Basalt fiber and glass fiber mixed reinforced resin, as well as preparation method and application thereof

A technology of basalt fiber and glass fiber, applied in the field of composite materials, can solve the problems of decreased mechanical properties of composite materials, poor wettability of resin matrix, few active functional groups, etc., and achieves excellent mechanical properties, improved performance, and cost-effective effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

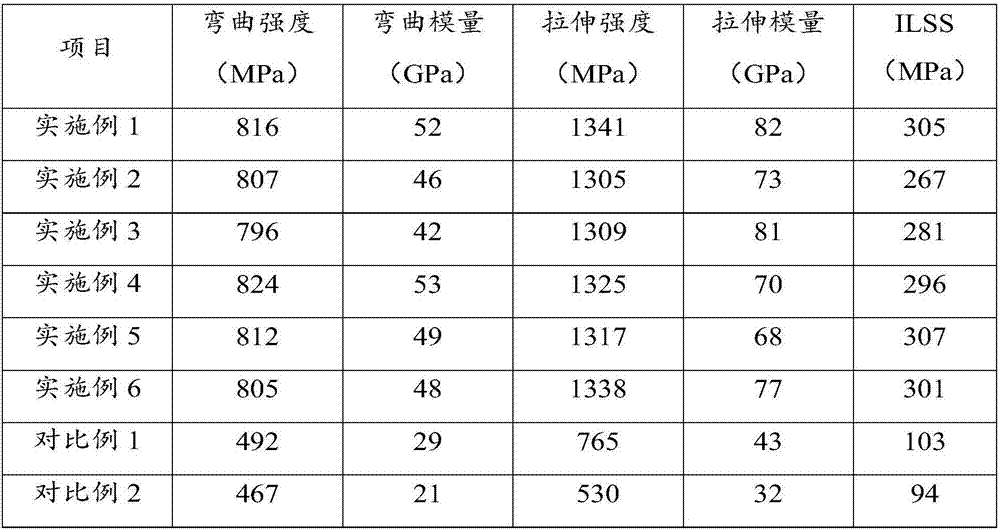

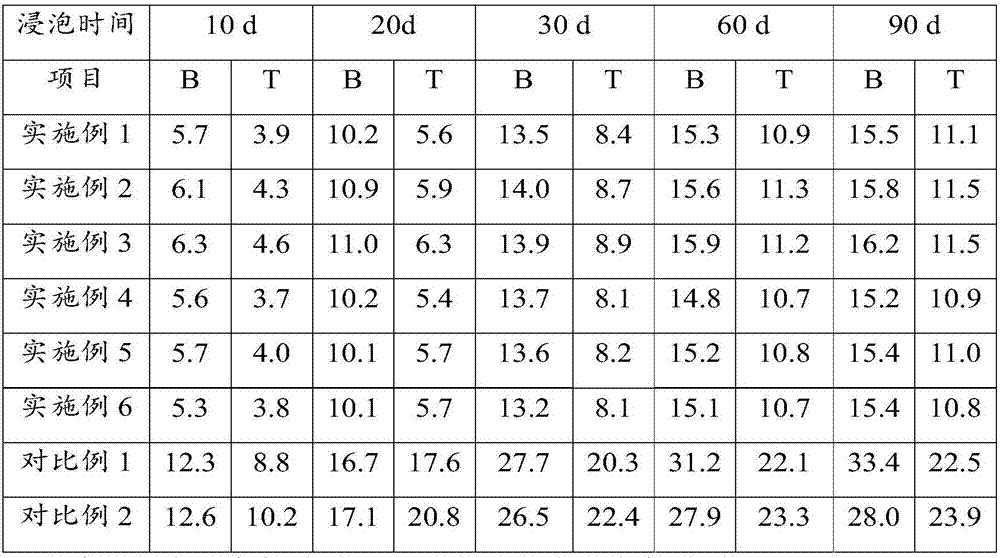

Examples

Embodiment 1

[0045] This embodiment provides a basalt fiber and glass fiber mixed reinforced resin, which is prepared according to the following steps.

[0046] First, graphene oxide was added to the aqueous solution at a material-to-liquid ratio of 15 mg / mL, and then a coupling agent with a mass fraction of 3% of the aqueous solution was added, mechanically stirred for 1-2 hours, and then ultrasonically dispersed for 1.5-3 hours to obtain a fiber treatment solution. Treat the mixed fibers with fiber treatment liquid for 50 minutes, and dry them under vacuum for 40 minutes to obtain reinforced materials. Wherein, according to parts by weight, the mixed fiber includes 50 parts of basalt fiber and 25 parts of glass fiber.

[0047] Secondly, the reinforcement material is placed in the plasma generator, with CF 4 It is the reaction gas, the reaction pressure is 15Pa, the reaction power is 150W, and the reaction time is 10min to obtain the modified reinforcing material.

[0048] Again, the na...

Embodiment 2

[0051] This embodiment provides a basalt fiber and glass fiber mixed reinforced resin, which is prepared according to the following steps.

[0052] First, graphene oxide is added to the aqueous solution at a material-to-liquid ratio of 10 mg / mL, then a coupling agent with a mass fraction of 1% of the aqueous solution is added, mechanically stirred for 1-2 hours, and then ultrasonically dispersed for 1.5-3 hours to obtain a fiber treatment solution. Treat the mixed fibers with fiber treatment liquid for 40 minutes, and dry them under vacuum for 50 minutes to obtain reinforced materials. Wherein, according to parts by weight, the mixed fiber includes 40 parts of basalt fiber and 30 parts of glass fiber.

[0053] Secondly, place the reinforcing material in the plasma generating device, with N 2 It is the reaction gas, the reaction pressure is 10Pa, the reaction power is 200W, and the reaction time is 15min to obtain the modified reinforced material.

[0054] Again, the nano zir...

Embodiment 3

[0057] This embodiment provides a basalt fiber and glass fiber mixed reinforced resin, which is prepared according to the following steps.

[0058] First, graphene oxide is added to the aqueous solution at a material-to-liquid ratio of 20 mg / mL, then a coupling agent with a mass fraction of 5% of the aqueous solution is added, mechanically stirred for 1-2 hours, and then ultrasonically dispersed for 1.5-3 hours to obtain a fiber treatment solution. The mixed fibers were treated with fiber treatment liquid for 60 minutes, and dried under vacuum for 50 minutes to obtain reinforced materials. Wherein, according to parts by weight, the mixed fiber includes 60 parts of basalt fiber and 20 parts of glass fiber.

[0059] Secondly, put the reinforcing material in the plasma generating device, with CCl 4 It is the reaction gas, the reaction pressure is 30Pa, the reaction power is 100W, and the reaction time is 3min to obtain the modified reinforcing material.

[0060] Again, the nano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com