High-ductility fiber concrete combination block masonry wall and construction method thereof

A fiber-reinforced concrete and masonry wall technology, applied to walls, building components, buildings, etc., can solve the problems of brittleness, crack resistance and poor seismic performance, and achieve the effects of convenient construction, good durability and good bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

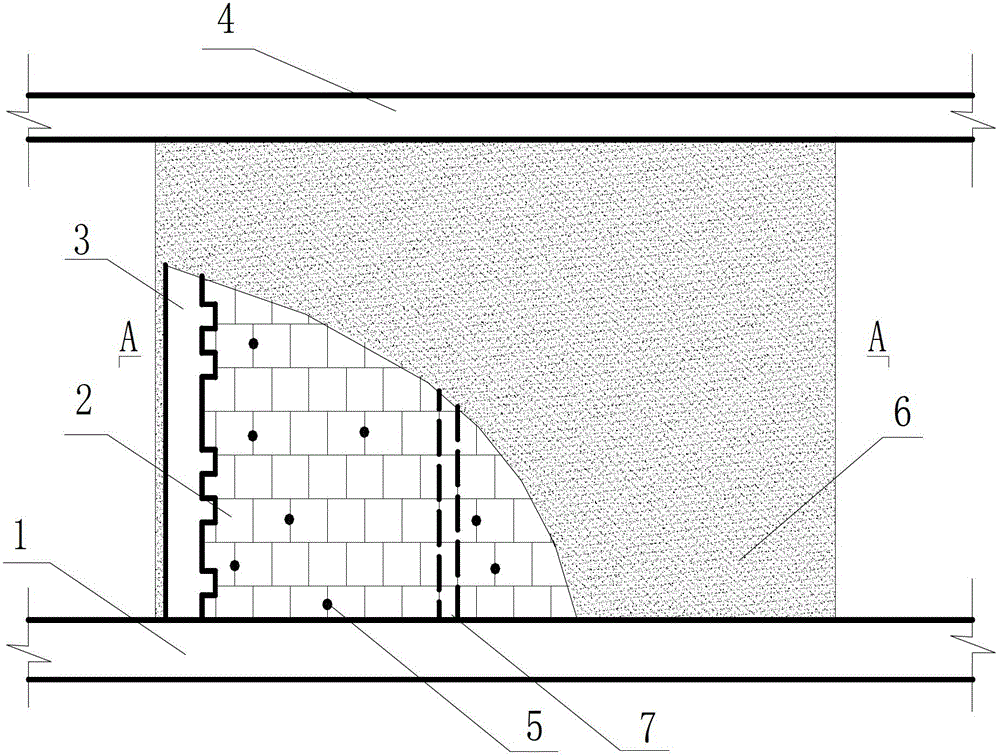

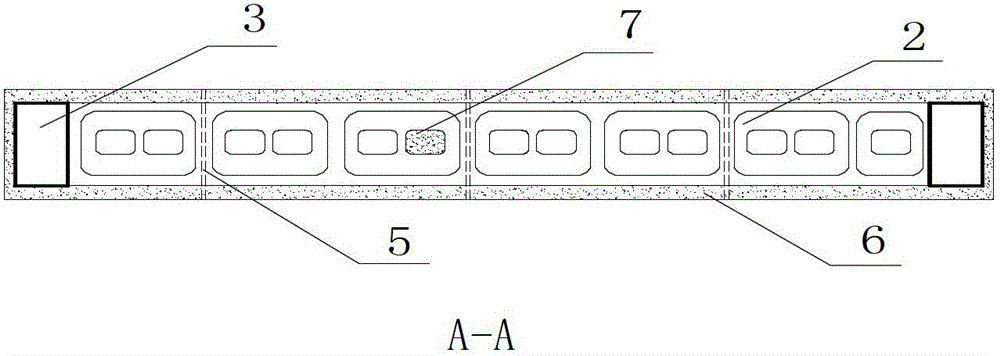

[0029] refer to figure 1 and figure 2 , the size of the concrete blocks in this embodiment is 390mm×190mm×190mm; the block masonry wall 2 has structural columns 3 and ring beams (1, 4), and the block masonry wall 2 has a length of 4.2m and a height of 3m, thickness 240mm; structural column 3 has a cross-sectional dimension of 120mm×240mm; ring beam 1 has a cross-sectional dimension of 340mm×400mm; ring beam 4 has a cross-sectional dimension of 180mm×240mm; high ductility fiber concrete core column 7 has a cross-sectional dimension of 120mm × 120mm, the spacing along the wall is 2m; the structure of the high ductility fiber concrete composite block masonry wall of this embodiment is: a number of short steel bars 5 are buried in the vertical mortar joints of the block masonry wall 2; The outer surface of the block masonry wall 2 is coated with a high-ductility fiber concrete surface layer 6 ; a high-ductility fiber concrete core column 7 is poured inside the block masonry wall...

Embodiment 2

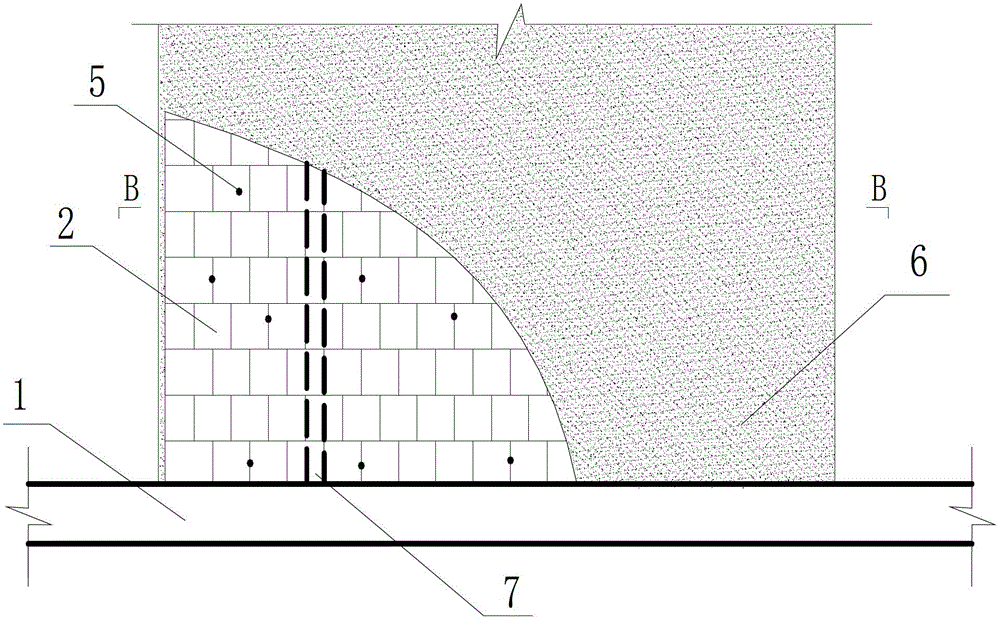

[0042] refer to image 3 with Figure 4 , the size of the concrete block in this embodiment is 390mm×190mm×190mm; the block masonry wall 2 has no structural column, the block masonry wall 2 has a length of 4.2m, a height of 3m, and a thickness of 240mm; ring beam 4 The section size of the high ductility fiber concrete core column 7 is 150mm×150mm, and the spacing along the wall is 2m; the other construction procedures are the same as in the first embodiment.

[0043] The present invention utilizes the advantages of the mechanical properties of high ductility fiber concrete and the good viscous performance with the block masonry wall, which not only produces a large lateral active restraint force on the block masonry wall, but also improves the shear resistance of the block masonry wall Strength, pouring high ductility fiber concrete core columns inside the block masonry wall can prevent the block masonry wall from being partially crushed, improve the integrity of the block ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com