Construction method of graphene-based thermal interface material with mutually vertical structure

A thermal interface material, technology perpendicular to each other, applied in the direction of graphene, nano-carbon, etc., can solve the problems of materials that cannot be prepared, and achieve the effects of simplified preparation, avoiding conventional freeze-drying, excellent interface thermal diffusion and conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

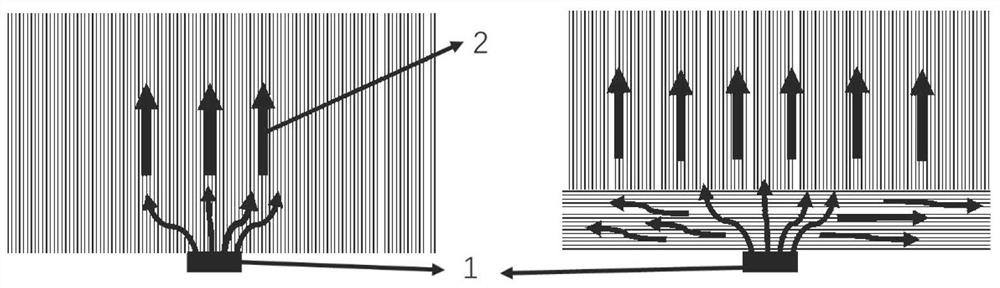

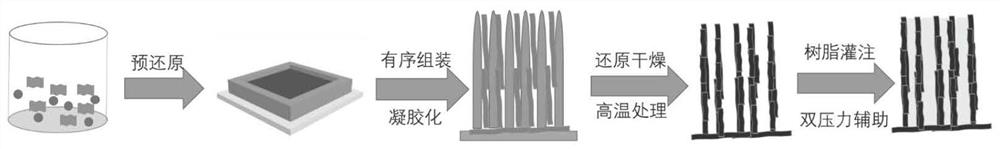

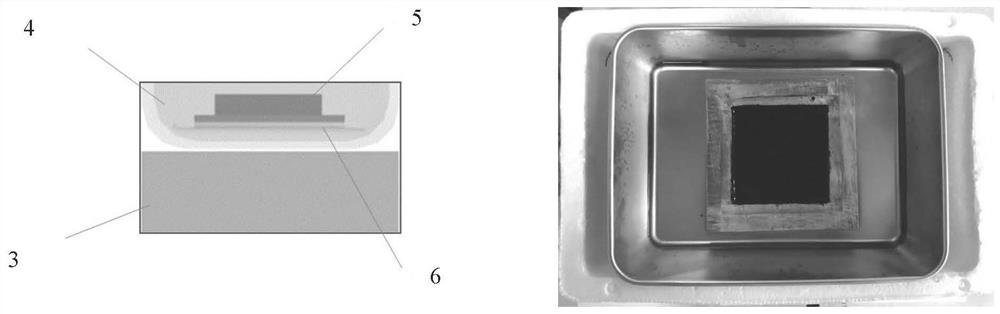

[0051] This embodiment provides a kind of preparation method of vertical graphene airgel, such as figure 1 As shown, the specific steps of the method are as follows:

[0052] 1) Preparation of graphene oxide dispersion: Weigh 4g flake graphite and put it in a beaker, pour 450ml of concentrated sulfuric acid and 50ml of phosphoric acid into the beaker to prepare mixed solution I, and stir at room temperature for 40min. Place the beaker in a water bath for heating, add 18g of potassium permanganate to the mixed solution I in 8 times to obtain the mixed solution II, heat the mixed solution II at 70°C, take it out after 16 hours and cool it at room temperature. After cooling to room temperature, the mixed solution II was slowly poured into 700ml hydrogen peroxide mixed with ice water, and after standing for 24 hours, the supernatant liquid was filtered off, and the lower layer solution was taken for centrifugal washing to obtain a high-concentration graphene oxide solution. Final...

Embodiment 2

[0067] This embodiment provides a kind of preparation method of vertical graphene airgel, such as figure 1 As shown, the specific steps of the method are as follows:

[0068] 1) Preparation of graphene oxide dispersion: Weigh 4g flake graphite and put it in a beaker, pour 450ml of concentrated sulfuric acid and 50ml of phosphoric acid into the beaker to prepare mixed solution I, and stir at room temperature for 40min. Place the beaker in a water bath for heating, add 18g of potassium permanganate to the mixed solution I in 8 times to obtain the mixed solution II, heat the mixed solution II at 70°C, take it out after 16 hours and cool it at room temperature. After cooling to room temperature, the mixed solution II was slowly poured into 700ml hydrogen peroxide mixed with ice water, and after standing for 24 hours, the supernatant liquid was filtered off, and the lower layer solution was taken for centrifugal washing to obtain a high-concentration graphene oxide solution. Final...

Embodiment 3

[0083] This embodiment provides a kind of preparation method of vertical graphene airgel, such as figure 1 As shown, the specific steps of the method are as follows:

[0084]1) Preparation of graphene oxide dispersion: Weigh 4g flake graphite and put it in a beaker, pour 450ml of concentrated sulfuric acid and 50ml of phosphoric acid into the beaker to prepare mixed solution I, and stir at room temperature for 40min. Place the beaker in a water bath for heating, add 18g of potassium permanganate to the mixed solution I in 8 times to obtain the mixed solution II, heat the mixed solution II at 70°C, take it out after 16 hours and cool it at room temperature. After cooling to room temperature, the mixed solution II was slowly poured into 700ml hydrogen peroxide mixed with ice water, and after standing for 24 hours, the supernatant liquid was filtered off, and the lower layer solution was taken for centrifugal washing to obtain a high-concentration graphene oxide solution. Finall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com