Graphene composite PE material and preparation method thereof

A graphene composite and graphene technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve problems such as low regularity of composite resin particles, low utilization rate of free radical initiators, and poor product quality , to achieve good mechanical properties and barrier properties, improved antistatic properties, and good dispersion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] Preparation of Graphene Oxide: Using the Modified Hummers Method

[0031] Step 1. Weigh 10g of natural graphite powder (G), 4g of potassium persulfate, and 10g of phosphorus pentoxide, and add them into a three-necked flask containing 24mL of sulfuric acid while stirring, and react in a constant temperature water bath at 60°C for 3h. Then move the three-necked flask into a constant temperature water bath at 25°C to react for 5 hours, filter with suction, wash with ionized water to neutrality, and dry in air to obtain pre-oxidized graphite (P-G);

[0032] Step 2, take by weighing 1g of pre-oxidized graphite, add in the there-necked flask that 25mL sulfuric acid is housed under the situation of stirring, put into ice-water bath, after pre-oxidized graphite is all dissolved, add the potassium permanganate of 3g, react 2h, and then moved the three-neck flask into a constant temperature water bath at 35°C for 40min, then added deionized water, continued to react at 35°C for ...

Embodiment 1

[0034] The present embodiment provides a kind of preparation method of graphene composite PE material, comprises the following steps:

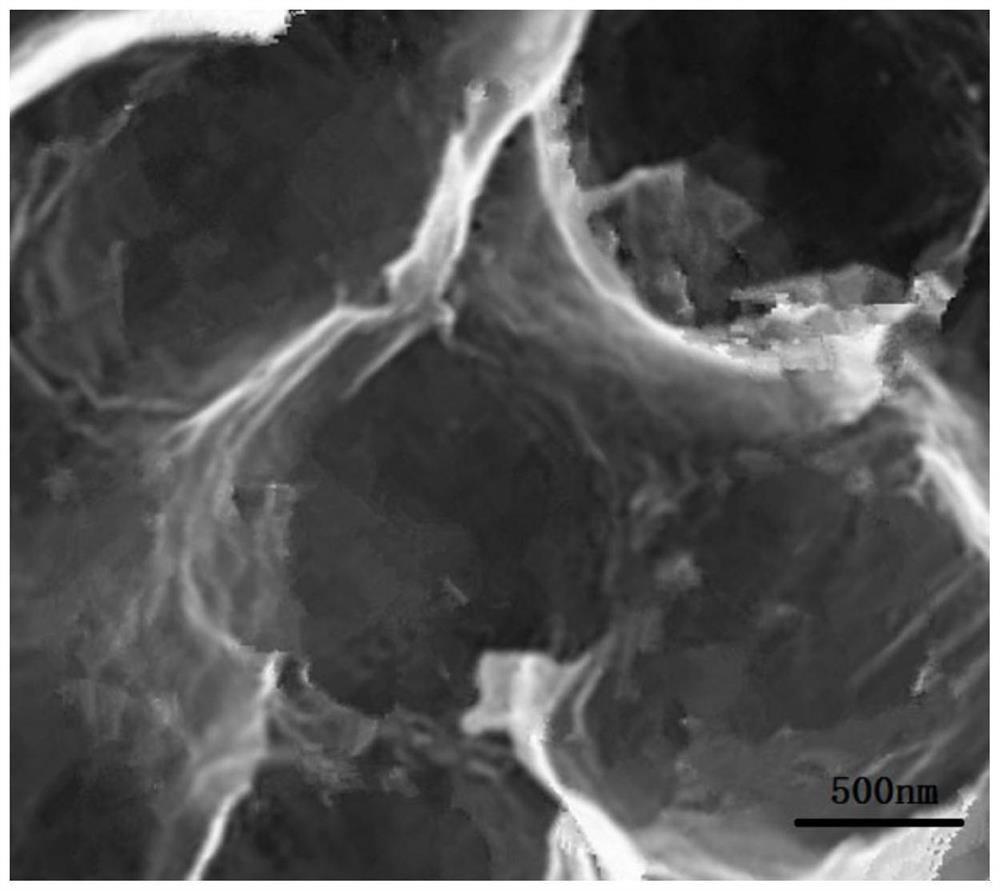

[0035]S1. After dissolving 10g of graphene oxide in 100mL of 25wt% ethanol aqueous solution, it is spray-dried. The spray-drying conditions are as follows: the inlet air temperature is 80°C, the outlet air temperature is 30°C, the evaporation water is 1500mL / h, and the fineness is over 100 mesh sieve to obtain wrinkled graphene oxide; figure 1 It is the SEM picture of the wrinkled graphene oxide prepared by the present invention, as can be seen from the figure, a wrinkled structure is formed.

[0036] S2. Add 10g of the wrinkled graphene oxide prepared in step S1 into 100mL of water, disperse with 1000W ultrasonic for 30min, add 3g of 25wt% ammonia water and 1g of hydrazine hydrate, heat and stir for reaction, the heating temperature is 80°C, the time is 1h, filter and wash , to obtain wrinkled graphene;

[0037] S3. Disperse 10g of the wrin...

Embodiment 2

[0041] The present embodiment provides a kind of preparation method of graphene composite PE material, comprises the following steps:

[0042] S1. After dissolving 10g of graphene oxide in 100mL of 45wt% ethanol aqueous solution, it is spray-dried. The spray-drying conditions are as follows: the inlet air temperature is 100°C, the outlet air temperature is 80°C, the evaporation water is 2000mL / h, and the fineness is over 100 mesh sieve to obtain wrinkled graphene oxide;

[0043] S2. Add 10g of the wrinkled graphene oxide prepared in step S1 into 100mL of water, disperse with 1000W ultrasonic for 30min, add 7g of 30wt% ammonia water and 3g of hydrazine hydrate, heat and stir for reaction, the heating temperature is 100°C, the time is 3h, filter and wash , to obtain wrinkled graphene;

[0044] S3. Evenly disperse 10g of the wrinkled graphene prepared in step S2 in 100mL of 80wt% ethanol aqueous solution, add a compound mixture of 1.5g of silane coupling agent KH570 and 1g of si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com