Organic compound, and electronic element and electronic device using same

An organic compound, fusion technology, applied in the direction of silicon organic compounds, electrical components, organic chemistry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0157] In one embodiment of the present application, the electronic component may be an organic electroluminescent device or a photoelectric conversion device.

[0158] In one embodiment of the present application, the electronic component may be an organic electroluminescence device.

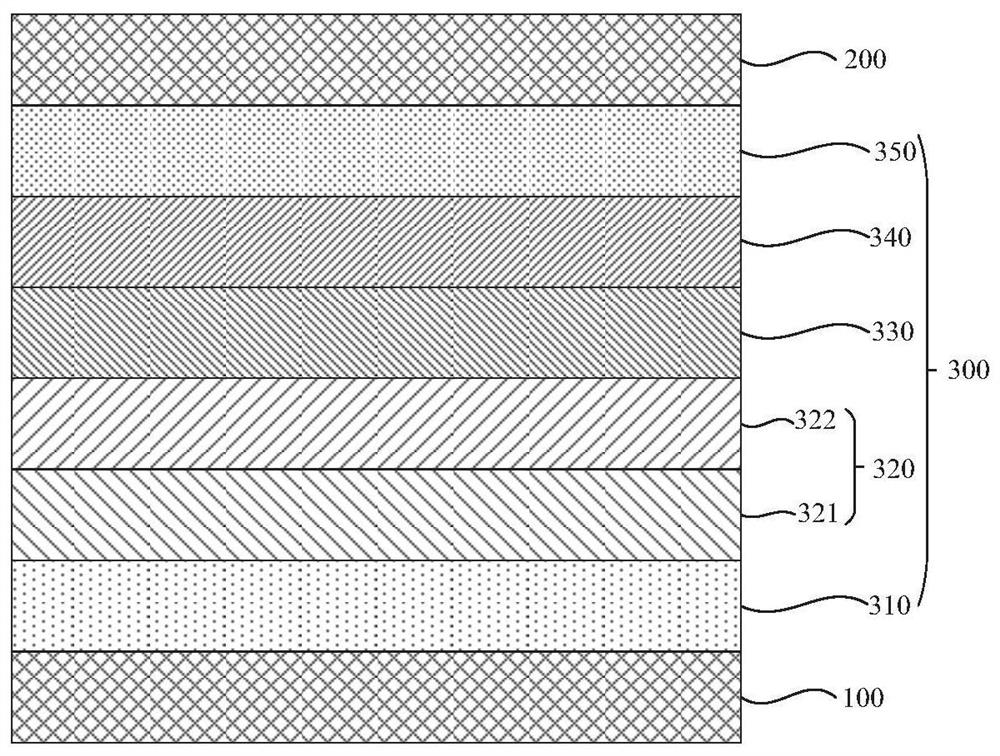

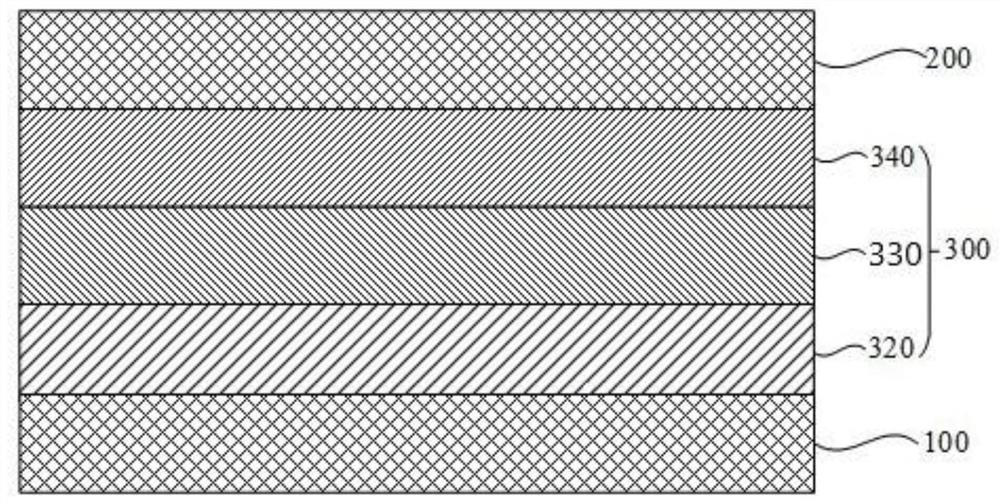

[0159] In one embodiment of the present application, the organic electroluminescence device may be a green device or a red device. Such as figure 1 As shown, the organic electroluminescent device may include an anode 100, a first hole transport layer 321, a second hole transport layer 322, an organic light-emitting layer 330 as an energy conversion layer, an electron transport layer 340, and a cathode 200 stacked in sequence. .

[0160] Optionally, the anode 100 includes the following anode material, which is preferably a material with a large work function (work function) that facilitates hole injection into the functional layer. Specific examples of anode materials include: metals such as ...

Synthetic example

[0182] 1. Preparation of intermediate a-1

[0183]

[0184] 2-Bromo-4-chloro-1-iodobenzene (50.0g, 157.5mmol), dibenzofuran-3-boronic acid (30.4g, 157.5mmol), tetrakis(triphenylphosphine) palladium (3.6g, 3.1 mmol), potassium carbonate (54.3g, 393.8mmol), tetrabutylammonium bromide (10.1g, 31.5mmol) were added in the flask, and a mixed solvent of toluene (440mL), ethanol (200mL) and water (100mL) was added, Under nitrogen protection, raise the temperature to 80°C, keep the temperature and stir for 24 hours, cool to room temperature, stop stirring, wash the reaction solution with water, separate the organic phase, dry with anhydrous magnesium sulfate, and remove the solvent under reduced pressure to obtain the crude product; use dichloromethane / n-heptane was purified by silica gel column chromatography as the mobile phase crude product to obtain intermediate a-1 (33.8 g, 60%) as a white solid product.

[0185] Substitute reactant A in Table 1 for 2-bromo-4-chloro-1-iodoben...

Embodiment 1

[0257] Embodiment 1: green organic electroluminescent device

[0258] Use the following methods to fabricate green organic electroluminescent devices:

[0259] The anode was prepared by the following process: the thickness of ITO was The ITO substrate was cut into a size of 40mm (length) × 40mm (width) × 0.7mm (thickness), and it was prepared into an experimental substrate with cathode, anode and insulating layer patterns by photolithography process, and ultraviolet ozone and o 2 :N 2 Plasma is used for surface treatment to increase the work function of the anode, and organic solvents can be used to clean the surface of the ITO substrate to remove impurities and oil on the surface of the ITO substrate. It should be noted that the ITO substrate can also be cut into other sizes according to actual needs, and there is no special limitation on the size of the ITO substrate in this application.

[0260] F4-TCNQ was vacuum evaporated on the experimental substrate (anode) to for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com