Sintered flux for EQNiCrFe-7 strip surfacing matching and preparation method thereof

A strip surfacing and sintering flux technology, which is applied in welding equipment, welding media, manufacturing tools, etc., can solve the problem of chemical composition, mechanical properties, thermal crack resistance, intergranular corrosion resistance, and welding process performance. Very poor, difficult slag removal and other problems, to achieve good welding process performance and mechanical properties, beautiful shape, easy slag removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] SiO 2 6.0kg, MgO 2.0kg, Al 2 o 3 26kg, CaF 2 35.0kg, CaO 3.0kg, MnO 6.5kg, NiO 8.0kg, Cr 2 o 3 7.0kg and Nb 2 o 5 Put 4.5kg of powder in a mixer, stir and mix evenly, add 18kg of potassium silicate to mix and granulate, then bake at 150°C, sinter at 600°C, and sieve to obtain the flux product.

Embodiment 2

[0043] SiO 2 7.5kg, MgO 1.5kg, Al 2 o 3 29kg, CaF 2 30.0kg, CaO 2.0kg, MnO 6.0kg, NiO 9.0kg, Cr 2 o 3 8.0kg and Nb 2 o 5 Put 5.0kg of industrial pure powder in a mixer, stir and mix evenly, add 18kg of potassium silicate to mix and granulate, then bake at 150°C, sinter at 600°C, and sieve to obtain flux products.

Embodiment 3

[0045] SiO 2 8.0kg, MgO 2.5kg, Al 2 o 3 28kg, CaF 2 27.0kg, CaO 4.0kg, MnO 7.0kg, NiO 7.0kg, Cr 2 o 3 9.0kg and Nb 2 o 5 Put 5.5kg of industrial pure powder in a mixer, stir and mix evenly, add 18kg of potassium silicate to mix and granulate, then bake at 150°C, sinter at 600°C, and sieve to obtain flux products.

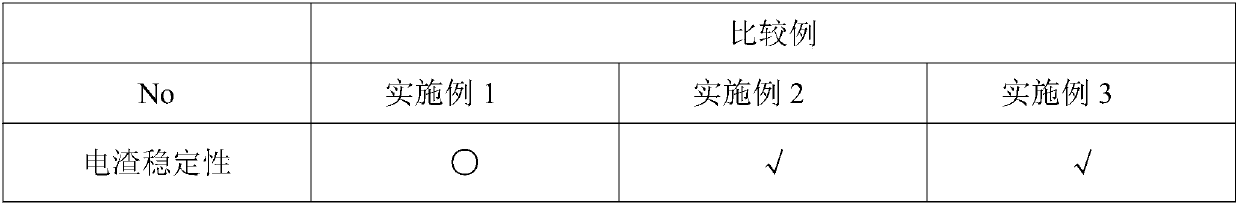

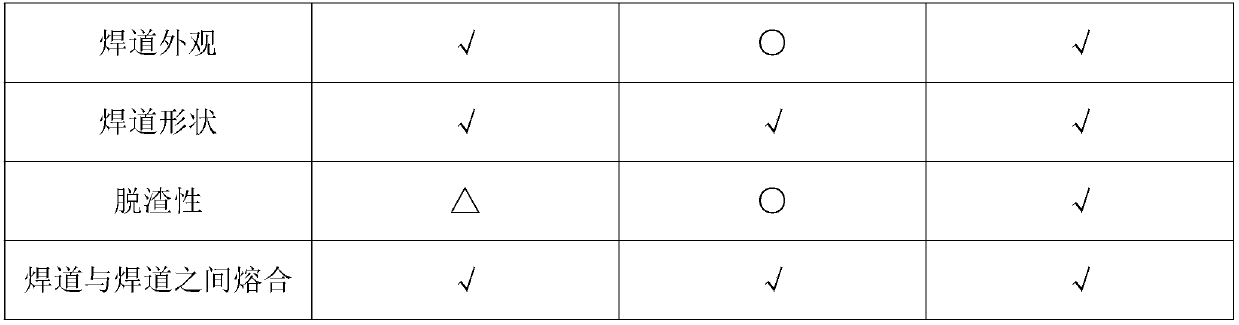

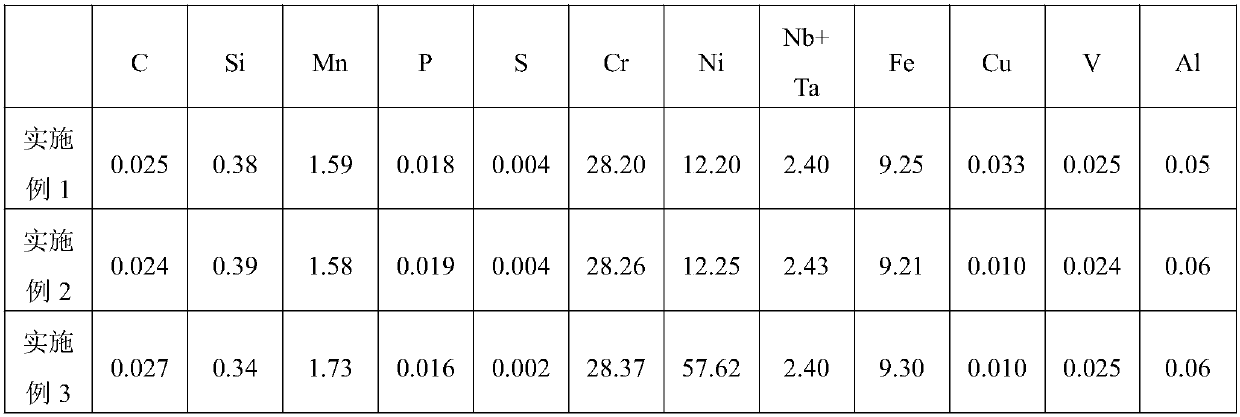

[0046] The welding flux of Example 1-3 is combined with the EQNiCrFe-7 welding strip to carry out the surfacing test on the Q345E steel plate with a thickness of 40 mm. The welding process performance is shown in Table 1; the chemical composition of the surfacing metal is shown in Table 2; the side bending, intergranular corrosion and non-destructive testing are shown in Table 3; the mechanical properties of the surfacing metal are shown in Table 4. In addition, in Table 1, evaluation √: excellent, ○: good, △: fair, ×: poor.

[0047] The surfacing welding base material used in this experiment is Q345E, and its chemical composition is: C 0.14, Mn 1.35, Si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com