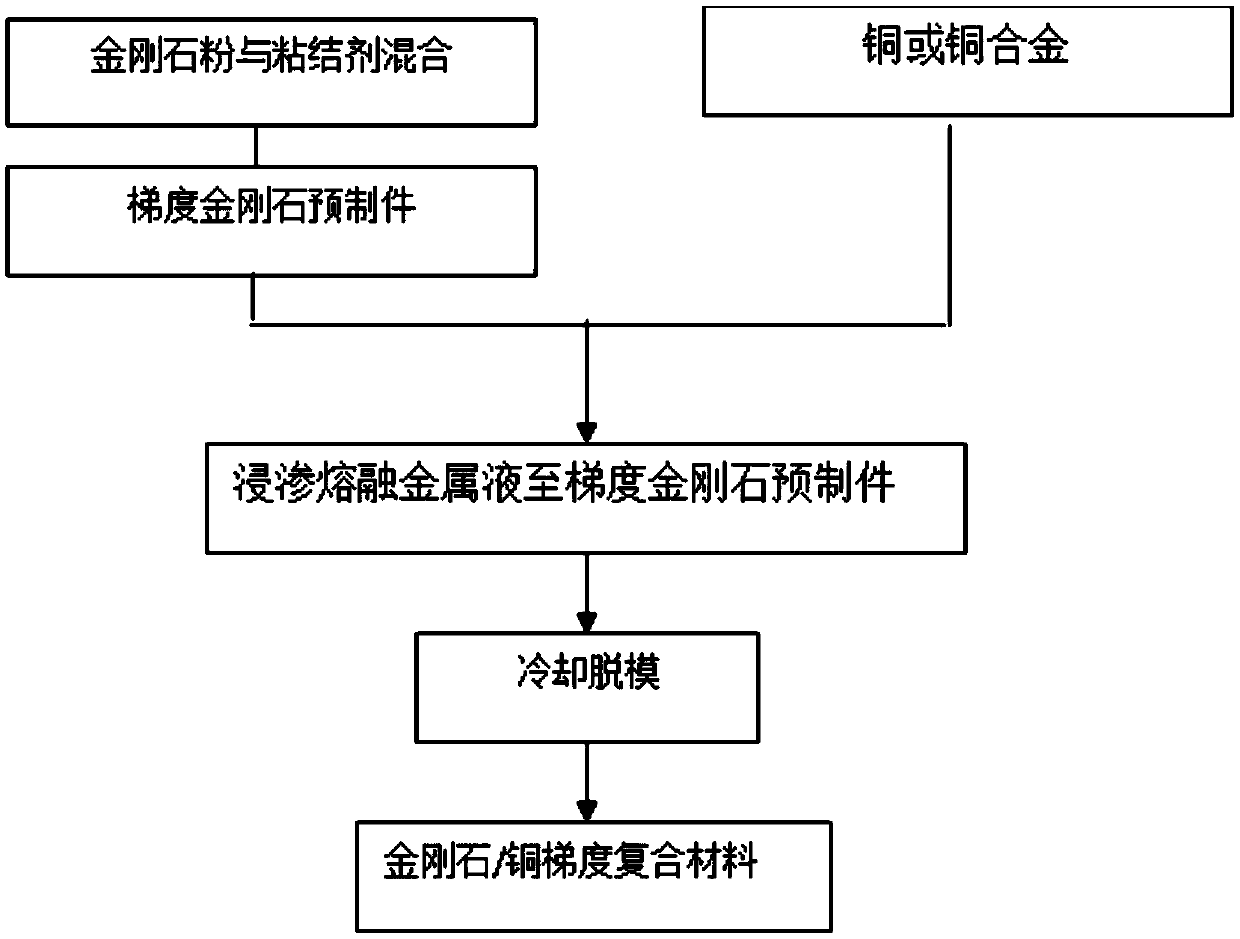

Diamond/copper gradient composite material and preparation method thereof

ActiveCN105506355AGive full play to excellent performanceHigh thermal conductivityElectronElectronics

The invention relates to a diamond / copper gradient composite material and a preparation method thereof. The preparation method comprises the following steps: respectively mixing coarse grain diamond and fine grain diamond with an adhesion agent at first; sequentially flatly laying fine grain diamond-coarse grain diamond-fine grain diamond by a certain thickness in a metal mold, pressing by using a cold pressing technology, demolding, and drying to obtain a gradient diamond preformed unit; and then permeating fused copper or copper alloy in the preformed unit, cooling and demolding and then obtain the diamond / copper gradient composite material. High heat conduction performance of the composite material prepared by coarse grain diamond can be kept, thermal resistance caused by the reason that the roughness of the surface, which is in contact with a chip, of a product is over high can also be reduced, excellent performance of the material is played fully, the technological process is simple, and the prepared diamond / copper gradient composite material can be widely used for electronic packaging devices such as semiconductor lasers and microwave power electronics.

Owner:GRIMAT ENG INST CO LTD

Manufacturing method of fiber reinforced polyethylene composite double-layered tube

InactiveCN105729747AGood photooxidative aging resistanceEasy constructionTubular articlesGlass fiberCarbon fibers

A manufacturing method of a fiber reinforced polyethylene composite double-layered tube comprises following steps: firstly, carbon fibers or glass fibers are cut into short fibers of 5 mm to 9 mm; secondly, the cut short fibers, polyethylene powder and an antioxygen are fully mixed to be extruded out for granulation through a double-screw extruder, and fiber reinforced polyethylene granules are obtained, wherein the polyethylene powder and the antioxygen are evenly mixed; and thirdly, a multi-layer co-extrusion technology is used, polyethylene and the fiber reinforced polyethylene granules in the step (2) are subject to double-layered extrusion, the double layers are combined through heat sealing, and after cooling, the fiber reinforced polyethylene composite double-layered tube is formed.

Owner:PETROCHINA CO LTD

Carbon nanotube composite plastic and preparation method thereof

InactiveCN107746519AEfficient catalytic preparationEvenly distributedCarbon compoundsMaifan StoneCarbon nanotube

The invention provides a carbon nanotube composite plastic and a preparation method thereof, and relates to the field of composite materials. The carbon nanotube composite plastic is formed through processing raw materials comprising a plastic and a carbon nanotube complex. A preparation method of carbon nanotube powder comprises the following steps: allowing a carbon nanotube catalysis element toform nanometer distribution on the surface of maifan stones in order to obtain a catalyst precursor; carrying out high temperature calcination to obtain a catalyst used for producing carbon nanotubes; placing the catalyst in a high temperature device, introducing a mixed gas containing C7 or less organic gases, an inert gas and a reducing gas, controlling the temperature at 500-1200 DEG C, and controlling the air speed of the mixed gas at 0.1-100 h<-1> in order to prepare the carbon nanotube powder. The carbon nanotube complex having an excellent phase connection fully performs the excellentperformances of the carbon nanotubes and the maifan stones and overcomes the disadvantages of the application of existing carbon nanotubes and mainfan stones to the composite plastic when applied to the plastic in the invention.

Owner:哈尔滨金纳科技有限公司

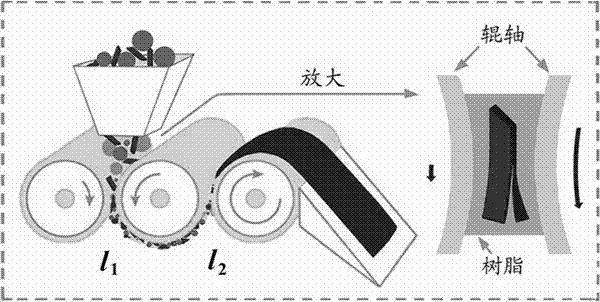

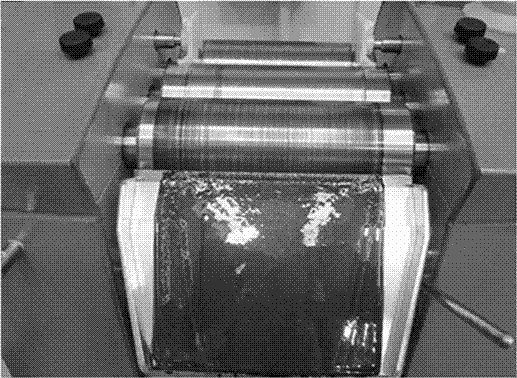

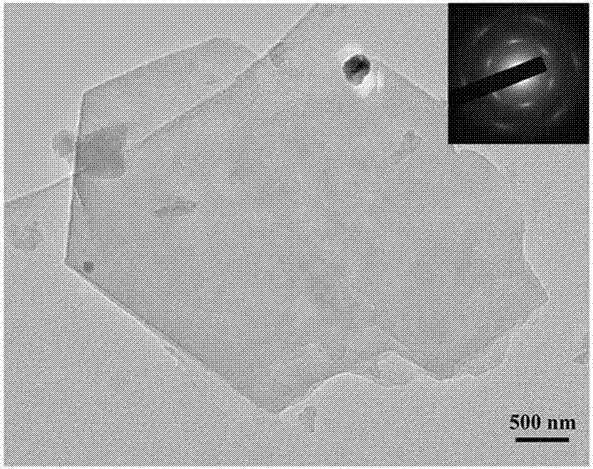

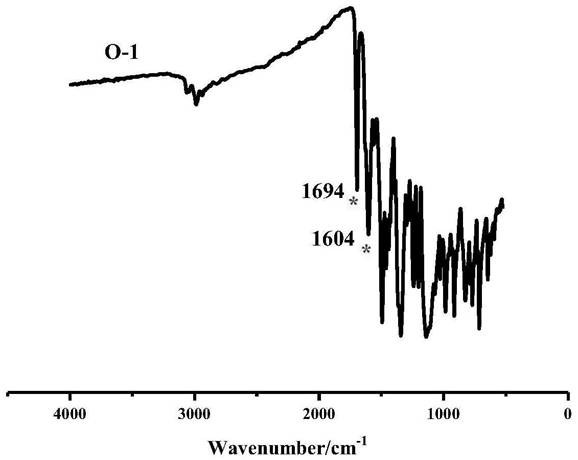

Preparation method of phenolic resin-based micro-nano graphite sheet mixture for carbon-containing fire-refractory material with low carbon content

ActiveCN107011624AGive full play to excellent performanceLarge specific surface areaGrain treatmentsRefractoryGraphite

The invention relates to a preparation method of a phenolic resin-based micro-nano graphite sheet mixture for a carbon-containing fire-refractory material with low carbon content. The preparation method adopts the technical scheme with the following steps of firstly, adding 0.1 to 15wt% of graphite (expanded graphite) raw material into 85 to 99.9wt% of phenolic resin to premix; adding the mixture into a three-roll grinding machine from a material feeding roll, and cyclically stripping by three rolls at differential speed, wherein the speed ratio of the three rolls is 1:3:9, and the gap among the three rolls is 0.1 to 30mu m; after cyclically stripping for 2 to 50 times, collecting the phenolic resin-based micro-nano graphite sheet mixture prepared by the invention from a material discharging roll. The prepared phenolic resin-based micro-nano graphite sheet mixture is mainly used for preparing the carbon-containing fire-refractory material, so that the carbon content is greatly reduced on the basis of maintaining / improving the comprehensive property of the carbon-containing fire-refractory material.

Owner:NANCHANG HANGKONG UNIVERSITY

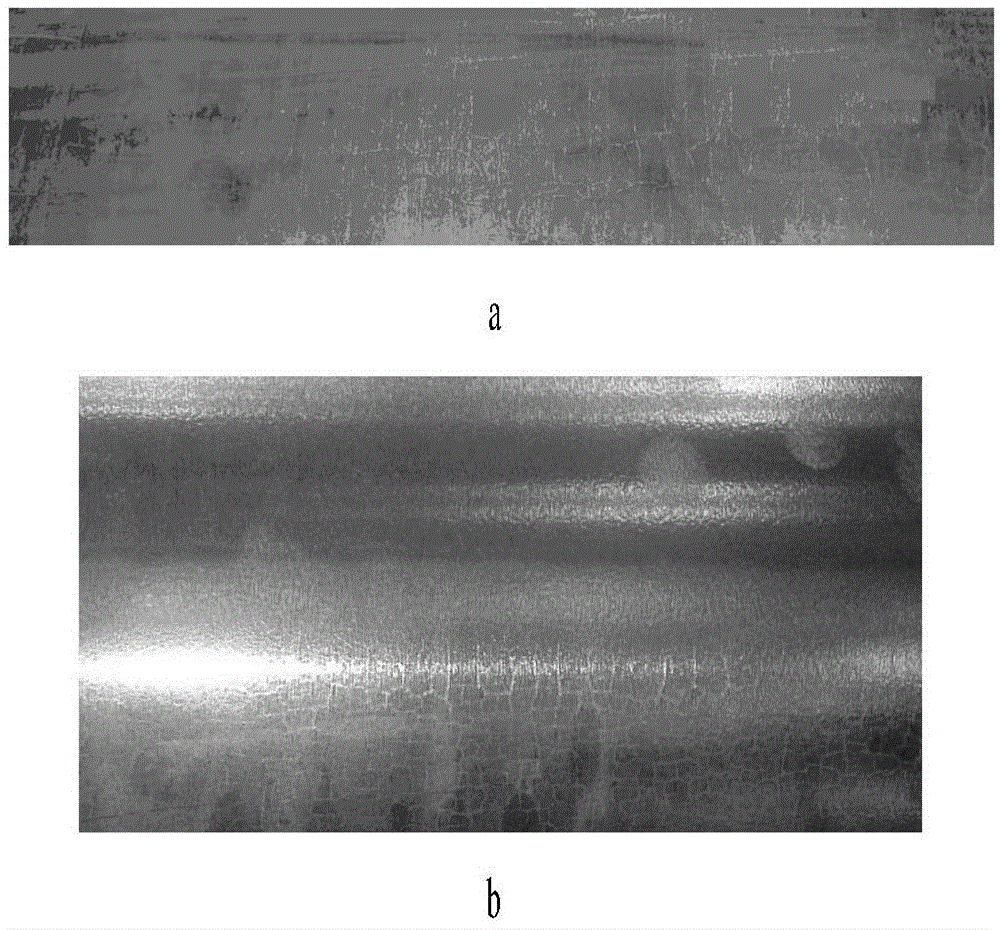

Treatment method of high-speed steel roller surface cracks

InactiveCN104458898AGuarantee product qualityReduce product costAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial magnetic variablesMagnetic particle inspectionCrazing

The invention belongs to the field of hot-rolled roller defect detection, and relates to a treatment method of high-speed steel roller surface cracks. Crack properties are classified through detection of a grinder eddy current flaw detector, and whether cracks are net type hot cracks is determined; shapes of surface cracks are observed through magnetic powder flaw detection to determine whether the cracks are without annular fractures; the determined cracks without the annular fractures are subjected to ultrasonic flaw detection, and whether the inside is in a stable state is determined; and the cracks in an instable state are polished and detected until the cracks are in a stable state. According to the method, various surface cracks can be clearly determined, and inside and outside forms of the cracks can be monitored, so that a correct treatment method can be adopted, and accordingly, a high-speed steel roller is safely used under the condition that part of surface cracks are not required to be cleared.

Owner:BENGANG STEEL PLATES

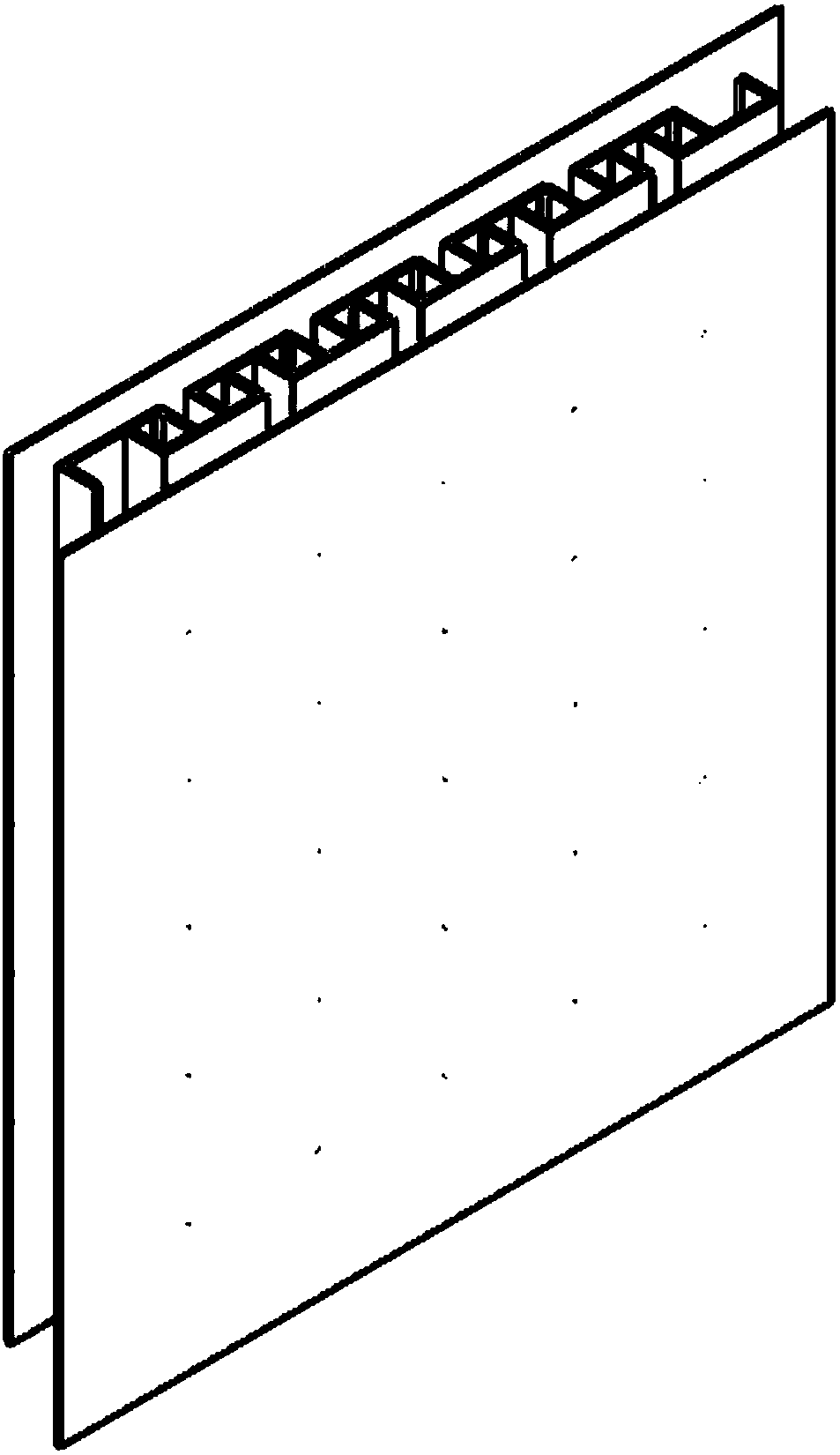

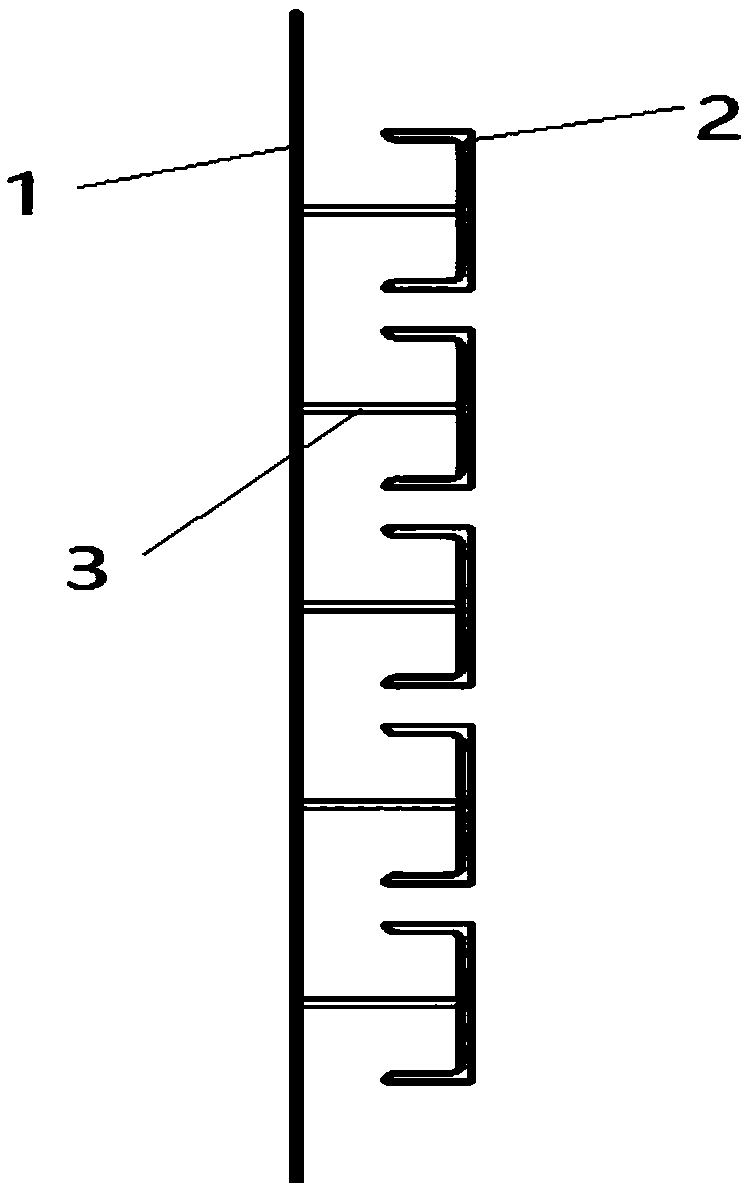

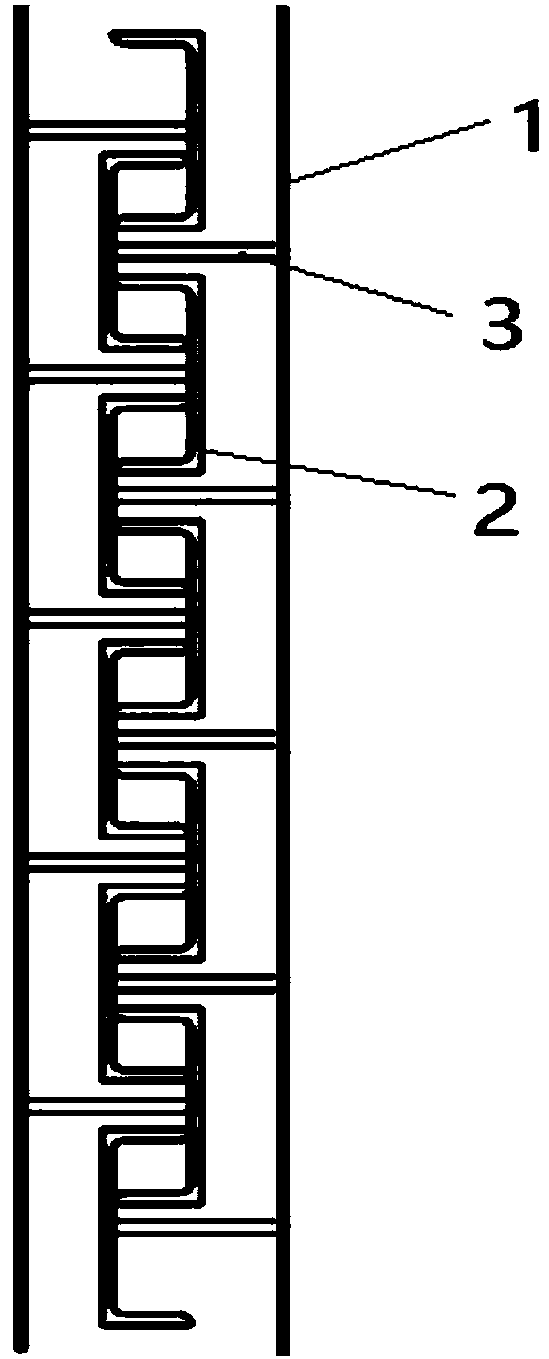

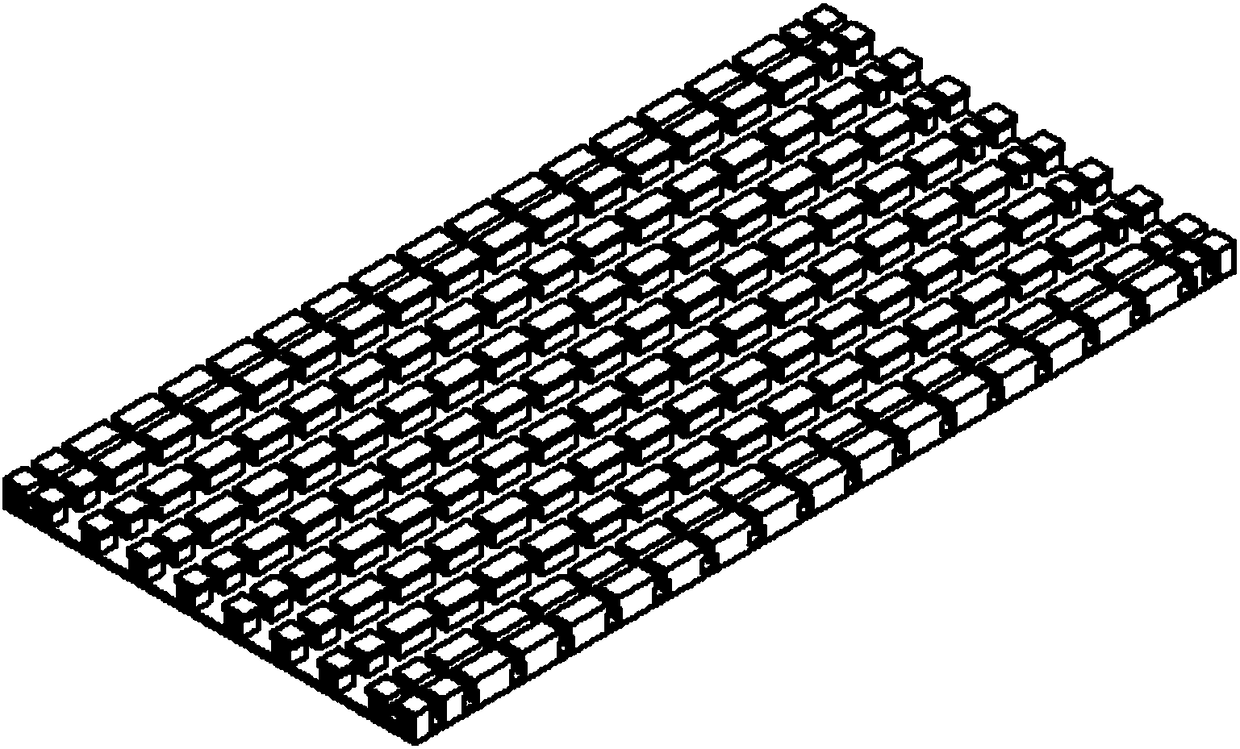

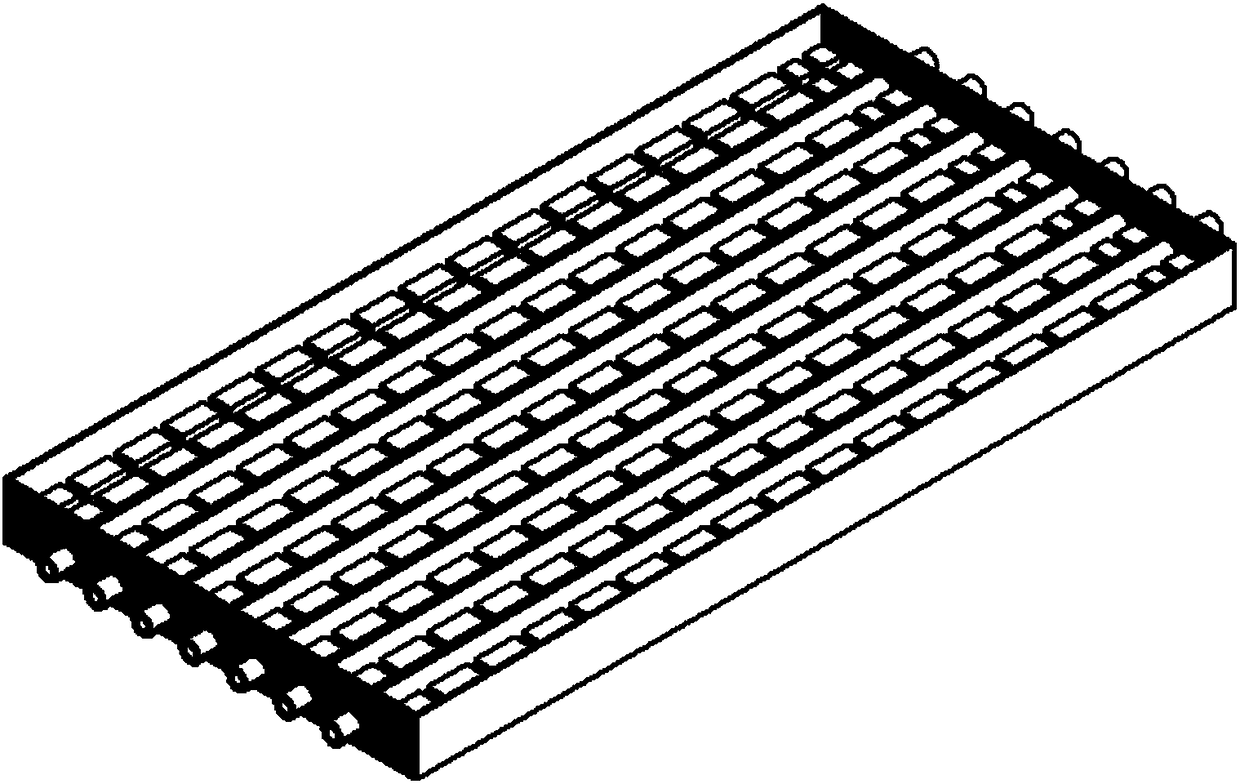

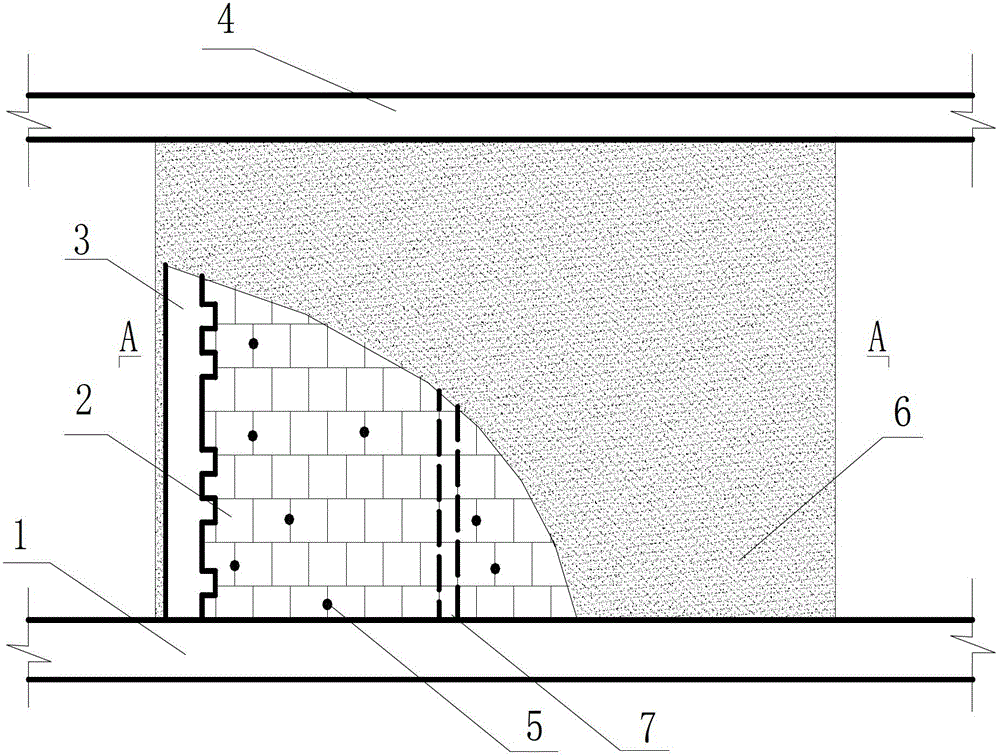

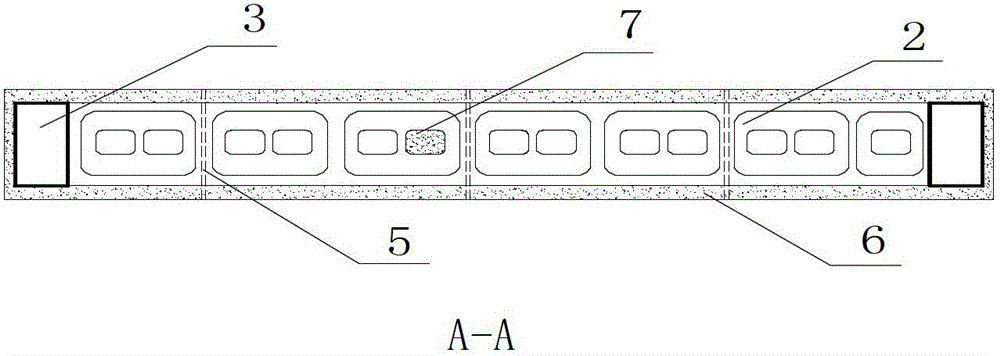

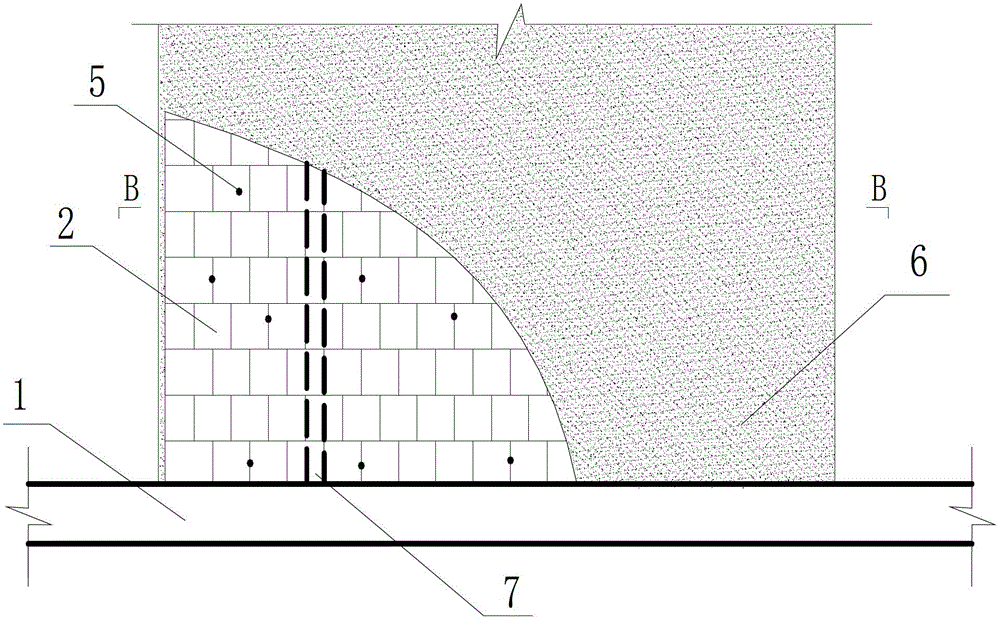

Double-steel-plate connecting component of building double-steel-plate concrete structure

PendingCN107795040AGive full play to excellent performanceSimple structureWallsSheet steelArchitectural engineering

The invention discloses a double-steel-plate connecting component of a building double-steel-plate concrete structure. The double-steel-plate connecting component comprises two steel plates which areoppositely arranged in a spaced mode, a plurality of pieces of box iron are fixed to each steel plate through connecting rods in the left-right direction at intervals and are arranged in the verticaldirection, and the connecting rods are arranged in the horizontal direction and fixedly connected with webs of the pieces of the box iron. The multiple pieces of box iron on the first steel plate andthe multiple pieces of box iron on the second steel plate are staggered, and two wing plates of each piece of box iron on the first steel plate are inserted in grooves of the two corresponding adjacent pieces of box iron on the second steel plate correspondingly and fixedly connected with the webs of the pieces of box iron on the second steel plate. According to the double-steel-plate connecting component, the structure is simple, material obtaining is convenient, machining is easy, construction is easy, the cost is saved, and the excellent performance of the double-steel-plate concrete structure is brought into full play.

Owner:TIANJIN UNIV

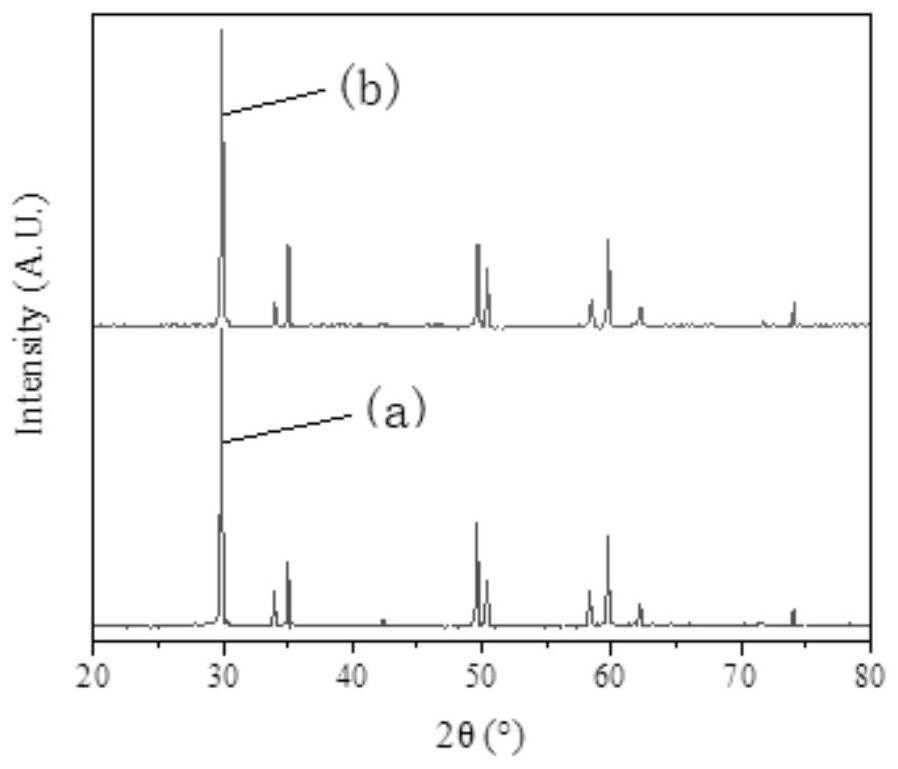

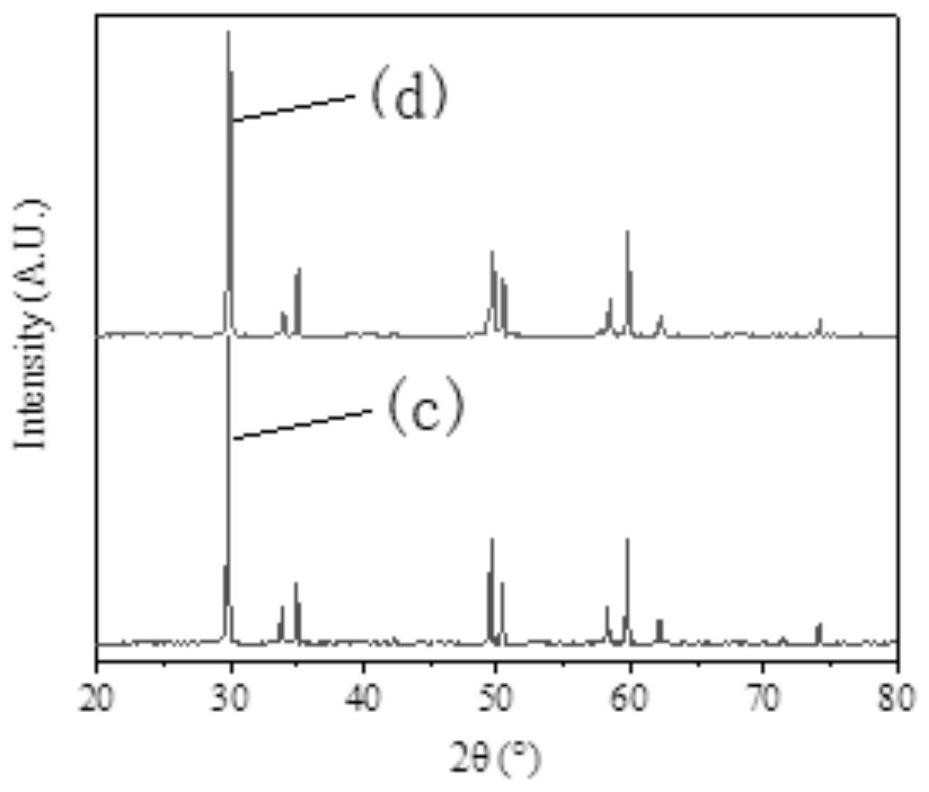

Tetragonal phase thermal barrier coating material and preparation method thereof

ActiveCN114478005AImprove anti-sintering performanceImprove toughnessEfficient propulsion technologiesThermal barrier coatingMaterials science

The invention relates to a tetragonal phase thermal barrier coating material and a preparation method thereof, and belongs to the technical field of thermal protection coatings. The thermal barrier coating material is prepared from the following raw materials: TiO2, Ta2O5, Ln2O3 and ZrO2 according to the mass ratio of (4 to 10): (8 to 10): (8 to 10): (70 to 80), and the Ln2O3 is prepared from Y2O3, Gd2O3 and Yb2O3. The invention further discloses a preparation method of the catalyst. The preparation method comprises the following steps: uniformly mixing dried Y2O3, Gd2O3, Yb2O3, ZrO2, Ta2O5 and TiO2 powder raw materials through ball milling to obtain mixed powder, sintering the mixed powder, and grinding after sintering to obtain sintered powder; and carrying out ball milling and crushing on the sintered powder, and drying. The thermal barrier coating material has good phase stability, fracture toughness and sintering resistance.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

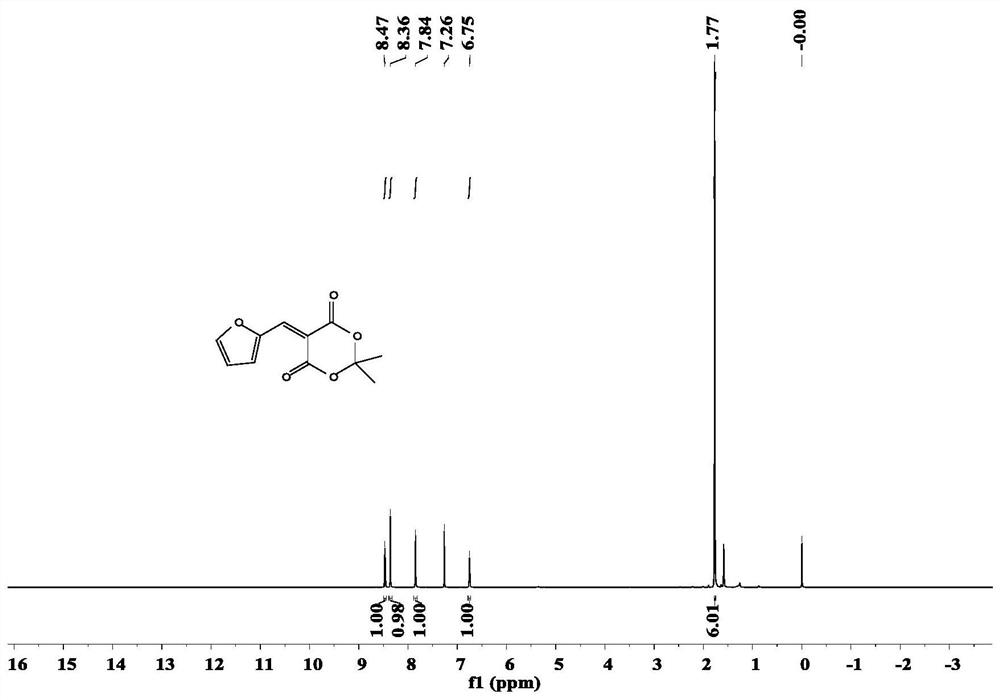

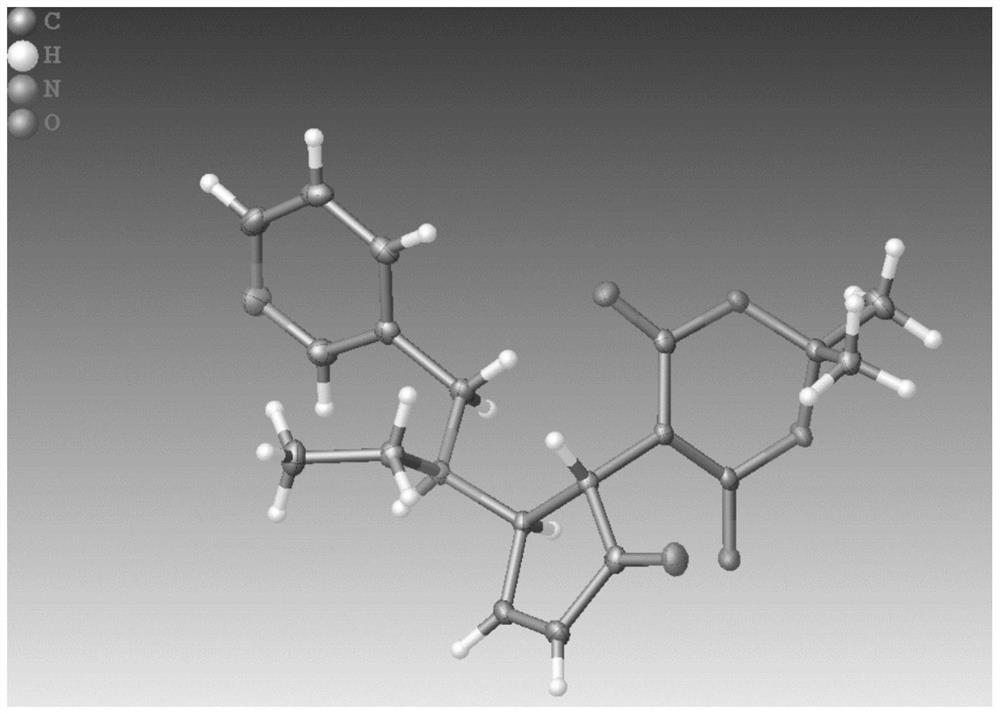

Stenhouse donor-receptor adduct of Meldrum's acid-activated furan and 3-pyridylethylamine, and synthesis method thereof

The invention discloses a Stenhouse donor-receptor adduct (DASA) based on Meldrum's acid activated furan and 3-pyridylethylamine, and a synthesis method of the Stenhouse donor-receptor adduct. The method specifically comprises the following steps: mixing 2-furan formaldehyde and cycloisopropyl malonate to react to synthesize an intermediate, and reacting the intermediate with 3-pyridylethylamine to generate a DASA compound. According to the method, the organic solvent with low toxicity is used for carrying out addition reaction under certain conditions to obtain the DASA compound with high yield and high content, and a catalyst is not needed, so that the production cost is effectively reduced; and the photophysical property test shows that the compound has different performances in different solvents, which indicates that the compound has a wide application range, can satisfy different demands in different fields, and fully exerts the excellent performances of the compound.

Owner:NANJING UNIV OF SCI & TECH

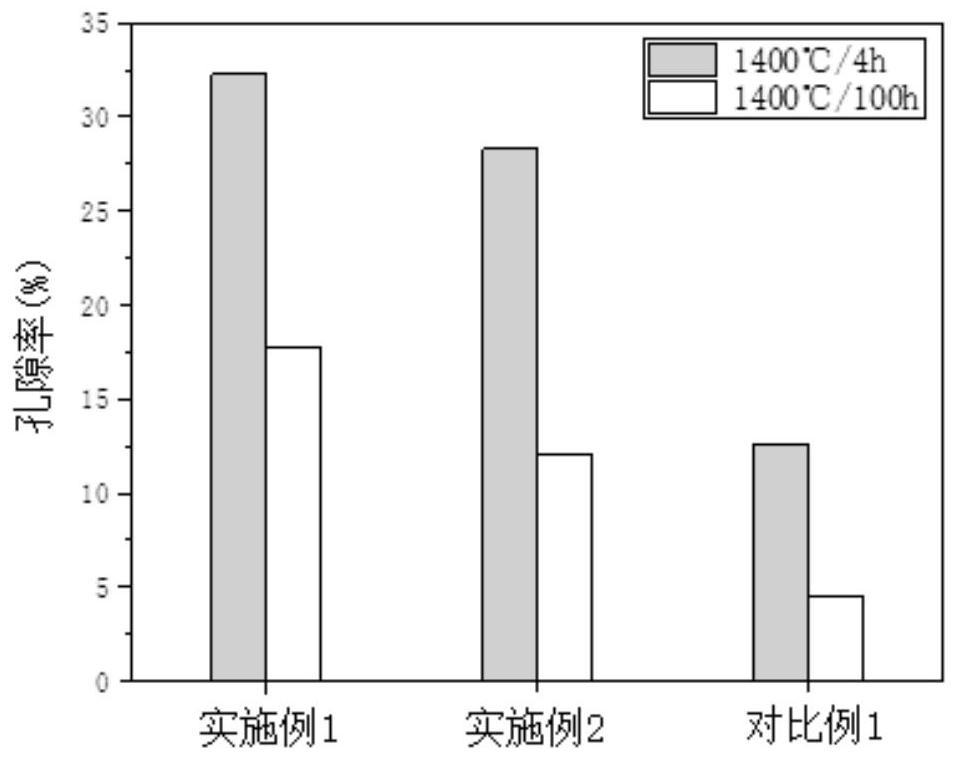

Low-carbon ultra-low-carbon zirconium carbon refractory material for continuous casting submerged nozzle and preparation method of refractory material

The invention discloses a low-carbon ultra-low-carbon zirconium carbon refractory material for a continuous casting submerged nozzle and a preparation method of the refractory material. The preparation method comprises the following steps: mixing a prepared nitrate anhydrous alcohol solution and phenolic resin; then pouring 0.1-6 wt% of scaly carbon thereinto and stirring for mixing; pouring a mixture into a three-roll grinder for performing differential circulating peeling 1-20 times, and collecting from a discharge roller to obtain a resin-based mixture of micro-nano graphite flakes; heating the resin-based mixture in a water bath of 40-90 DEG C for 5-30 min; putting ZrO2 particles and the heated resin-based mixture in a mixing mill for mixing for 3-15 min, finally adding ZrO2 fine powder and an antioxidant for continuous mixing for 4-15 min to prepare pug, and ageing a mixture for 1-24 h; then preparing into green bricks; roasting and curing in a drying kiln at the temperature of 140-300 DEG C for 7-36 h; then performing carbon sequestration treatment at 1300-1600 DEG C for 2-12 h to obtain the refractory material. According to the low-carbon ultra-low-carbon zirconium carbon refractory material disclosed by the invention, carbon content can be substantially reduced on the basis of maintaining / improving the comprehensive property of the ZrO2-C refractory material.

Owner:NANCHANG HANGKONG UNIVERSITY

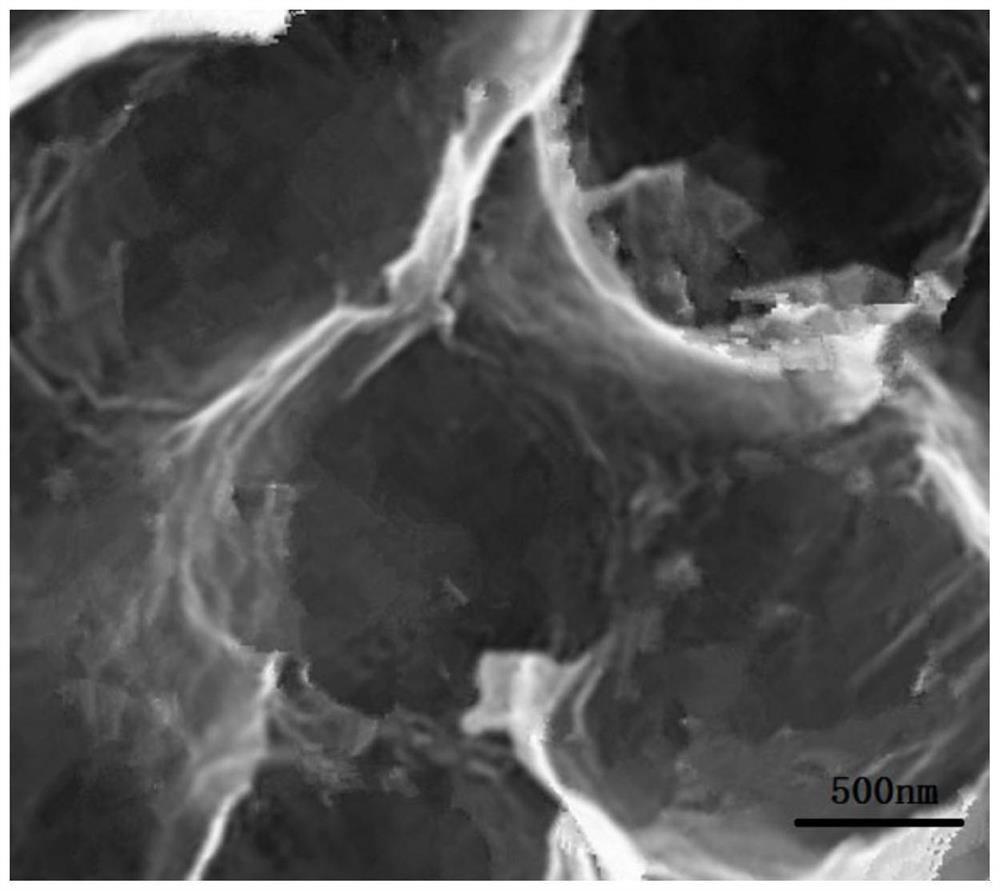

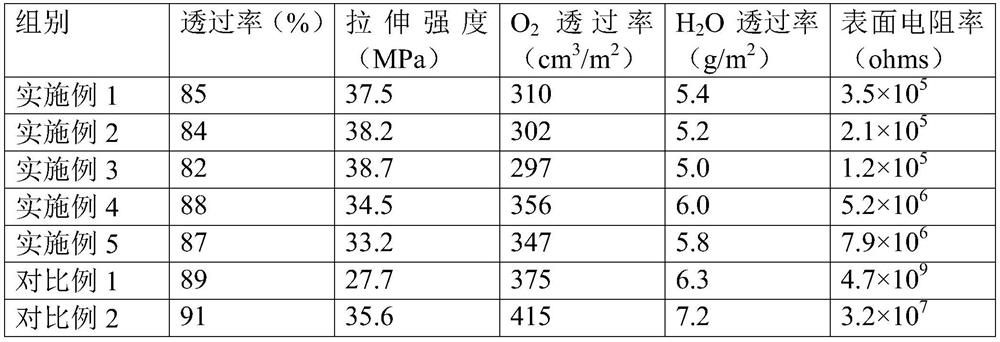

Graphene composite PE material and preparation method thereof

ActiveCN114163712AReduce stackingAvoid reunionCarbon compoundsMechanical properties of carbon nanotubesGraphene

The invention provides a graphene composite PE material and a preparation method thereof, and belongs to the technical field of PE materials. Comprising the following steps: S1, preparing wrinkled graphene oxide; s2, preparing a wrinkled graphene forehead; s3, preparing the modified folded graphene; s4, preparing a premix; and S5, preparing the graphene composite PE material. The graphene composite PE material prepared by the invention has good mechanical property and barrier property, the antistatic property is obviously improved, the dispersion effect of graphene is good, and the graphene composite PE material has a wide application prospect.

Owner:ANHUI LIANJIAXIANG SPECIAL CABLE

A kind of nano cobalt powder slurry and preparation method thereof

InactiveCN102258952AGive full play to excellent performanceImprove performanceMixing methodsPowder mixturePhosphate

The invention discloses a nano cobalt powder slurry. The nano cobalt powder slurry is composed of the following components in parts by weight: 0.5-20 nano cobalt powder, 0.05-3 dispersant, and 85-100 solvent; Wherein the dispersant is anionic alkyl salt, polymer compound, fatty acid, fatty acid salt or alkali metal phosphate, silane coupling agent, titanate coupling agent; the solvent is alcohols, water, ketones , Esters, aliphatic hydrocarbons, alicyclic hydrocarbons, halogenated hydrocarbons, aromatic hydrocarbons. The preparation method comprises the following steps: (1) adding the dispersant into the solvent according to the proportion and stirring evenly; (2) putting the nano-cobalt powder into the above mixed liquid; (3) ultrasonicating for 0.05-0.5 hours; (4) ) ball milling and dispersing for 0.3-1 hour to obtain a finished product. The present invention uses a suitable dispersant to process the nano-cobalt powder, plus the joint action of ultrasound and ball milling, so that the nano-cobalt powder can be highly dispersed in the medium to form a uniform and stable slurry.

Owner:BEIJING NACHEN TECH DEV

Super thermal insulation aerogel composite material and preparation process thereof

ActiveCN111848114AGive full play to excellent performanceGood heat insulationSilicon compoundsCeramicwareCatalytic methodPtru catalyst

The invention discloses a super thermal insulation aerogel composite material and a preparation process thereof, the aerogel composite material is formed by compounding silica aerogel and reinforced foam, the mass ratio of the silica aerogel in the aerogel composite material is 80%-95%, and the reinforced foam is a heat insulation sponge foaming material. The preparation method comprises the stepsof sol preparation, gum dipping aging, hydrophobic modification, drying treatment and the like, a single ammonium fluoride aqueous solution is adopted as a catalyst for sol preparation, one-step catalytic method for sol preparation is achieved, and the used catalyst is an ammonium salt, so that damage to equipment and a human body is avoided. According to the aerogel composite material prepared by the preparation method disclosed by the invention, the mass ratio of the silicon dioxide aerogel is about 80%-95%, the excellent performance of the silicon dioxide aerogel can be fully exerted, theheat insulation performance is excellent, and the compressibility is good.

Owner:航天海鹰(镇江)特种材料有限公司

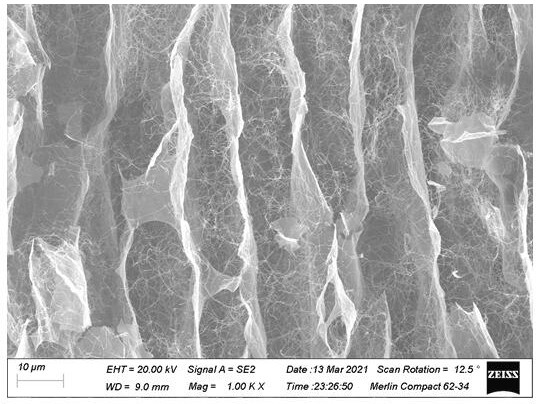

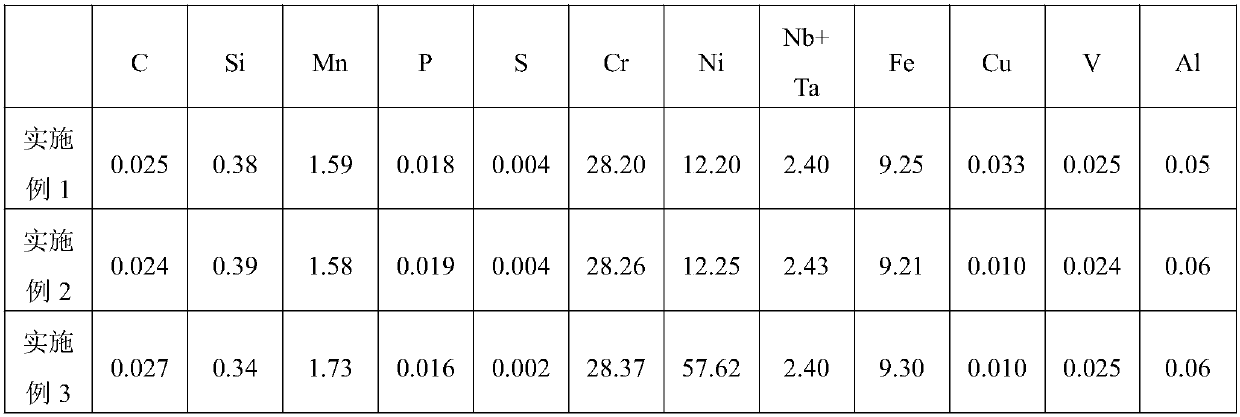

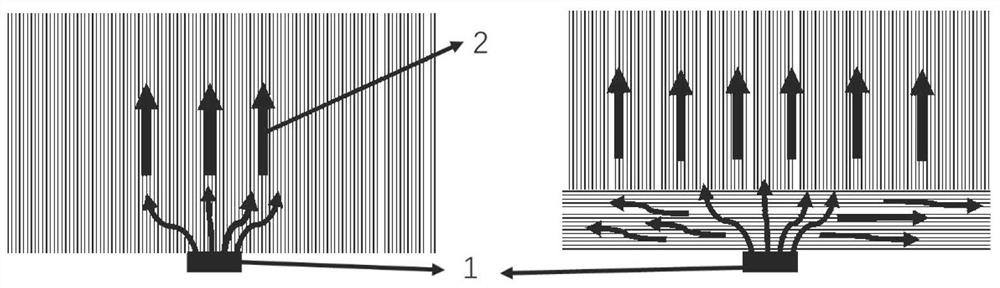

Preparation method of in-situ growth carbon nanotube/graphene composite sponge

InactiveCN113044830AGive full play to excellent performanceImprove conductivityGrapheneCarbon nanotubesCarbon nanotubeGraphene

The invention discloses a preparation method of an in-situ growth carbon nanotube / graphene composite sponge. The method comprises the following steps of 1, preparing an oriented graphene sponge, 2, preparing graphene sponge loaded with nickel nitrate, and 3, preparing the carbon nanotube / graphene composite sponge. A chemical vapor deposition method is adopted for in-situ growth of carbon nanotubes in oriented graphene sponge pores, such that the carbon nanotube / graphene composite sponge is obtained. Compared with the prior art, the method for preparing the carbon nanotube / graphene composite sponge has the advantages that the chemical vapor deposition method can regulate and control the morphology of the carbon nanotube by adjusting the nickel nitrate concentration and the vapor deposition time, so that the internal structure of the composite sponge is adjusted, different use requirements are met, and the application range of the composite sponge is expanded. Meanwhile, the in-situ grown carbon nanotubes not only improve the conductivity of the composite sponge, but also improve the mechanical properties of the composite sponge.

Owner:深圳烯创先进材料研究院有限公司

Manufacturing method of heat exchanger based on combination of vacuum hot melting and explosion cladding

The invention discloses a manufacturing method of a heat exchanger based on combination of vacuum hot melting and explosion cladding. The method comprises the steps that a tungsten plate with a certain groove profile is selected to be used as a substrate, and micro-machining is carried out on the groove profile according to requirements; the interface of the tungsten plate is cleaned up, a stainless steel pipe is preset at a certain position of the tungsten plate, and the tungsten plate is placed in a specially-made mold; a copper block or a copper plate used for covering the plate is placed on the tungsten plate and the stainless steel pipe, the copper block or copper plate, the tungsten plate and the stainless steel pipe are put into a vacuum high-temperature furnace together, when the temperature is heated to 1083.4 DEG C-1300 DEG C, copper is fully melted, while both the stainless steel pipe and tungsten are not melted; part of the molten copper flows into the tungsten groove, thestainless steel pipe is immersed at the same time, and under the mechanical action of the high-temperature liquid and the mechanical action of the groove profile, preliminary compositing of cover plate copper and substrate tungsten is achieved; the material is taken out from the vacuum high-temperature furnace after cooling; the stainless steel pipe is removed according to the size of the preset stainless steel pipe, and a heat exchange channel of the heat exchanger is formed; and hole expansion is carried out by using an explosive cladding method, and explosion fiber is inserted into the channel for explosion so as to enable the copper to be tightly cooperated with the tungsten.

Owner:UNIV OF SCI & TECH OF CHINA

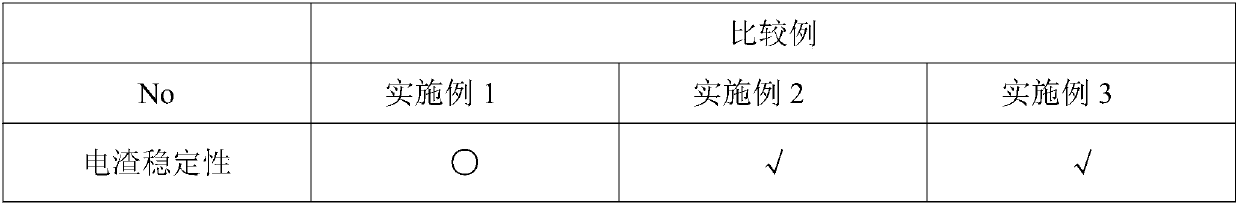

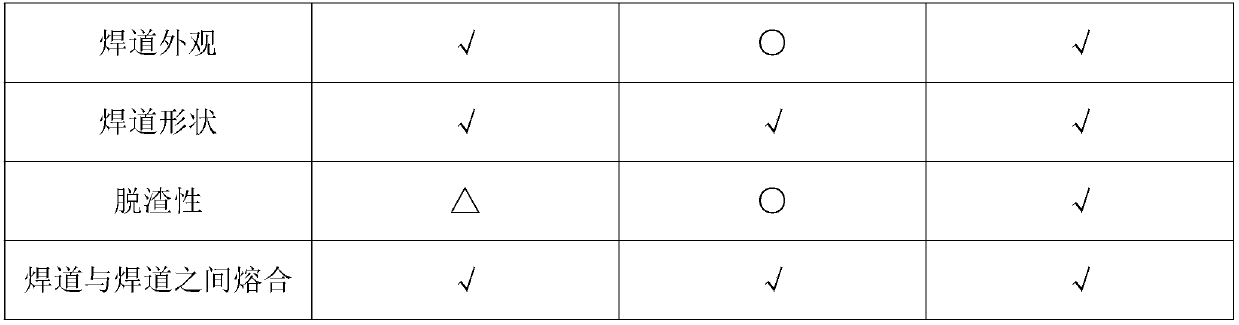

Sintered flux for EQNiCrFe-7 strip surfacing matching and preparation method thereof

ActiveCN107900557AFulfil requirementsSimple processWelding/cutting media/materialsSoldering mediaWelding defectWeld line

The invention discloses a sintered flux for EQNiCrFe-7 strip surfacing matching and a preparation method thereof. The flux is prepared from the following components: 6.0 to 10.0 weight parts of SiO2,1.0 to 3.0 weight parts of MgO, 25.0 to 35.0 weight parts of Al2O3, 25.0 to 40.0 weight parts of Caf2, 2.0 to 4.0 weight parts of CaO, 5.0 to 7.5 weight parts of MnO, 7.0 to 9.0 weight parts of NiO, 6.0 to 9.0 weight parts of Cr2O3 and 4.0 to 6.0 weight parts of Nb2O5. During welding, the sintered flux is stable in welding process; welding beads and a base metal as well as one welding bead and another welding bead are well fused; deslagging is facilitated; the surfaces of the welding beads are attractive, and welding lines have tidy edges; and no welding defects such as undercut, pores and cracks occur.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

Epoxy resin with modified organic silicon

The invention provides epoxy resin with modified organic silicon. The main purpose by using organic silicon for modification is to increase toughness and reduce internal stress of the epoxy resin. Toughening effect of the epoxy resin with organic silicon added in depends on phase domain size and distribution of a second phase in an epoxy resin system, and further self features, system solidifying conditions and the like are important factors affecting the toughening effect. In order to obtain the optimum toughening effect, two standards should be met: toughening agent or modifying agent initially can be dissolved in the resin and precipitates to form dispersed phase particles before gel coagulating; and resin matrix should have high-degree plastic ductility, and cross-linking density, rigidity of curing agent, functionality degree and the modifying agent should be appropriate. In addition, forming of a cross-linked structure of the epoxy resin is affected by various factors and determines performance of cured matters. The cross-linking density is a most frequently-used parameter for indicating physical performance of the modified resin, the toughening effect is directly related with the cross-linking density, and the higher the cross-linking density of the epoxy resin is, the higher glass transition temperature is and the larger the toughening difficulty is.

Owner:徐孝华

Three-dimensional structure graphene composite intermediate layer assisted brazing method

ActiveCN104625283BEasy to operateGood repeatabilitySoldering apparatusChemical vapor deposition coatingGas phaseFiller metal

Owner:HARBIN INST OF TECH

Chitin silk fabric and processing technology thereof

ActiveCN112553927ABrightly dyedHigh color fastnessTextile/flexible product manufactureBiochemical treatment with enzymes/microorganismsPolymer sciencePolymer chemistry

The invention provides a chitin silk fabric and a processing technology thereof. The processing technology comprises the following steps that S1, spinning is conducted, specifically, 40%-60% of tenceland 40%-60% of chitin fibers are blended to serve as weft yarns; and mulberry silk fibers are used as warp yarns; S2, weaving is conducted; S3, dyeing is conducted, specifically, a treatment solutionis added for pretreatment, a leveling agent is added for dyeing, and a color fixing agent is added for color fixation; and S4, fabric after-treatment is conducted. According to the processing method,the chitin fibers and the tencel fibers are blended and then woven with the mulberry silk, and the obtained fabric has the softness of the real silk, the strength is improved, and the antibacterial effect is achieved.

Owner:那坡同益新丝绸科技实业有限公司

Magnetic liquid based on oxidation-resistant alpha olefin synthetic oil and preparation method thereof

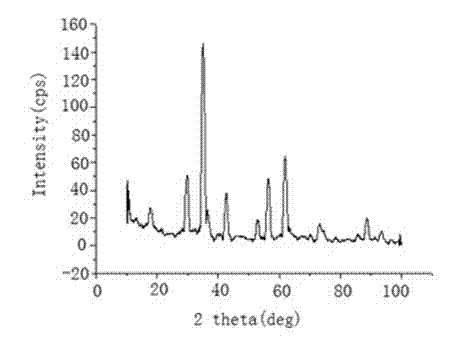

InactiveCN103177839AStrong oxidation abilityStrong magnetic propertiesMagnetic liquidsOxidation resistantMagnetic liquids

The invention relates to the field of nanoscale science and technology, and discloses magnetic liquid based on oxidation-resistant alpha olefin synthetic oil and a preparation method of the magnetic liquid based on the oxidation-resistant alpha olefin synthetic oil. The magnetic liquid comprises magnetic nano-particles, surfactants and carrier liquid, and is characterized in that the magnetic nano-particles are ferrite-class magnetic particles DxM1-xFe2O4, wherein the D and the M are Co, Mn, Ni, Mg or Zn, and x=0-1, and the carrier liquid is the alpha olefin synthetic oil or mixed oil with the alpha olefin synthetic oil and other basic oil. According to the magnetic liquid based on the oxidation-resistant alpha olefin synthetic oil and the preparation method of the magnetic liquid based on the oxidation-resistant alpha olefin synthetic oil, the DxM1-xFe2O4 magenetic particles are small in particle diameter, overcome the defects that existing magnetic liquid is poor in oxidation resistance and stability, and the like, are good in oxidation resistance, good in modification effect, and are capable of being dispersed in the carrier liquid, and good magnetic performance can be kept for a long time under a high-temperature environment. The preparation method of the magnetic liquid based on the oxidation-resistant alpha olefin synthetic oil is simple in operation, high in production efficiency, and low in requirement on equipment, and has good application prospects.

Owner:SUN YAT SEN UNIV

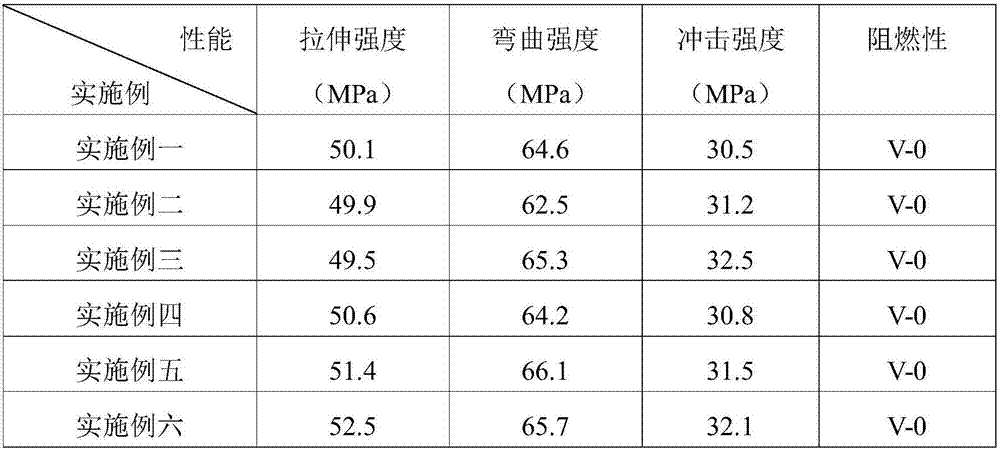

ABS composite material and preparation method thereof

InactiveCN107383758AGive full play to excellent performanceGuaranteed excellenceGlass fiberFire retardant

The invention discloses an ABS composite material. The ABS composite material comprises ABS resin, a fire retardant, long glass fiber, nano alpha-Al2O3, nanometer titania, polyethylene wax, a toughening agent, an antioxygen, a lubricating agent and a compatilizer. The invention further discloses a preparation method of the ABS composite material. The preparation method includes: sequentially weighing the components before drying treatment; adding the ABS resin, the fire retardant, the nano alpha-Al2O3, the nanometer titania, the polyethylene wax, the toughening agent, the antioxygen, the lubricating agent and the compatilizer which are dried into a high-speed mixing machine for high-speed mixing; adding the raw materials mixed at the high speed in the step 2 into a twin-screw extruder for melt extrusion, adding the long glass fiber dried in the step 1 into a die head for infiltration coating prior to cooling, pulling and pelletizing to obtain the ABS composite material. The ABS composite material disclosed is high in intensity, good in wear resistance and toughness, low in cost, free of pollution and environment friendly.

Owner:广州湘融新材料科技有限公司

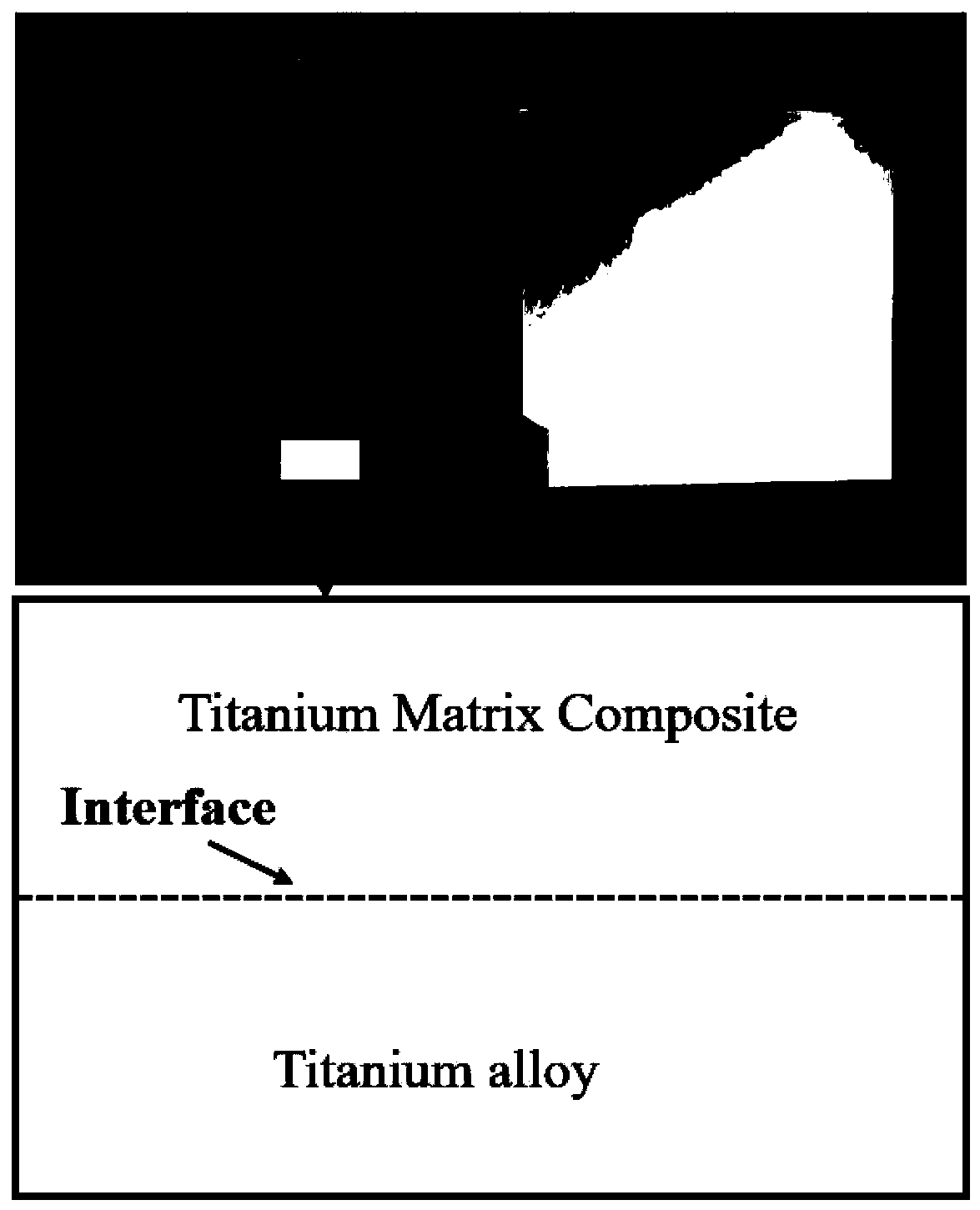

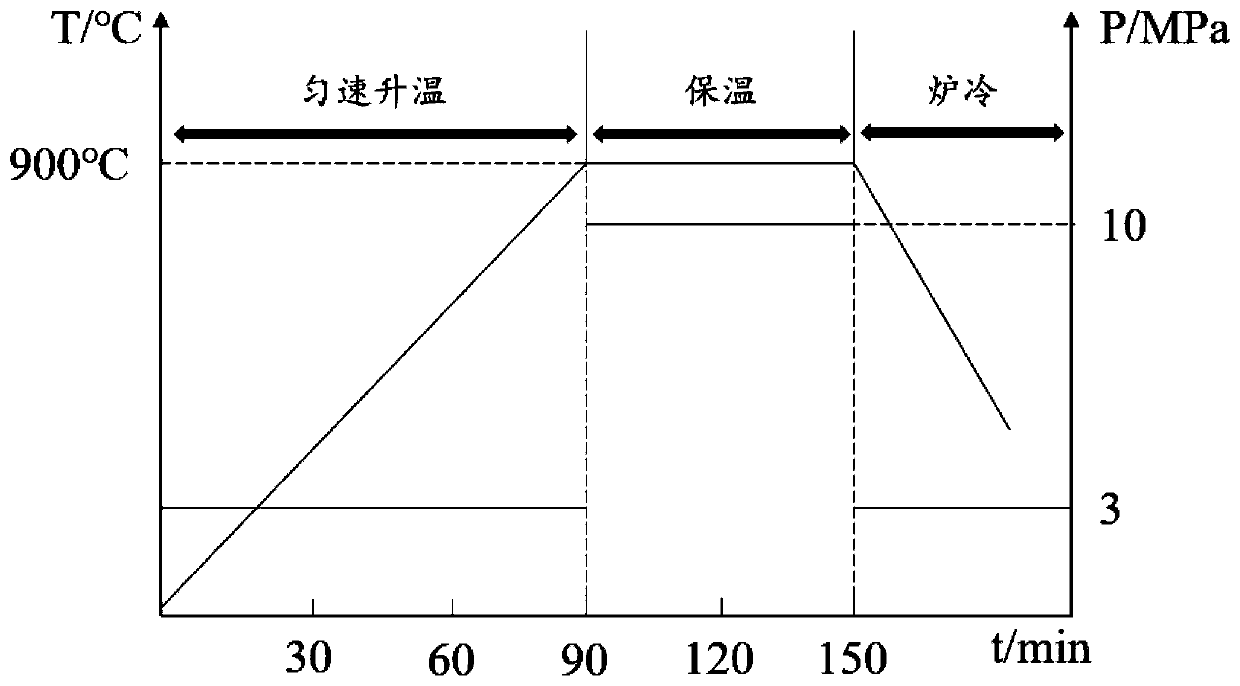

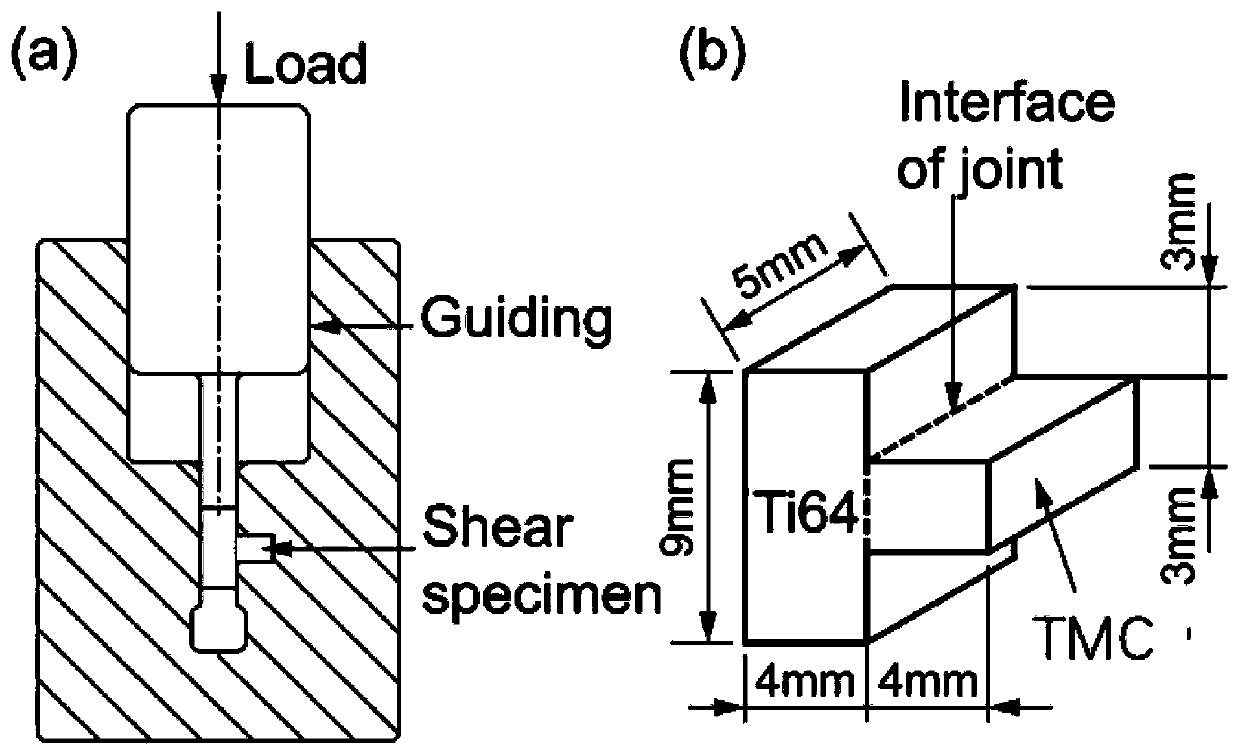

In-situ synthesized titanium-based composite material composite laminated component, and preparation method and application thereof

ActiveCN111590997AReduce oxidationGood connectionLamination ancillary operationsLaminationPlastic propertySurface preparation

The invention discloses a preparation method of an in-situ synthesized titanium-based composite material composite laminated component, and relates to the field of metal-based composite materials. Themethod comprises the following steps: A, carrying out linear cutting machining on a titanium alloy base material and a titanium-based composite material plate sample; B, performing surface treatmenton the plate sample; C, tightly attaching at least one layer of the titanium alloy base material and at least one layer of the titanium-based composite material plate sample to obtain a composite plate component, and coating the surface of the composite plate component with a BN solution, putting the coated component into a pressure mold, and fixing; and D, carrying out heat insulation on the composite board component at 850-950 DEG C under 5-15 MPa for 0.5-1.5 h to obtain the titanium-based composite material double-layer board or multi-layer board component without the interface cavity defect. The interface shear strength of the composite component is 640-670 MPa, the composite component has good strength and plasticity, a new solution is provided for machining of the high-strength-and-toughness titanium-based composite component, and the composite component has far-reaching strategic significance in preparation of the ultrahigh-strength multi-layer composite component.

Owner:SHANGHAI JIAO TONG UNIV

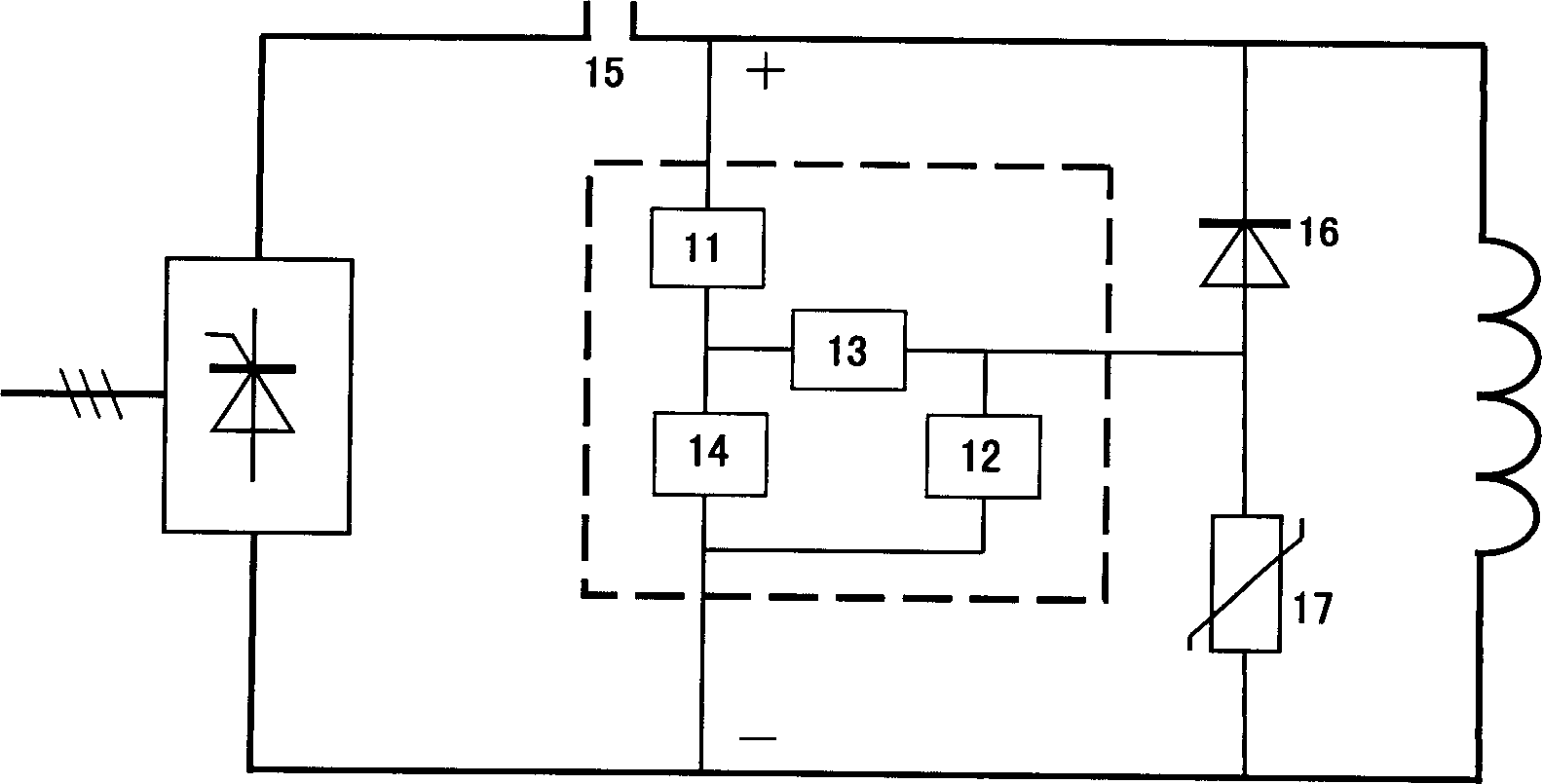

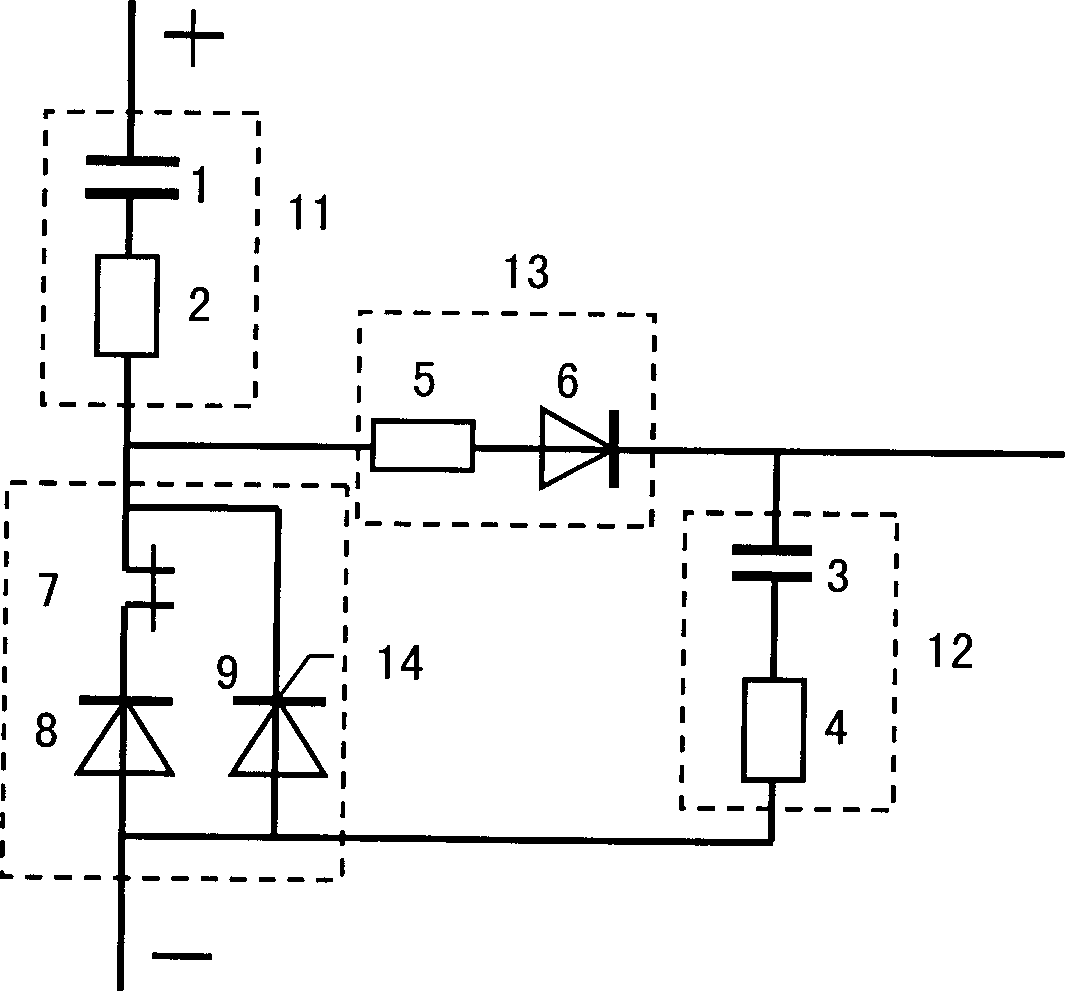

Passive zero breaking automatic de-excitation device and method

ActiveCN1829028ABreakthrough capacityBreaking through the limiting bottleneck of interdiction capabilityEmergency protective circuit arrangementsOvervoltageElectrical resistance and conductance

The present invention discloses passive zero on / off automatic excitation cut-off device and method. Said invention utilize passive electric power electronic device assembling plurality of function group to form topology network connection, providing powerful absorbing harmonic overvoltage function, once receiving demagnetization instruction, double starting up function group action, switching-on function discharging channel, function group rapid discharging transferring magnetic field current, reverse charging establishing voltage to conduct demagnetization resistor to complete demagnetization. Said invention can greatly improve demagnetization performance and save cost by more than 50 per cent.

Owner:CHINA YANGTZE POWER

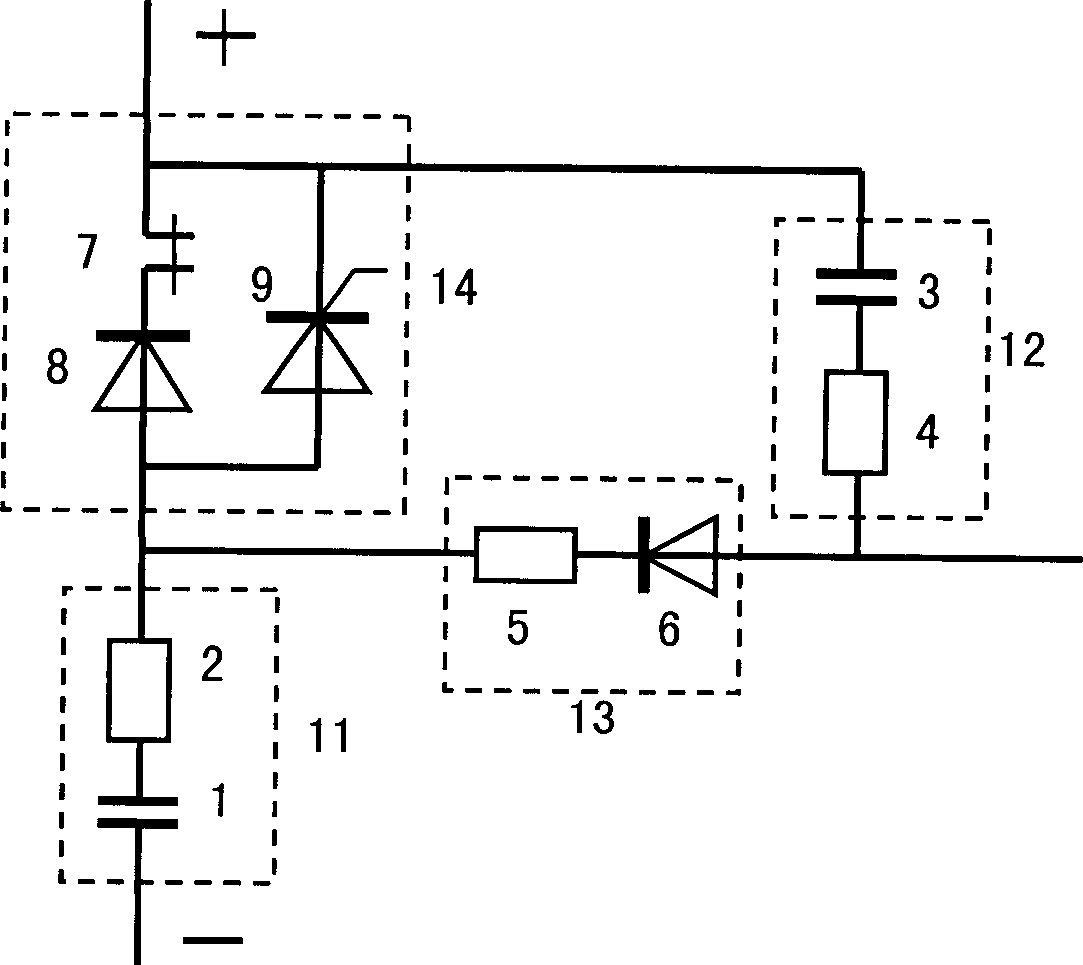

Construction method of graphene-based thermal interface material with mutually vertical structure

InactiveCN112477181AAvoid Routine Freeze DryingEasy to manufactureGrapheneHeat managementGraphene flake

The invention discloses a construction method of a graphene-based thermal interface material with a mutually vertical structure. According to the construction method, in order to realize mutually vertical arrangement of graphene sheet layers, a temperature gradient is introduced by utilizing one-way freezing of a flat plate, under the driving action of the temperature gradient, the height directional arrangement of graphene sheets in the vertical direction can be achieved, wherein the pre-reduced graphene hydrogel forms a bottom parallel structure under the induction of gravity and the bottomof a container, the upper part of the pre-reduced graphene hydrogel is vertically arranged, and a directional structure with the parallel bottom and the vertical upper part is kept under the subsequent reduction. The graphene macroscopic body prepared by the method has a special directional structure with the parallel bottom and the vertical upper part, can fully exert excellent performance of graphene in a plane direction, solves the problems of local hot spots and heat conduction at an interface, and can be used as a thermal interface material to be applied to the field of thermal management.

Owner:SHENZHEN STRONG ADVANCED MATERIALS RES INST CO LTD

High-ductility fiber concrete combination block masonry wall and construction method thereof

The invention discloses a high-ductility fiber concrete combination block masonry wall and a construction method thereof, and solves the problems of fragility, poor anti-seismic property and poor integrity of the conventional common block masonry wall. The high-ductility fiber concrete combination block masonry wall comprises a block masonry wall, a short reinforcing steel bar, a high-ductility fiber concrete core column and a high-ductility fiber concrete pavement; the construction method comprises the following steps of: during construction, firstly, building a common block masonry wall, and embedding the short reinforcing steel bar in a vertical mortar joint of the wall; secondly, pouring the high-ductility fiber concrete core column into the built block masonry wall; and at last, smearing high-ductility fiber concrete on the surface of the wall. The block masonry wall, provided by the invention, has the advantages of better compressive capacity, shearing resistance and anti-seismic property than the conventional block masonry wall, difficulty in having brittle failure, simple construction and lower construction cost.

Owner:西安五和新材料科技集团股份有限公司

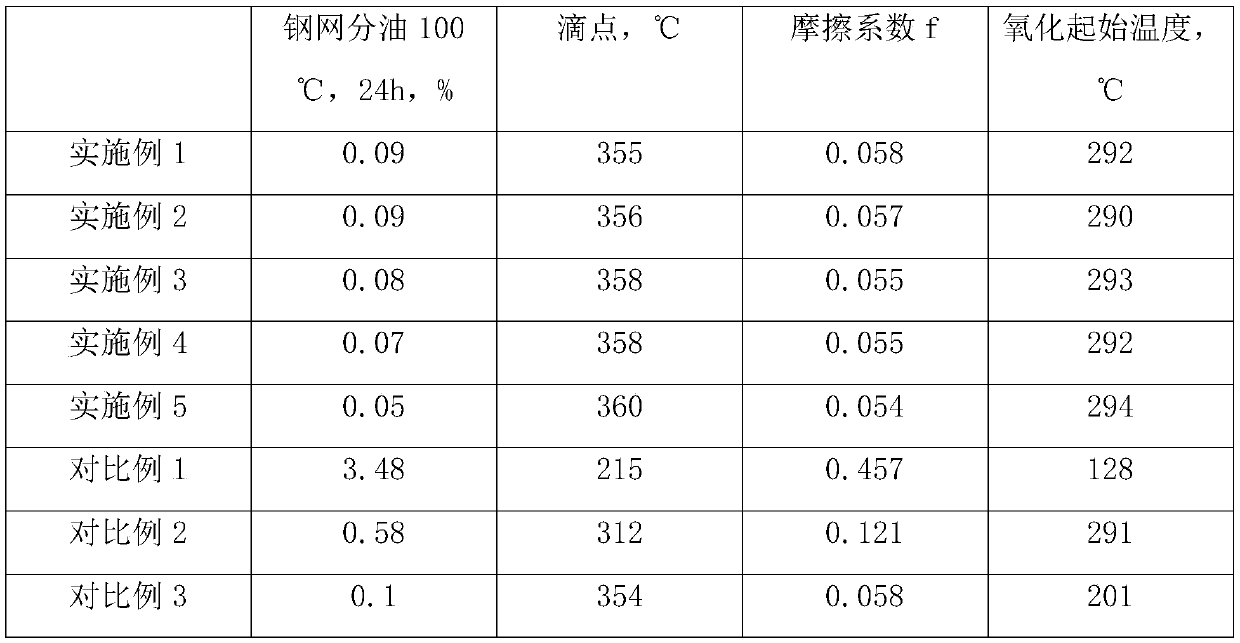

Preparation method of graphene composite lubricating grease

ActiveCN111471510ADrop point highGood colloidal stabilityLubricant compositionCalcium hydroxideLithium hydroxide

The invention provides a graphene composite lubricating grease and a preparation method thereof. Base oil, graphene, a high-molecular acid, calcium hydroxide, a low-molecular acid, and lithium hydroxide are used as raw materials, and after two times of saponification, the lubricating grease is prepared. The base oil and graphene are uniformly fed in two times, and the lubricating grease has advantages of good colloid stability, high dropping point, excellent friction reducing performance and excellent oxidation resistance.

Owner:贵州中时烯材科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com