Patents

Literature

101results about How to "Reliable disengagement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mobile terminal

PendingCN108023987AReliable disengagementNot easy to run intoTelephone set constructionsAeroshellComputer terminal

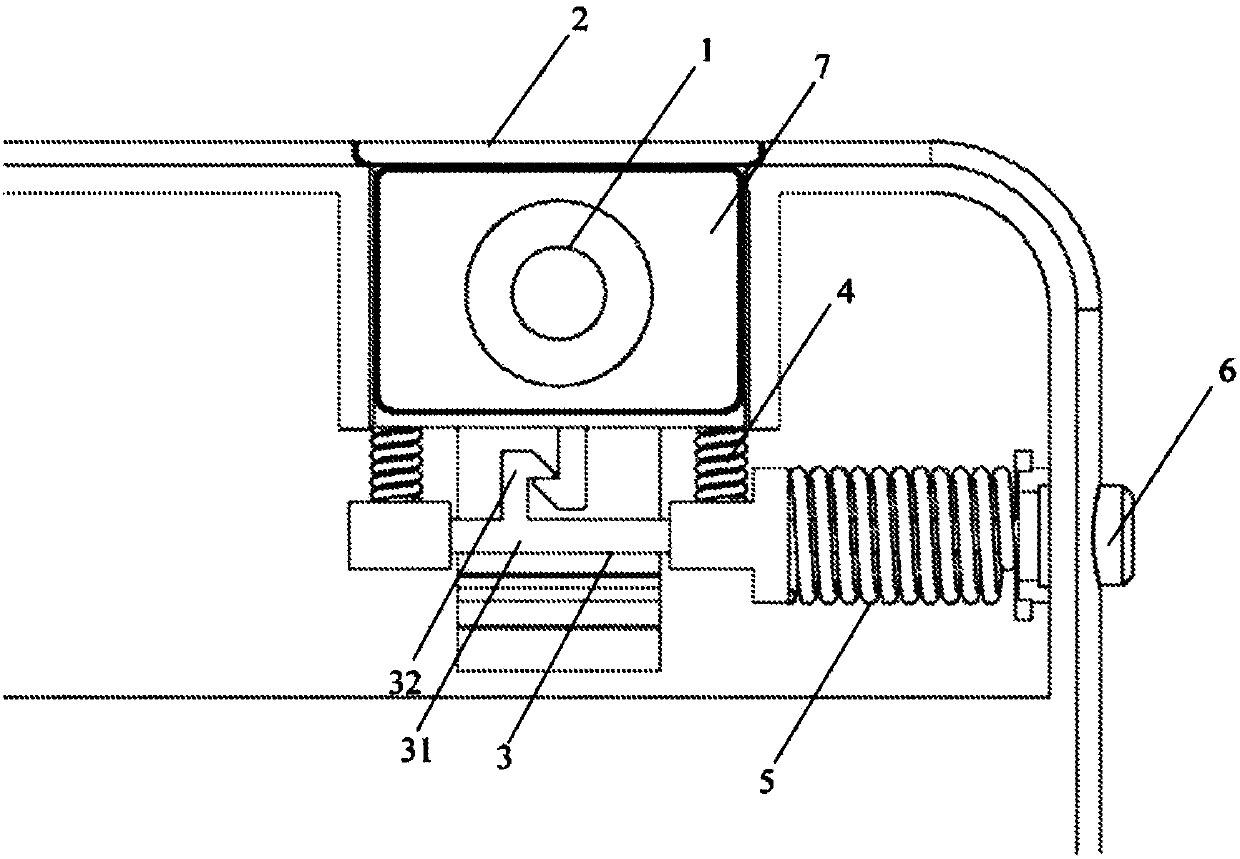

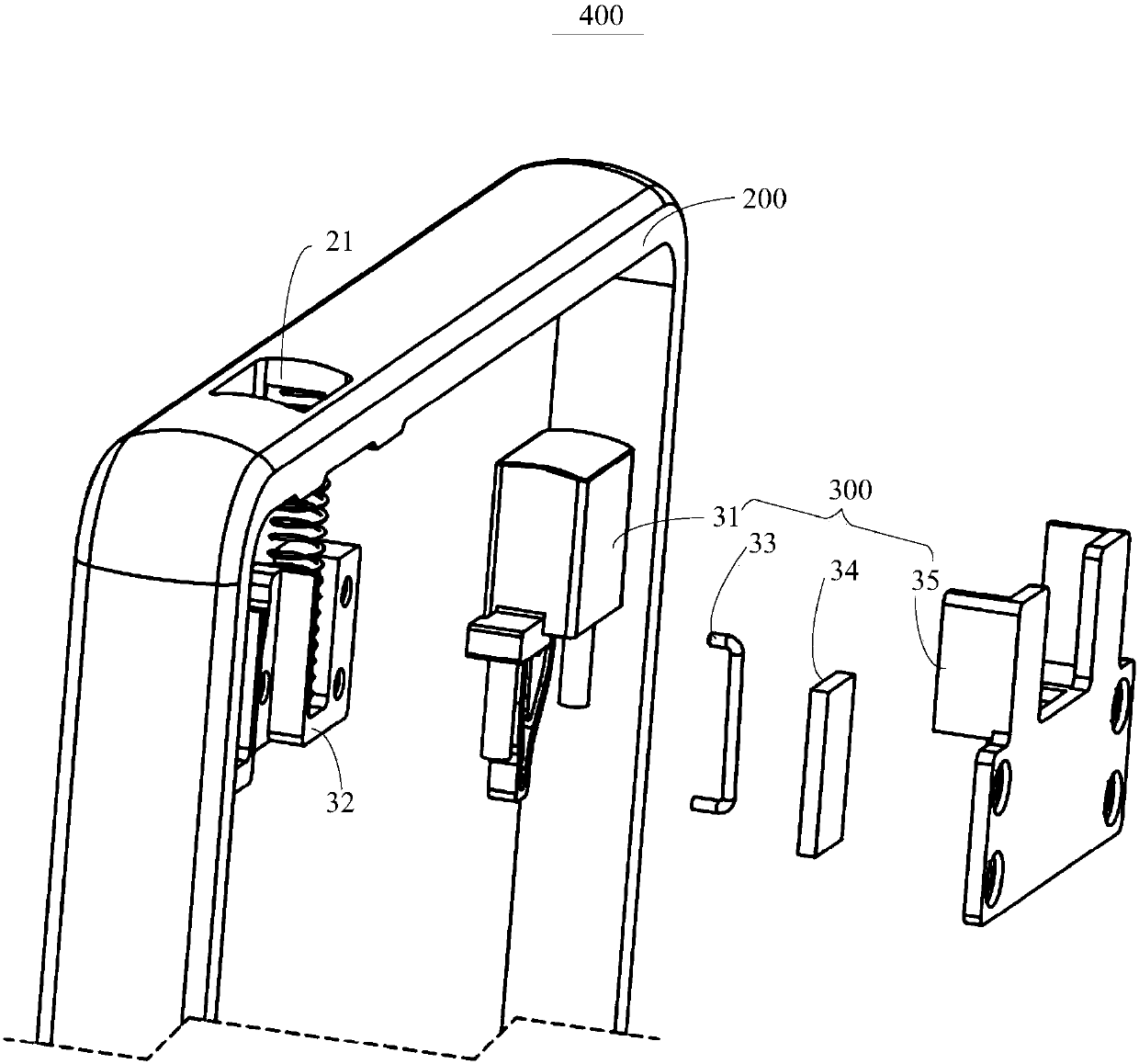

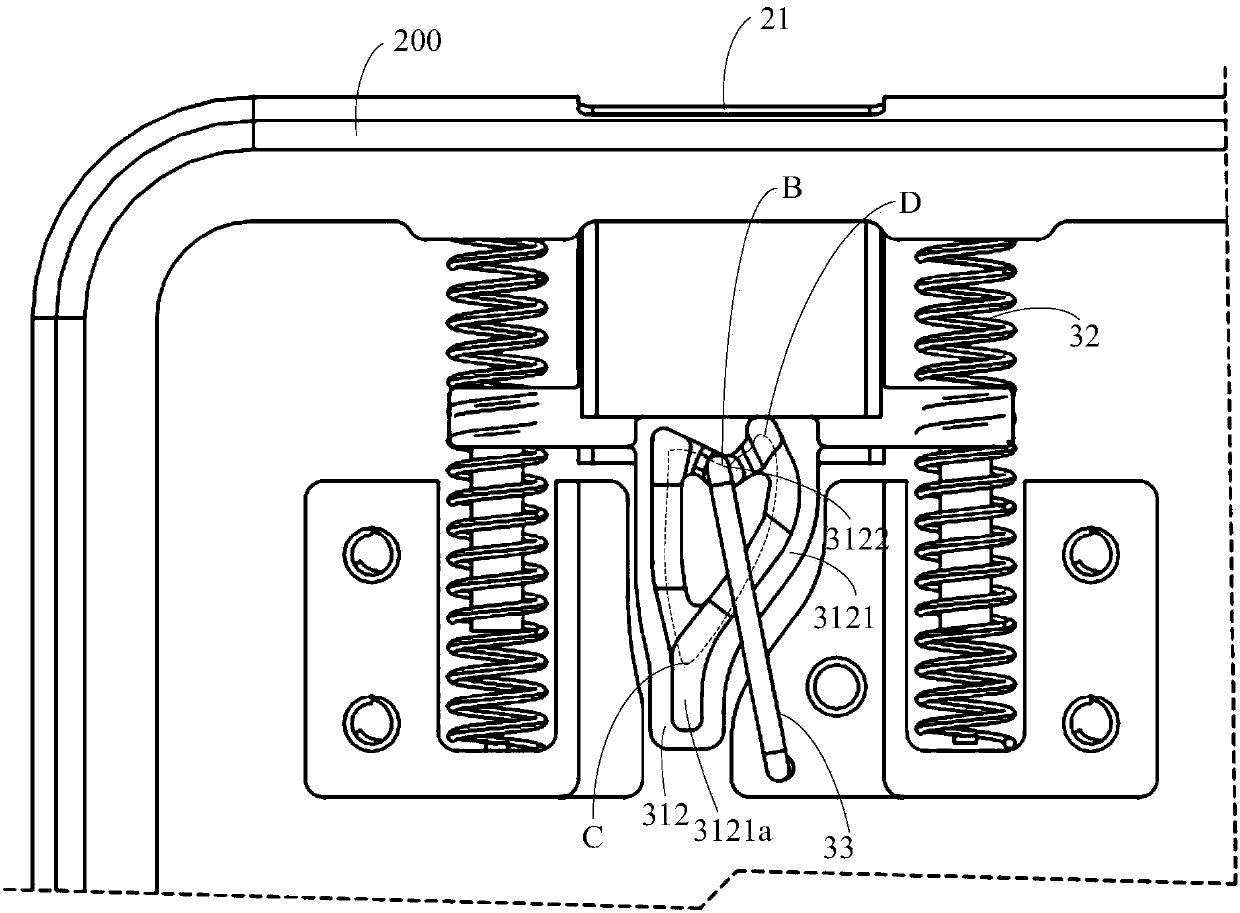

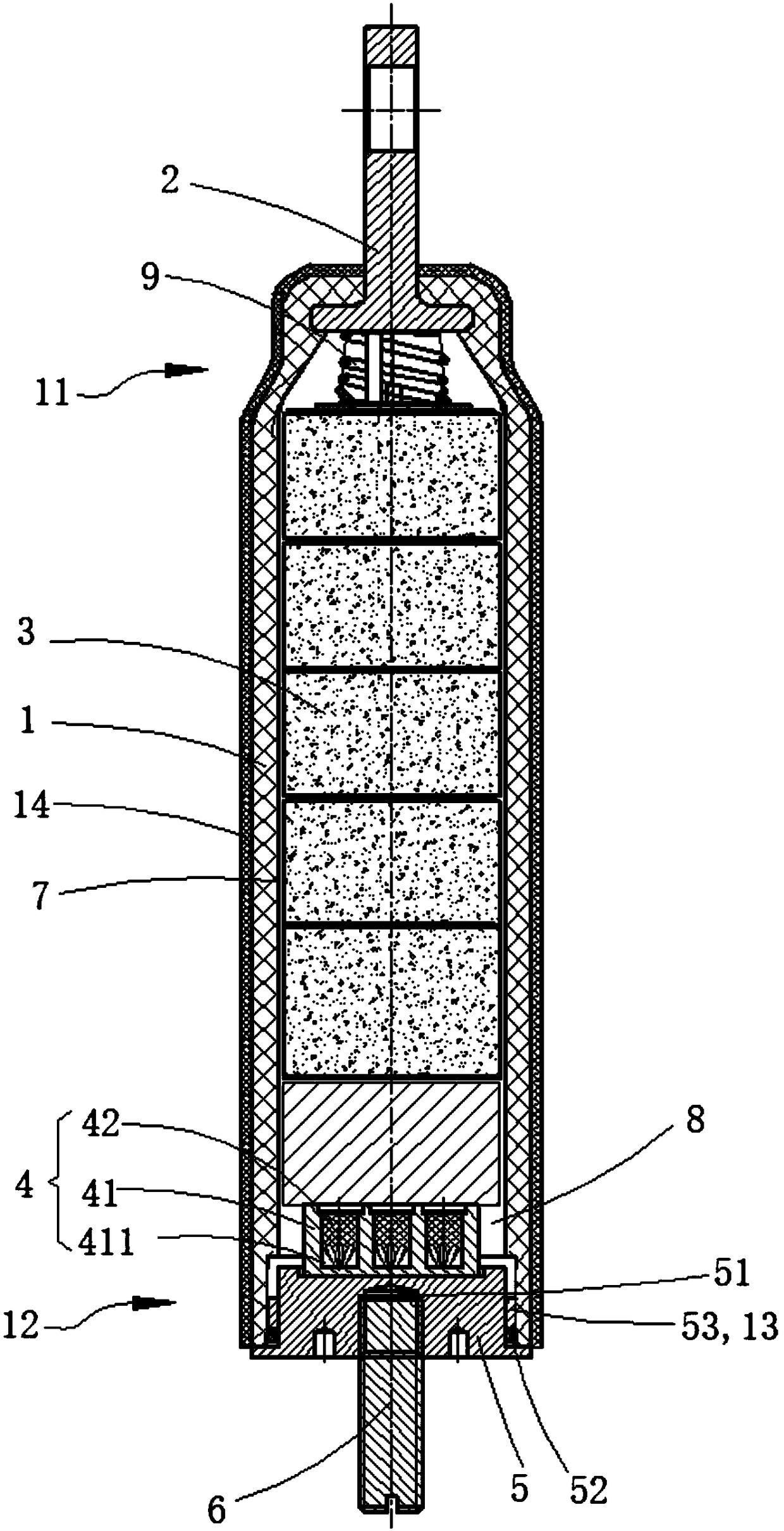

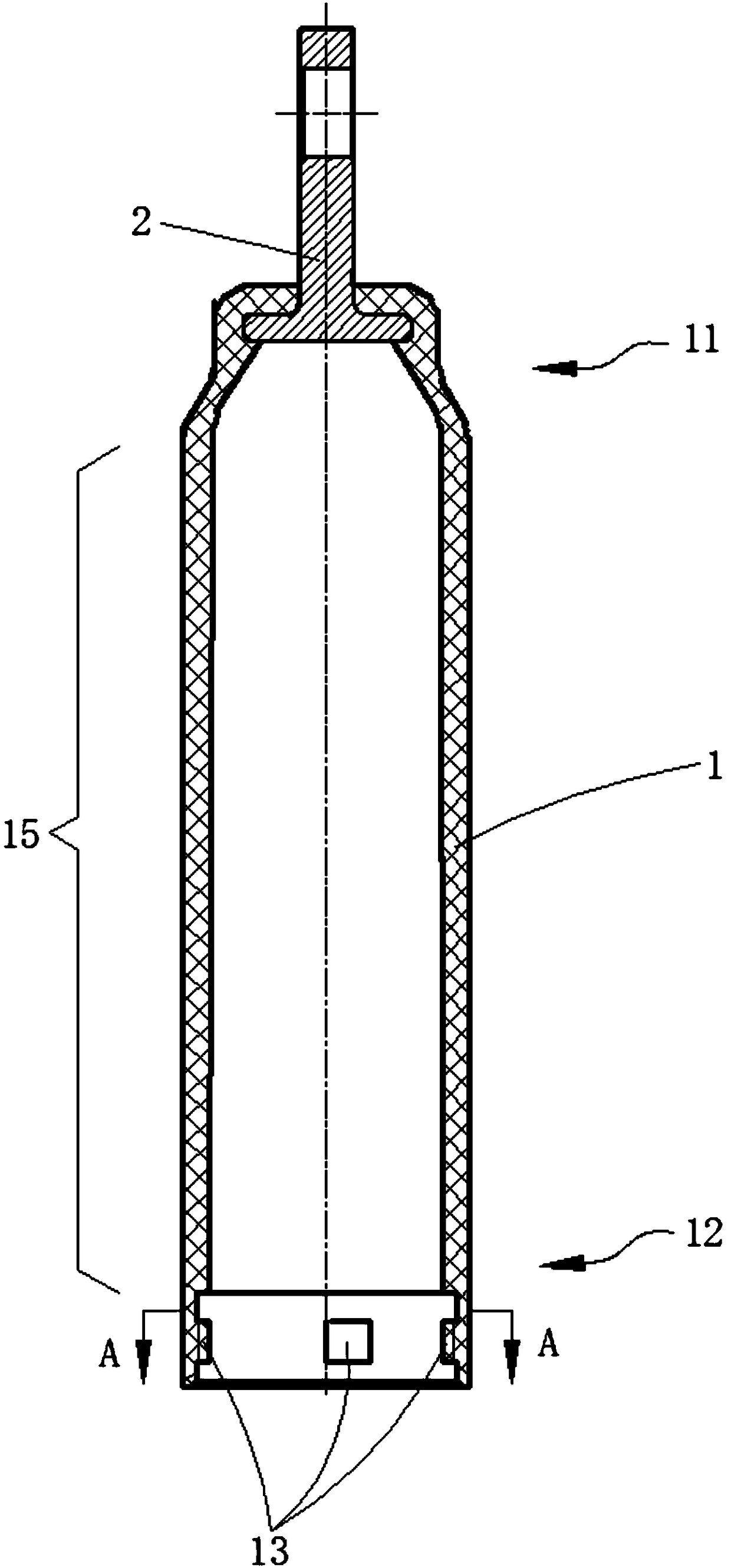

The invention relates to the technical field of terminals and particularly relates to a mobile terminal. The mobile terminal comprises a machine shell and a camera module arranged in the machine shell, wherein a through hole is formed in the machine shell; the camera module comprises an elastic assembly, a camera assembly and a locking assembly; the camera assembly comprises a connecting part, a groove is formed in the connecting part, a buckling part is arranged in the groove, and the locking assembly is connected with the buckling part; when an external force is applied to the camera assembly, the locking assembly falls into a chute in the groove and is separated from the buckling part so as to push the camera assembly to be popped out of the machine shell through the through hole; and when the camera assembly popped out of the machine shell is received by an external force, the elastic assembly drives the camera assembly to retract into the machine shell, the locking assembly slidesalong the chute of the groove and is buckled into the buckling part, and then the camera assembly retracts into the machine shell through the through hole. According to the mobile terminal, the camera assembly can be reliably popped out or retracted.

Owner:GREE ELECTRIC APPLIANCES INC

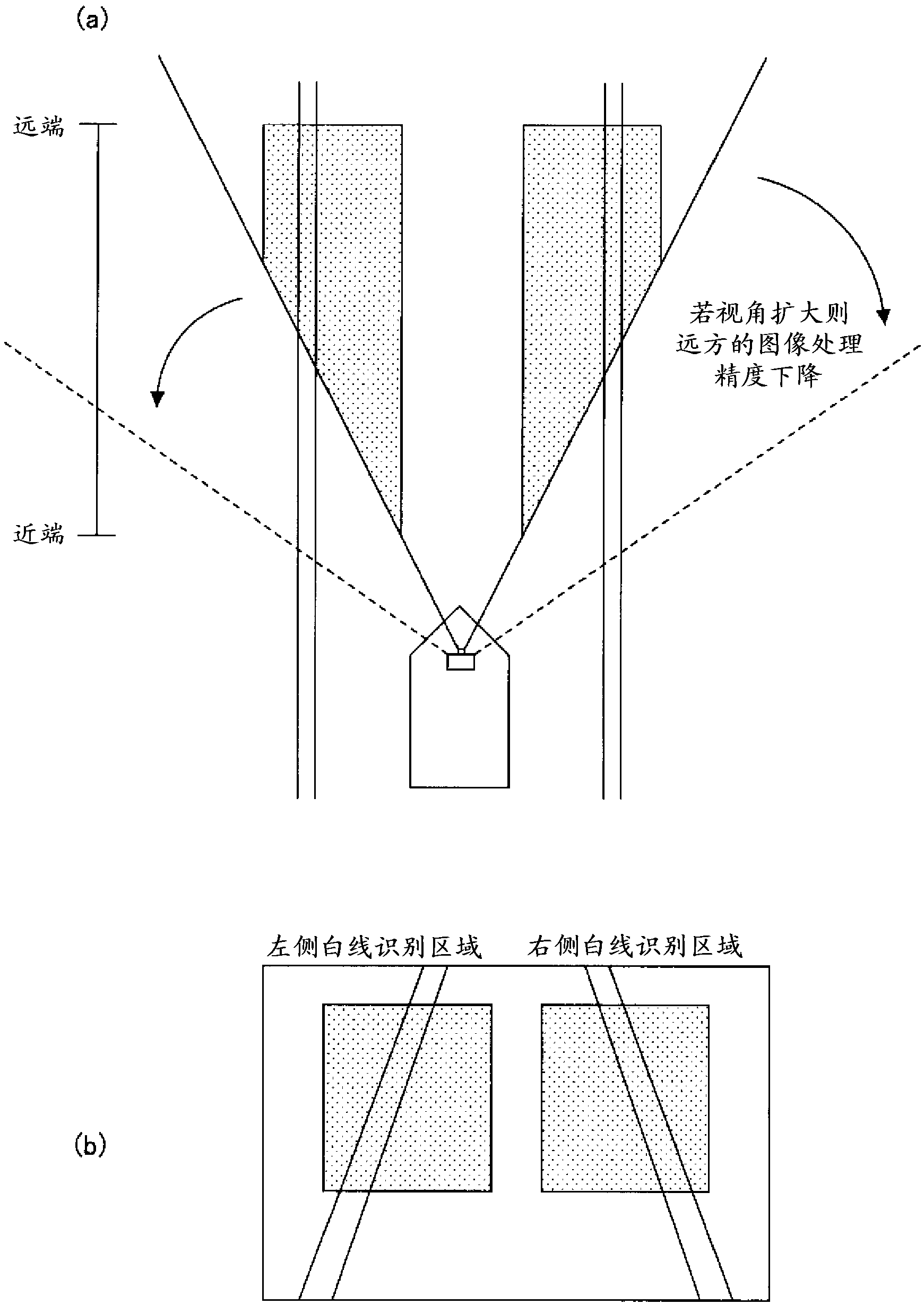

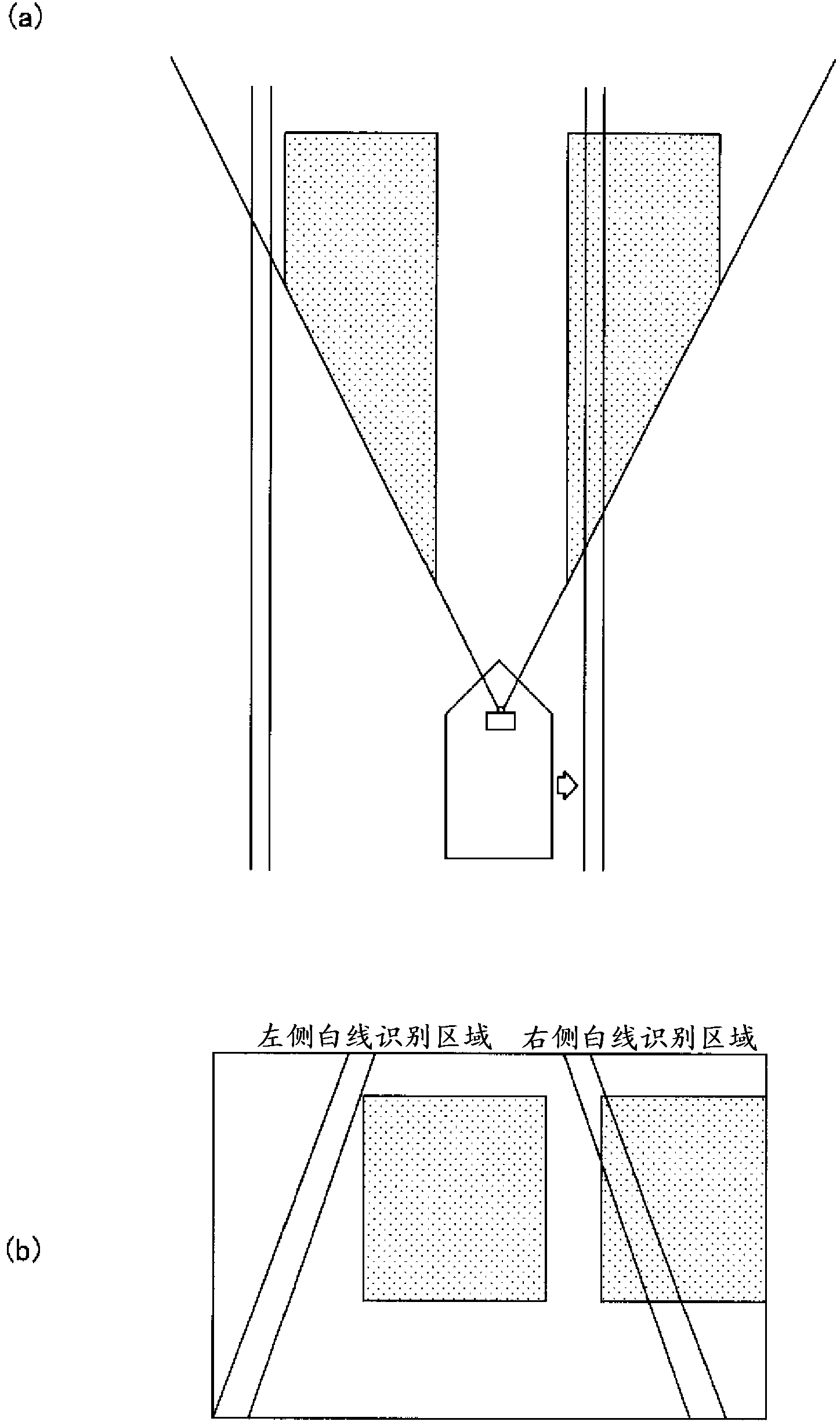

Lane departure avoidance assistance device, separator display method, and program

ActiveCN103052976AReliable disengagementArrangements for variable traffic instructionsAnti-collision systemsLocation detectionSimulation

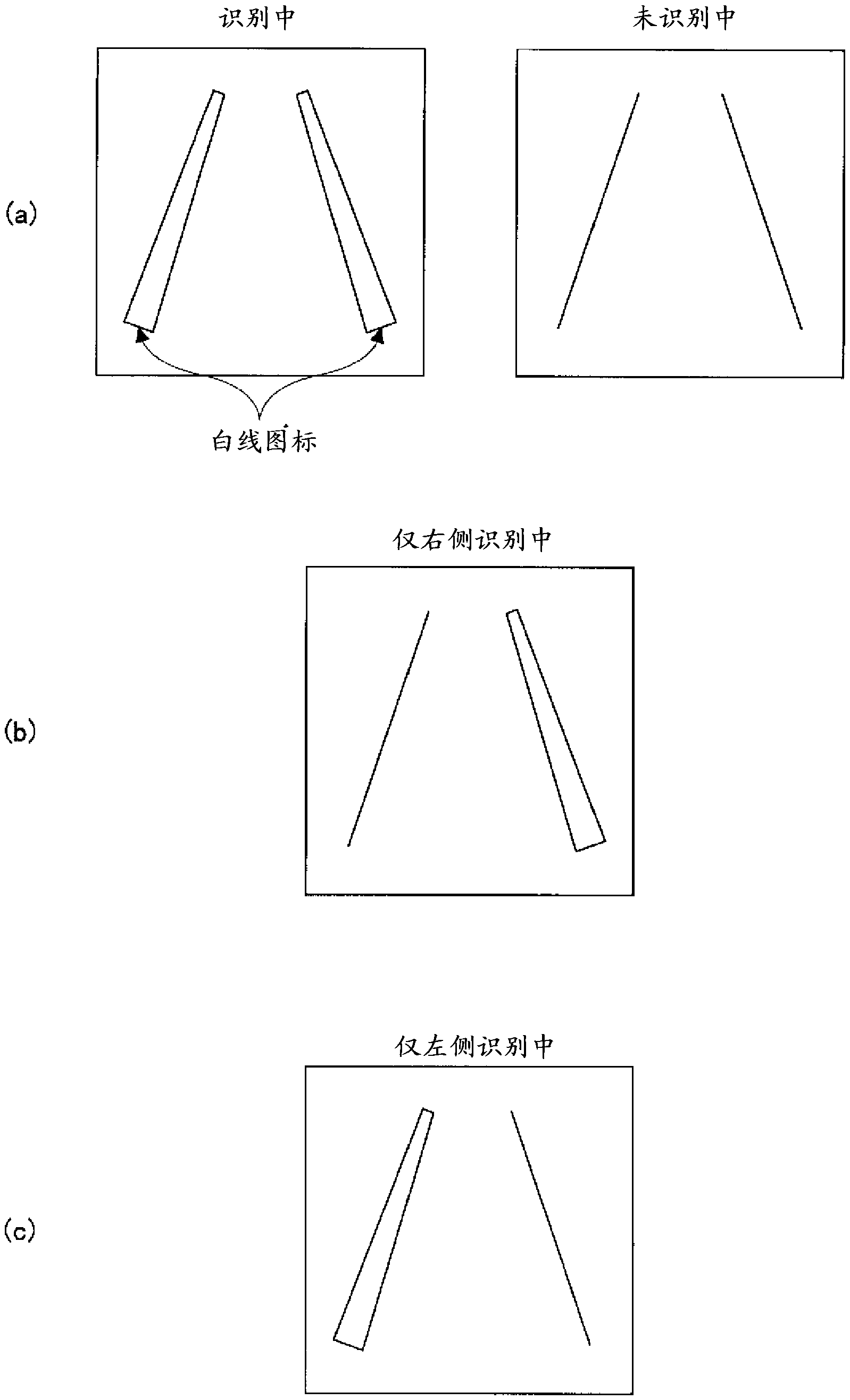

The present invention relates to a LANE DEPARTURE AVOIDANCE ASSISTANCE DEVICE, a SEPARATOR DISPLAY METHOD, AND a PROGRAM. The lane departure avoidance assistance device comprises: a photography means for photographing a lane separator which separates driving lanes; a host vehicle location detection means for recognizing the lane separator from a photographed image data recognition region and detecting a host vehicle location in the width direction within the lane; a driving assistance means for carrying out driving assistance using the result of recognizing the lane separator; and a display means for displaying the result of recognizing the lane separator. The lane departure avoidance assistance device further comprises a recognition result display control means for displaying, if either the left or right white line is not recognized, the non-recognized lane separator in a display state which is not a display state which denotes non-recognition according to the host vehicle location.

Owner:TOYOTA JIDOSHA KK

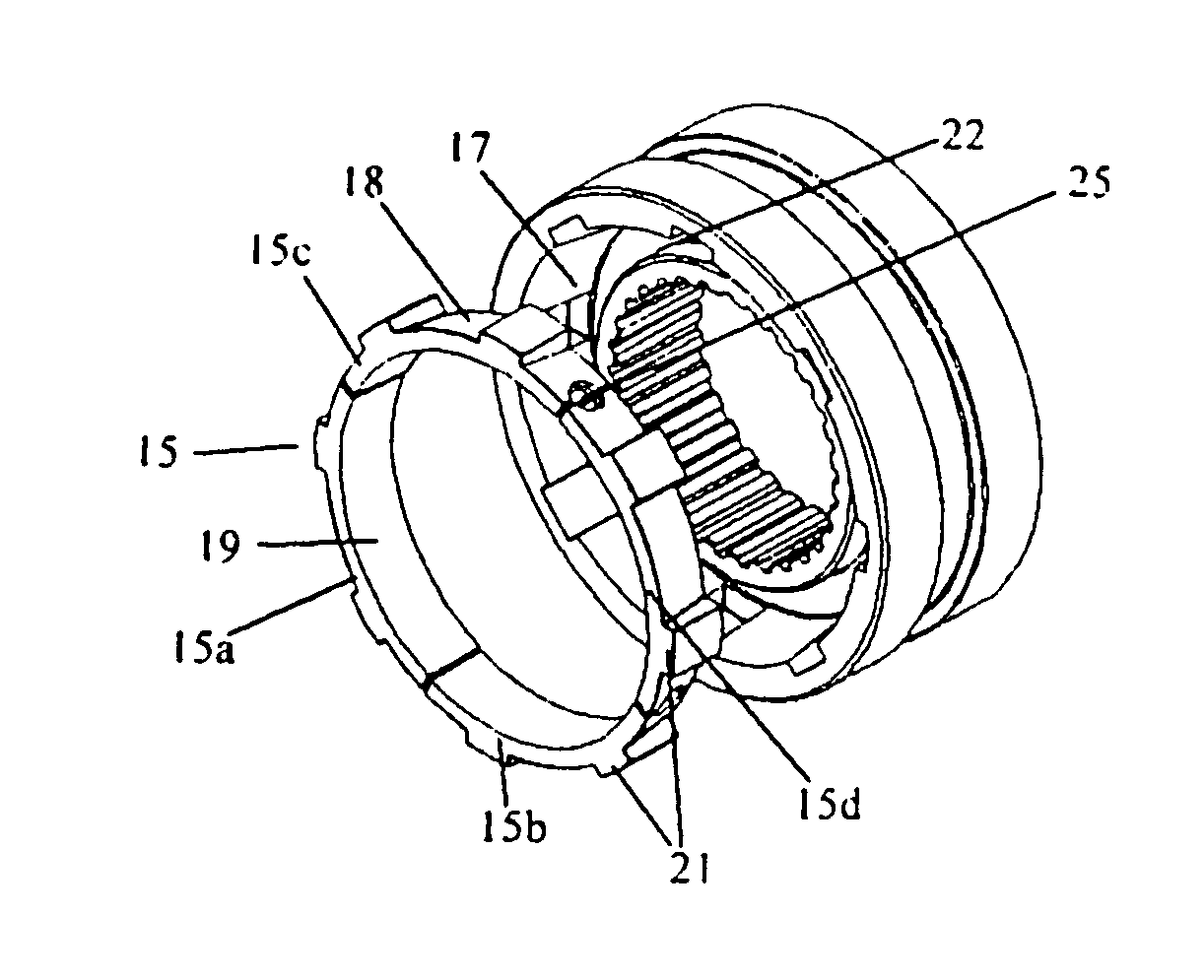

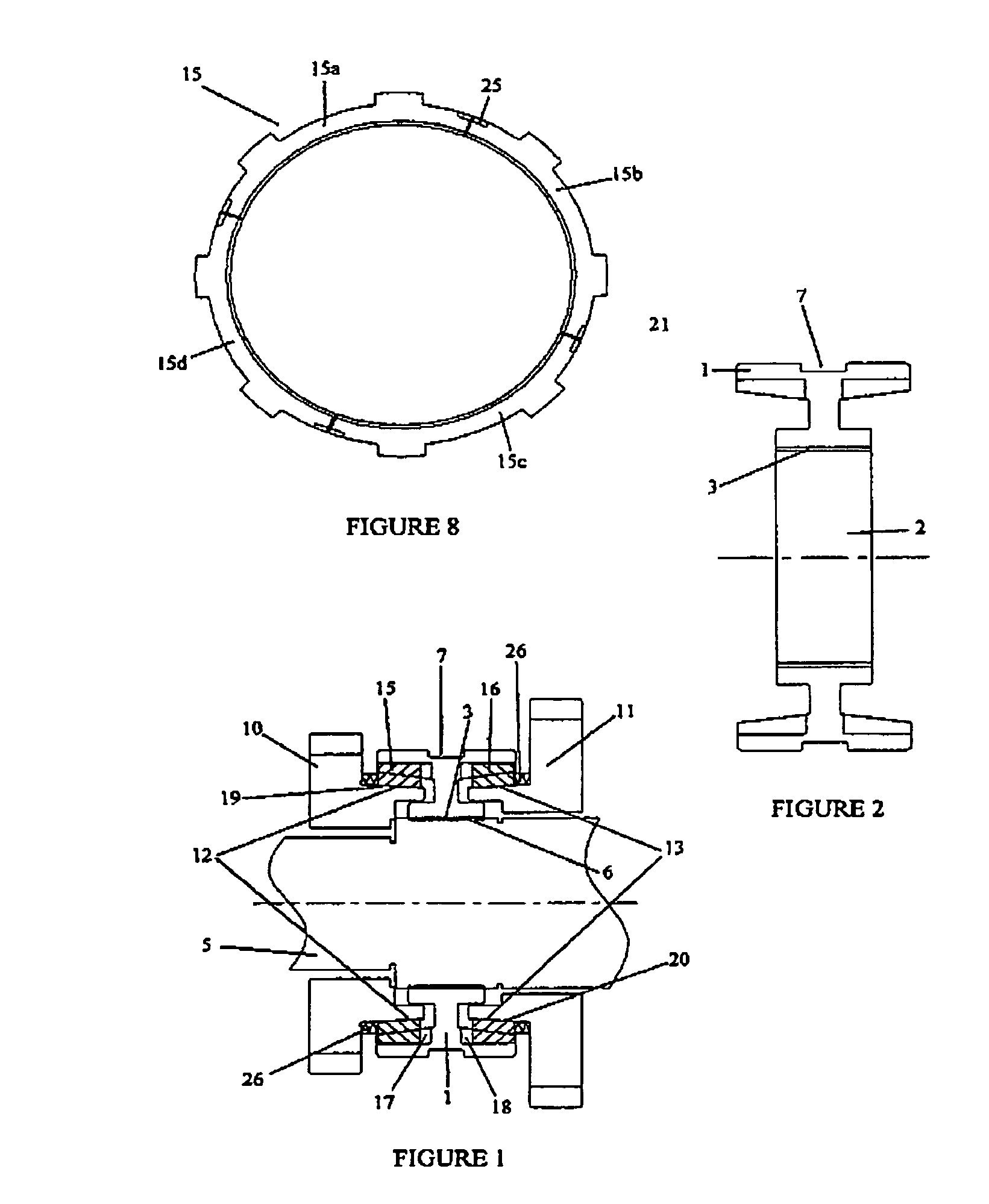

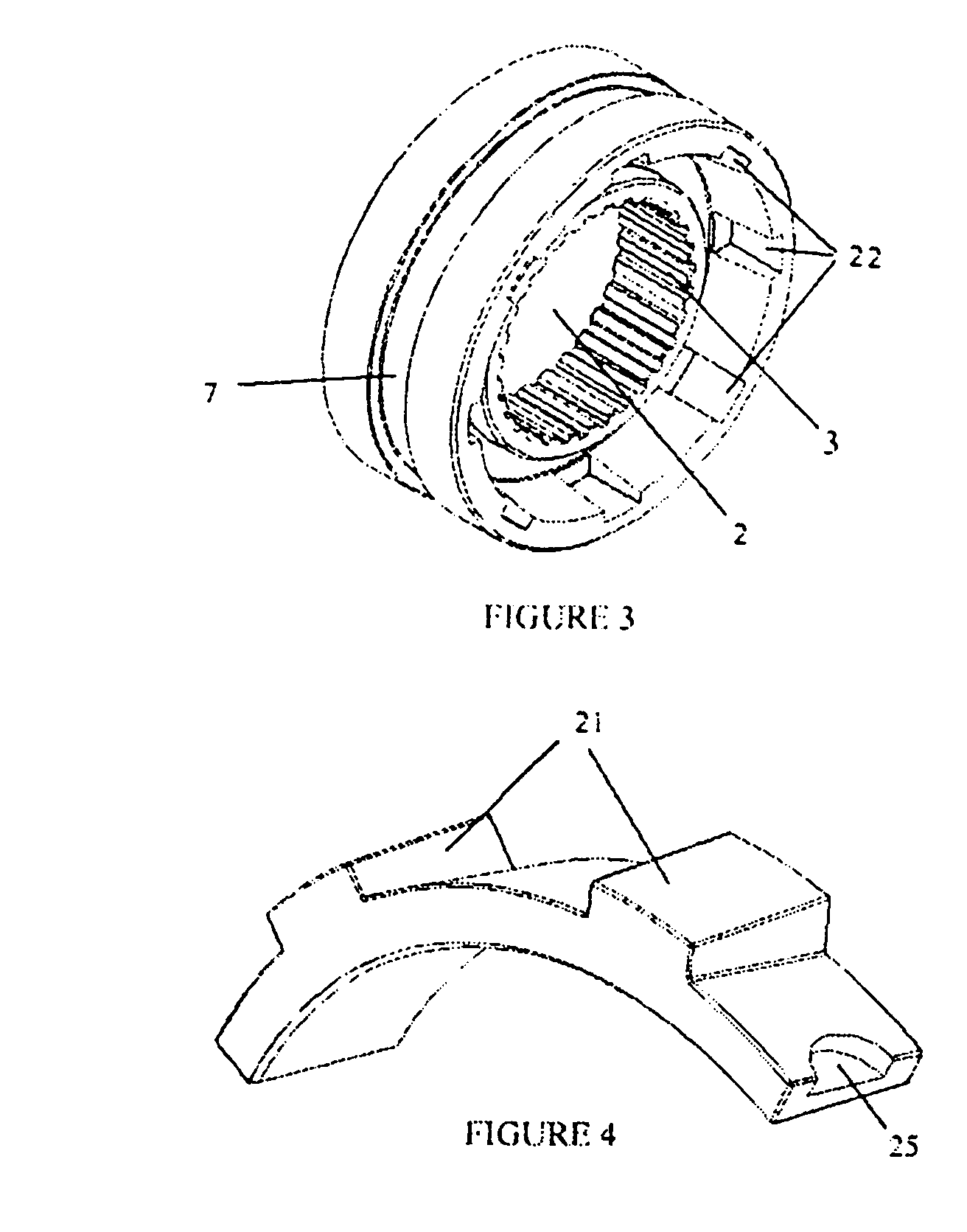

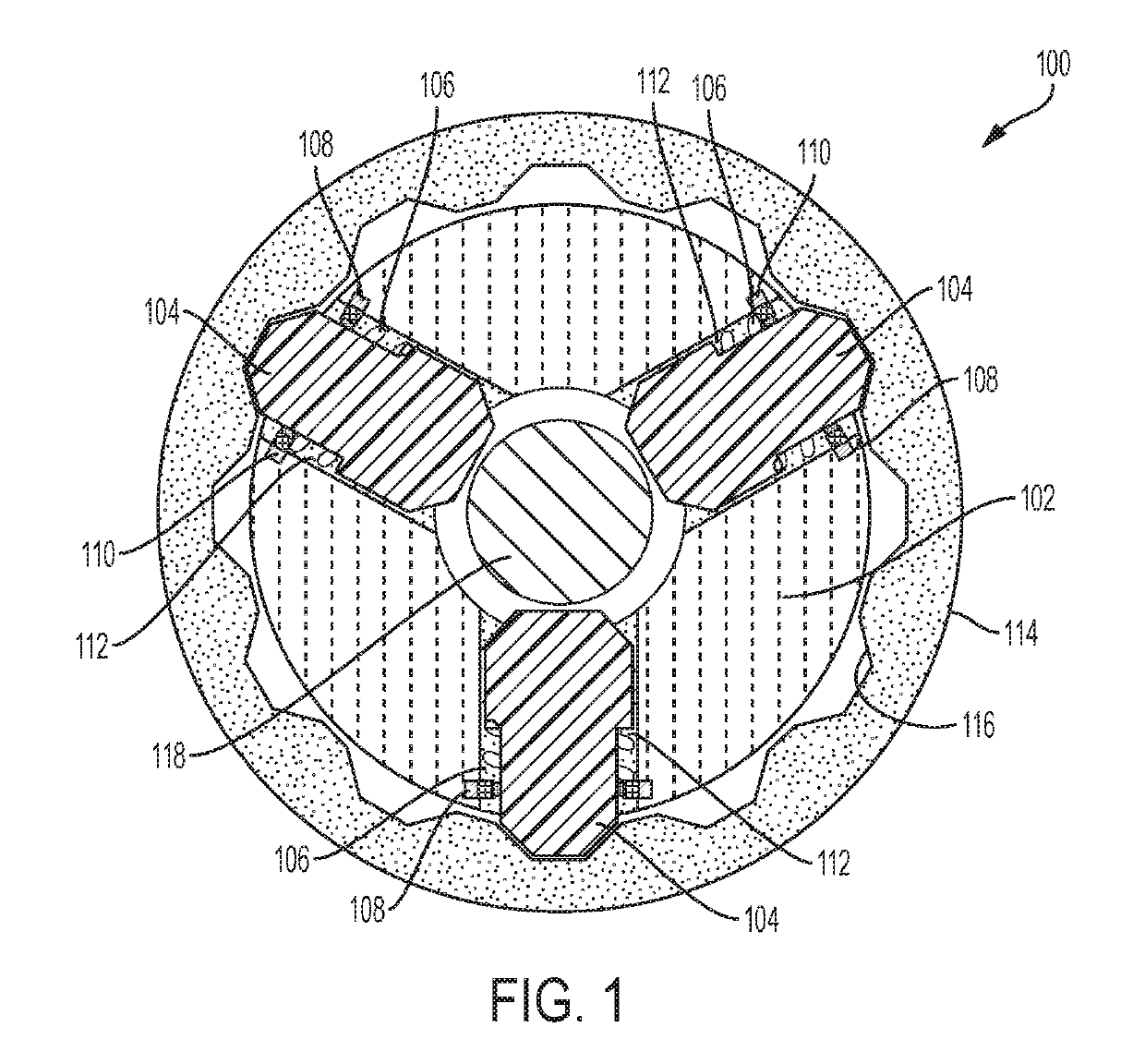

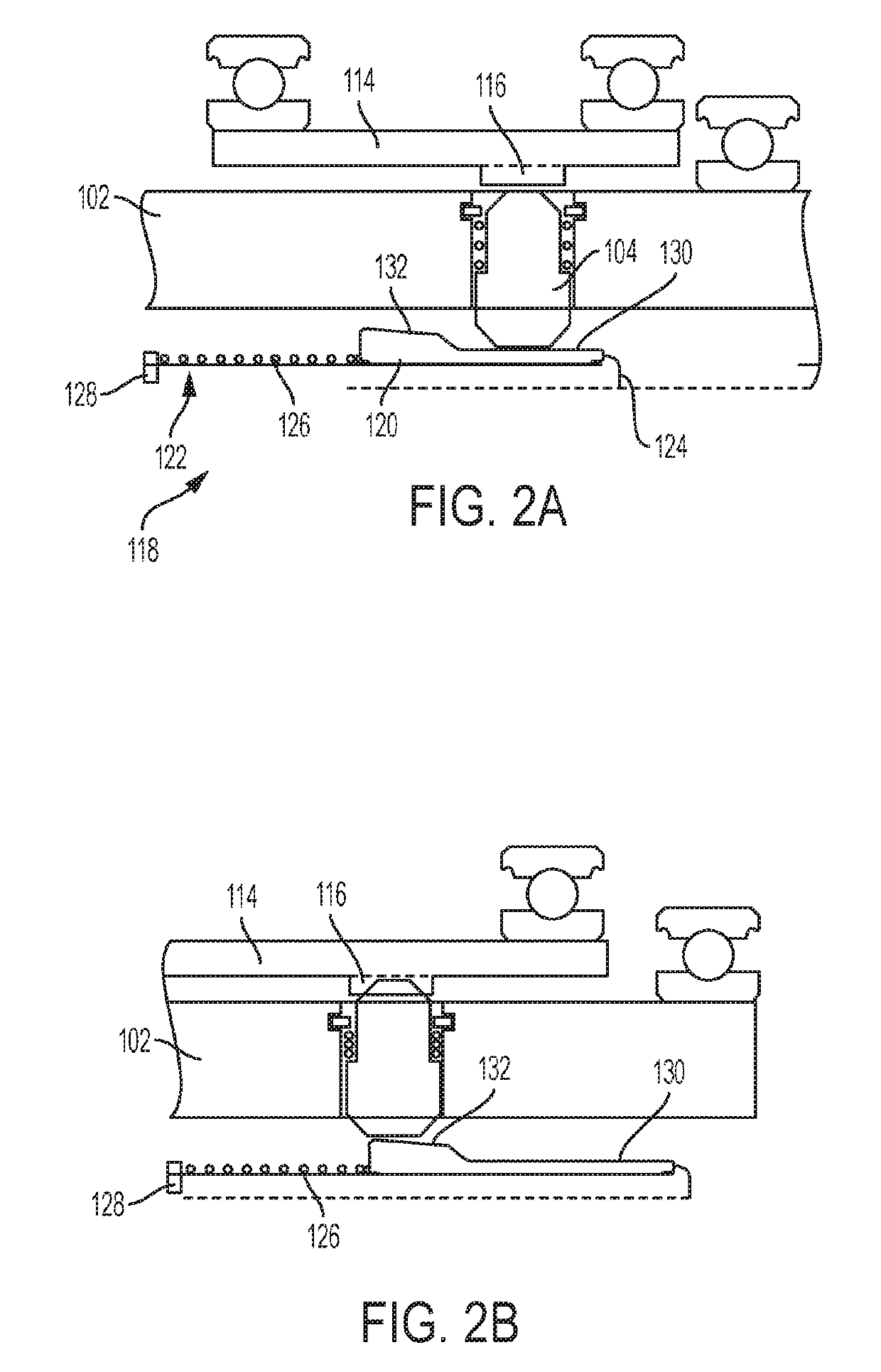

Segmented synchronizer clutch

ActiveUS7121393B1Easy to assembleReliable couplingFriction clutchesInterengaging clutchesEngineeringFriction force

A synchronizer clutch assembly includes a clutch hub which is axially movably mounted on a shaft, a gear which is axially spaced from the hub and which is journally mounted on the shaft and rotatable independent thereof, one of the hub or the gear having a conical friction surface formed thereon, and a synchronizer ring positioned between the hub and the gear. The synchronizer ring is coupled to the hub or the gear for rotation therewith and has a complementary conical friction surface formed thereon which is engageable with the conical friction surface on the hub or the gear. The synchronizer ring is composed of a plurality of separate arcuate segments arranged in a ring, which are movable between a first expanded configuration and a second, contracted configuration.

Owner:SULZER FRICTION SYST US

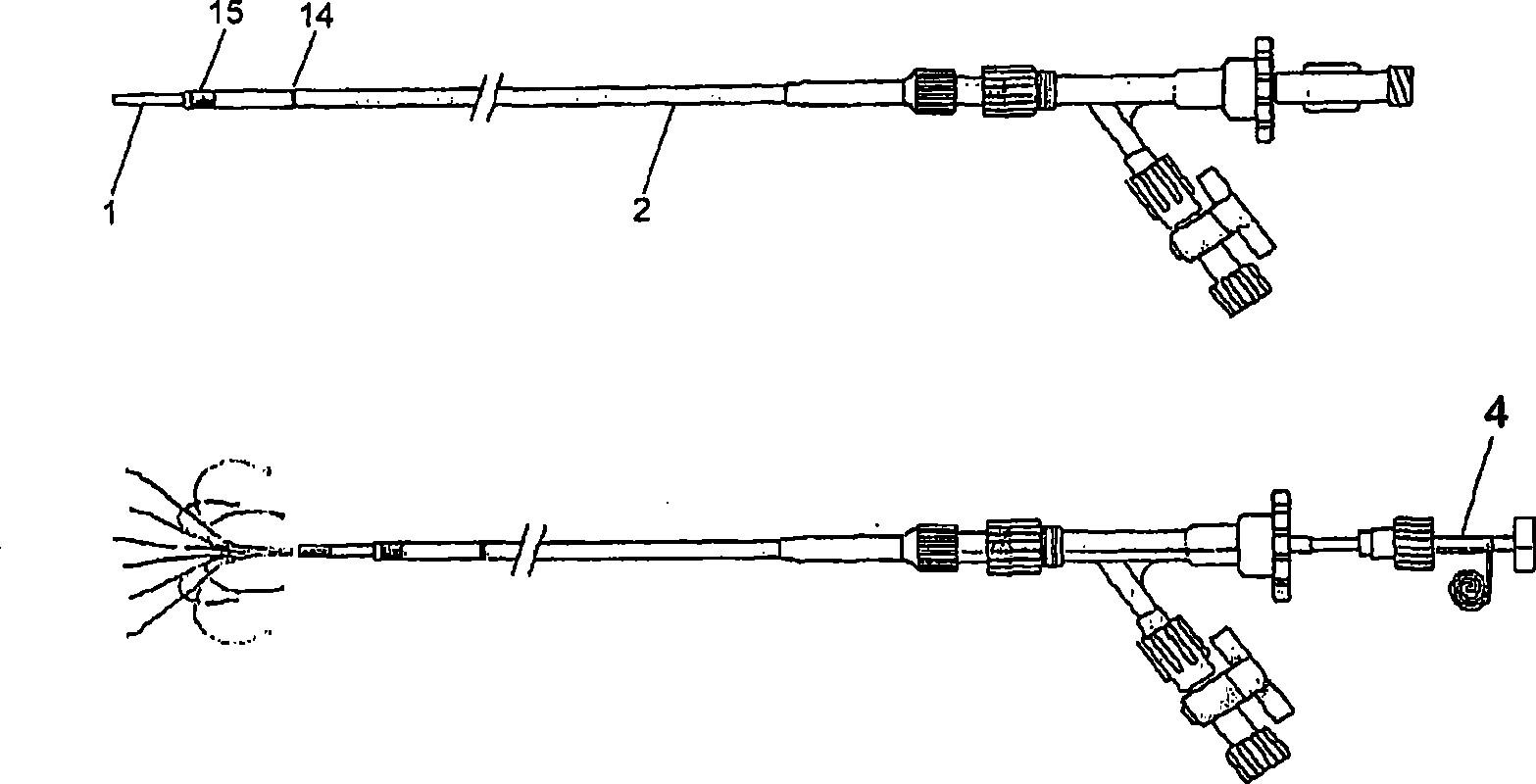

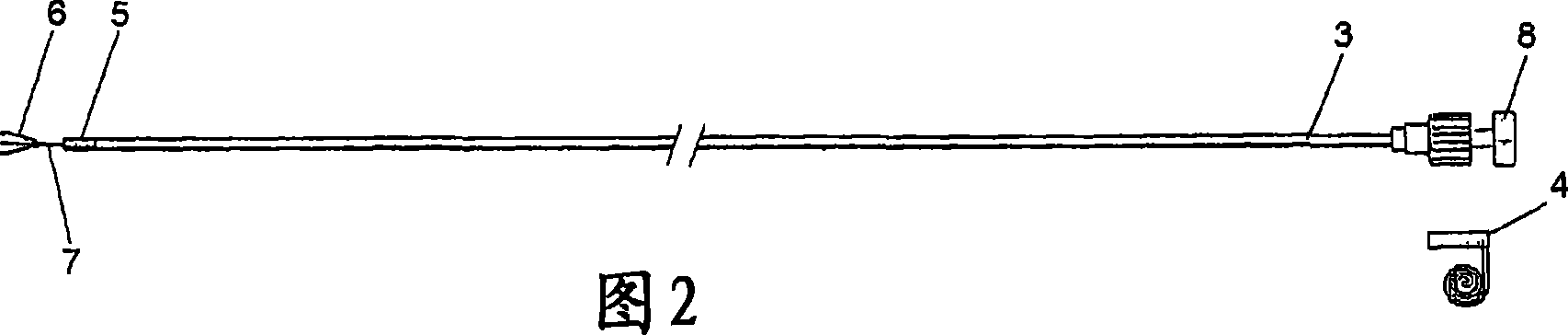

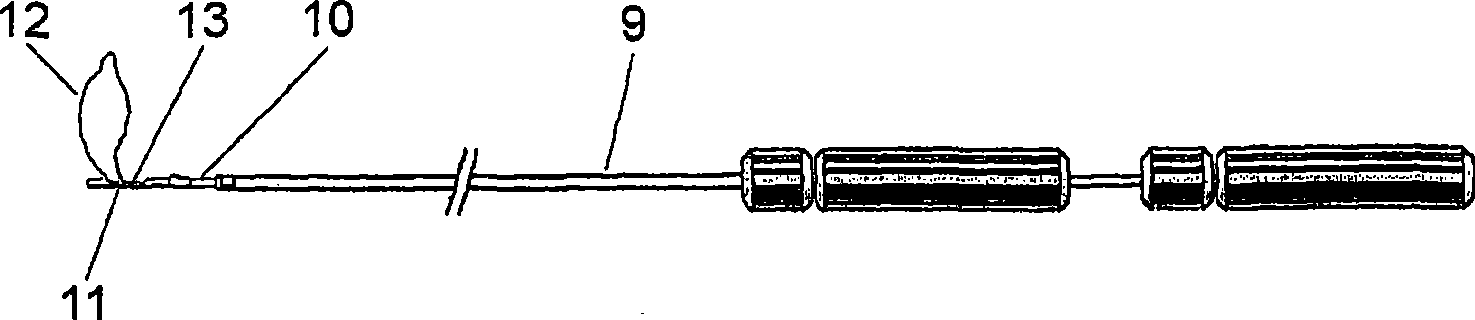

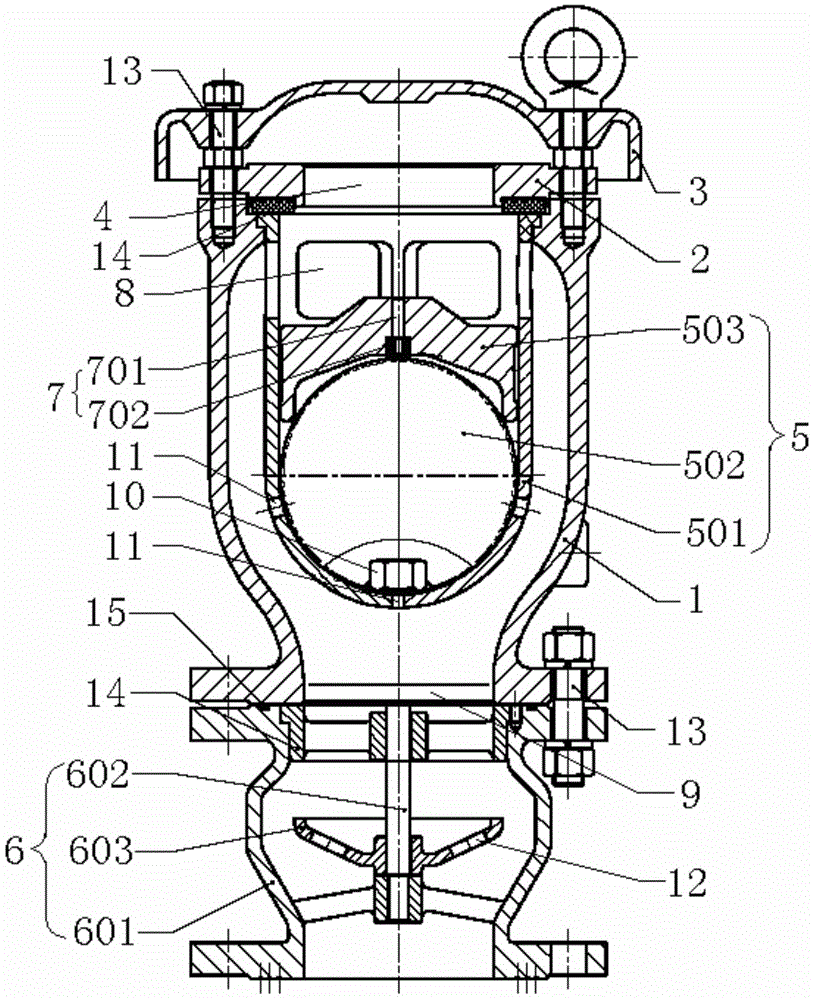

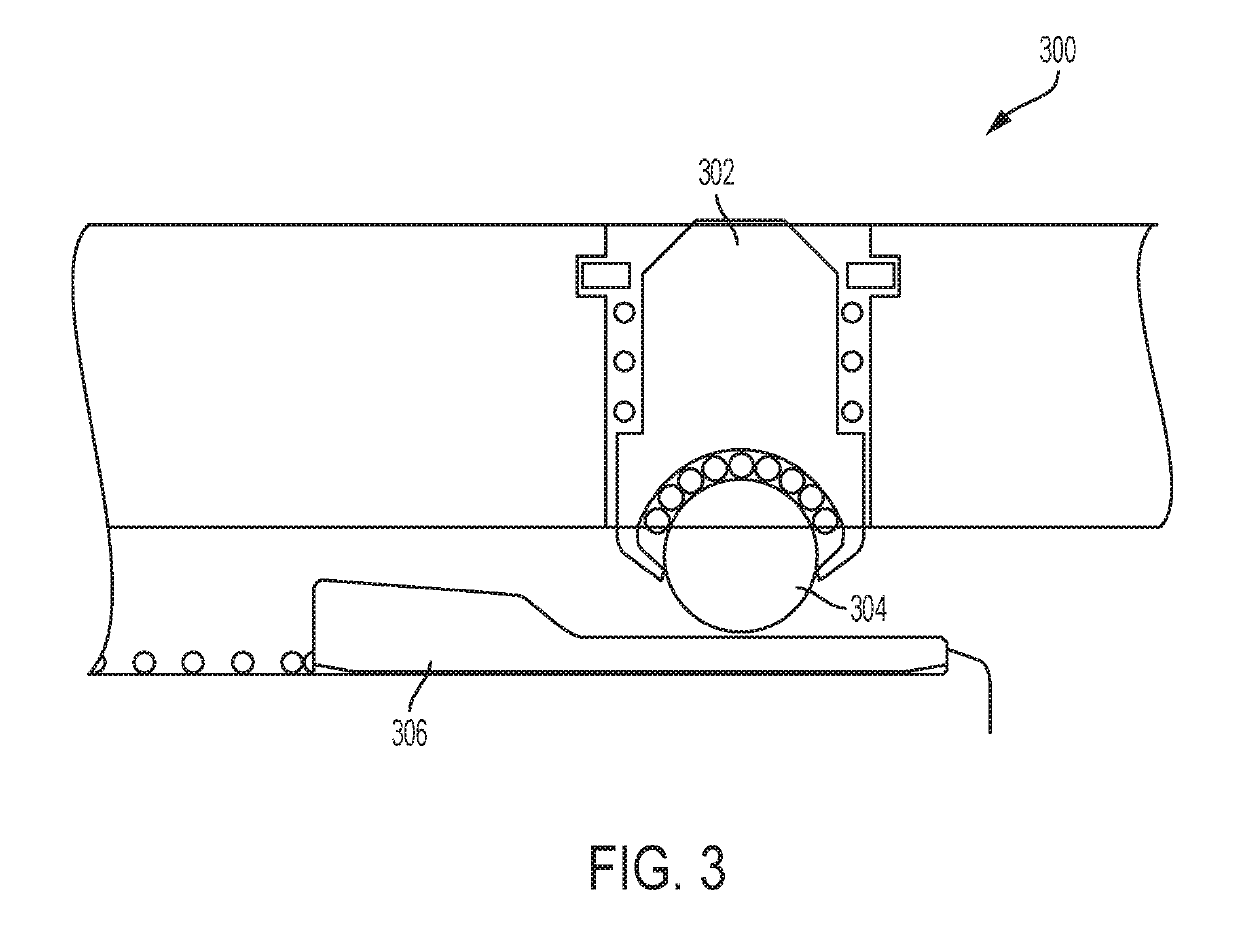

Set for preventing a lung artery thrombembolia and an intravenous filter

InactiveCN101389289AImprove filtering effectReliable captureDiagnosticsExcision instrumentsFastenerSurgical instrument

The group of useful inventions concerns the field of medical technology, more specially to surgical instruments for catching of thromoemboli and to devices for their transport to an installation site. The a set for preventive maintenance of a thromboembolism of a pulmonary artery comprises a filter and a mounting device for its installation and extraction. In the mounting device for the installment of the filter the pusher (3) is provided with a movement limiting stop (4), and its working block is made in the form of a capsule (5) with an axially movable therein clamping cartridge (6) and a mechanism for its movement. The working block (10) of the extractor device is made in the form of a casing (13) with an aperture and a loop extending therefrom in perpendicular direction to the axis of the extractor. In the filter, the free ends (19, 20) of the fixing and centering elements are bent outwards. The threads (23) of both elements have an identical radius of bend at the end (18). The free ends (20) of the centering element have blunted ends and are made in the form of a circular-arch segment preventing the blunted ends of the fully unfolded centering legs from touching the walls of the vena cava and being directed to the centre of the lumen of the vein. The free ends (19) of the fixing element (17) are provided with protective areas (20) located between the conical part and the bent outwards fastener part and in parallel to the axis of the vein.

Owner:弗里·格里马诺维奇·安德烈耶夫 +1

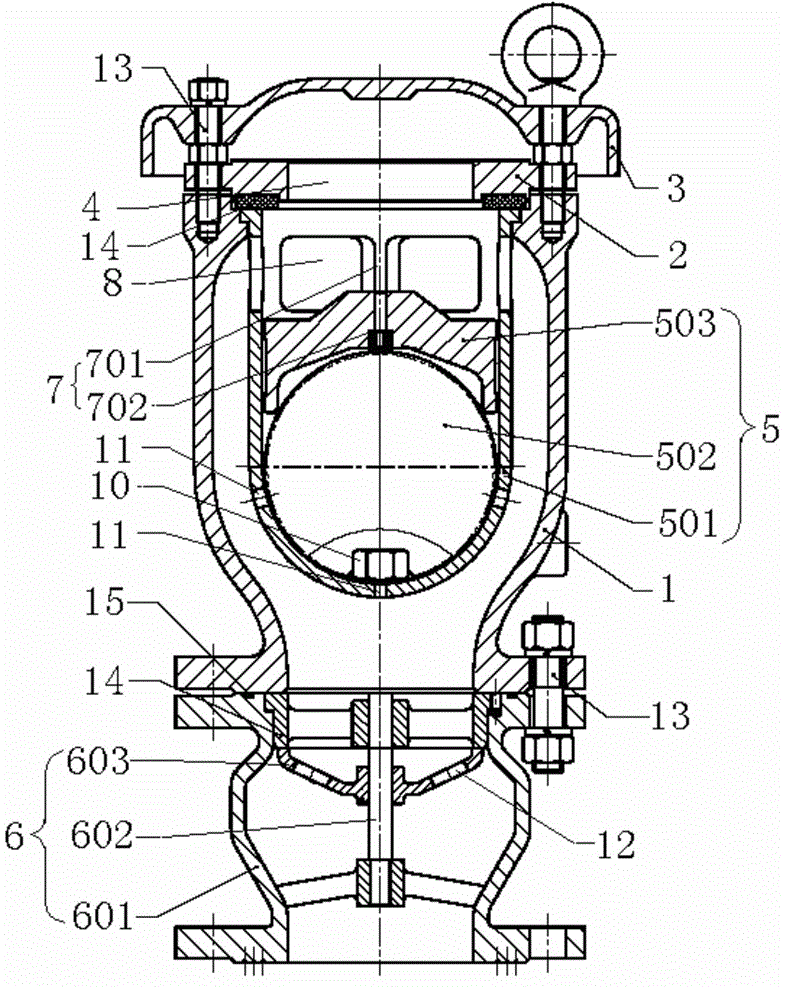

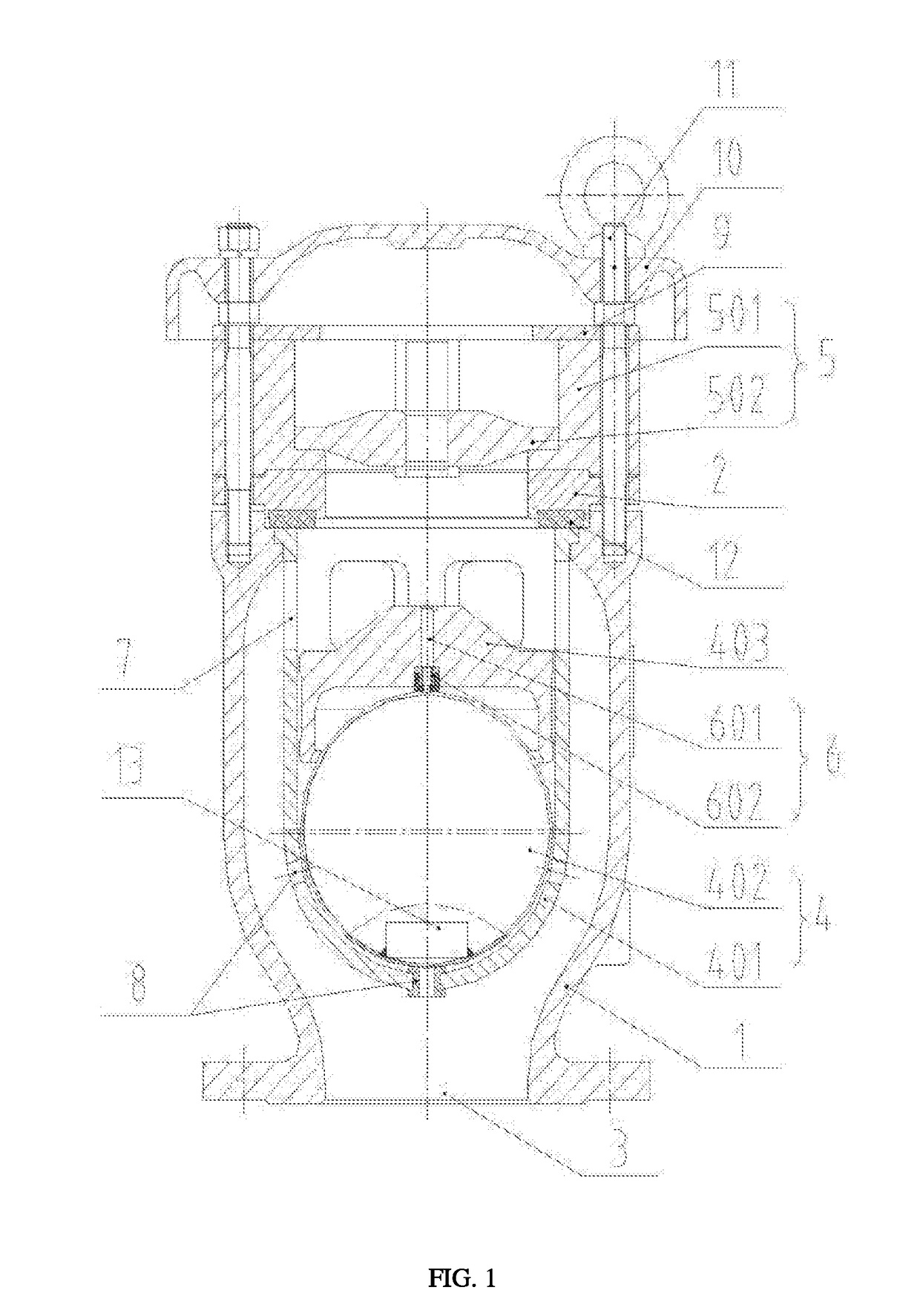

Water hammer air valve and water hammer gas discharging method during pipeline use

ActiveCN104896184AAvoid blowingAvoid air blockageValve members for absorbing fluid energyPipe elementsEngineeringWater hammer

The invention discloses a water hammer air valve and a water hammer gas discharging method during pipeline use. The water hammer air valve comprises a valve body, a bonnet and a protective cover, wherein the bonnet is provided with an opening, the protective cover is disposed on the opening, the valve body is provided with a valve opening for being communicated with a pipeline, a high-speed gas feeding and discharging device which is used for discharging gases stayed in the pipeline during water filling to the outside and shutting down the valve after pipeline water filling is completed is disposed in the inner cavity of the valve body, the output end of the high-speed gas feeding and discharging device is communicated with the outside through the opening of the bonnet, and the valve opening of the valve body is communicated with a bottom gas discharging throttling device for limiting the gas displacement of the pipeline to the inner cavity of the valve body; a trace gas discharging device for discharging mixed, residual and / or precipitated gases in the pipeline to the outside through the opening of the bonnet after the high-speed gas feeding and discharging device shuts down the valve is further disposed in the high-speed gas feeding and discharging device. By the water hammer air valve, water hammer reduction and pipeline safety protection are achieved, blowing blocking during high-speed gas discharging is avoided, and valve closing water hammer is eliminated.

Owner:ZHUZHOU SOUTHERN VALVE

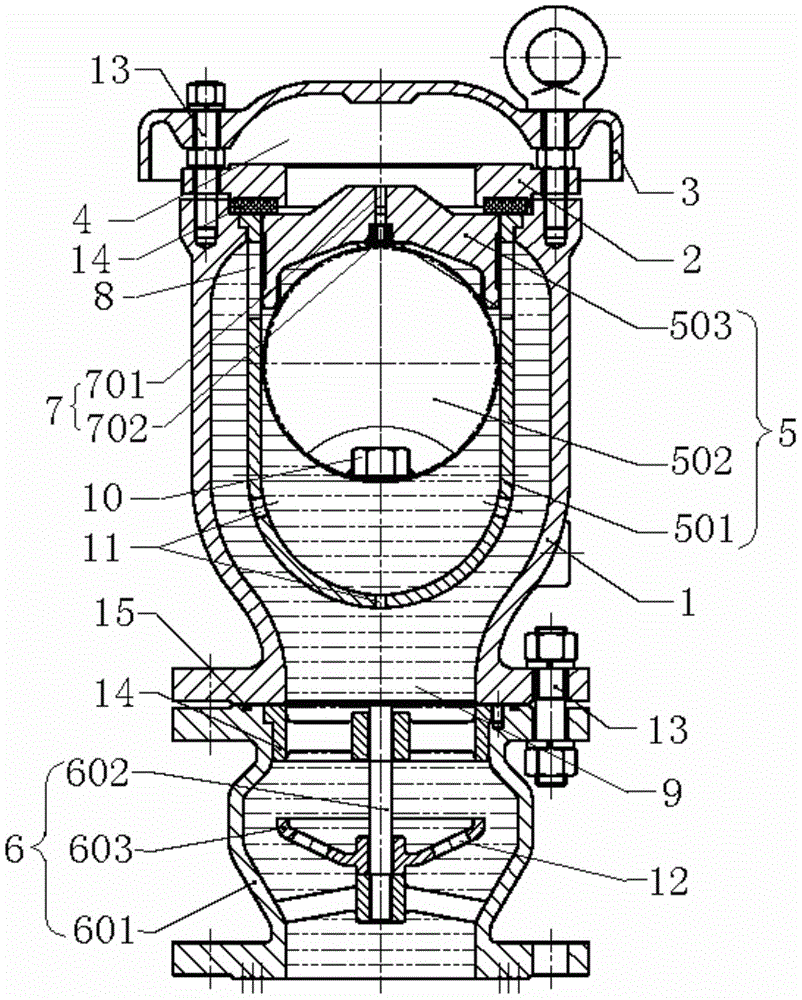

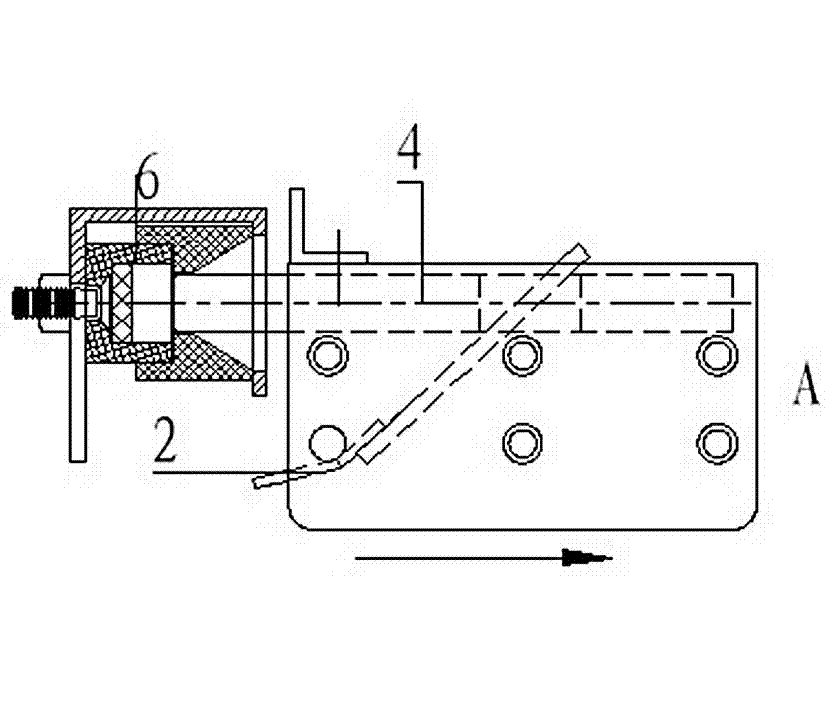

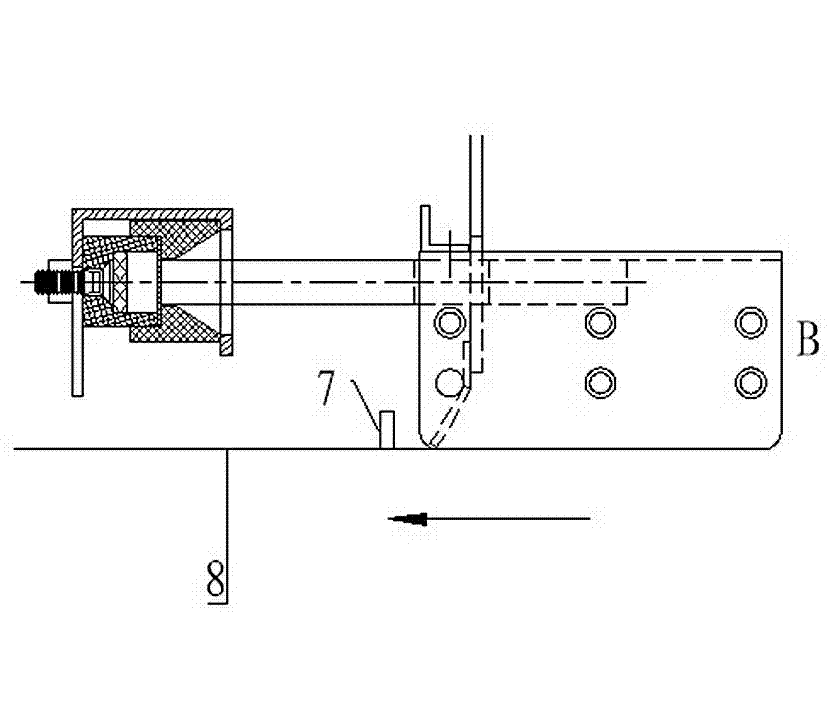

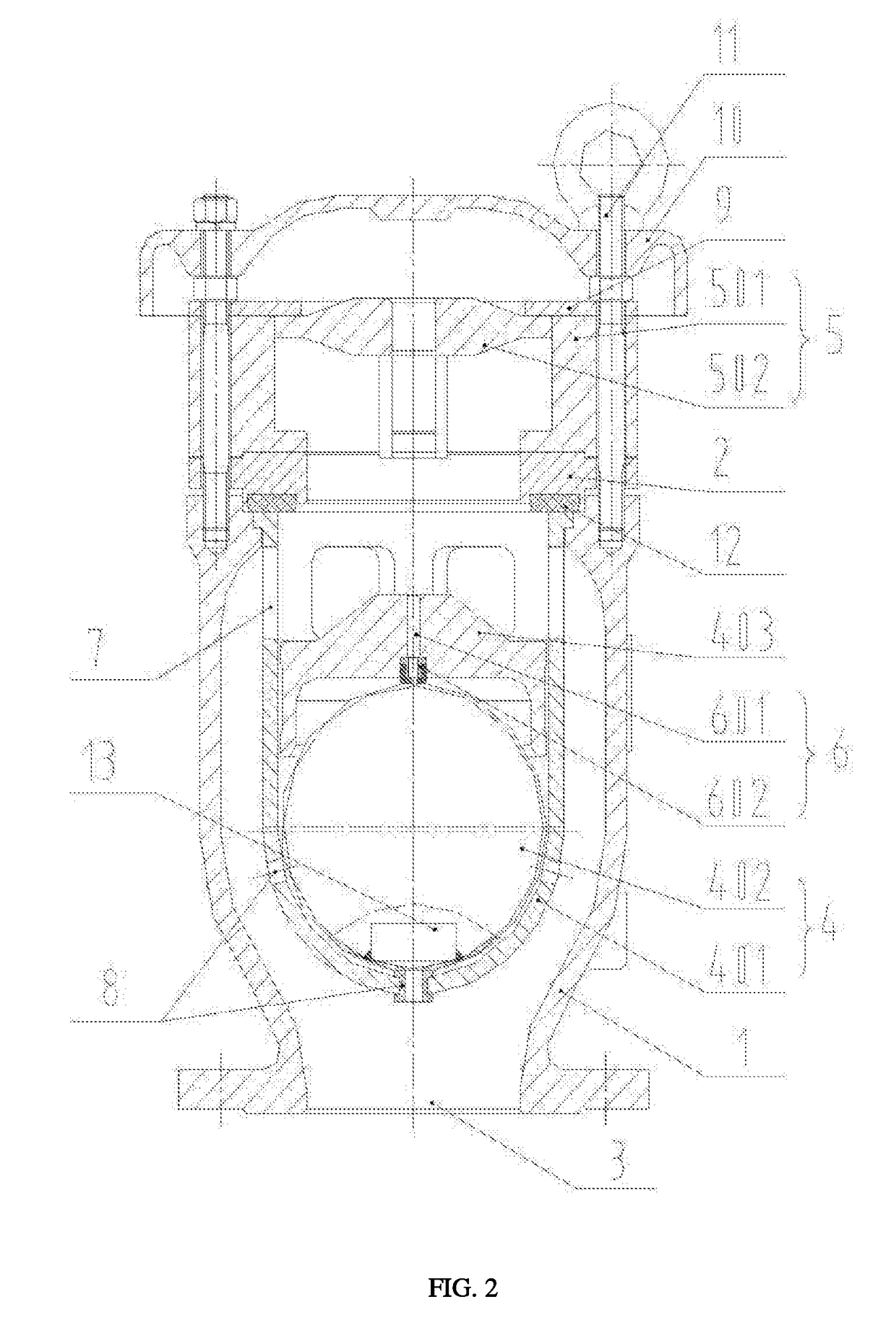

Parachute opening force measuring system and method applied to spacecraft airdrop test

ActiveCN104215376AGuaranteed Continuity and EffectivenessEnsure normal parachute opening procedureApparatus for force/torque/work measurementWork programPull force

The invention provides a parachute opening force measuring system and method applied to a spacecraft airdrop test. The system is characterized in that one end of a pulling force sensor is mounted and connected to a parachute suspender through a first adapter connector, and while the other end of the pulling force sensor is abutted and mounted to a parachute connecting and disconnecting mechanism on a cabin body through a second adapter connector and an adapter connecting suspender; a data cable on the pulling force sensor is mounted and fixed to the cabin body through a separable electric connector, wherein the separable electric connector sleeves a rope pin of the second adapter connector through a pulling rope. According to the parachute opening force measuring system and method applied to the spacecraft airdrop test, the parachute is pulled out of a parachute cabin, a closed opening is released and then the parachute is fully charged with air; the puling force sensor measures the parachute opening force during dropping the parachute and inputs the data to an inner recorder for storing through the data cable by utilizing the separable electric connector; the pulling rope of the separable electric connector is pulled while the parachute is separated from the cabin body according to the preset working program, and thus the separable electric connector is separated from the cabin body; when the cabin body arrives at the ground, the data can be read from the inner recorder.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

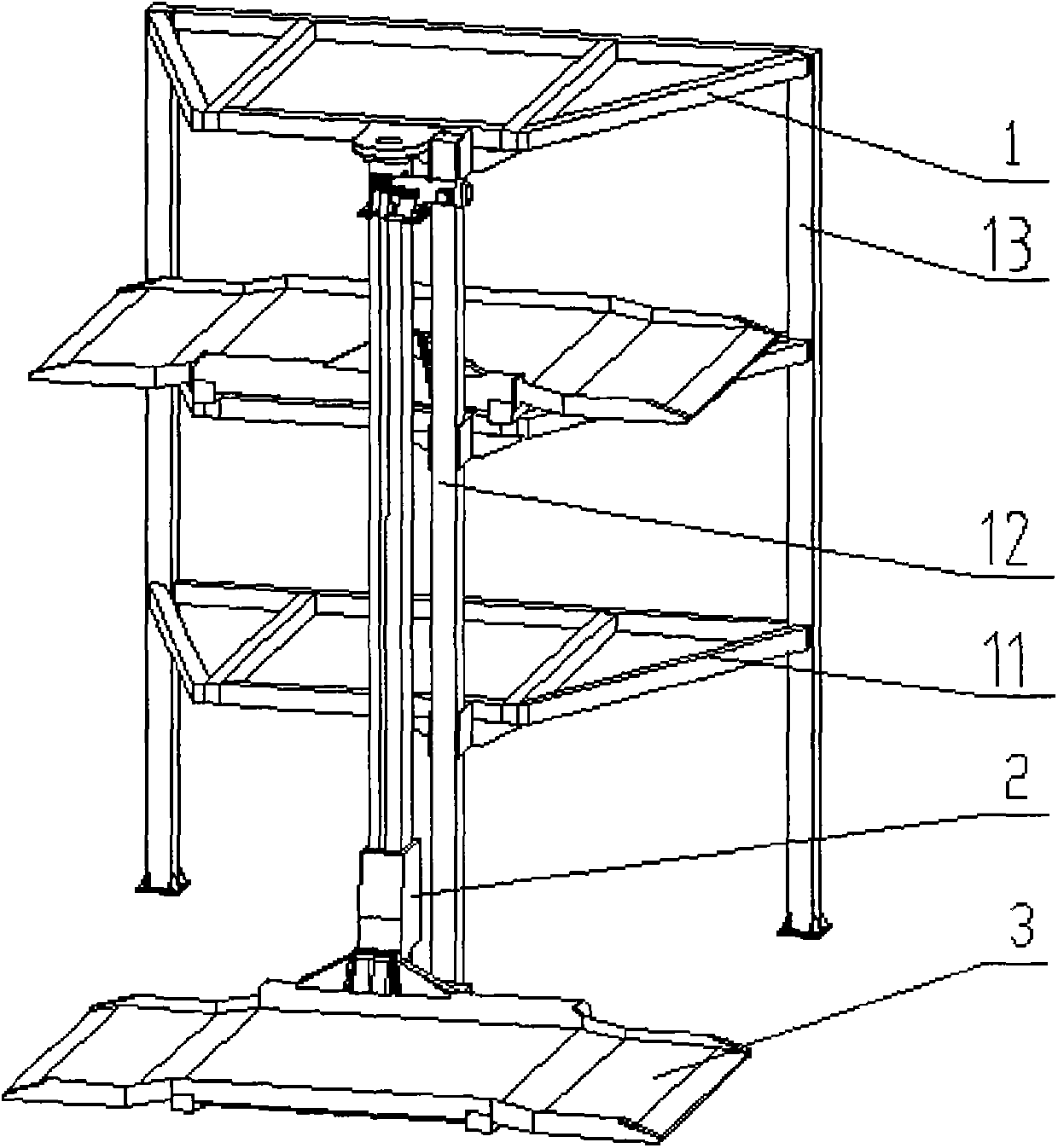

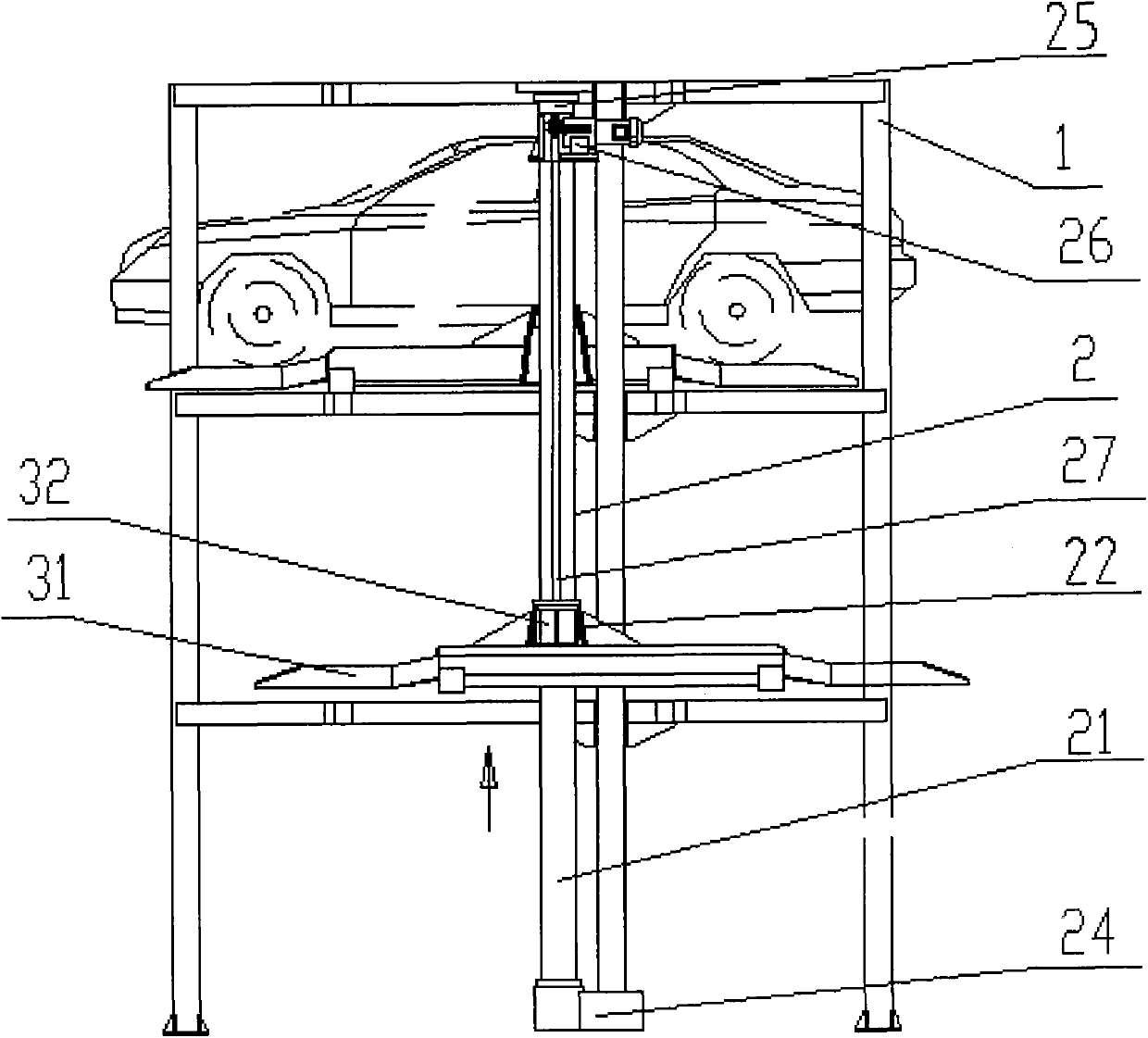

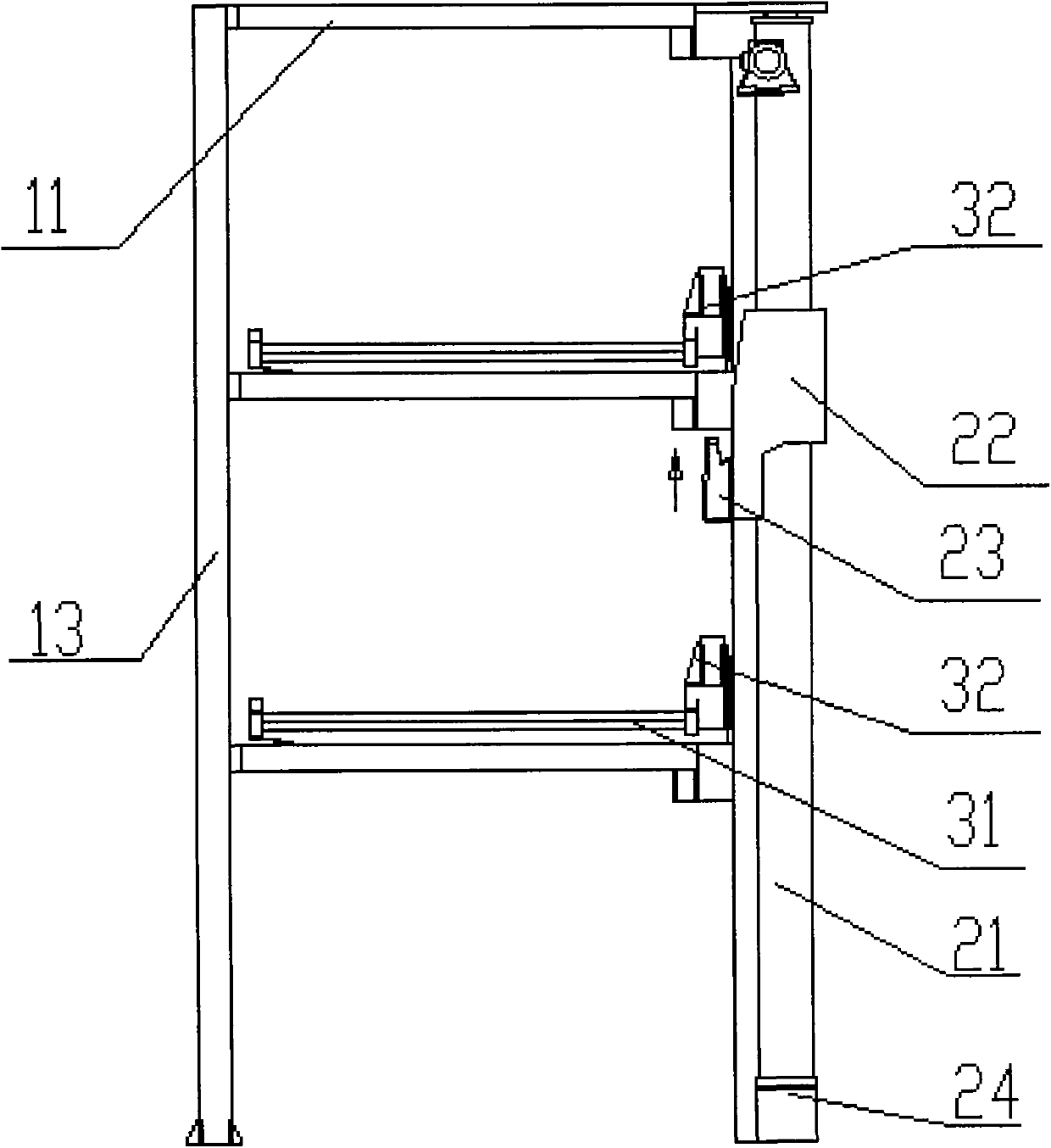

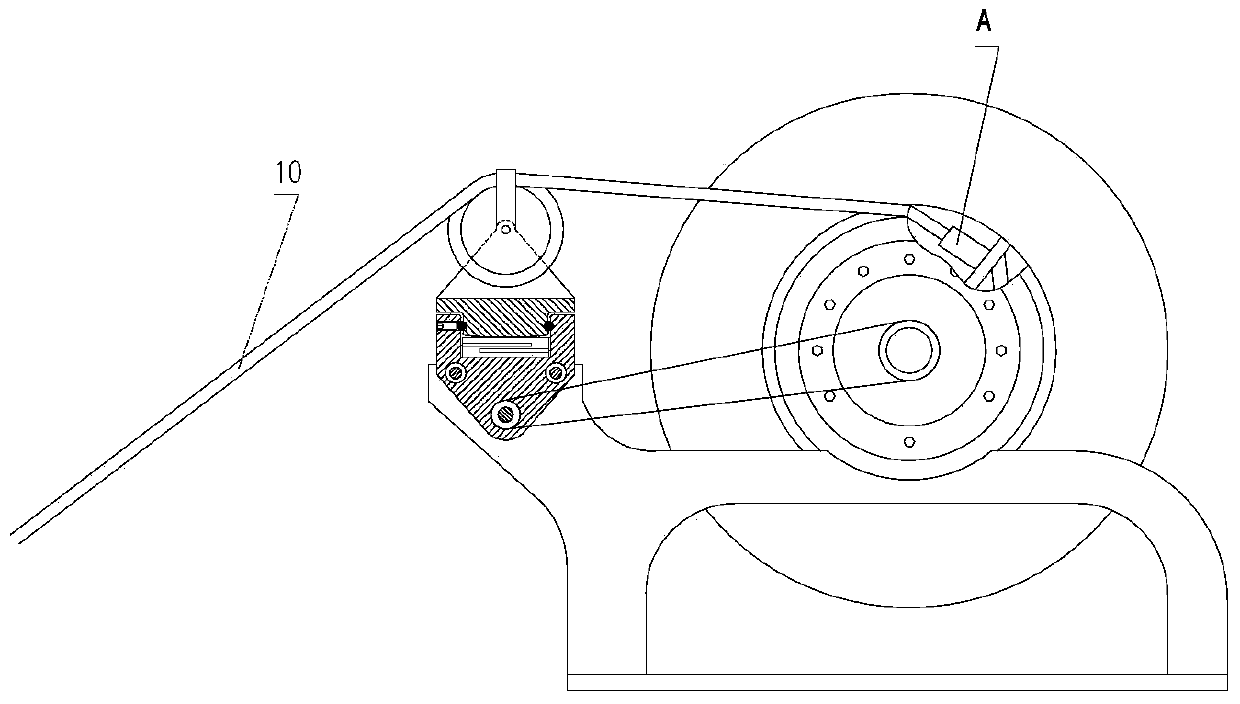

Automatic electricity-getting mechanism and automatic electricity-getting method for gantry crane

ActiveCN102229405ARealize free plug and take powerImprove mobilityLoad-engaging elementsElectricityLocking mechanism

The invention discloses an automatic electricity-getting mechanism which is accurately and automatically connected with and reliably fixed to a socket frame through a plug frame and used for a gantry crane and an automatic electricity-getting method. The automatic electricity-getting mechanism for the gantry crane comprises a connecting mechanism, wherein the connecting mechanism is connected with the plug frame through a coupling mechanism which can be separated; the plug frame is mated with the socket frame; and the plug frame and the socket frame can be fixed together through a locking mechanism. According to the invention, the automatic insertion and extraction of a power socket is realized during the field transfer of the gantry crane with a cable reel for power supply, the field transfer efficiency is improved, the safety hazards in the prior art are eliminated during the insertion and extraction of the power plug, the mechanism has the advantages of simple operation and control, and is safe, convenient and rapid, the maneuverability of the gantry crane can be improved greatly, thus under the premises of finishing the same operation amount, the quantity of used gantry cranes can be reduced.

Owner:凯伏特(上海)动力技术有限公司

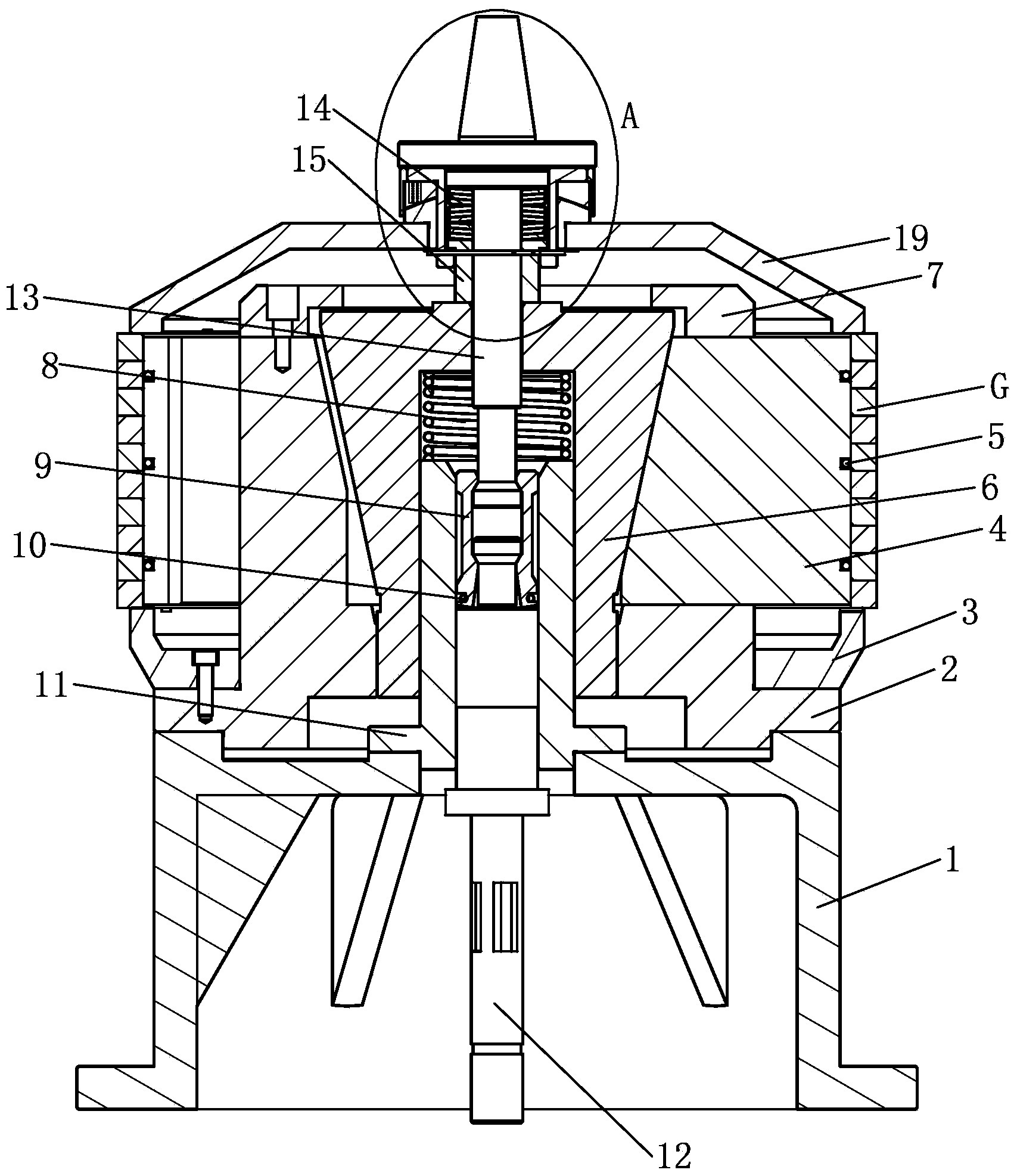

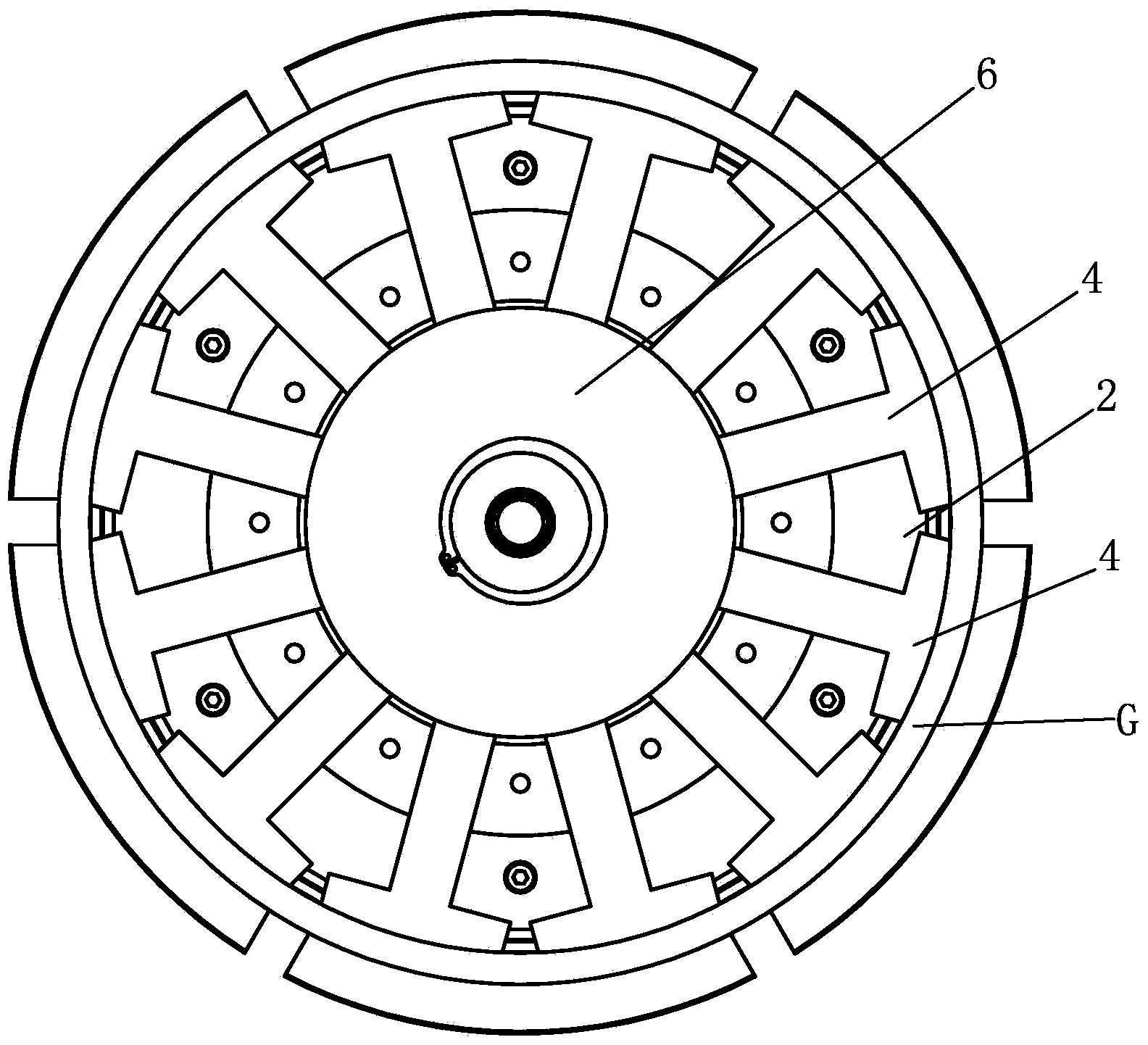

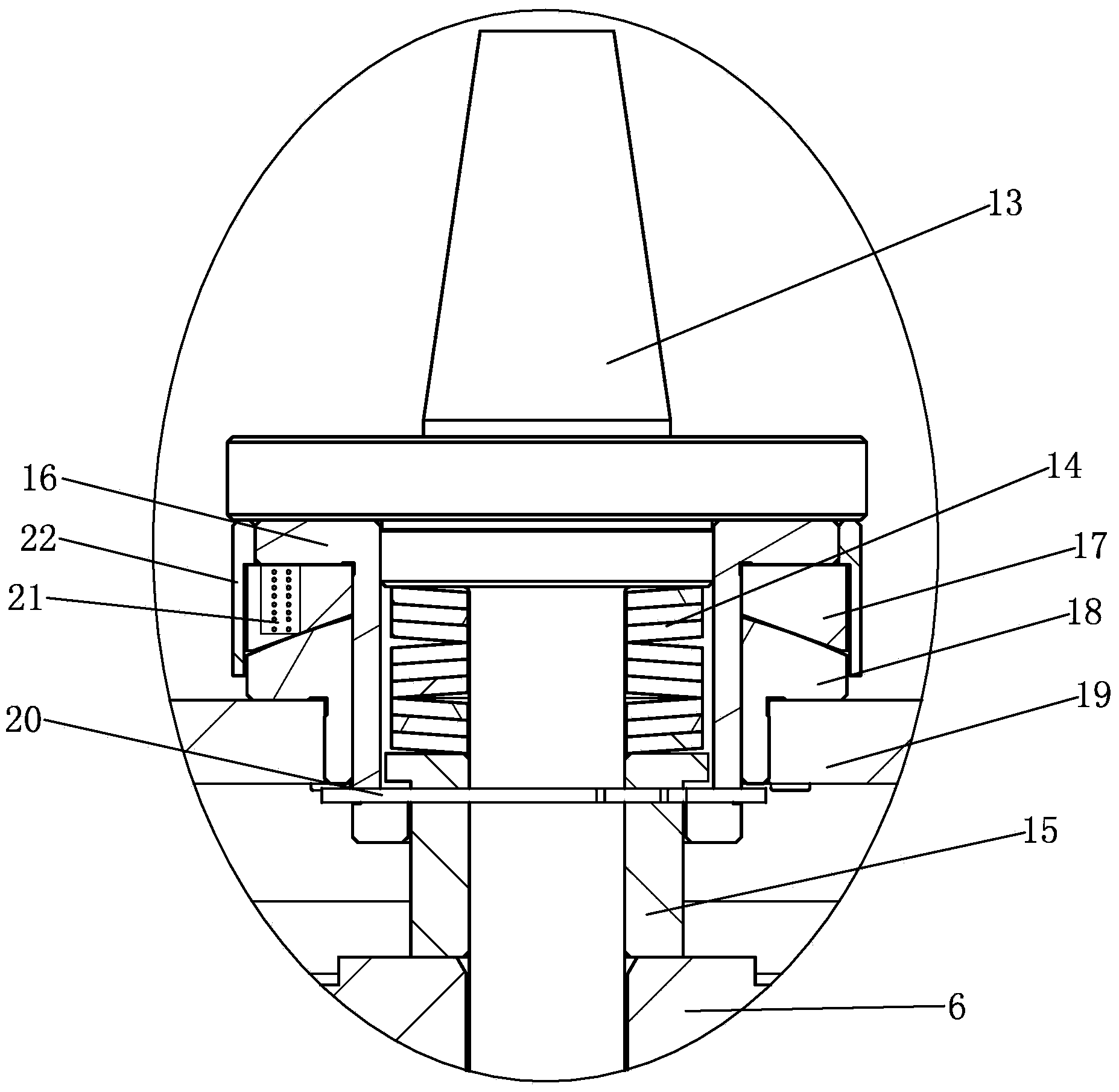

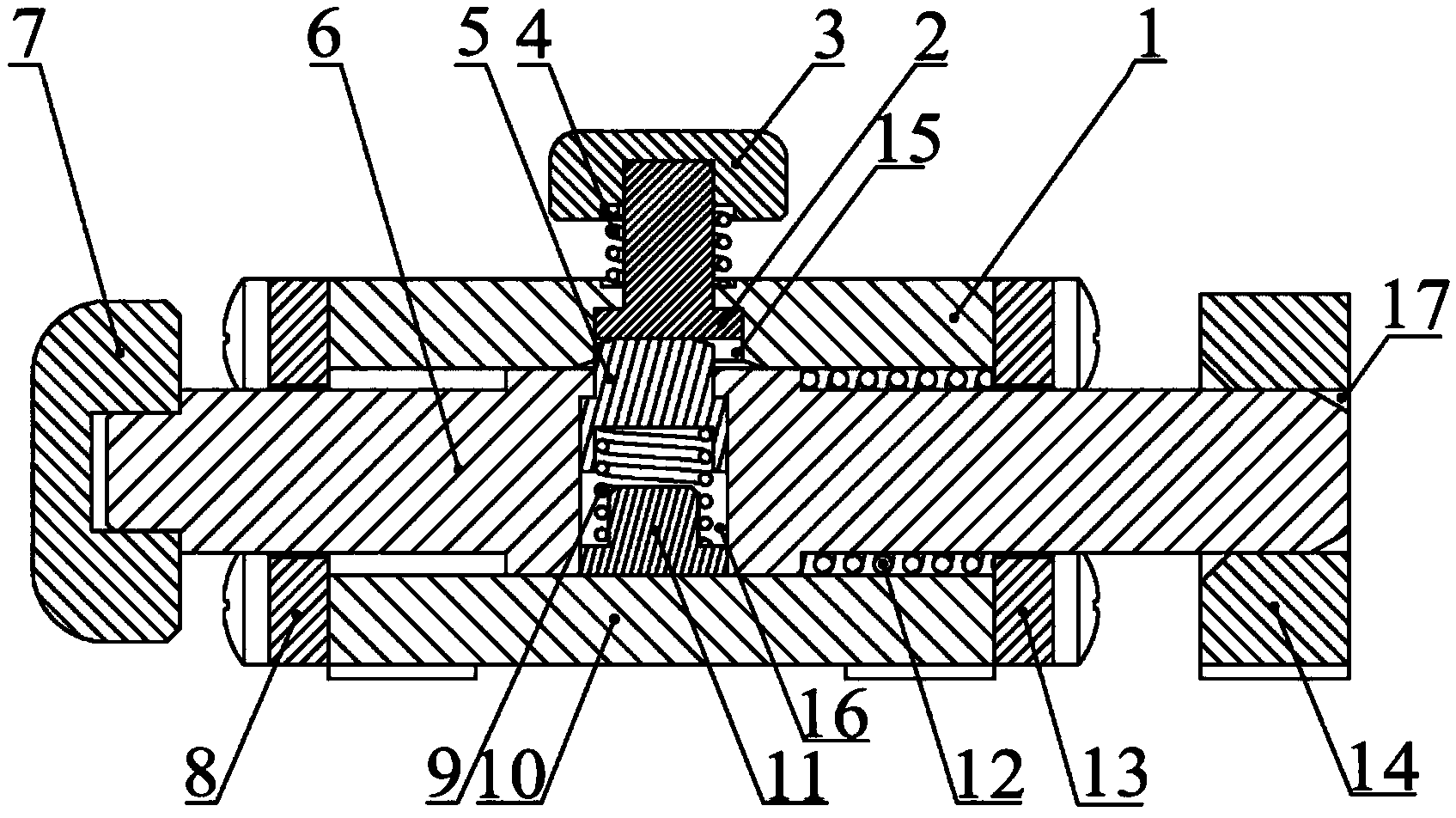

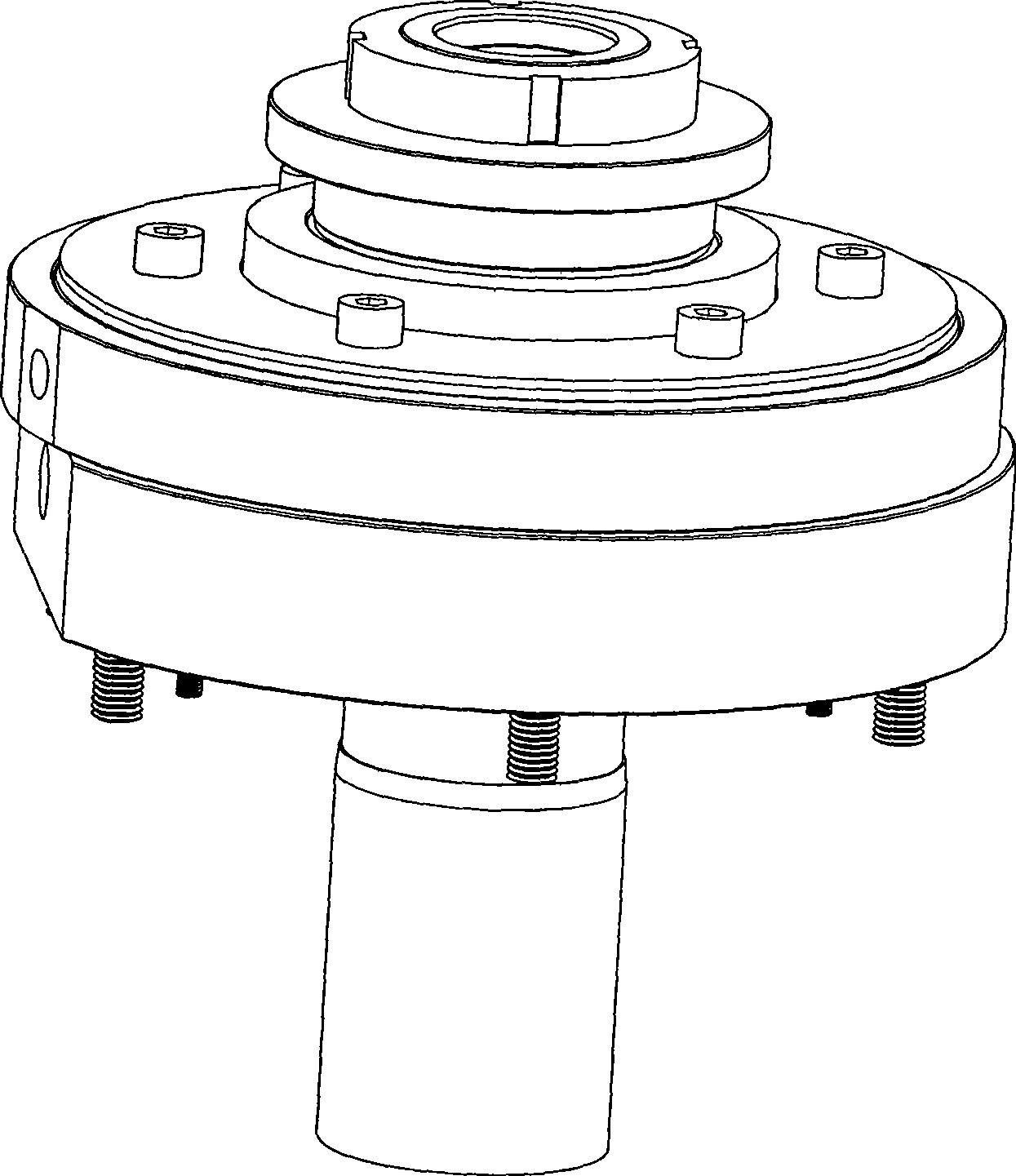

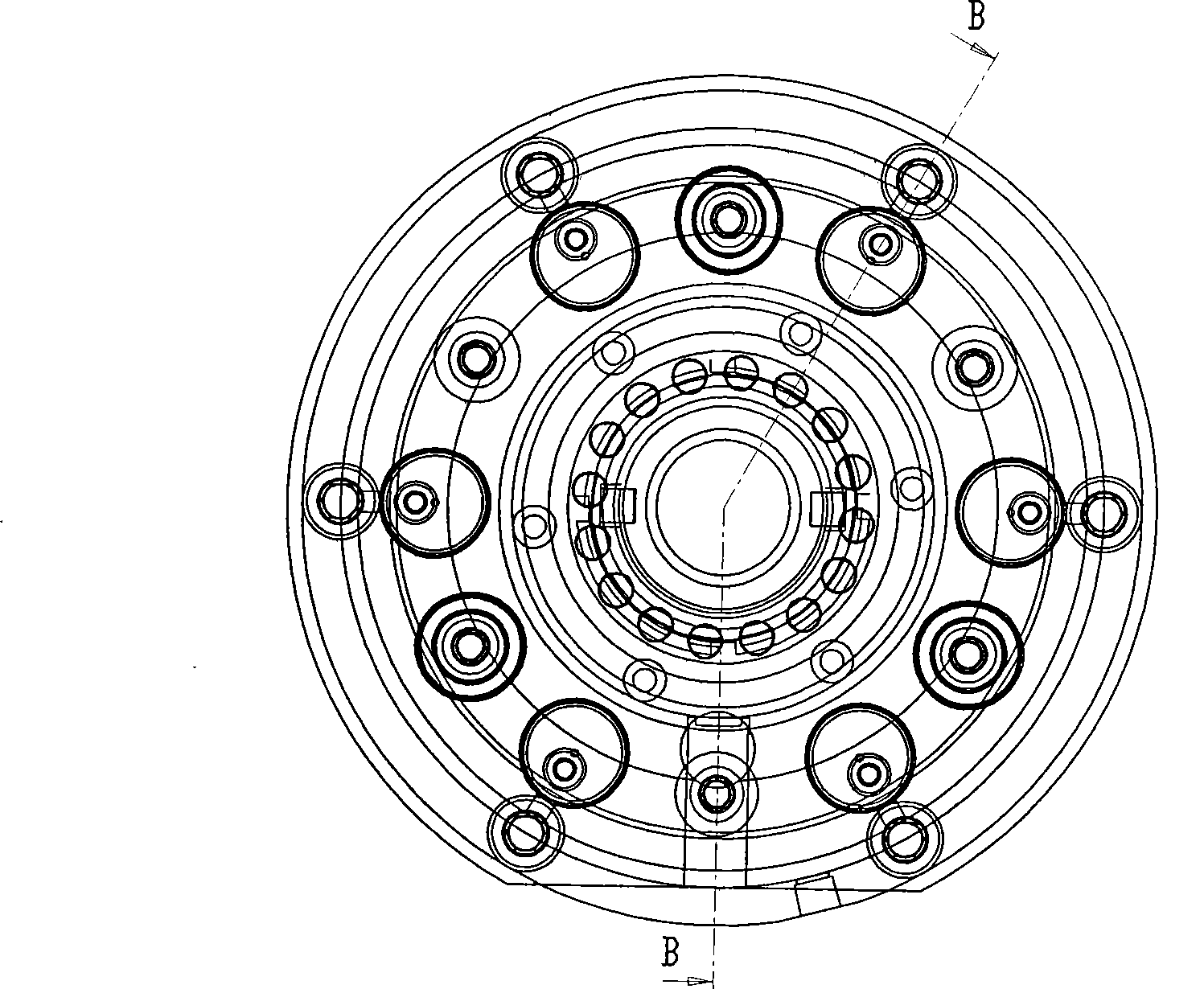

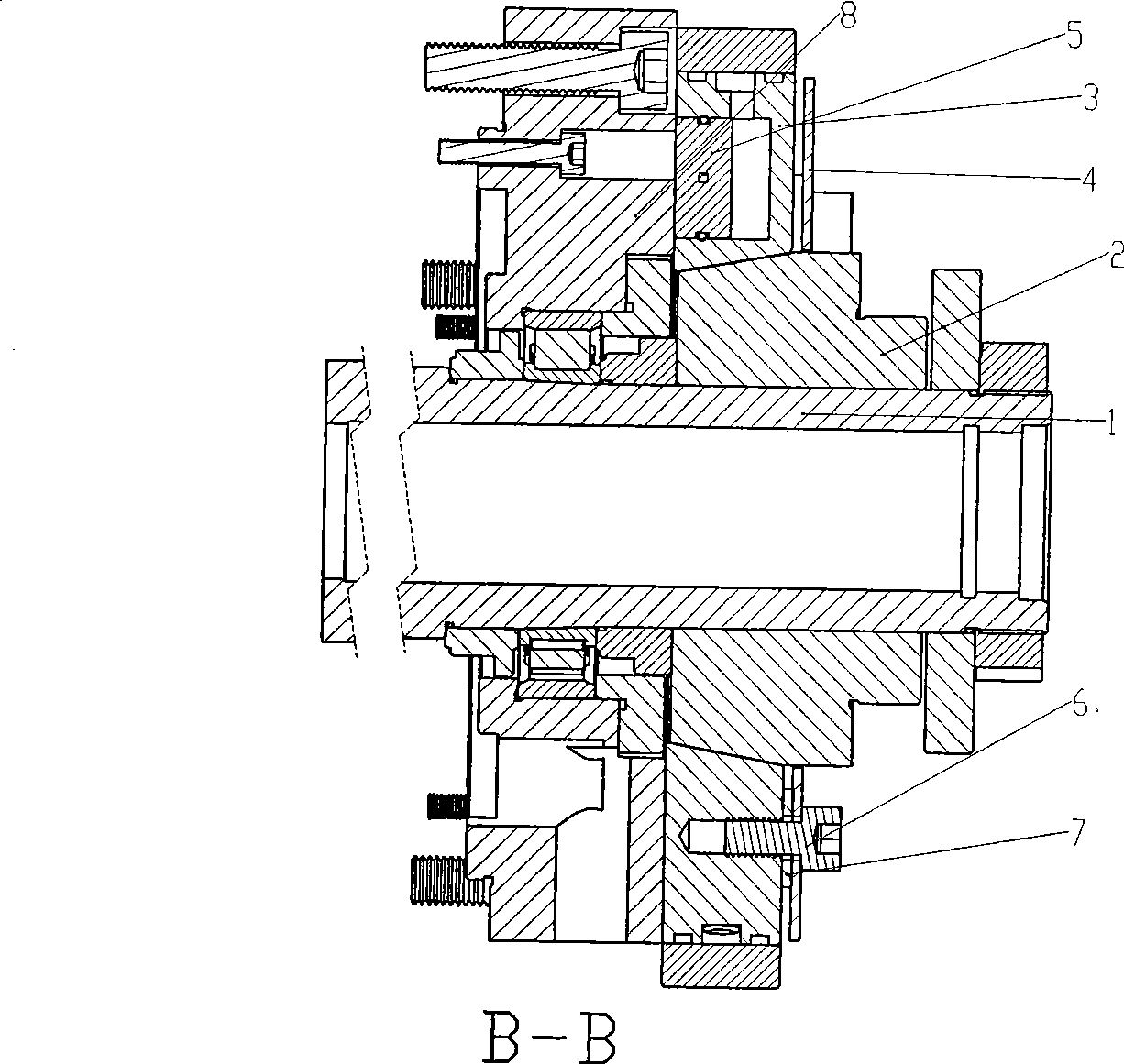

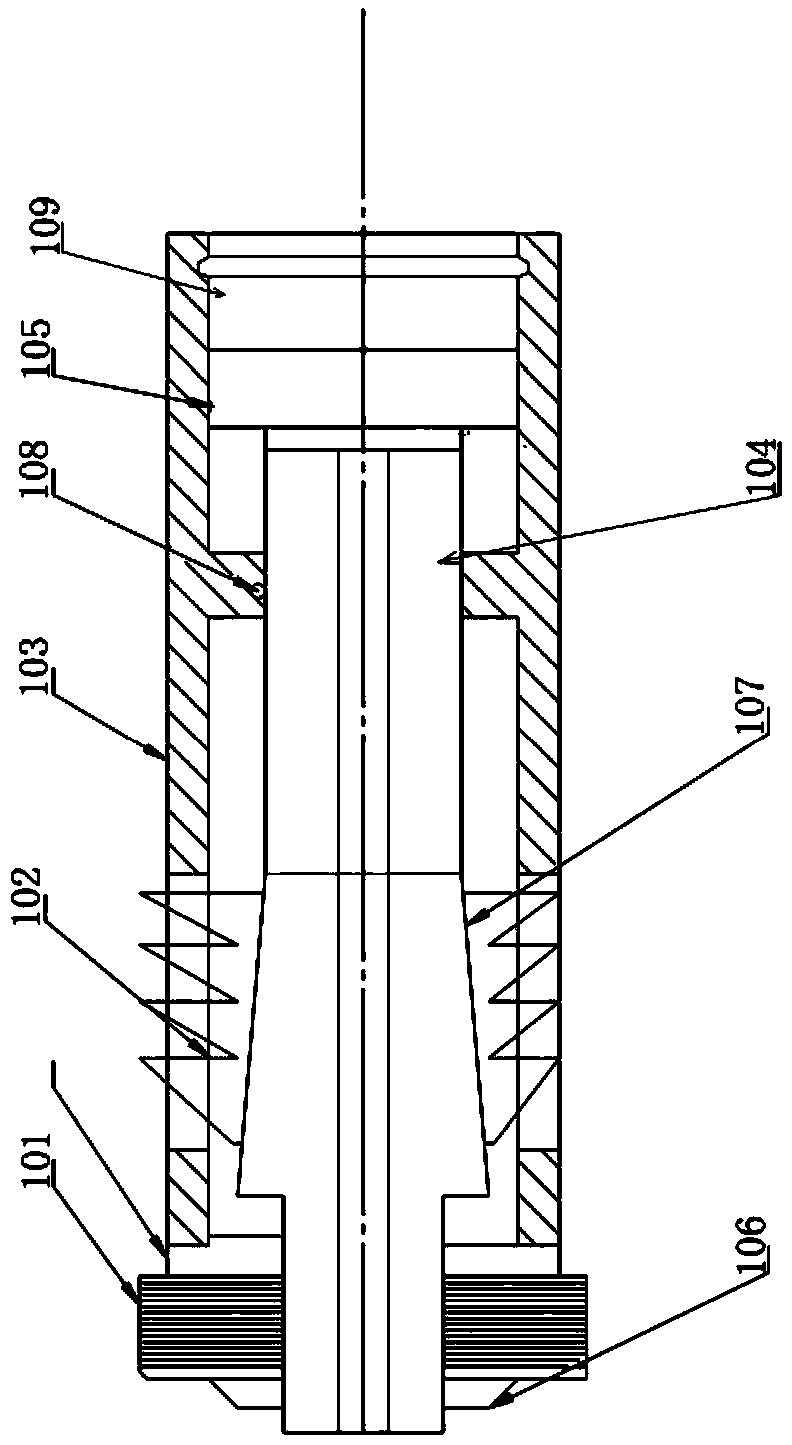

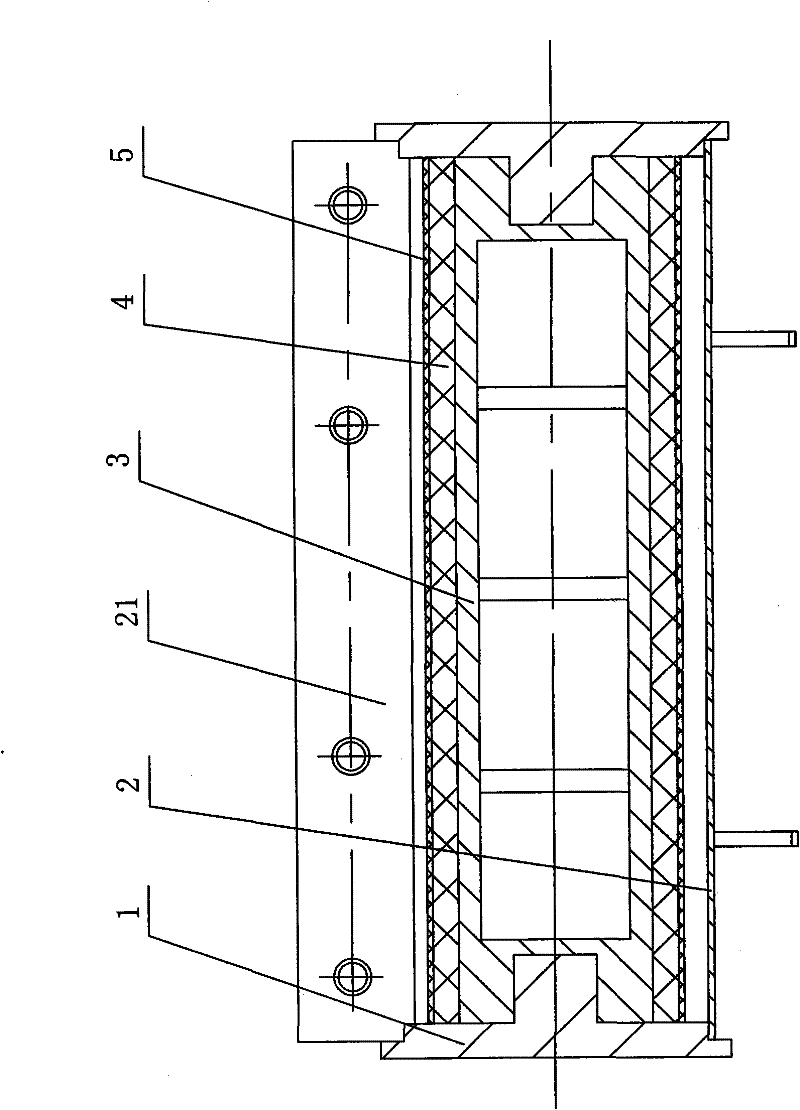

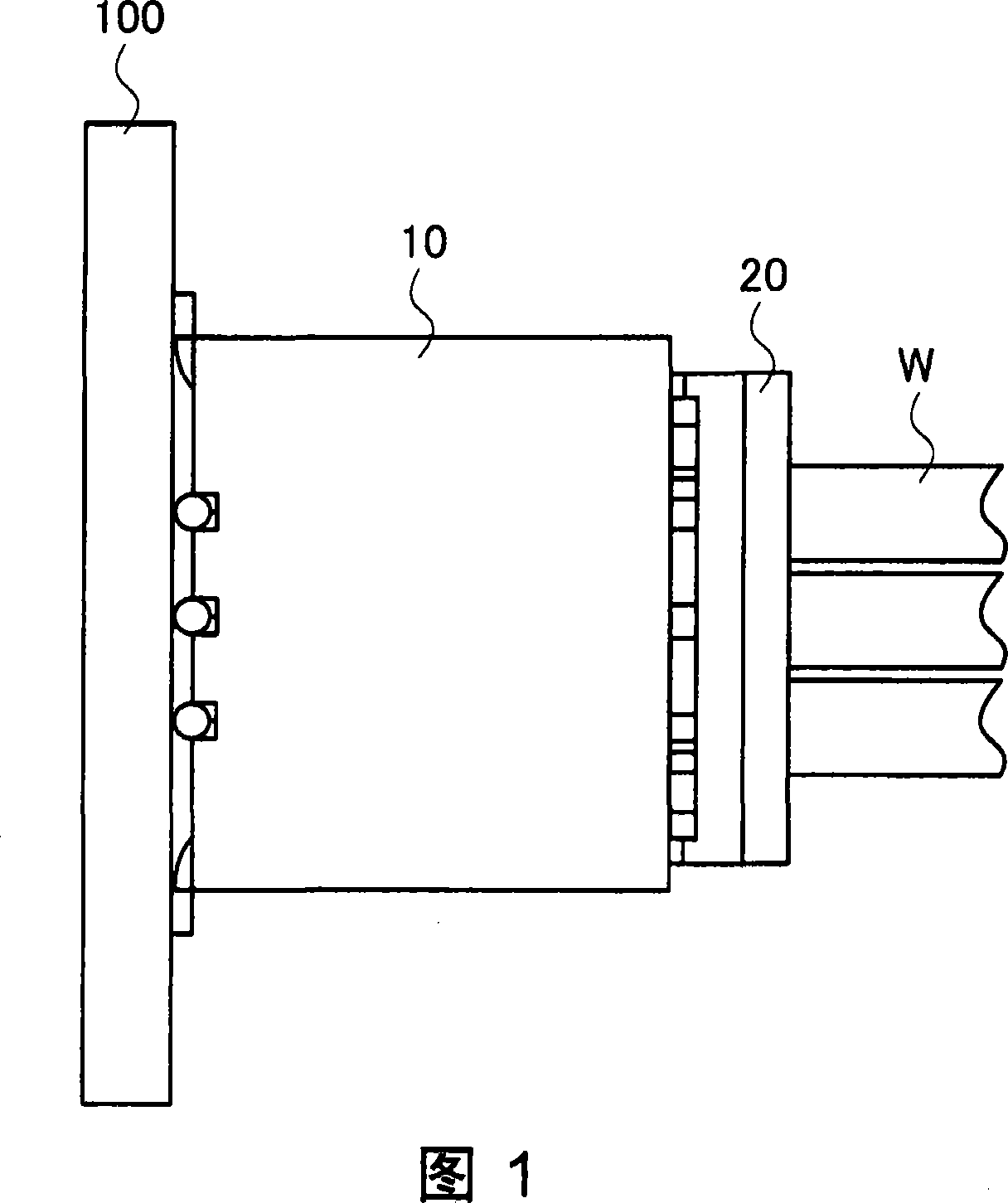

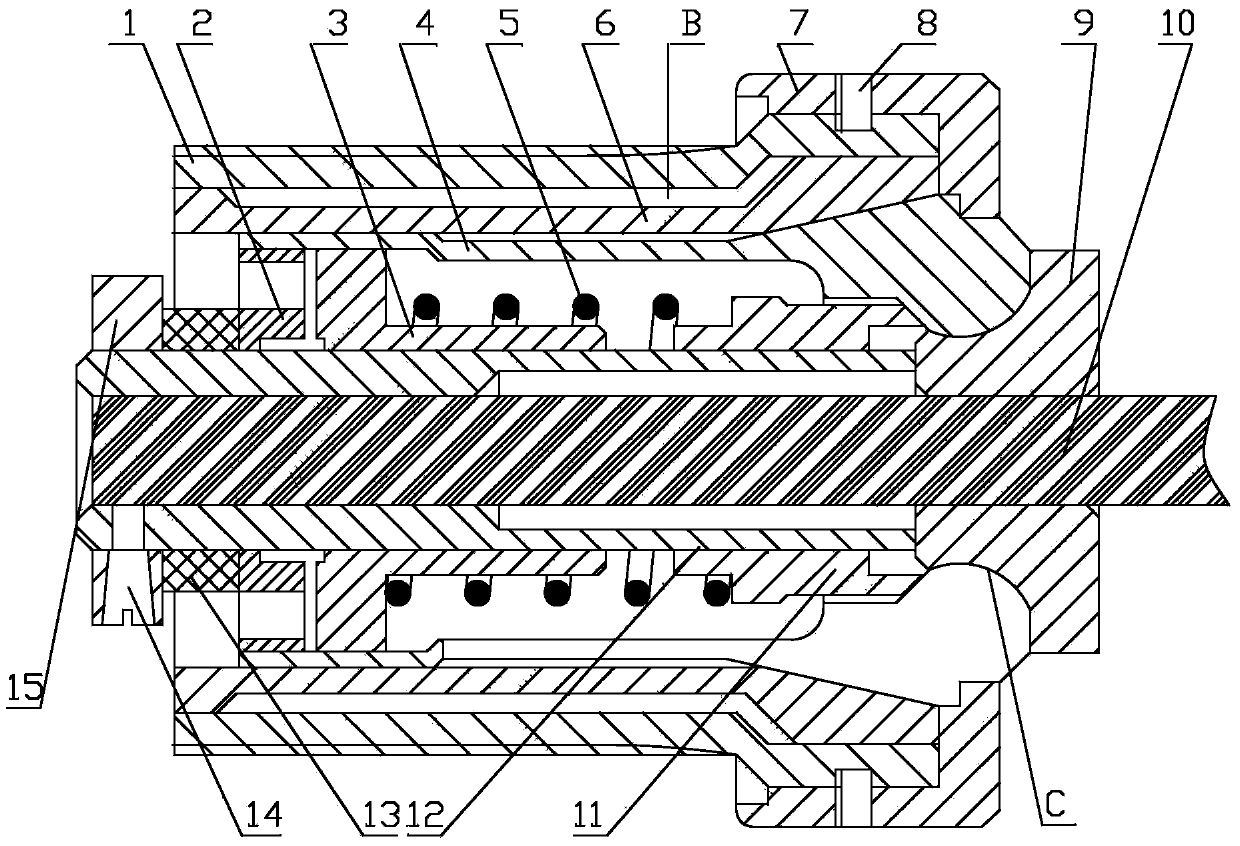

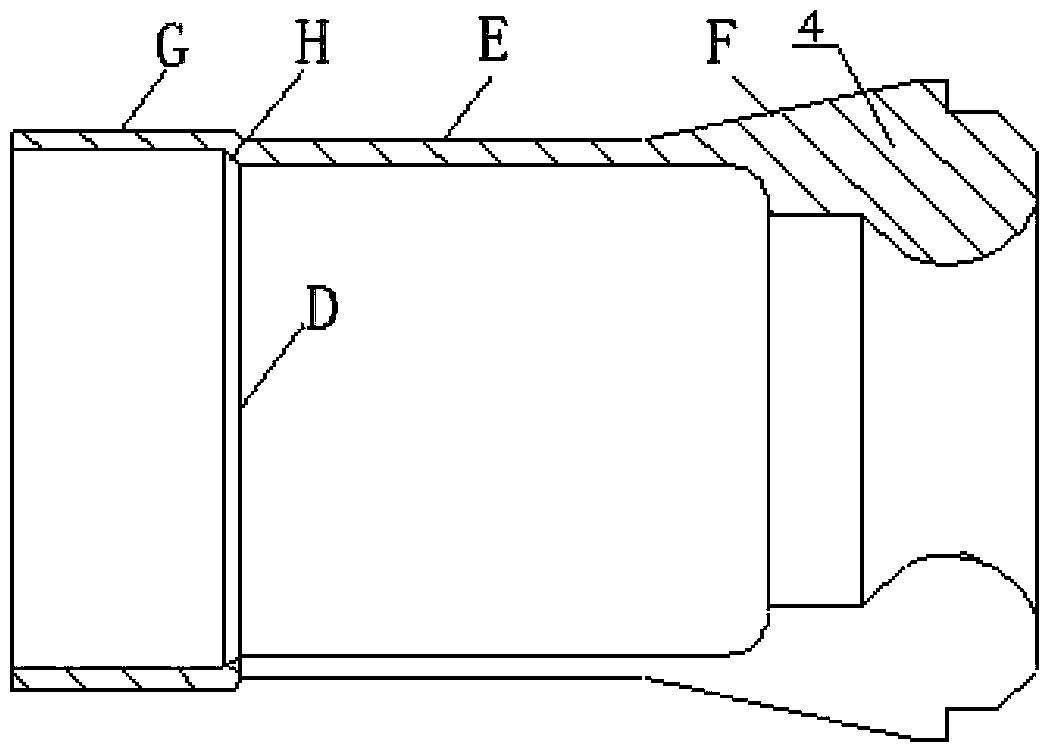

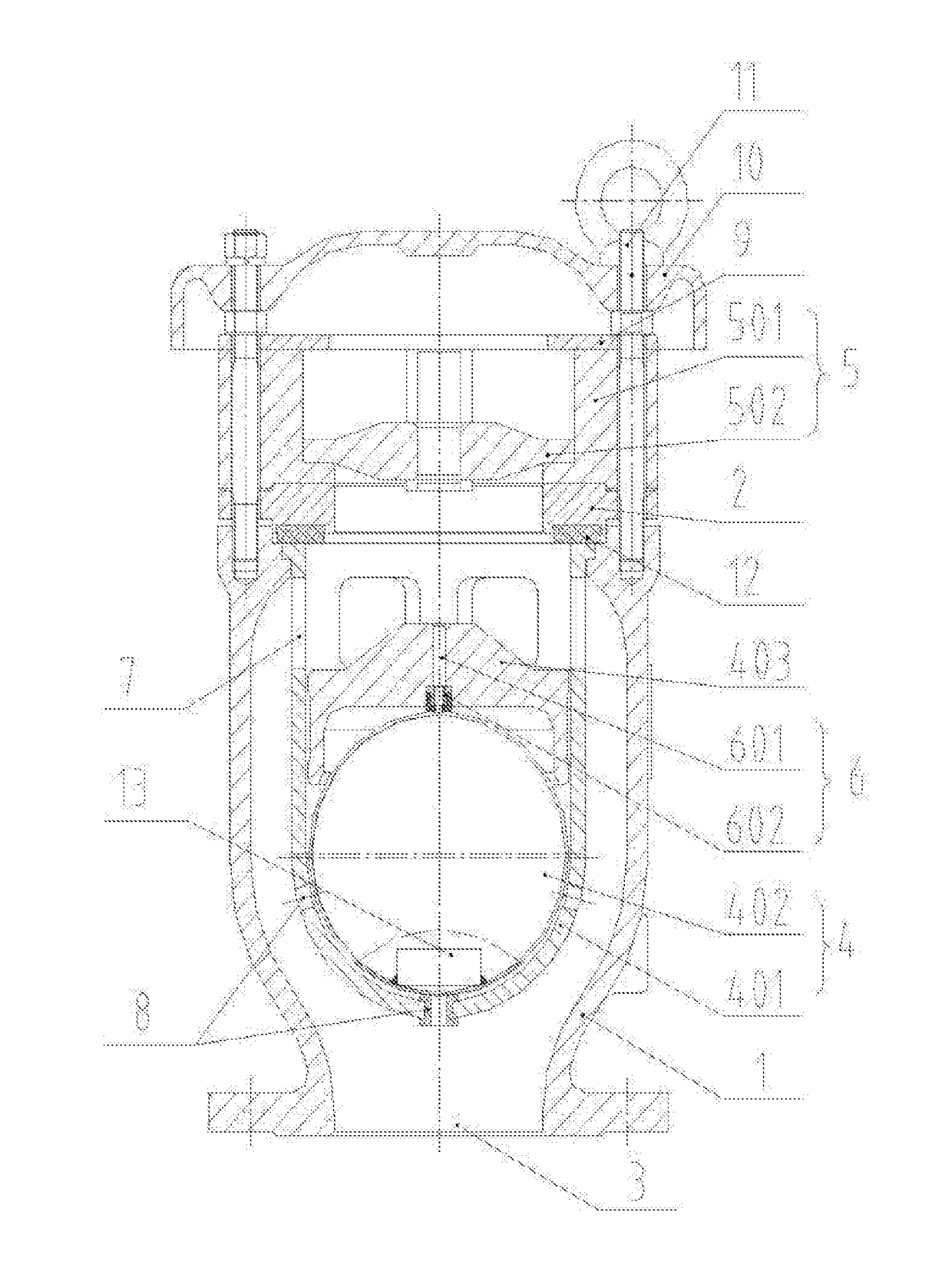

Hobbing clamp for clamping a plurality of parts with big gear rings

The invention discloses a hobbing clamp for clamping a plurality of parts with big gear rings. The hobbing clamp for clamping the parts with the big gear rings comprises a pressing portion and a centering portion, wherein the centering portion comprises a base, a first spring, a locating sleeve, force transmission blocks, a lower pull rod and the like, a support is arranged on the top surface of the base, the support is sleeved with a supporting disk, the pressing portion comprises an upper pull rod and a press plate, the upper pull rod is sleeve with a disk spring and a pressing sleeve in sequence from top to bottom, the disk spring and the pressing sleeve are sleeved with a bushing in a spaced mode, a supporting plate is arranged at the bottom of the press plate, the top surface of the supporting plate is a big-end-down conical surface, the conical surface is attached to the bottom surface of the press plate, the lower end of the supporting plate is fixedly sleeved with a gland, the lower end of the upper pull rod is provided with a T-shaped portion, and the T-shaped portion penetrates through a small-diameter section of a center hole of a taper sleeve and a center hole of a reset spring, and then is clamped into a large-diameter section of a cylindrical hole formed by inner surfaces of all the force transmission blocks. According to the hobbing clamp for clamping the parts with the big gear rings, centering of workpieces with big gear rings can be well carried out through expansion blocks, the workpieces can be tightly pressed at the same time, and centering accuracy can be ensured.

Owner:CHONGQING MACHINE TOOL GROUP

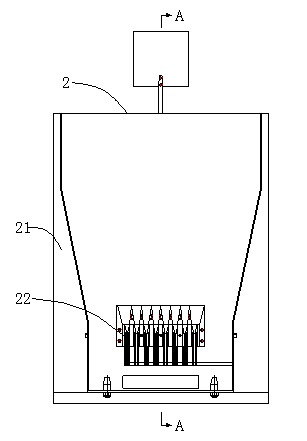

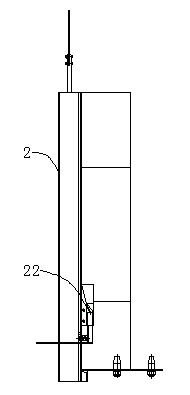

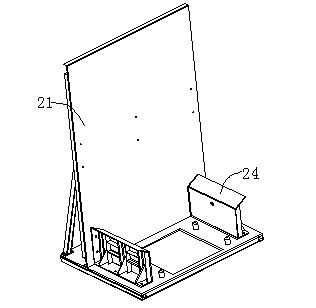

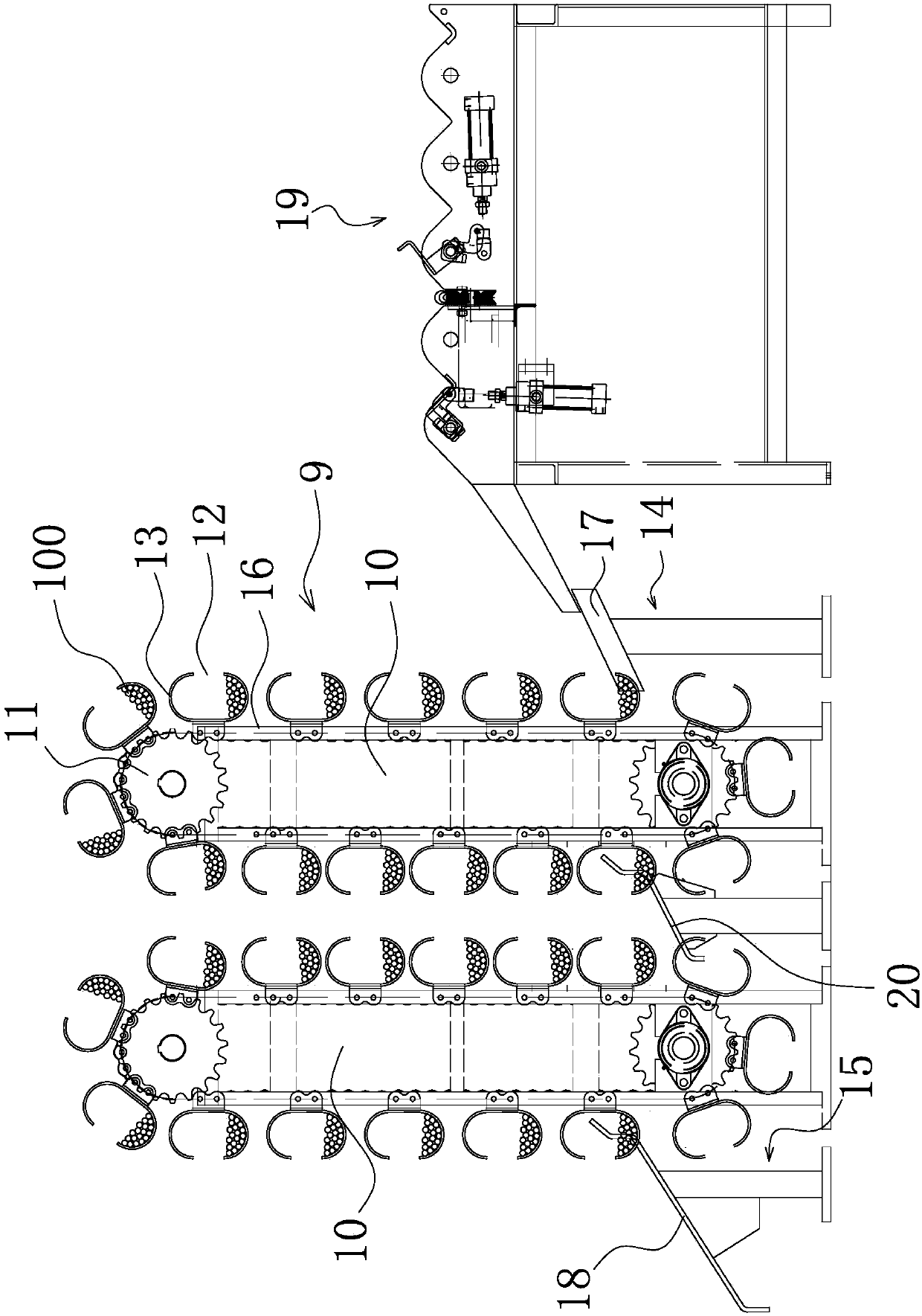

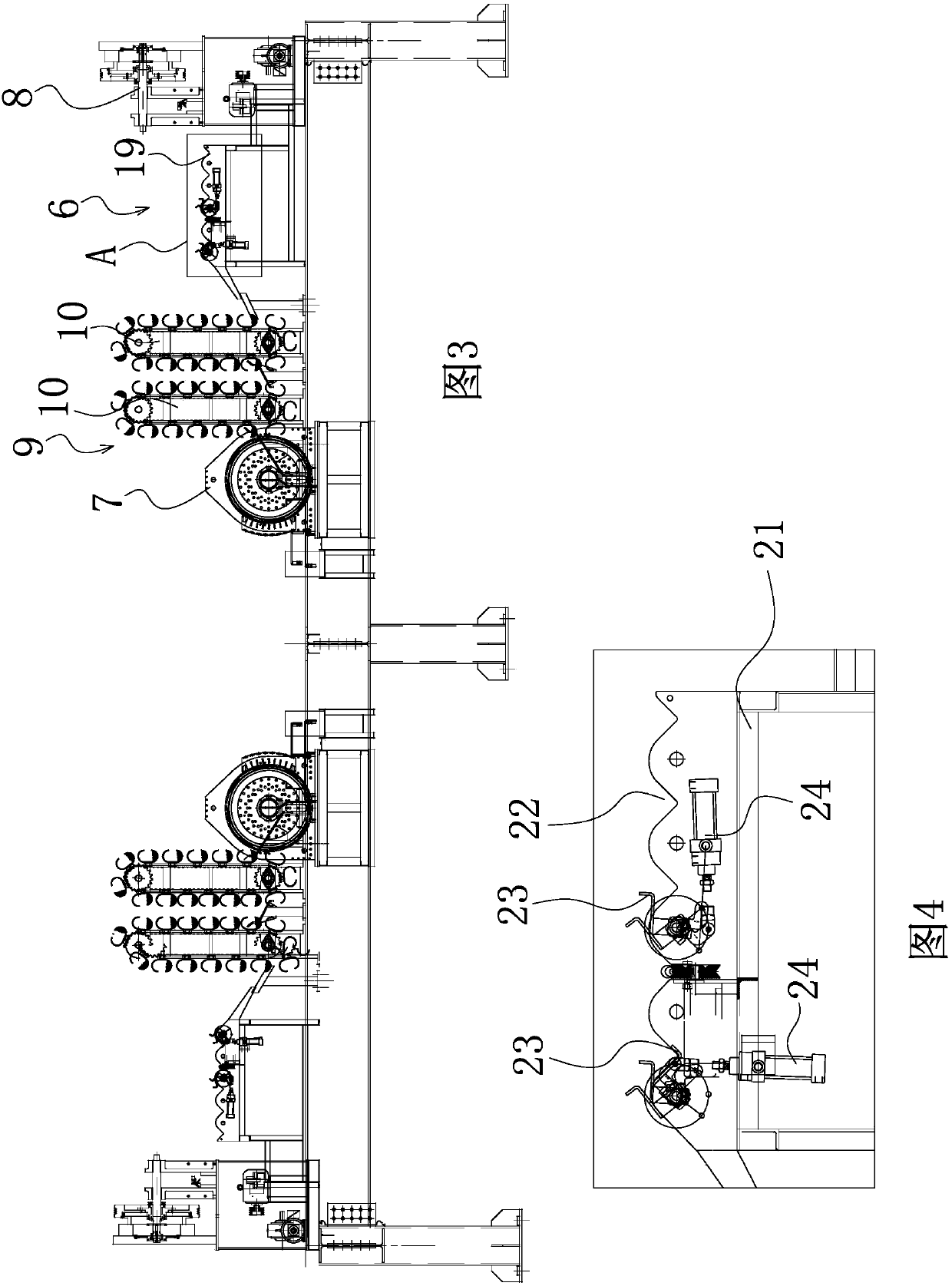

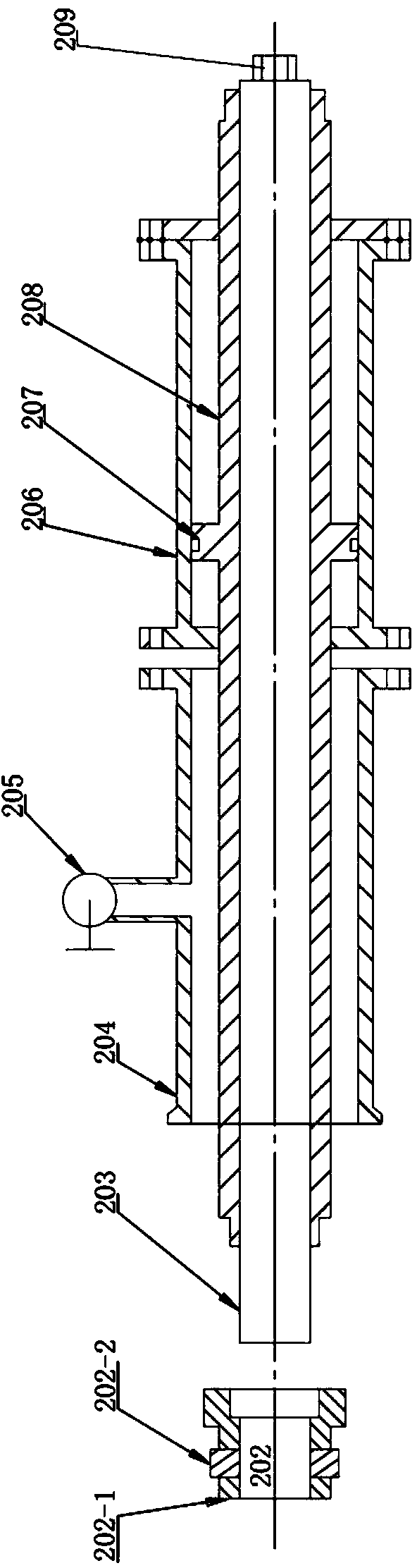

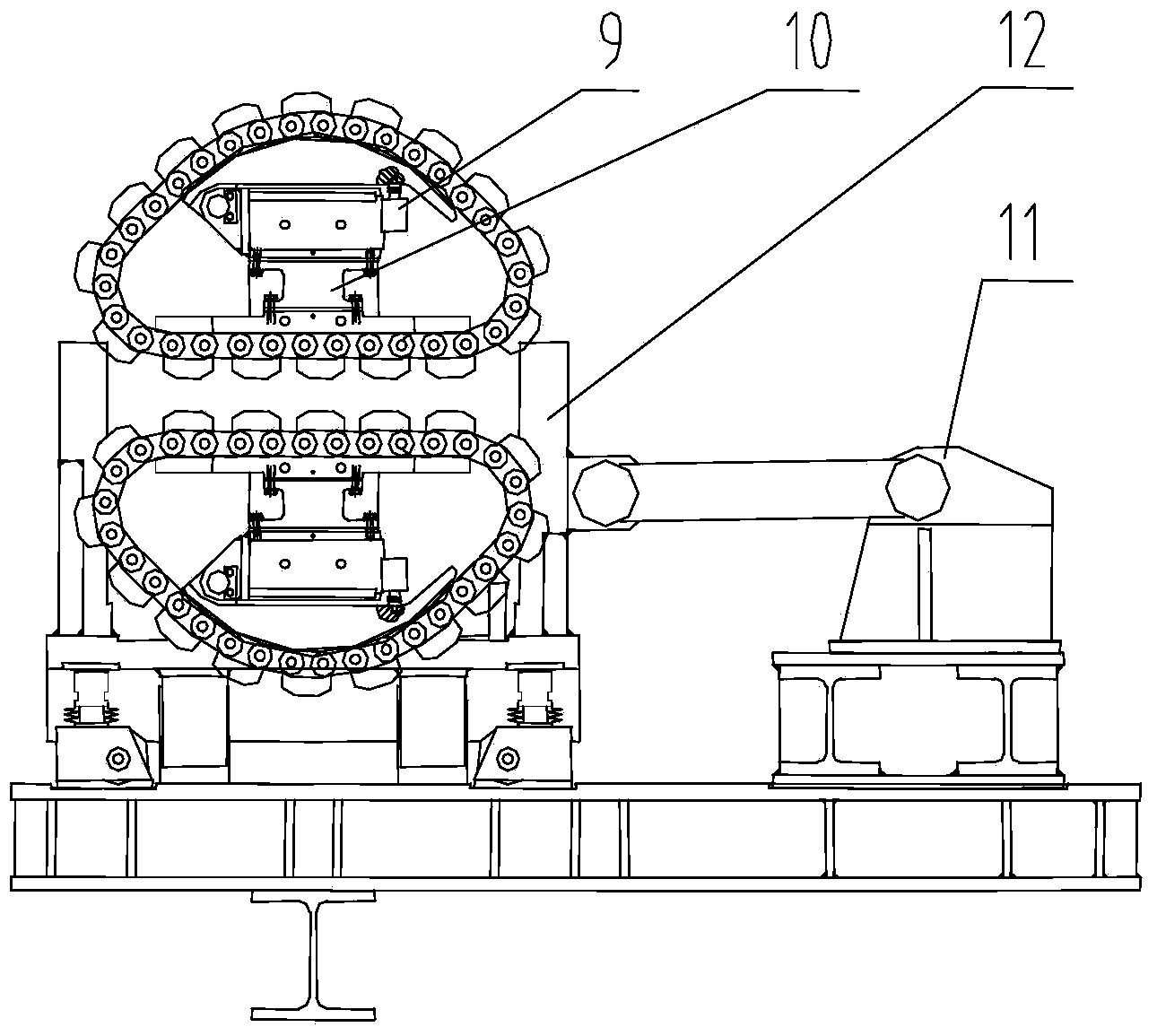

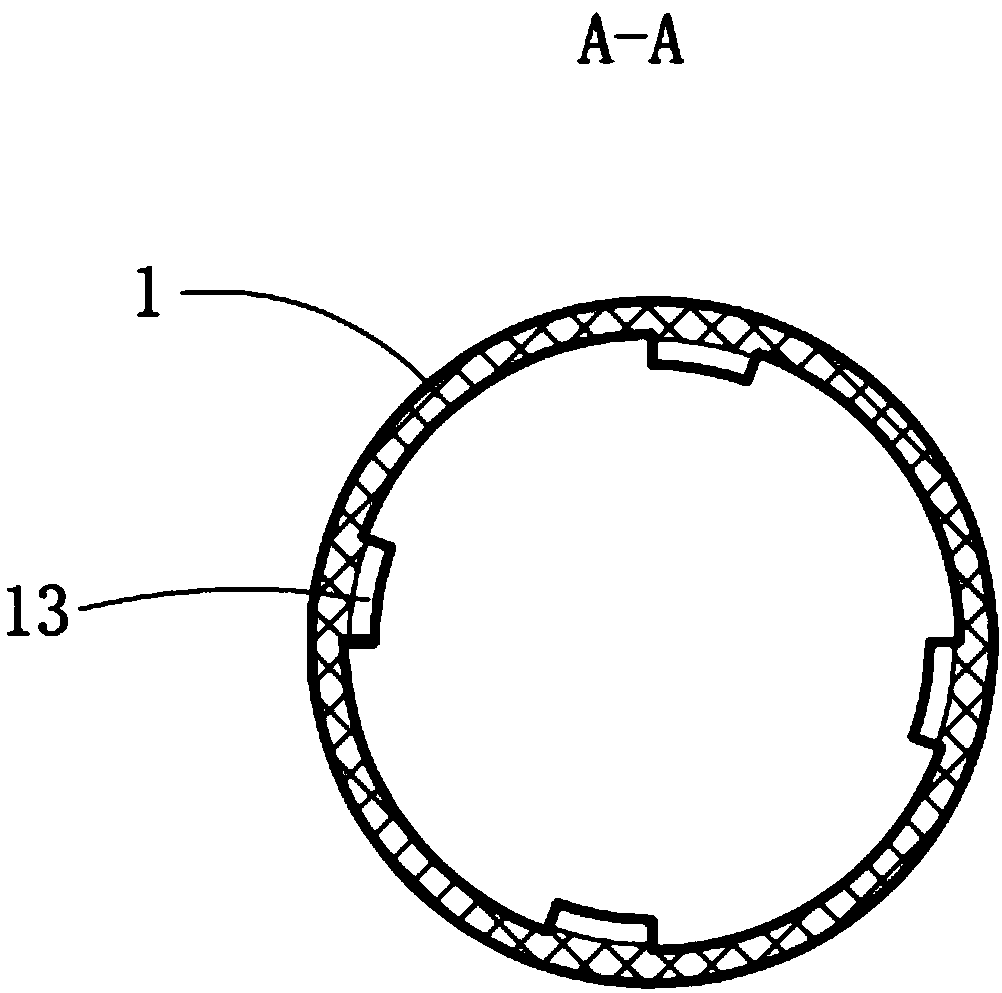

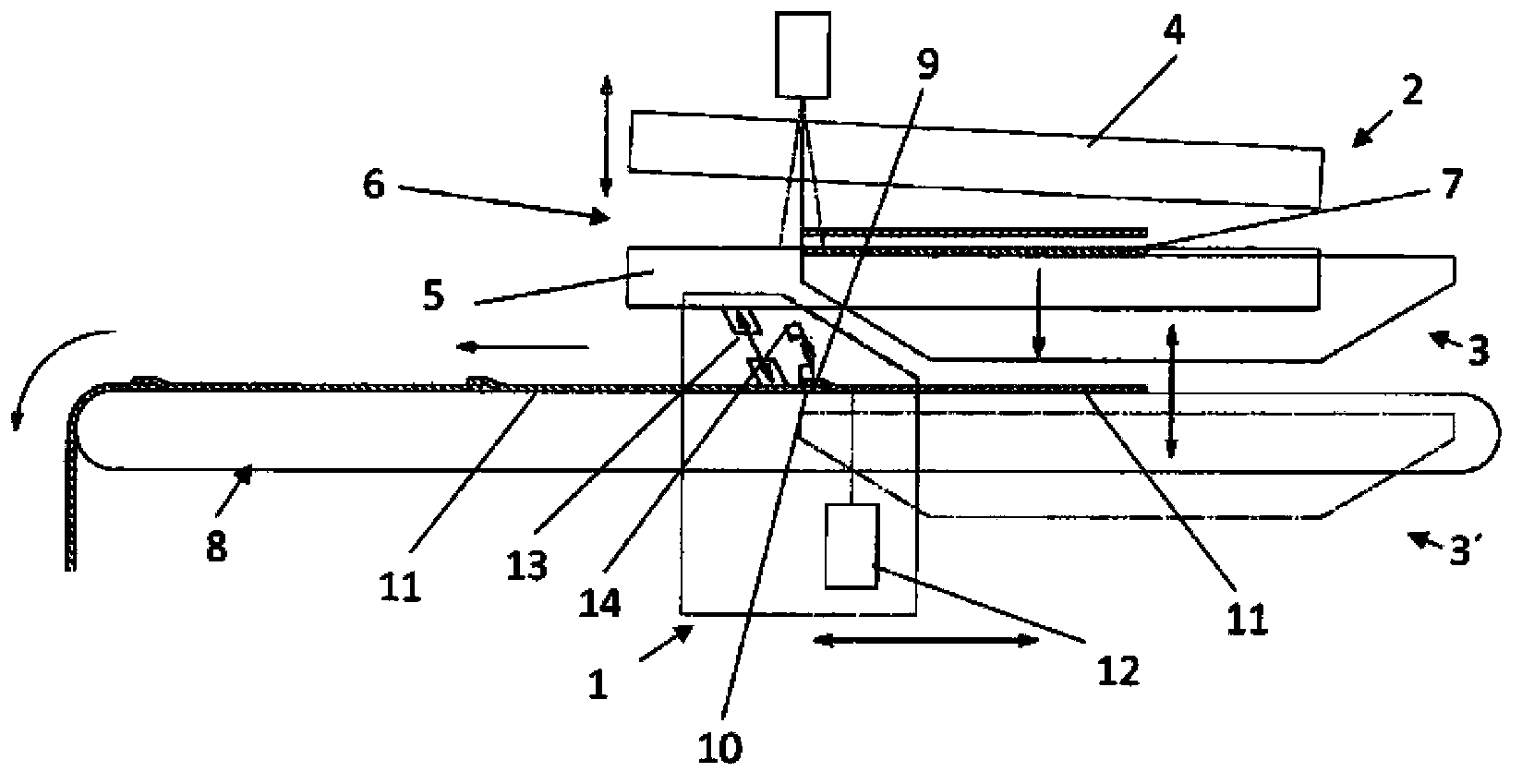

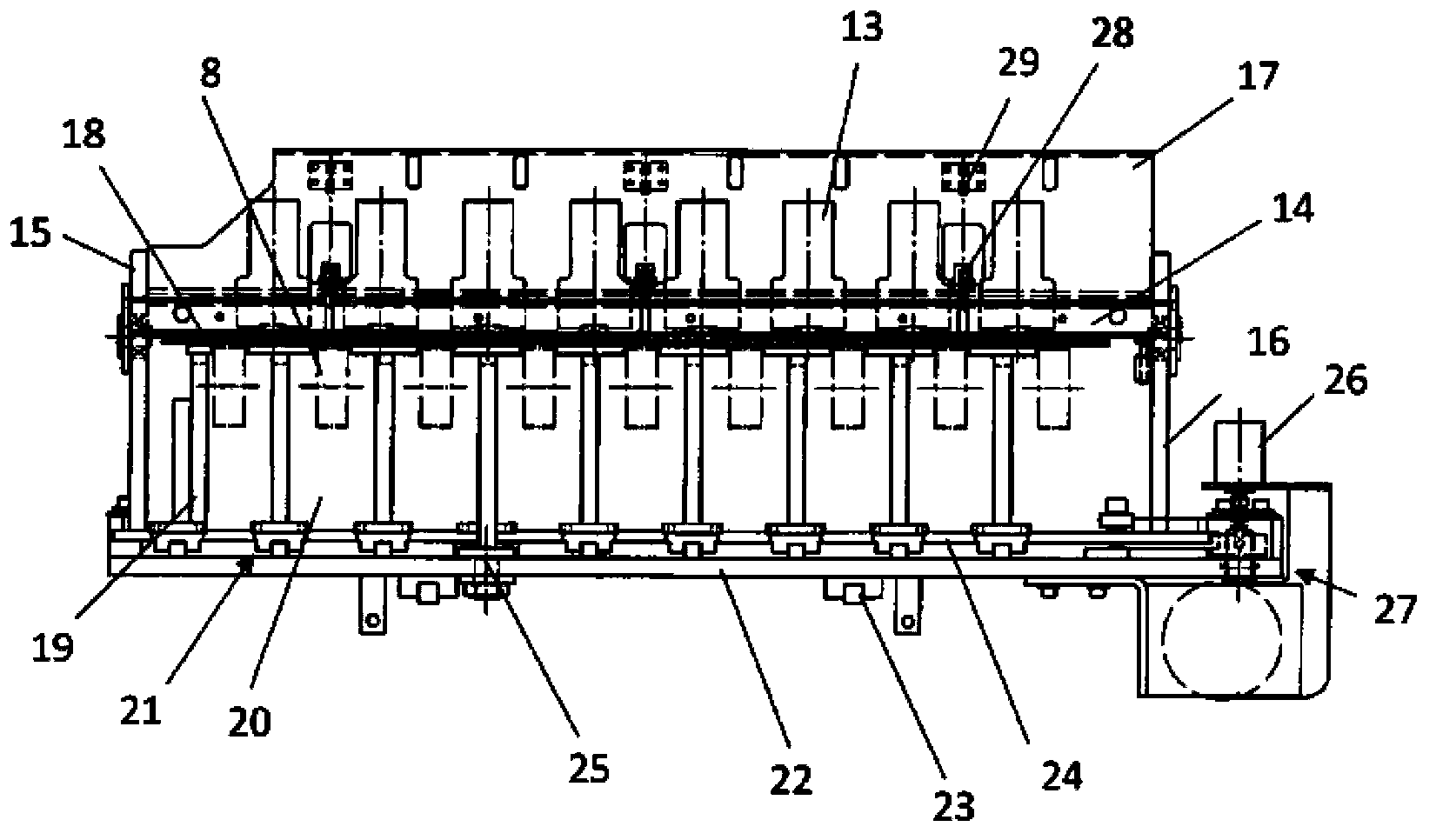

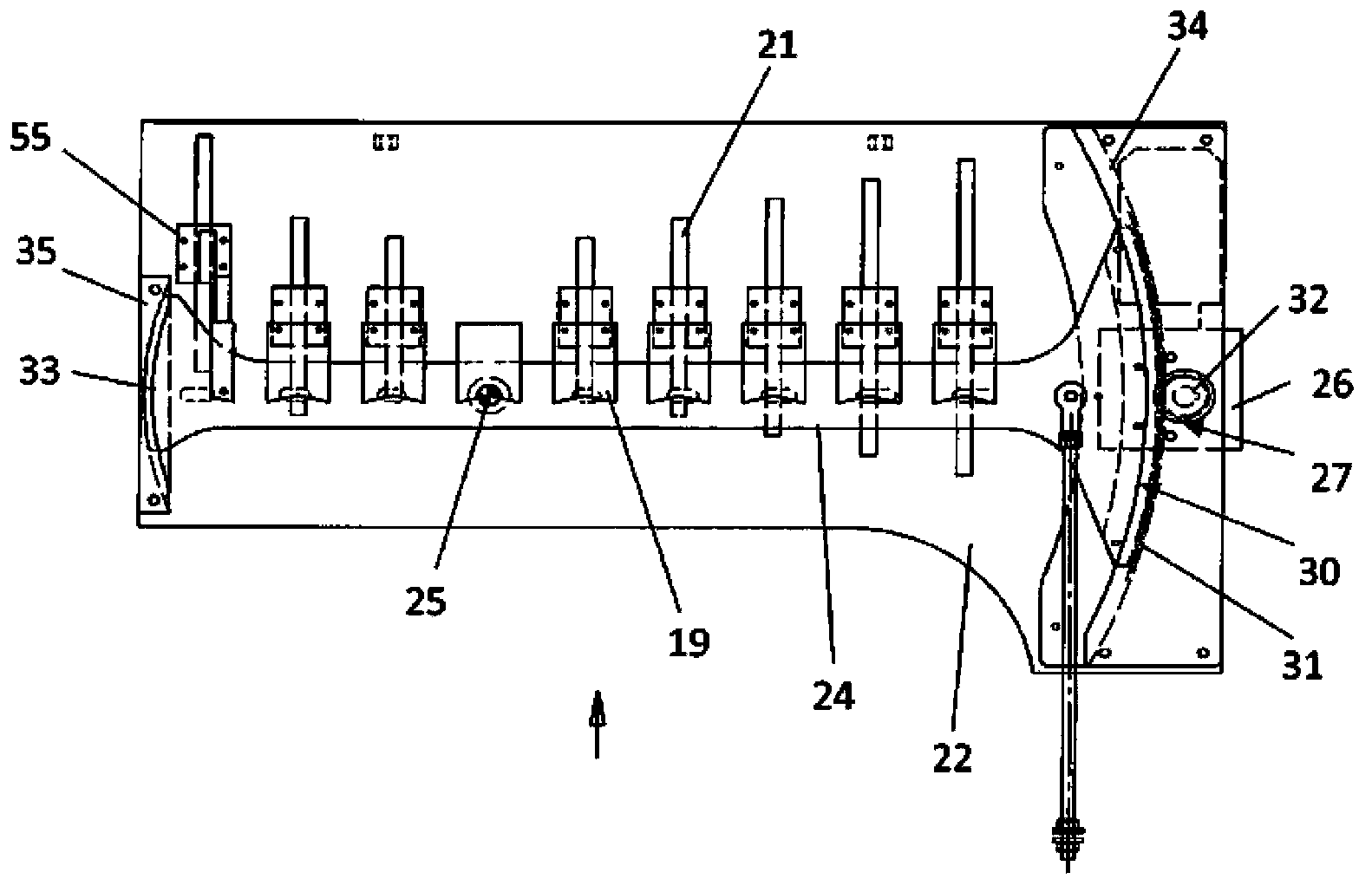

Fully automatic pipe pile production line

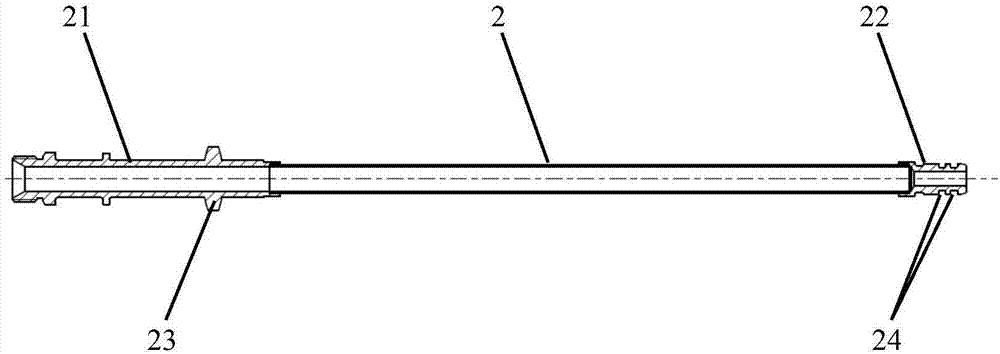

ActiveCN105599128BReliable disengagementSafe escapeCeramic shaping plantsShaping reinforcementsProduction lineDrive shaft

The invention belongs to the technical field of construction and relates to a fully-automatic tubular pile production line. The fully-automatic tubular pile production line comprises a material distribution device, die assembly devices, centrifugal devices, steaming-curing and maintaining devices, a die disassembly device and a cage making device and further comprises an automatic pile outputting device; the automatic pile outputting device comprises pile outputting and overturning arms and a pile outputting maintaining frame, the pile outputting overturning arms are connected with pile outputting and overturning arm drivers, the pile outputting and overturning arm drivers are provided with drive shafts capable of rotating in the peripheral direction, the pile outputting maintaining frame is connected with a maintaining frame driver, and the maintaining frame driver is provided with a drive shaft capable of rotating in the peripheral direction; when the pile outputting and overturning arms drive a pipe die to rotate, the pile outputting maintaining frame is pressed into a tubular pile of the pipe die and can conduct synchronous rotation with the pile outputting and overturning arms. By means of the fully-automatic tubular pile production line, continuous demoulding can be achieved, and thus production efficiency is improved.

Owner:浙江兆弟技术有限公司

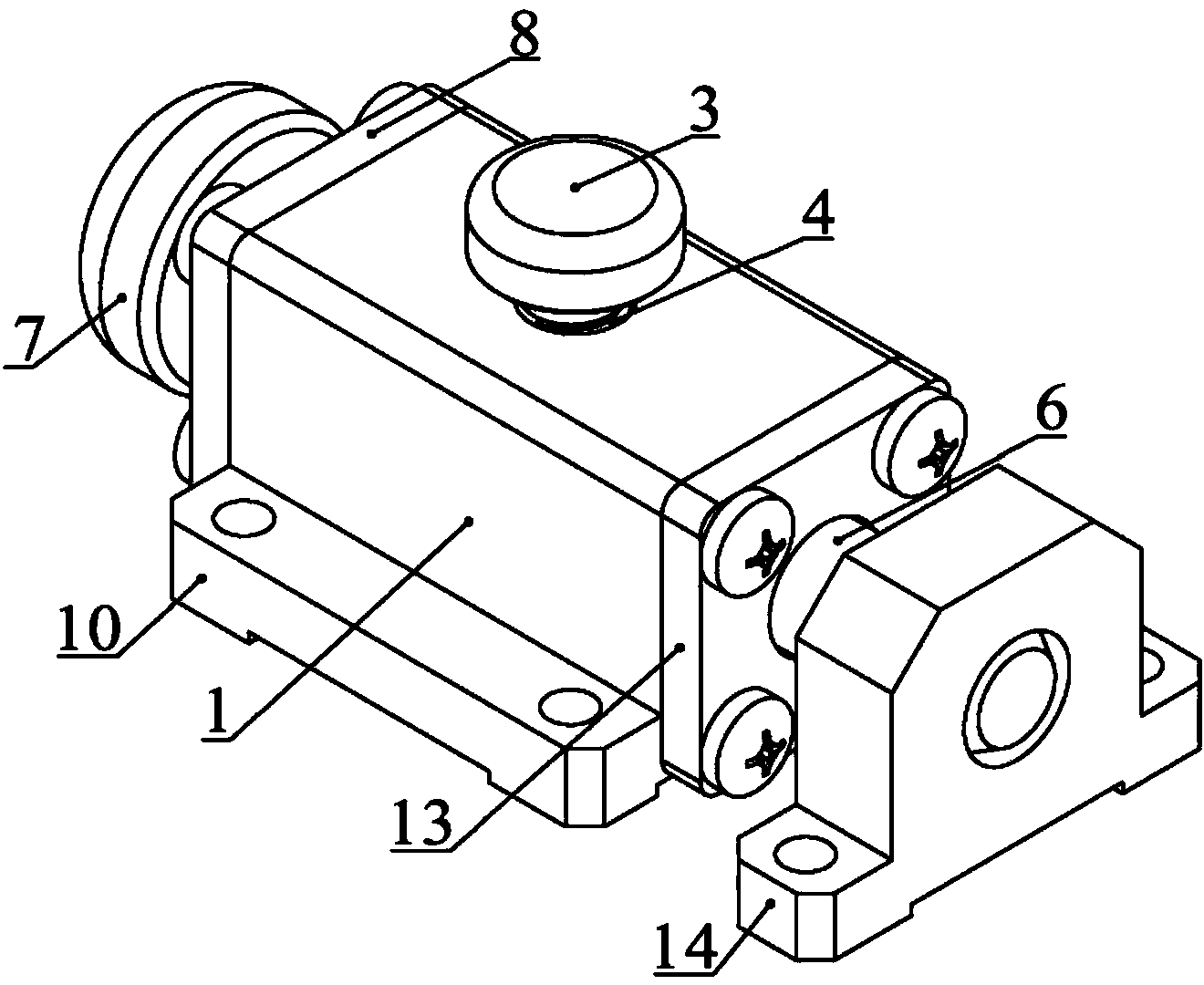

Locking device with automatic unlocking function

InactiveCN103967882AReliable lockingSimple and efficient operationSecuring devicesEngineeringSquare cross section

The invention discloses a locking device with the automatic unlocking function, belongs to the technical field of mechanical locking devices, and aims to solve the problems that working efficiency is low and operation is inconvenient in the prior art. The locking device comprises a guide base, a supporting base plate, a telescopic rod and a locating hole base, wherein the lower end of the guide base is fixedly connected with the supporting base plate, a square guide cavity is formed in the middle of the guide base, a limiting hole is formed in the upper portion of the guide base, and an unlocking mechanism is arranged in the limiting hole; the telescopic rod is located in the square guide cavity and can extend and contract freely in the square guide cavity, the cross section of the middle of the telescopic rod is square, the cross sections of the two ends of the telescopic rod are round, and a cylindrical guide hole is formed in the middle of the square cross section; a locking mechanism is arranged in the cylindrical guide hole, a compression spring is arranged at one end of the telescopic rod, one end of the compression spring makes contact with the square cross section of the middle of the telescopic rod, the other end of the compression spring makes contact with a compression spring base fixed to the guide base, and an unlocking limiting plate is fixed to the other end of the guide base; the telescopic rod extends and contracts in the square guide cavity to be matched with or separated from a locating hole in the locating hole base.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

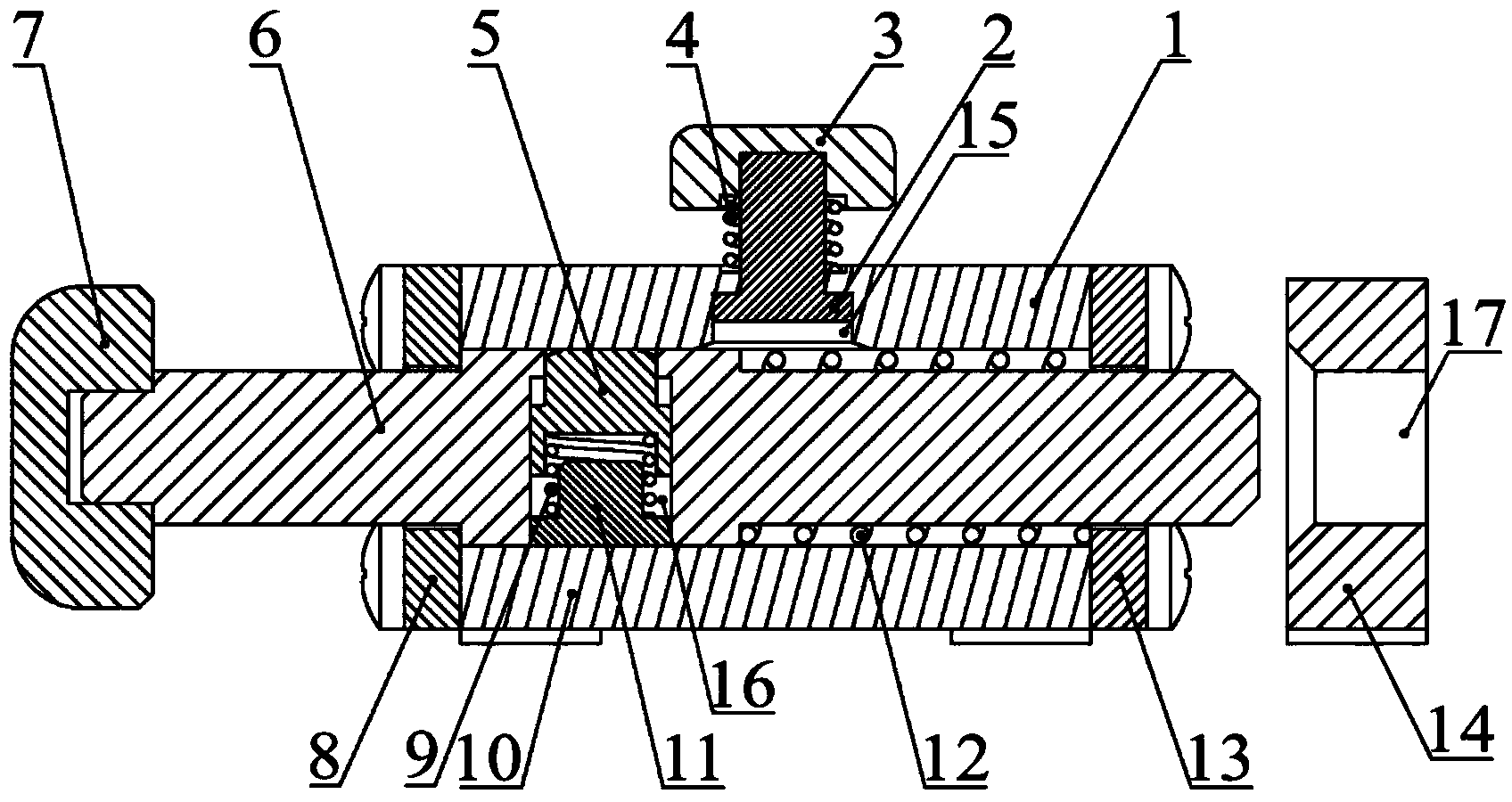

Apparatus for locking main shaft

The invention discloses a spindle locking device and relates to a precise spindle locking device. The spindle locking device consists of an internal expansion sleeve, an external expansion sleeve, a spring disc, a piston block and a fixed post, a fixing bolt and a fixing bolt. The internal expansion sleeve is fixed on a spindle and can rotate together with the internal expansion sleeve. The external expansion sleeve is sleeved on the internal expansion sleeve. Conical surfaces which are matched with each other are arranged between the internal expansion sleeve and the external expansion sleeve. The external expansion sleeve is sleeved on the internal expansion sleeve through the conical surfaces. The spring disc is sleeved on the internal expansion sleeve. The external expansion sleeve is positioned between a rear flange of the spindle and the spring disc. The spring disc is fixed with the rear flange through the fixed post and the fixing bolt. The spring disc and the external expansion sleeve are locked through the locking bolt. The piston block is arranged between the rear flange and the external expansion sleeve. Using the deformation characteristic of the spring disc and a taper locking mode, the locking device avoids any influence on the precision of the spindle when the spindle is locked and absolutely reliable locking is achieved, thereby ensuring the precision of processed parts, the precision of the spindle and the service life of the spindle.

Owner:GUANGZHOU WEIJIA MACHINE

Discharging device

InactiveCN103070083AAvoid blind spotsFirmly connectedAnimal feeding devicesAvicultureEngineeringMagnet

The invention discloses a discharging device, which comprises a support and a discharging scraper rotating around an upper pivot of the support. When the discharging scraper rotates to contact the bottom of a trough, the discharging device moves from the end part of the trough to the middle for discharging; and when the discharging scraper rotates to leave the bottom of the trough, the discharging device retreats to the end part of the trough and cannot push a residual feed at the bottom of the trough back to the end part of the trough. The discharging device can automatically clean two ends of the trough thoroughly without leaving dead angles, and is connected with a feed levelling device through a magnet, so that the discharging device and the feed levelling device are connected and separated more reliably, and the safety is higher.

Owner:广州市翔顺畜牧设备有限公司

Improved overheat overvoltage protection machine

ActiveCN1738133AKnow the damageAvoid short circuitArrangements responsive to excess voltageElectrical resistance and conductanceOvervoltage

Disclosed over-heat over-voltage protective device, comprises a housing, at least a voltage-sensitive resistor, at least a top pin and a low pin. It is characterized in that: a heat release unit is amounted between said voltage-sensitive resistor and the top pin, which is also on the surface of one electrode of said voltage-sensitive resistor; a deterioration indicating pin is extended from said voltage-sensitive resistor; said housing is filled with epoxide resin to form a whole mold. The voltage-sensitive resistor is in the cascade connection with the heat release unit while the release point extends from the center of voltage-sensitive surface to make the voltage-sensitive resistor which is deteriorated release from the electrified wire netting automatically and reliably, for avoiding the short circuit between electrodes and improving the protective function; the voltage-sensitive resistor and the heat release unit are contained in one housing, which utilizes the surge absorbing function of voltage-sensitive resistor and the inner operation of heat protective release unit to concentrate the heating points, shorten the heat transmission distance, and confirm the fast, reliable release between the deteriorated voltage-sensitive resistor and the electrified wire netting.

Owner:SICHUAN ZHONGGUANG LIGHTNING PROTECTION TECH

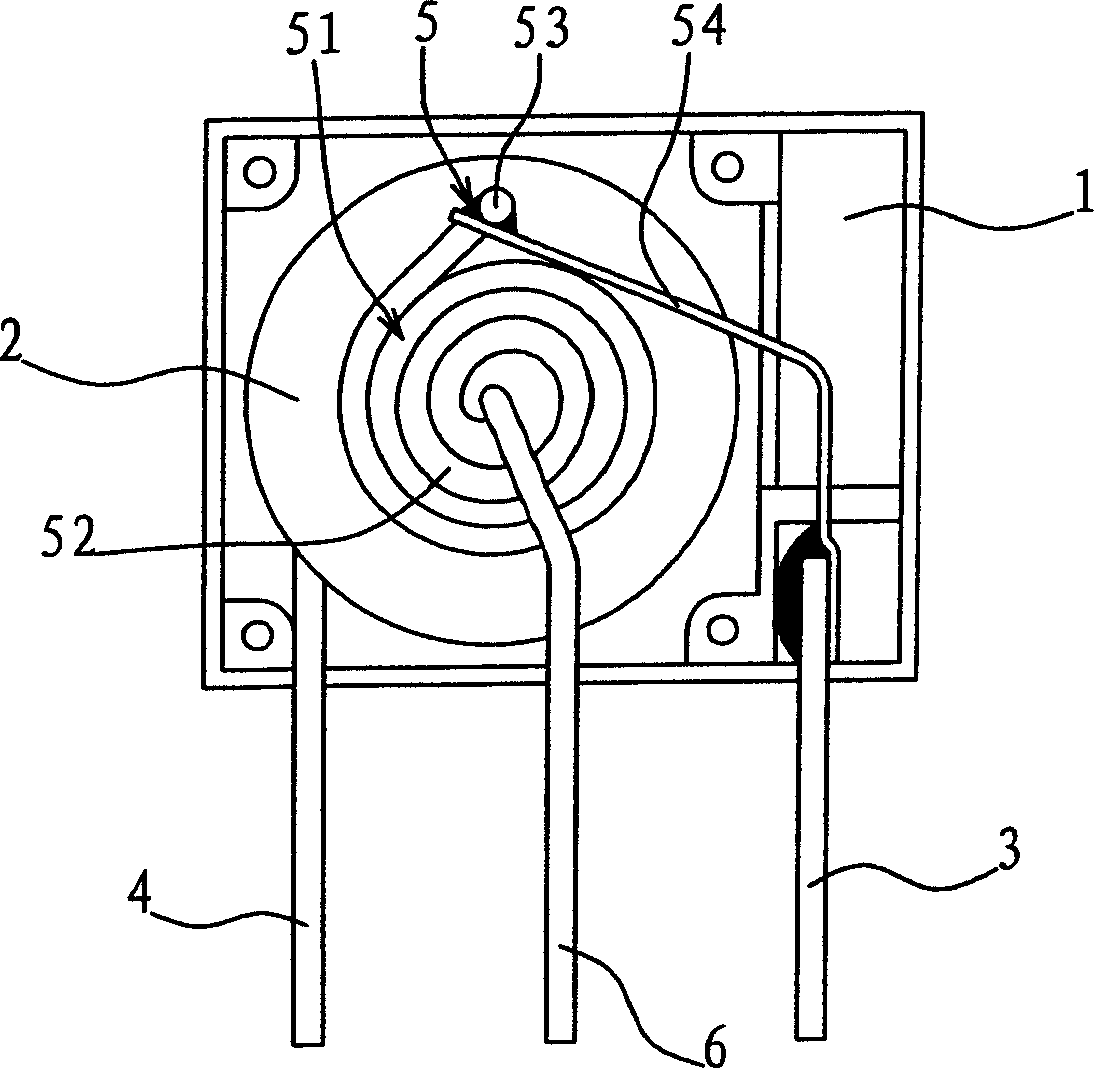

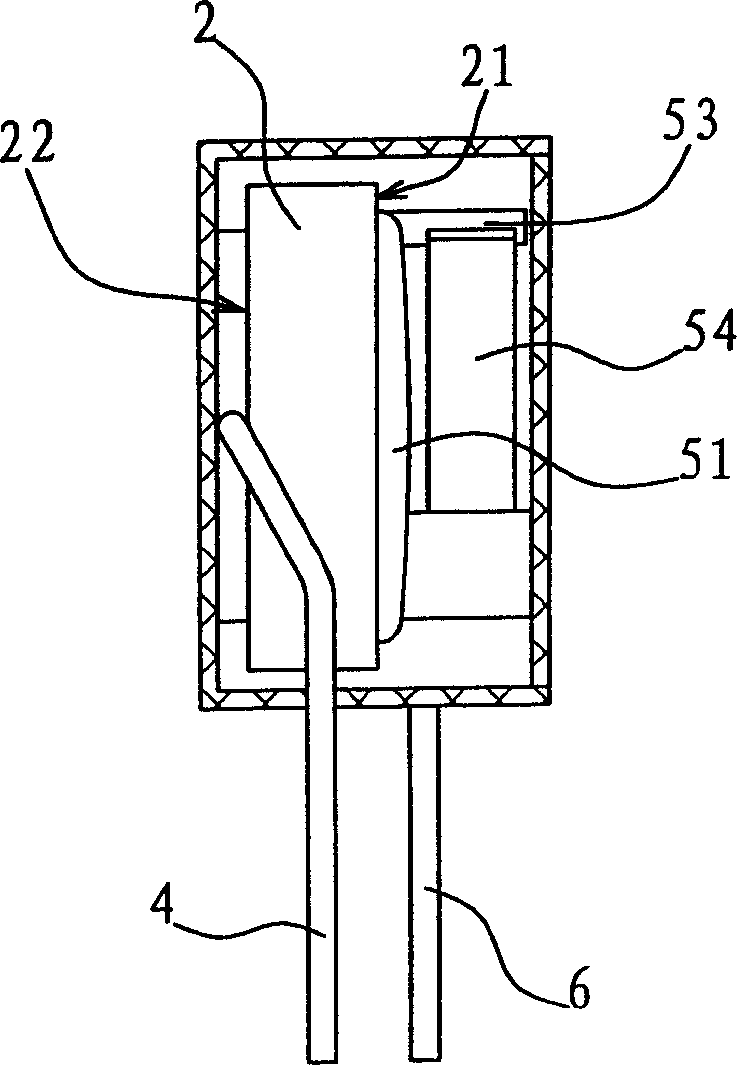

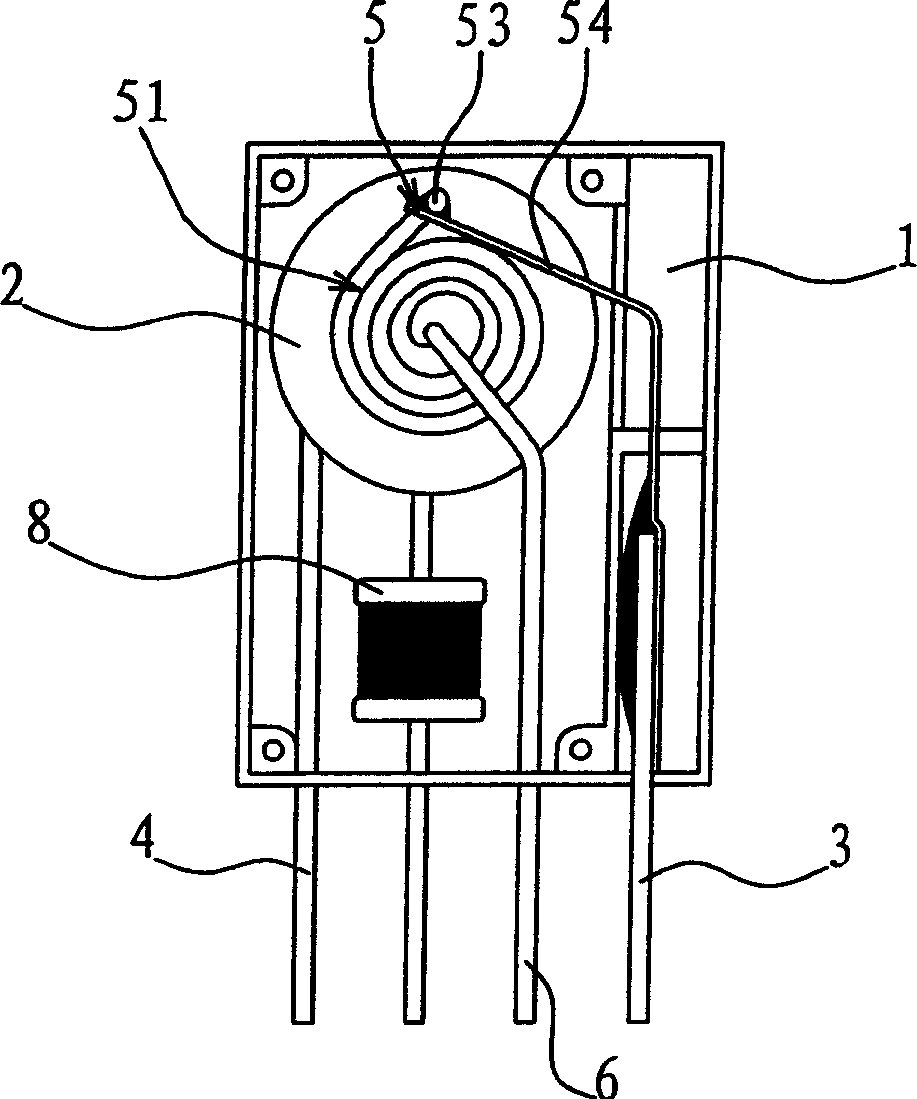

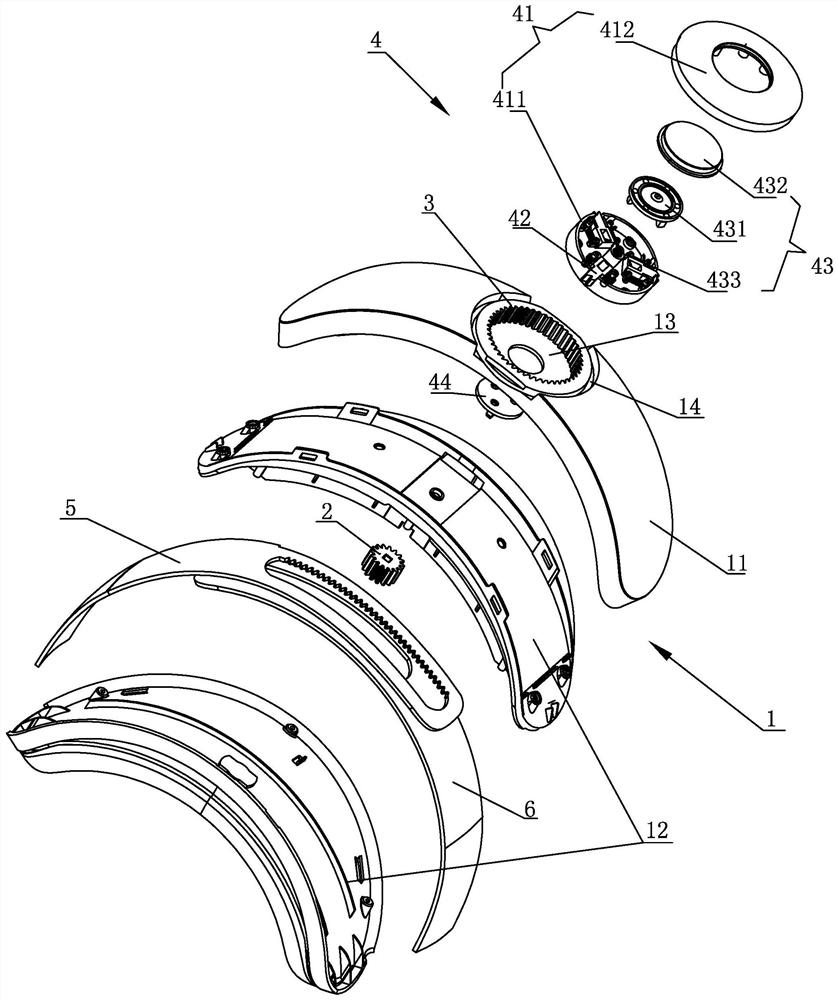

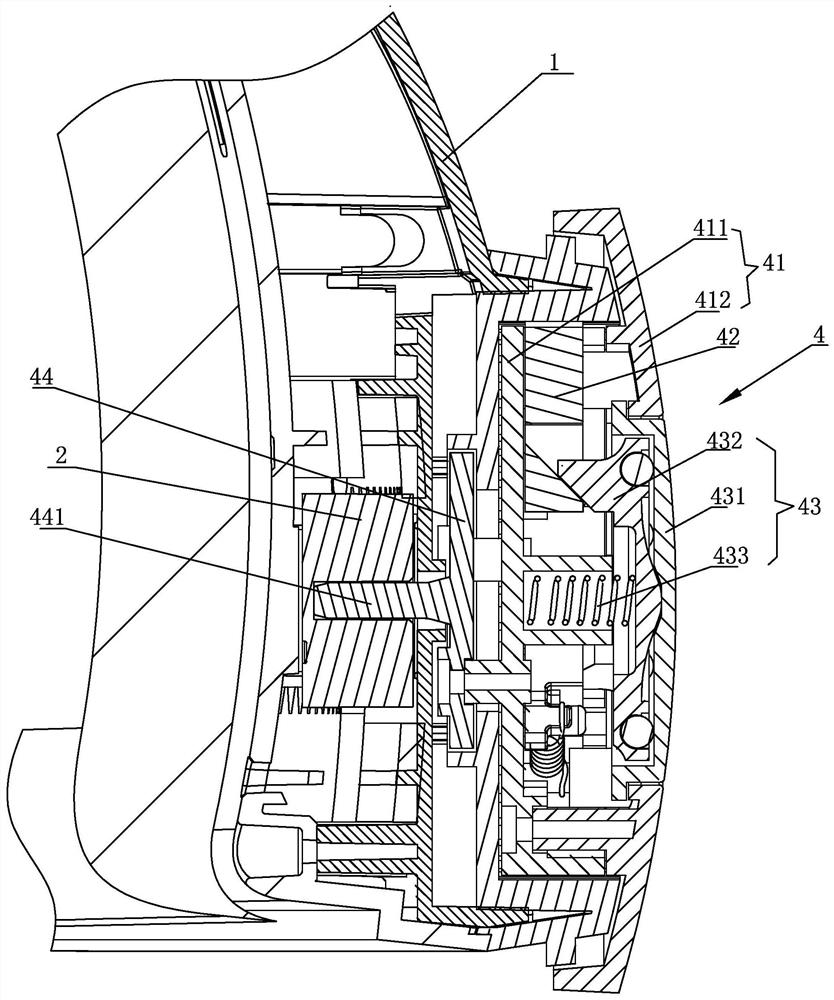

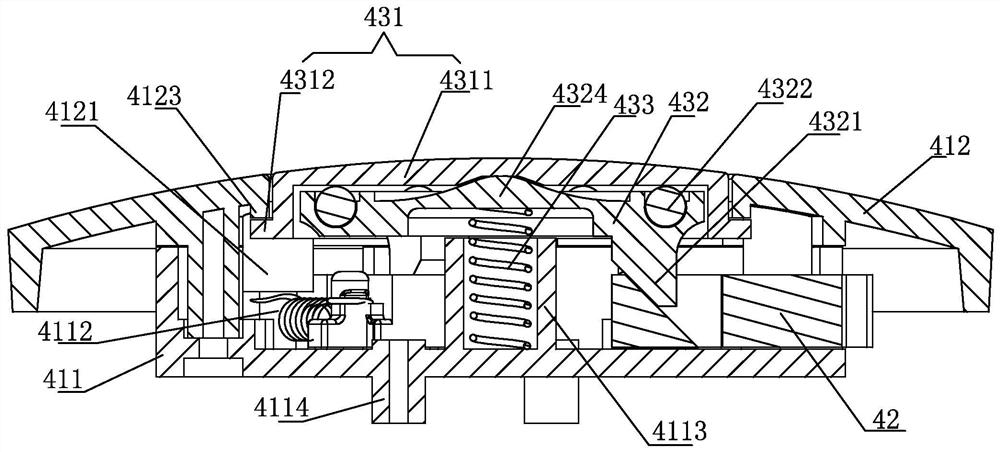

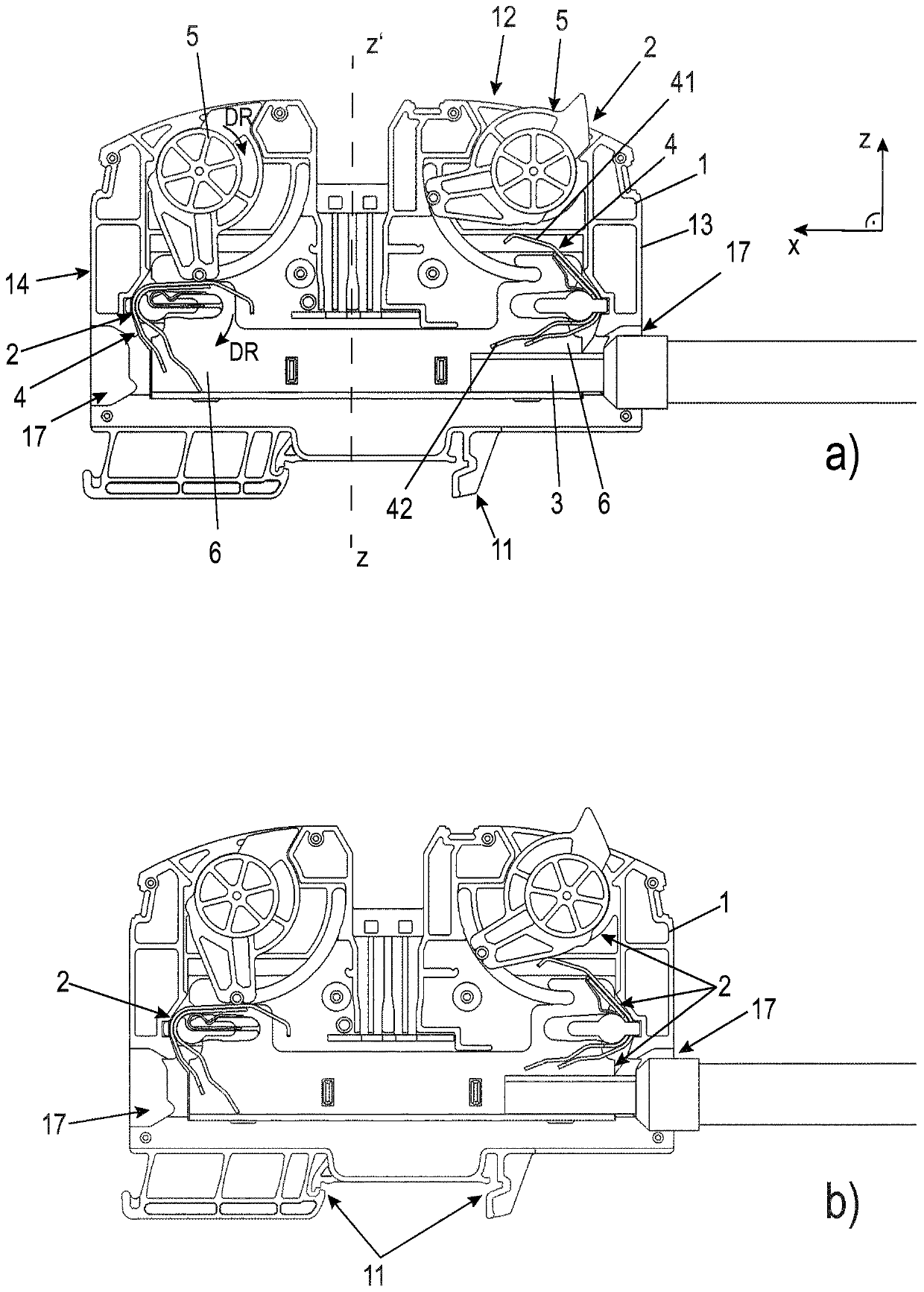

Rear bandage adjusting device, rear bandage and head-mounted display equipment

The invention discloses a rear bandage adjusting device, a rear bandage and head-mounted display equipment. The rear bandage adjusting device comprises a shell and a bandage adjusting gear; a one-wayrotation stopping structure and a pressing type clutch mechanism are arranged in an installation circular groove in the shell; and the pressing type clutch mechanism comprises an adjusting base rotationally installed in the installation circular groove and connected with the bandage adjusting gear, a self-resetting sliding block structure installed in the adjusting base in a radial sliding mode and a pressing driving structure arranged on the adjusting base, and the end, stretching out of the adjusting base, of the self-resetting sliding block structure is meshed with the one-way rotation stopping structure. The rear bandage comprises the rear bandage adjusting device, a left bandage body and a right bandage body. The head-mounted display equipment comprises the rear bandage and a head-mounted host. When the pressing driving structure is not pressed, only the adjusting base can be rotated unidirectionally to drive the bandage adjusting gear to rotate; and when the pressing driving structure is pressed, the self-resetting sliding block structure slides in the radial direction to be separated from the one-way rotation stopping structure, and the bandage adjusting gear can rotate in two directions. The rear bandage adjusting device, the rear bandage and the head-mounted display equipment are easy to assemble, high in reliability and low in noise during use.

Owner:GOERTEK INC

Device capable of replacing valve under pressure

ActiveCN103742710AReliable stuckEnsure construction safetyValve arrangementsPipe elementsHydraulic cylinderInternal pressure

The invention provides a device capable of replacing a valve under pressure. The device comprises a plugging device, a combining part, a blowout prevention pipe, a hydraulic cylinder, a piston rod and an operating rod. One end of the combining part is detachably connected to the plugging device, and the blowout prevention pipe contains the plugging device and the combining part and is connected with the hydraulic cylinder. The plugging device is mainly composed of a sealing rubber sleeve, a slip bowl seal assembly, a differential pressure type piston and slips, the slips can be automatically unfolded through fluid pressure, and thus safe bowl seal is achieved. One end of the combining part is connected with the hydraulic cylinder through the piston rod and the operating rod which penetrate through the blowout prevention pipe. The invention further provides a method for replacing a valve under pressure with the device capable of replacing a valve under pressure. The device achieves seal, bowl seal, seal removal and internal pressure balance of a tool, the complex functions can be continuously and automatically completed in one travel, and thus the device is easier and more reliable to operate. Uncertainty caused by manual operation is reduced, safety in the construction process is guaranteed, no pollution will be caused to the environment, and construction cost is greatly reduced.

Owner:袁占良

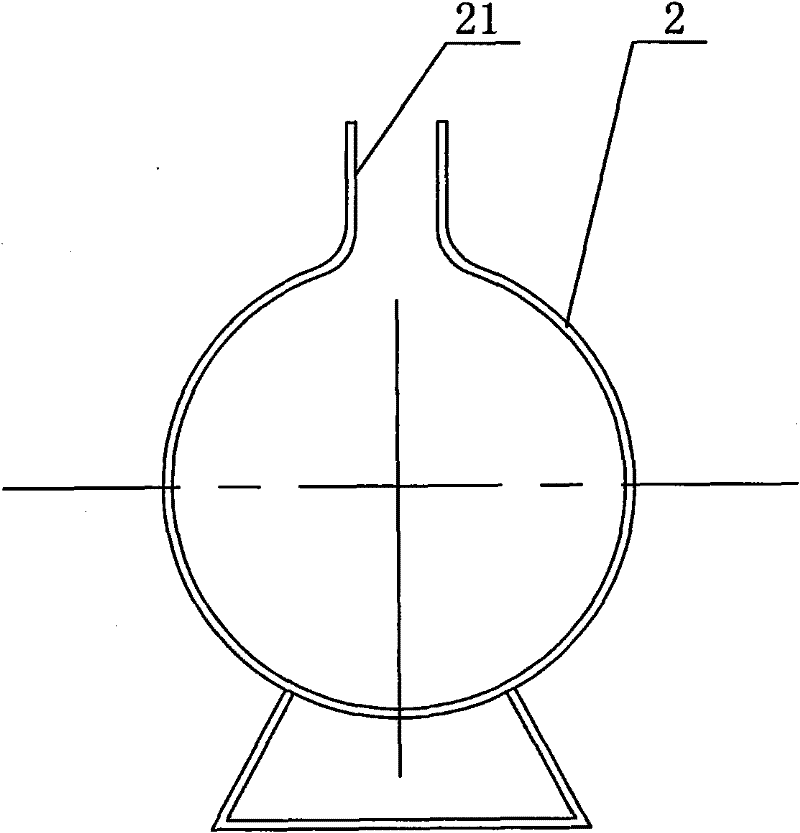

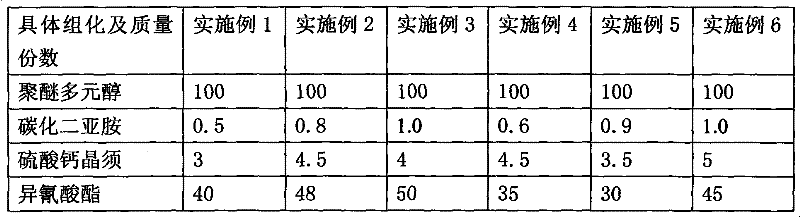

Method for preparing polyurethane fiber guide wheel used for cutting silicon slice

The invention relates to a method for preparing a polyurethane fiber guide wheel used for cutting a silicon slice. The method comprises the following steps of: mixing 0.5-1.0 part of carbodiimide and 3-5 parts of calcium sulphate crystal whisker with 100 parts of polyether polyol, then stirring, heating and dehydrating the materials in a reaction kettle, and adding 30-50 parts of isocyanate to the reaction kettle for a polymerization reaction to prepare a prepolymer and defoaming the prepolymer; mixing the defoamed prepolymer with a liquid polyurethane solidifying agent in the ratio of 100: (15-30) in a casting machine to prepare a polyurethane liquid material, placing an assembled die and a metal spindle into a heating box for heating, and pouring the polyurethane liquid material to a hollow cavity between an adhesive layer and the die and to a hooped pouring opening; and placing the die poured with the polyurethane liquid material into the heating box, then carrying out vulcanization forming treatment, demolding, carrying out additional vulcanization, and machining a guide groove on the surface of a polyurethane coating. The method for preparing the polyurethane fiber guide wheel used for cutting the silicon slice has the characteristics of light weight and improved production efficiency and quality of the guide wheel.

Owner:CHANGZHOU JUNHE TECH

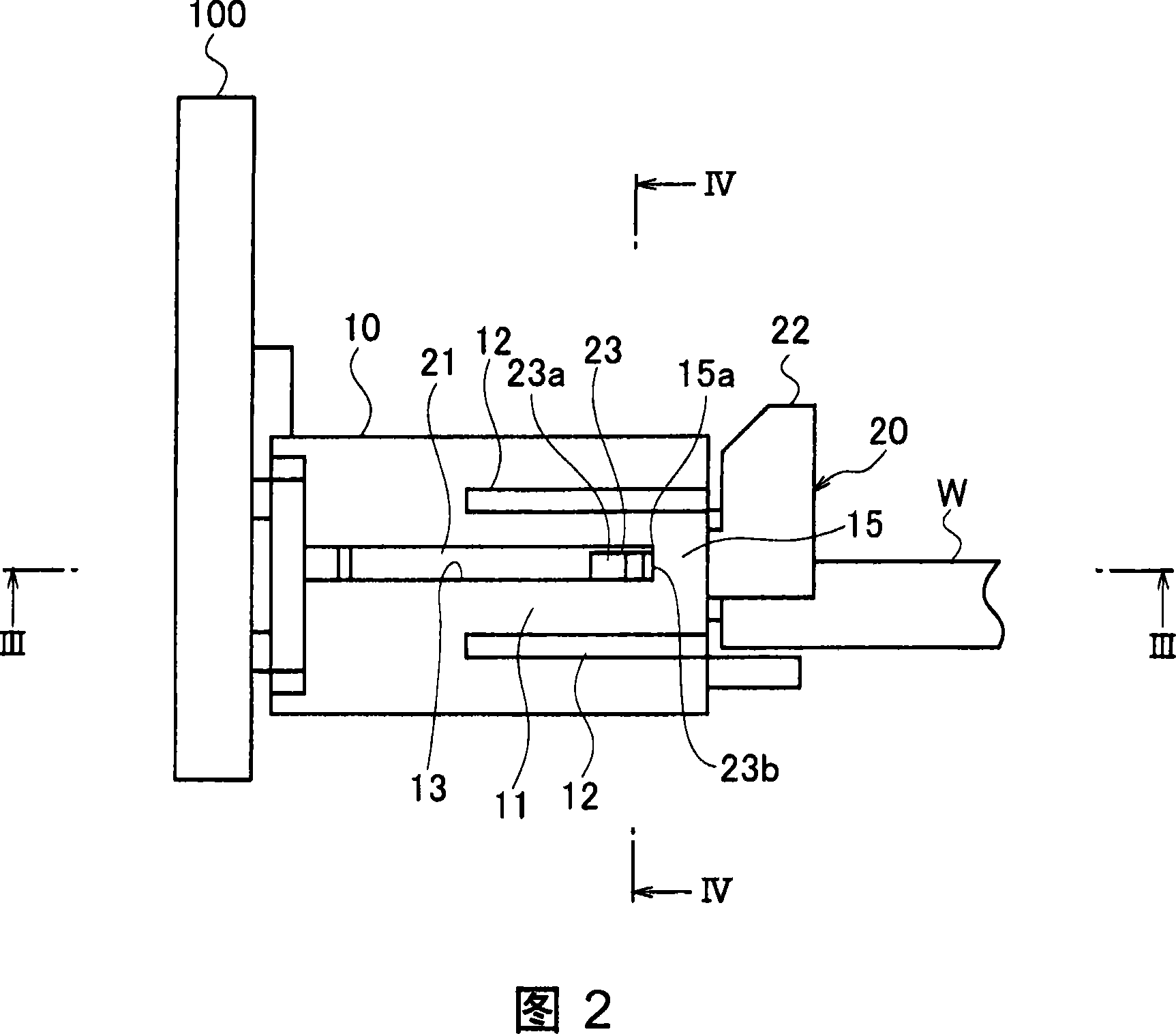

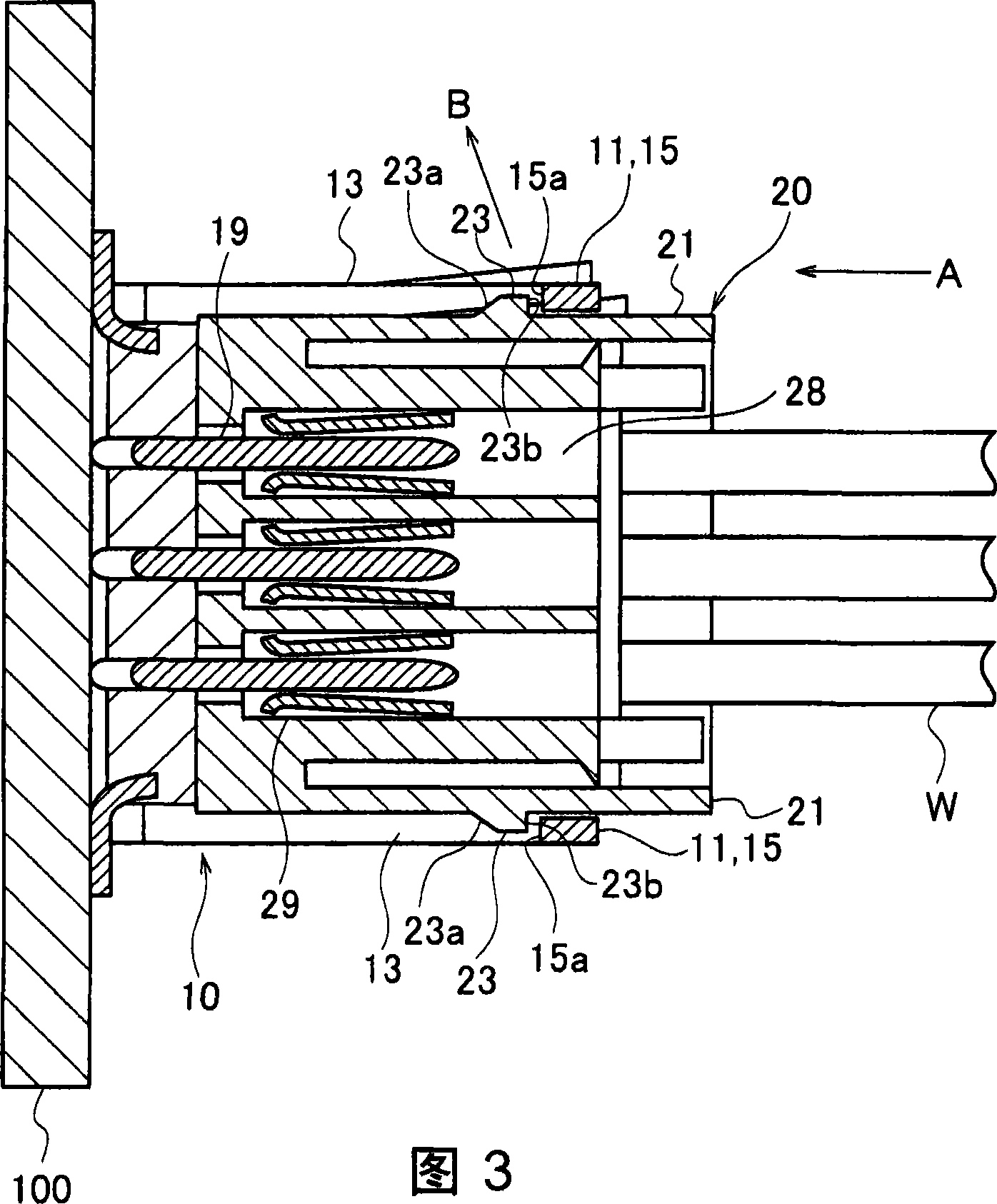

Locking mechanism of connector

InactiveCN101227041AReliable disengagementWill not increase the quantityCoupling device detailsEngineeringElectrical and Electronics engineering

A locking mechanism of connector comprises a first and second locking part (15, 23). The first and second locking part (15, 23) are respectively formed on the shells of the first and second connector (10, 20) intercalated with each other. The first and second connectors are intercalated with each other at the right position to be locked at intercalating status. A depressed part (14) or groove for keeping the disarm state is formed on the inner face of the first connector. When the second locking part moves to the position for releasing the intercalating relation with the first locking part, the second locking part is kept at the position.

Owner:YAZAKI CORP

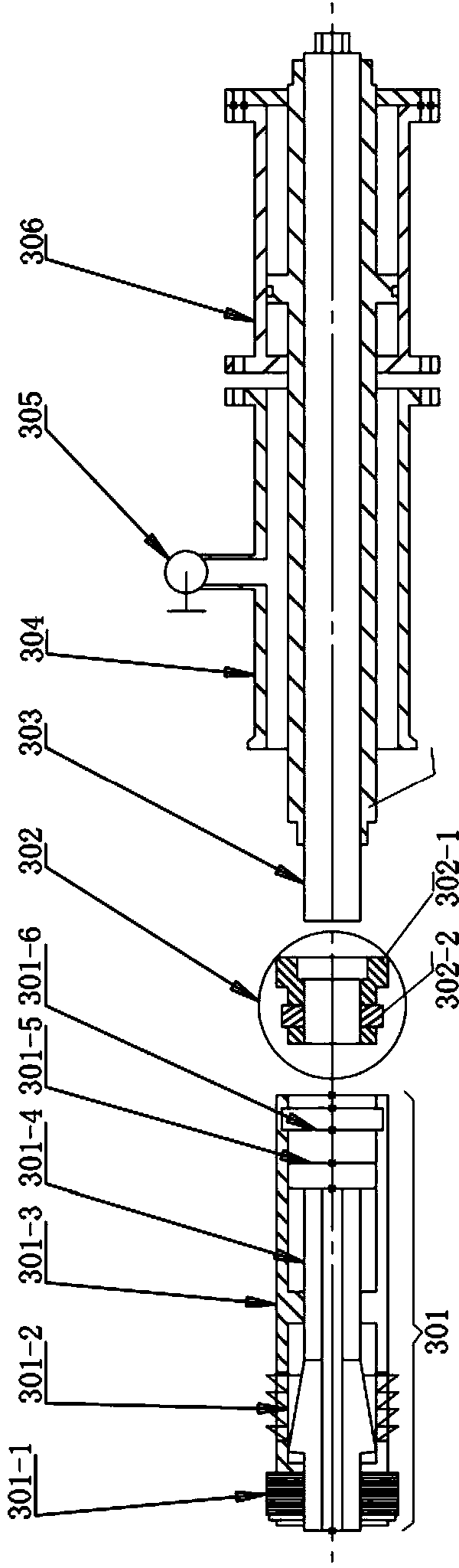

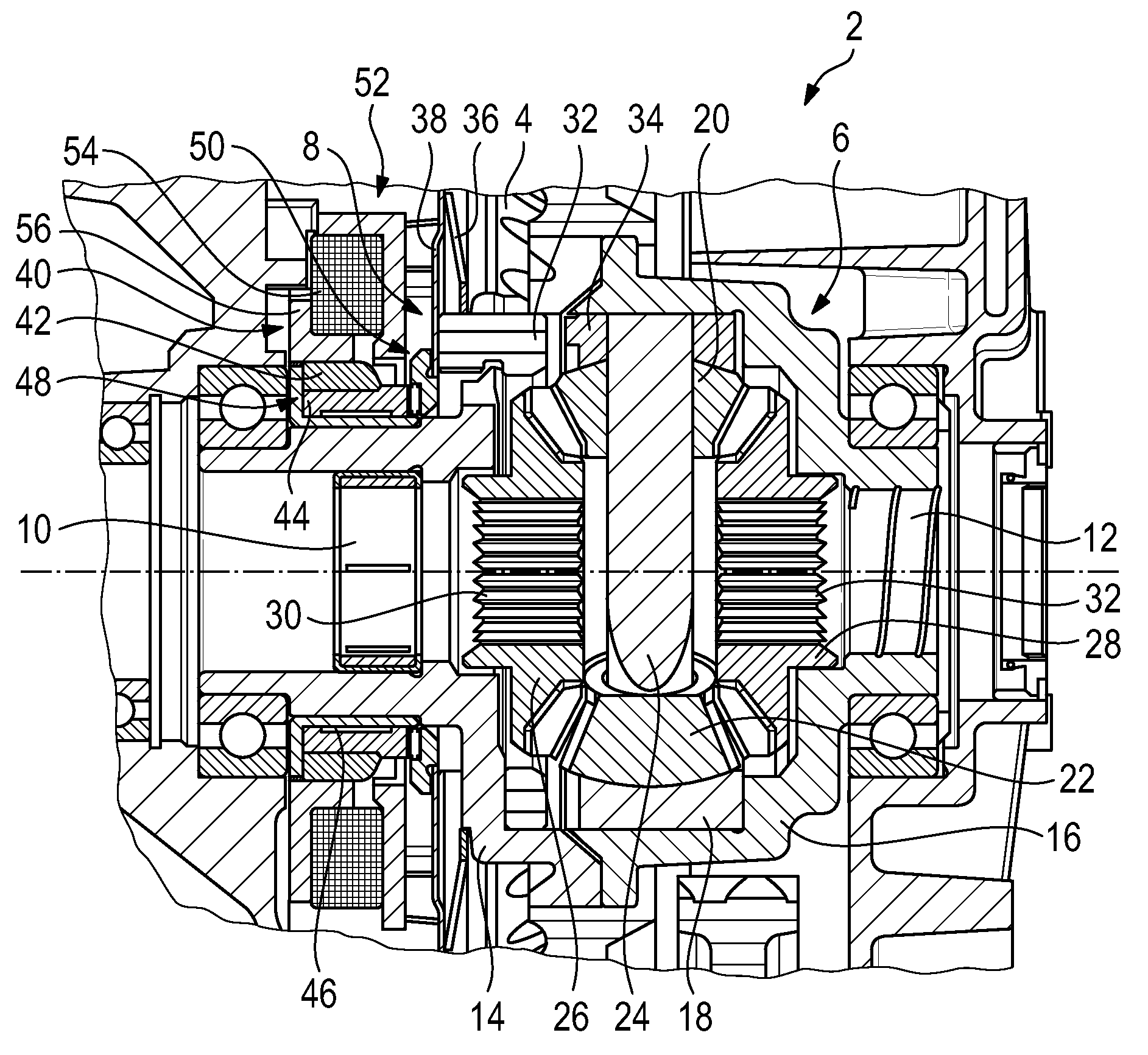

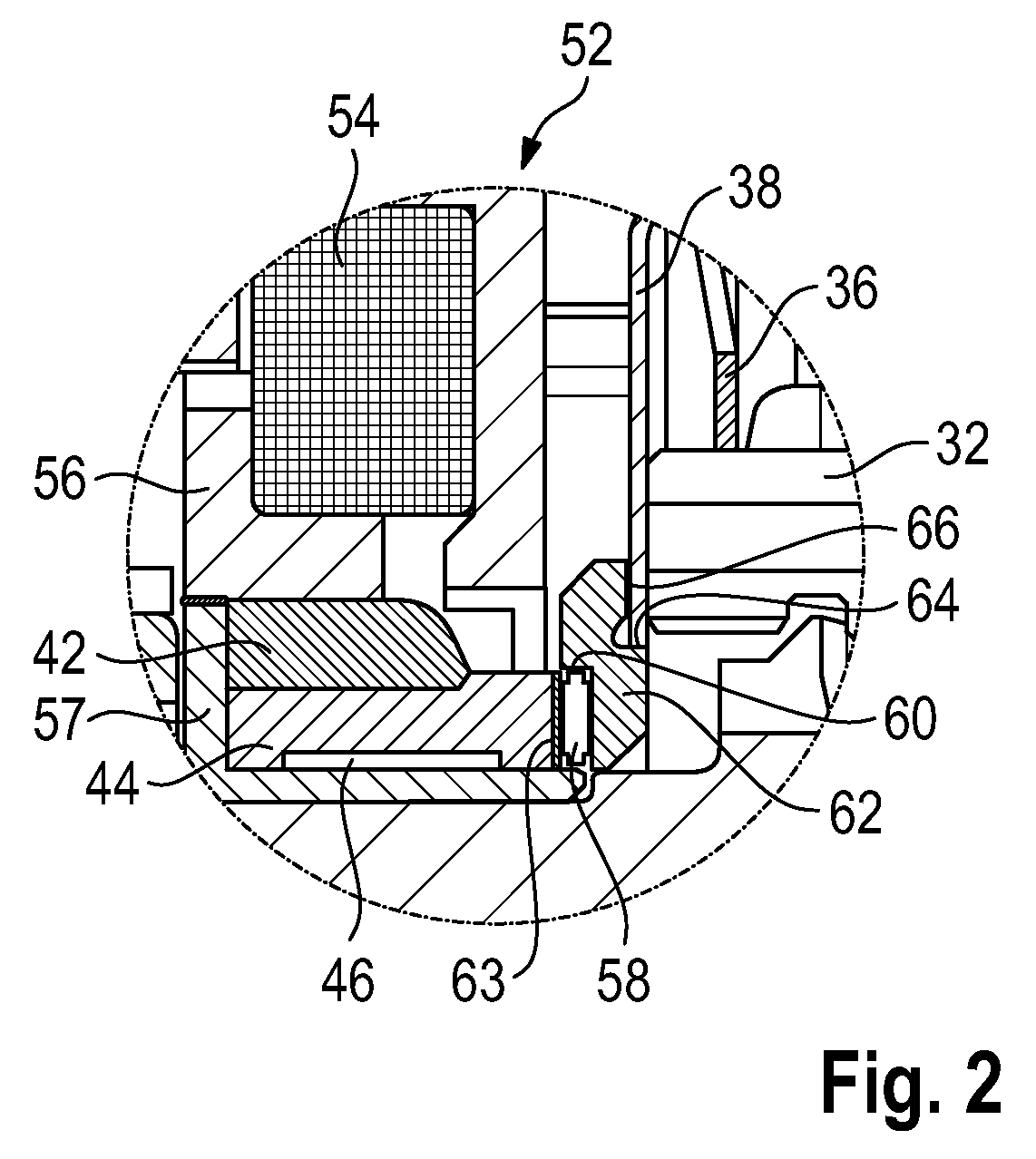

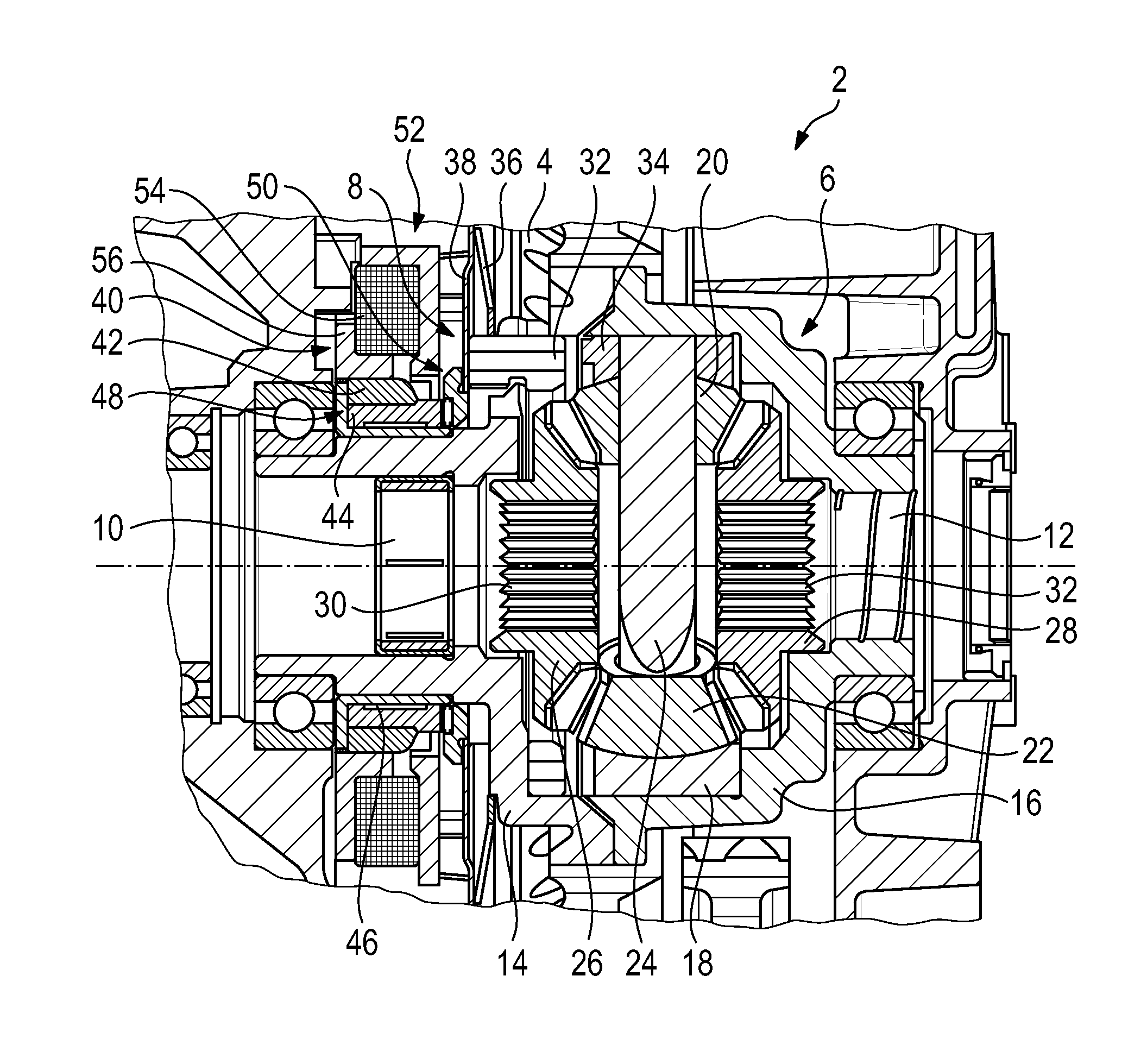

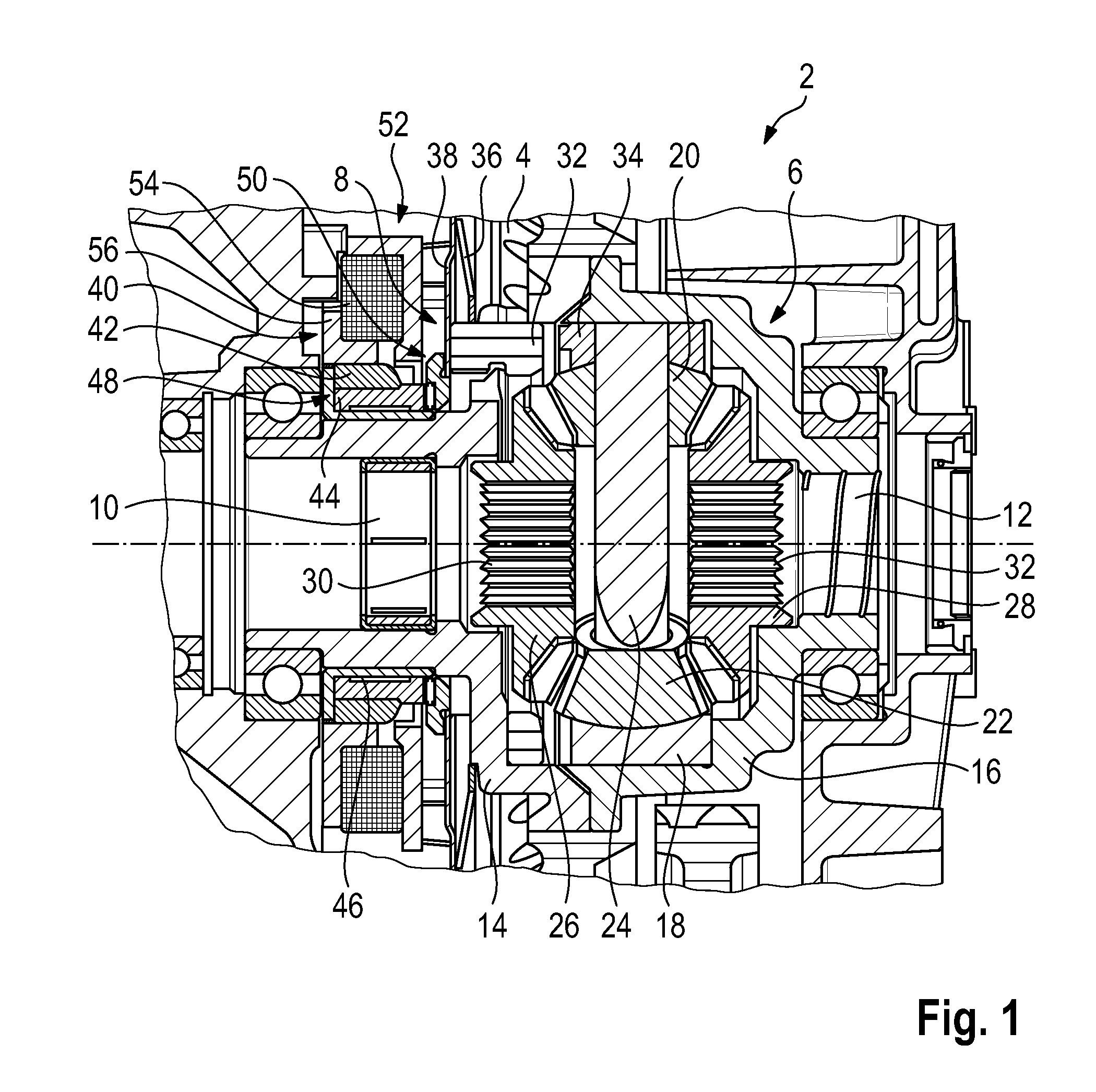

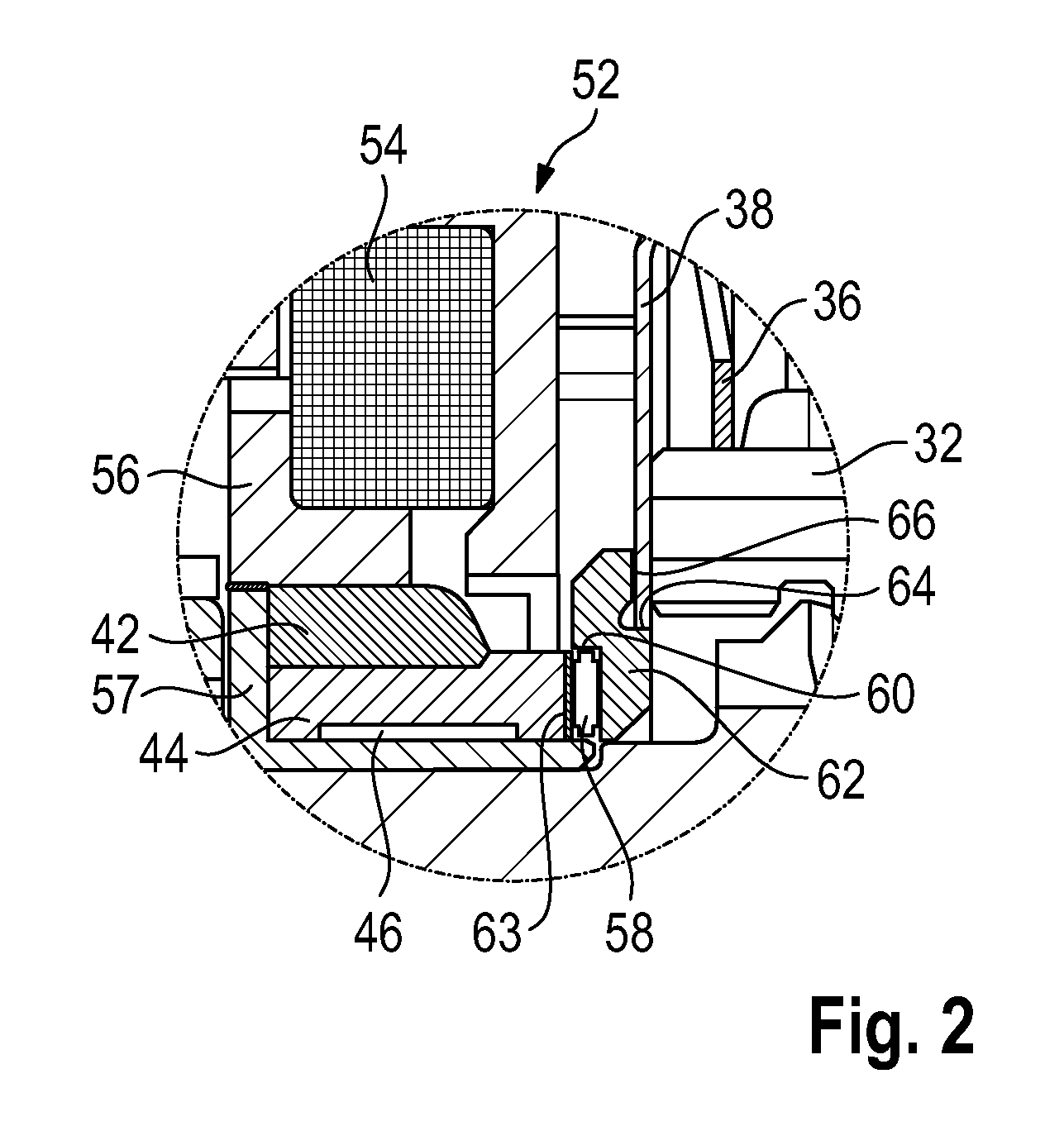

Torque transmission arrangement for a motor vehicle

ActiveUS9033843B2Reliable disengagementReliable monitoringMagnetically actuated clutchesInterengaging clutchesTorque transmissionEngineering

A torque transmission arrangement for a motor vehicle has a drive element (4) and at least one output element connected to one another via a transmission (6) and a shift clutch arrangement (8). The shift clutch arrangement (8) has an actuator (40) that moves a first clutch element (32) axially in the direction of a second clutch element (34) via a displacement element (42, 44) in such a way that a positive connection can be produced between the drive element (4) and the output element. The first clutch element (32) bears via an axial bearing arrangement (50) against the displacement element (42, 44) as seen in the axial direction. The axial bearing arrangement (50) has a rolling bearing (58) and a bearing disk element (62) directed toward the first clutch element (32).

Owner:DR ING H C F PORSCHE AG

Safe releasing mechanism

InactiveCN103466042AReliable disengagementProtect life safetyTowing/pushing equipmentEngineeringWinch

The invention discloses a safe releasing mechanism which comprises a connecting shell, a retaining ring, a movable spring seat, a flexible chuck, a spring, an inner sleeve, an outer sleeve, a breakable pin, a fixing ring, a tow rope, a tapered slider, a compression sleeve and the like. The safe releasing mechanism is mounted on a winch of a navigation body in high-speed navigation, and absorbs certain impact energy to reduce influences of internal impact to a take-up towing system when an underwater carrier connected with the navigation body encounters accidents and then towing tension of the tow rope is increased. When the towing tension is increased to certain value, the breakable pin in the mechanism is broken off under the action of the towing force, so that the towing rope can be reliably separated from the winch, the high-speed navigation body can navigate normally, overturning accidents are avoided, and injuries of operators due to breakage of cables can also be avoided.

Owner:710TH RES INST OF CHINA SHIPBUILDING IND CORP

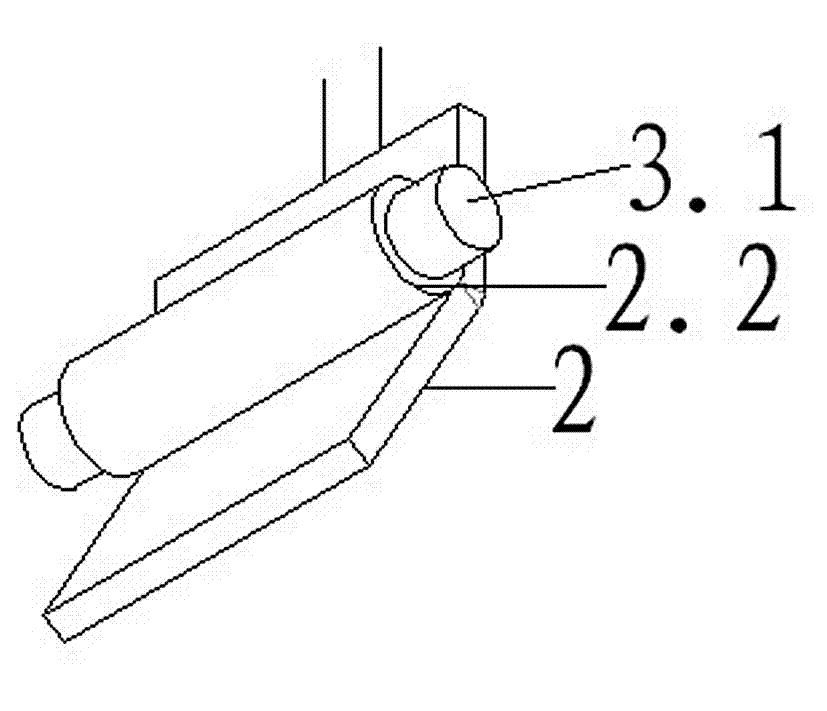

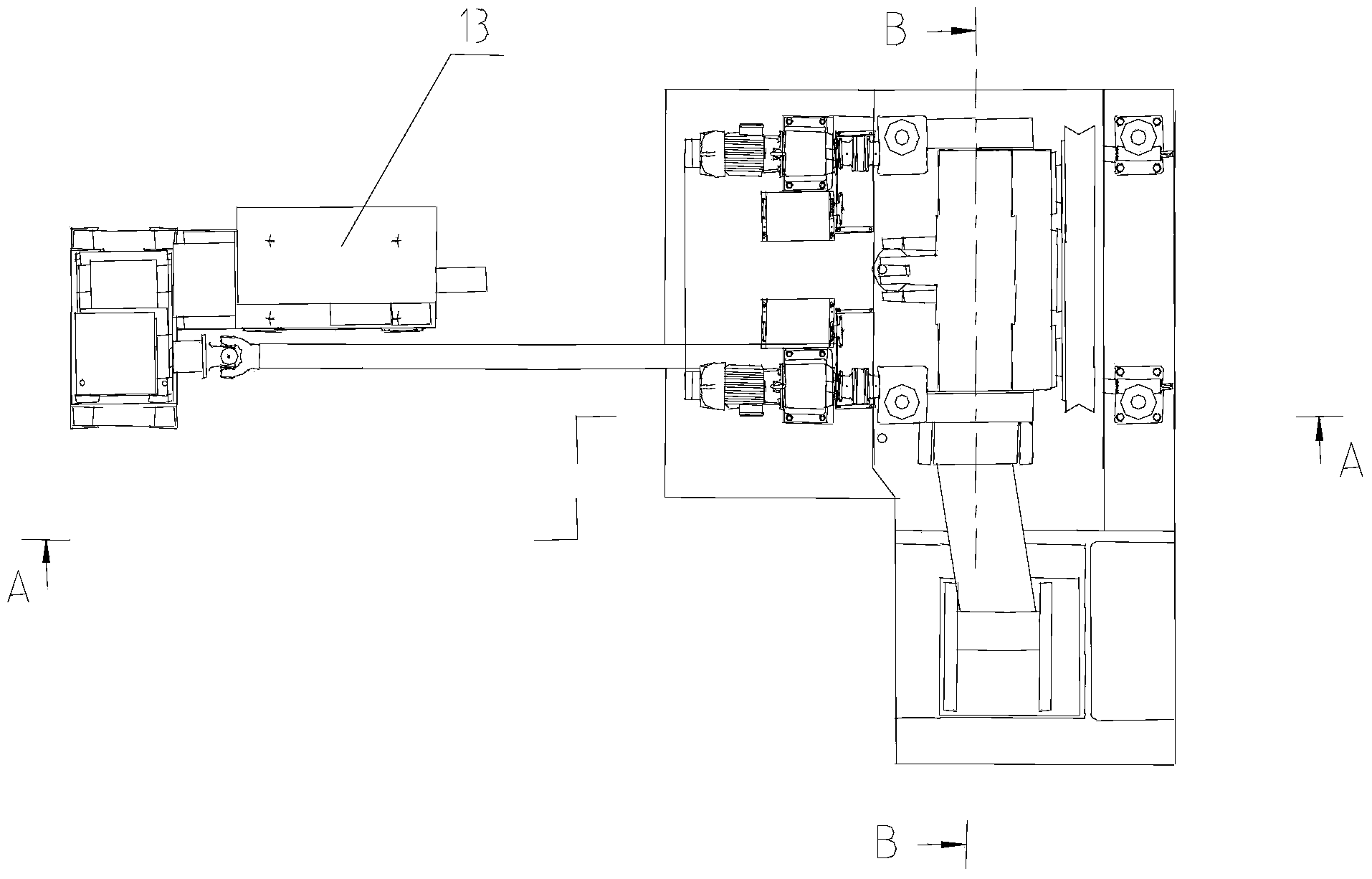

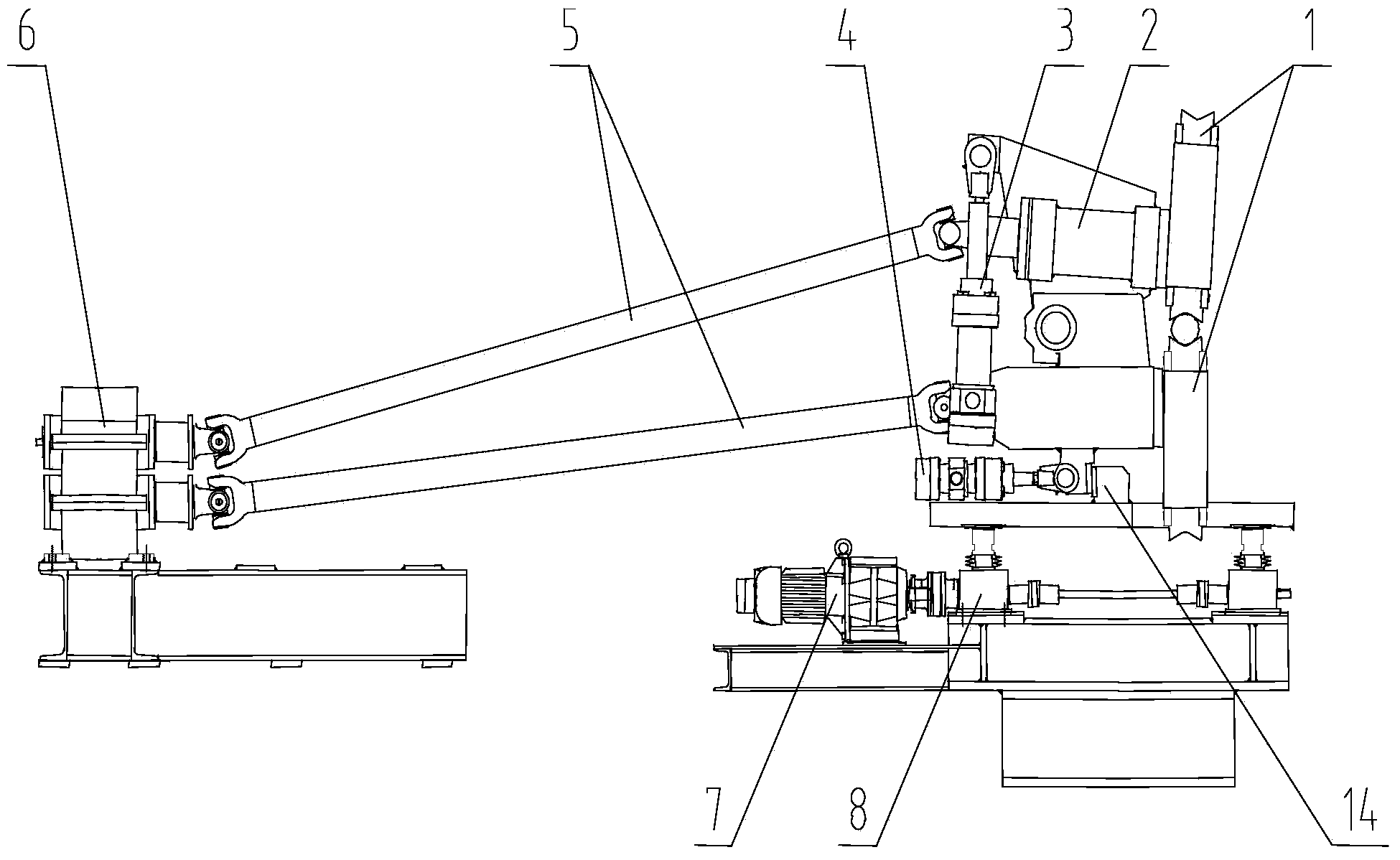

Top-rod separating device for perforating seamless steel pipe

InactiveCN103624082AIncreased requirements for efficient piercing productionReliable disengagementMandrelsMetal rolling arrangementsMotor driveUniversal joint

The invention provides a top-rod separating device for perforating a seamless steel pipe. The top-rod separating device comprises a closed V-shaped pinch chain group, an opening and closing mechanism, a lifting device and a transmission device, wherein the opening and closing mechanism is used for controlling the closed V-shaped pinch chain group; the lifting device comprises a spiral lifting machine, an alternating-current variable-frequency speed reducing motor and an adjusting bracket; the alternating-current variable-frequency speed reducing motor drives the spiral lifting machine to drive the adjusting bracket to lift and fall so as to adjust the position of the top-rod separating device for clamping the working center line; the transmission device comprises a two-output-shaft speed reducing box, universal joint shafts and an alternating-current variable-frequency motor; and the alternating-current variable-frequency motor drives the two-output-shaft speed reducing box to drive the universal joint shafts and accelerate the pinch chain group to set speed, so that a top rod is pulled out of a rough pipe. The top-rod separating device provided by the invention has the advantages that the top rod can be reliably separated from the rough pipe, so that the time for replacing a top head and the top rod is saved and further the requirement for high-efficiency perforation production of the seamless steel pipe is improved.

Owner:BERIS ENG & RES CORP

Water hammer-proof air valve and water hammer-proof exhaust method for in-use pipeline

ActiveUS20180149287A1Avoid pressure fluctuationsReliable disengagementOperating means/releasing devices for valvesValve members for absorbing fluid energyGas pipelineValve opening

A water hammer-proof air valve that has a valve body and a bonnet, that are fixedly connected, a valve opening is provided on the valve body, and a high-speed intake and exhaust device is provided in an inner cavity of the valve body. A bonnet opening is provided on the bonnet, an output end of the high-speed intake and exhaust device penetrates the bonnet opening and is communicated with a high-speed exhaust throttling device for limiting an exhaust amount of gas of the high-speed intake and exhaust device, an output end of the high-speed exhaust throttling device is communicated with an outside air, and a trace exhaust device for discharging the gas separated out from the pipeline to the outside through the high-speed exhaust throttling device after the high-speed intake and exhaust device closes the valve is further provided in the high-speed intake and exhaust device.

Owner:ZHUZHOU SOUTHERN VALVE

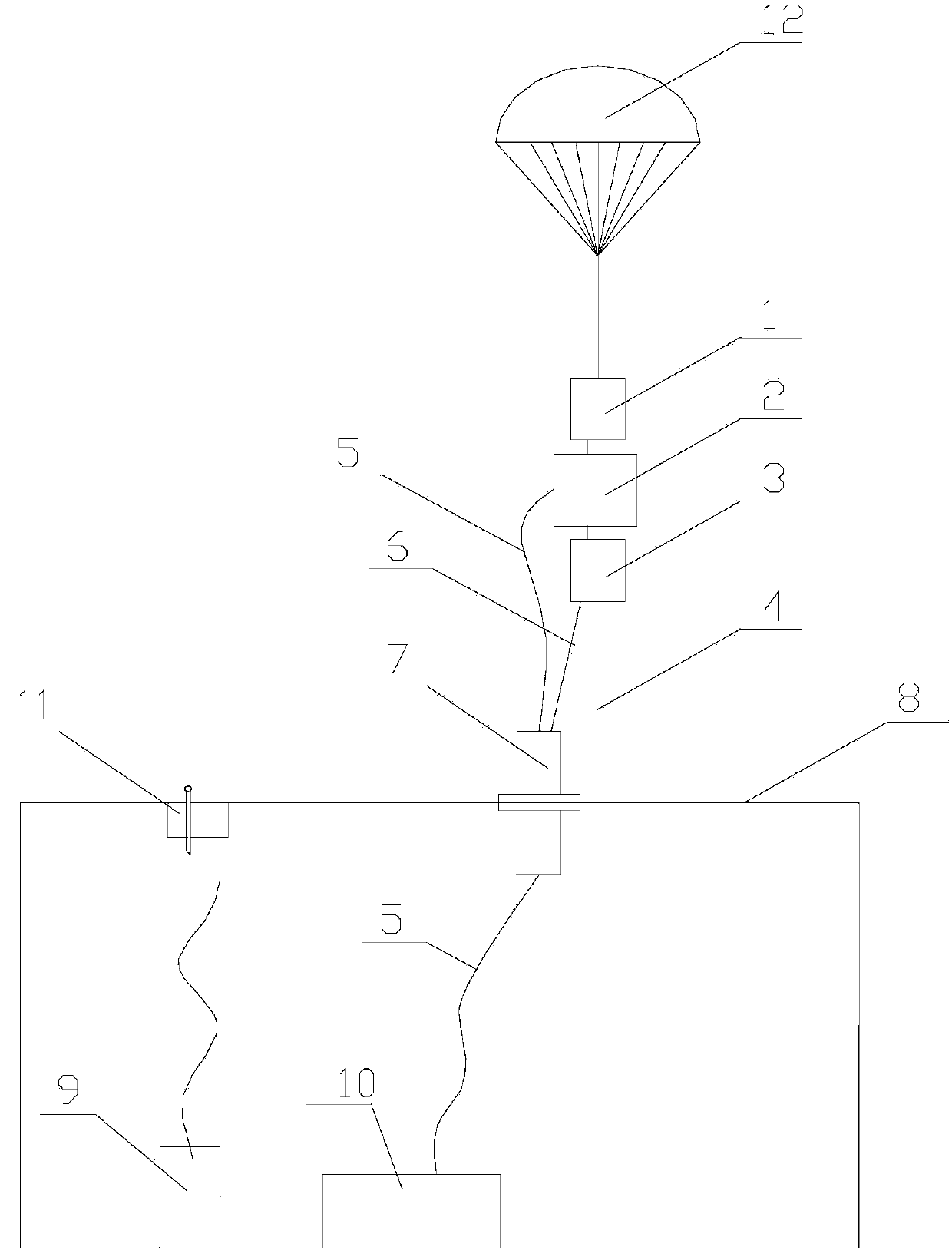

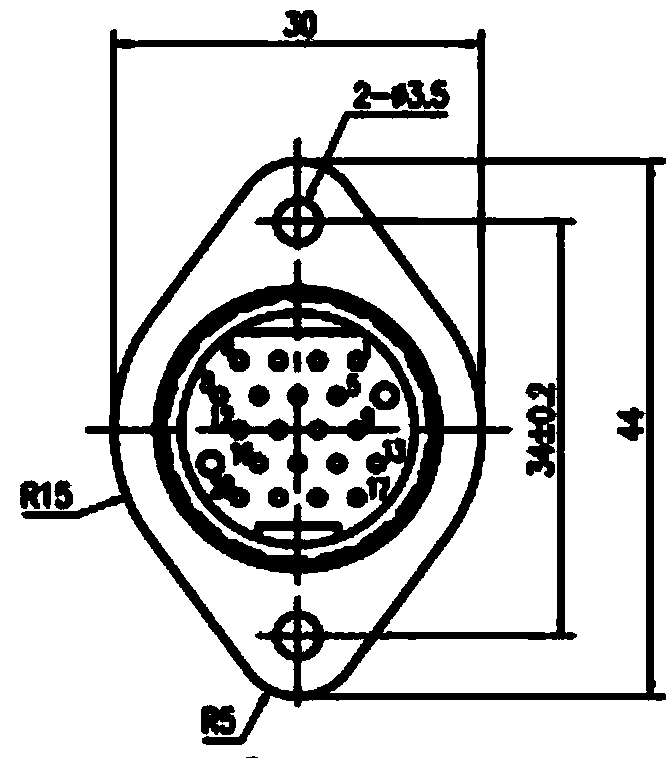

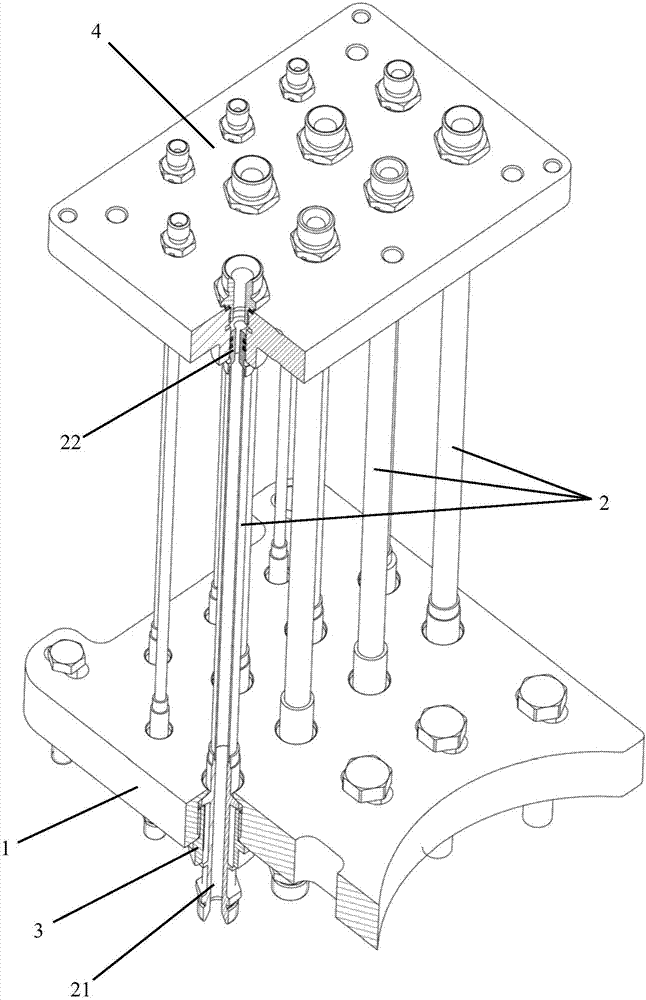

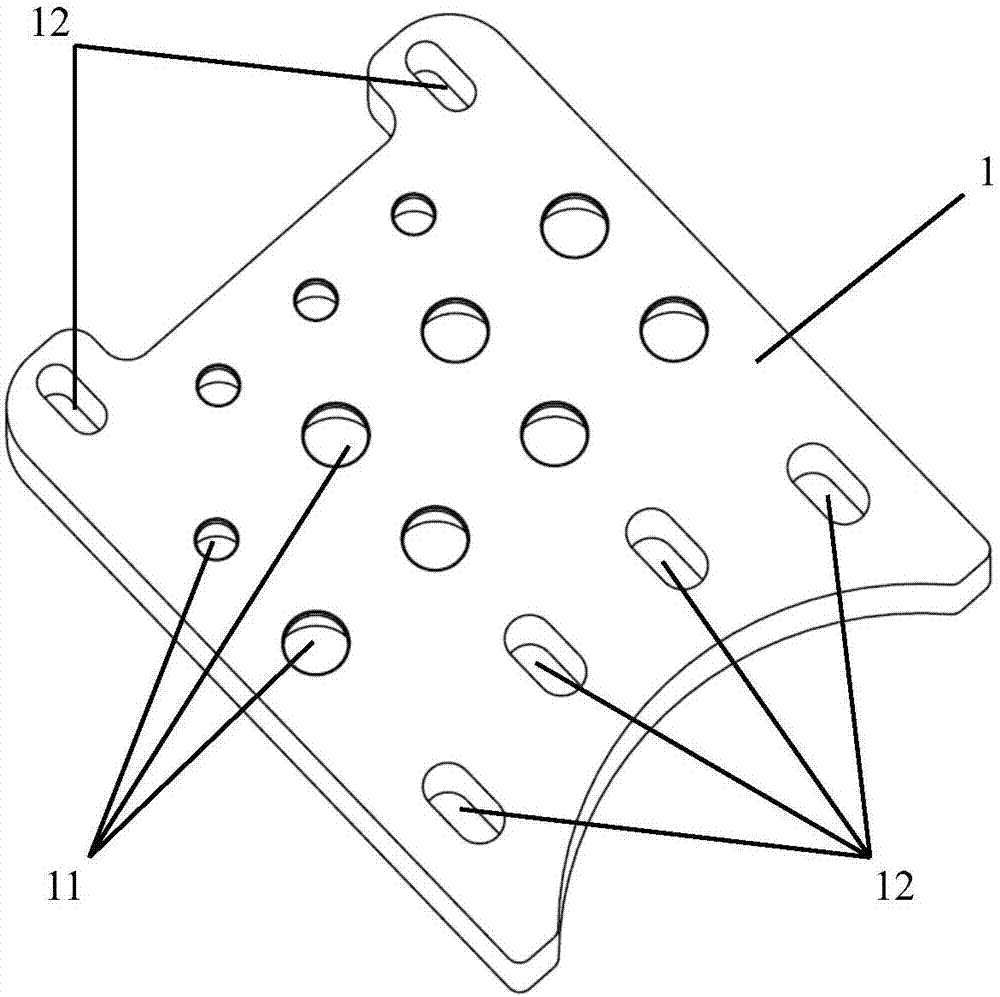

Supported rocket air supply connector

ActiveCN107542990ASimple structureEasy to operatePipe supportsCouplingsArchitectural engineeringRocket

The invention discloses a supported rocket air supply connector, which comprises a support plate and a plurality of air supply pipes. A plurality of through holes are formed in the support plate. Thethrough holes are stepped hole structures and the inner mesa of each through hole is a concave spherical surface. The lower end and the upper end of each air supply pipe are correspondingly provided with a nozzle joint and a cannula joint. A limiting ring table of which both sides are convex spherical surfaces is arranged on the outer circumferential wall of the nozzle joint. A sealing ring grooveand a sealing ring are arranged on the outer circumferential wall of the cannula joint. The nozzle joint passes through the through holes and is limited by a limiting sleeve. The limiting ring tableon the nozzle joint is located on the underside of the mesa in each through hole. The upper half of the limiting sleeve is rotatably mounted in the through holes and its upper end is located on the underside of the limiting ring table of the nozzle joint. The nozzle joint and the limiting ring seat are matched with the inner peripheral walls of the through holes at intervals. The inner peripheralwall of the limiting sleeve and the outer peripheral wall of the nozzle joint are matched at intervals. The supported rocket air supply connector has the advantages of simple structure, convenient operation, reliable sealing, and strong adaptability and can achieve long-term docking and zero-second shedding.

Owner:BEIJING INST OF SPACE LAUNCH TECH +1

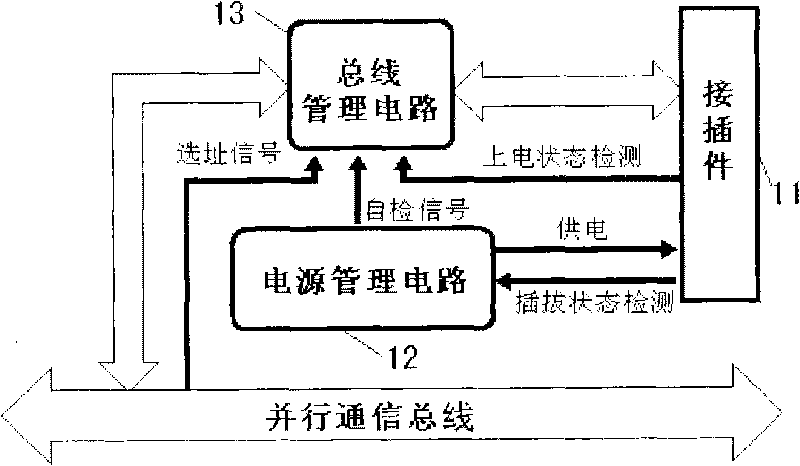

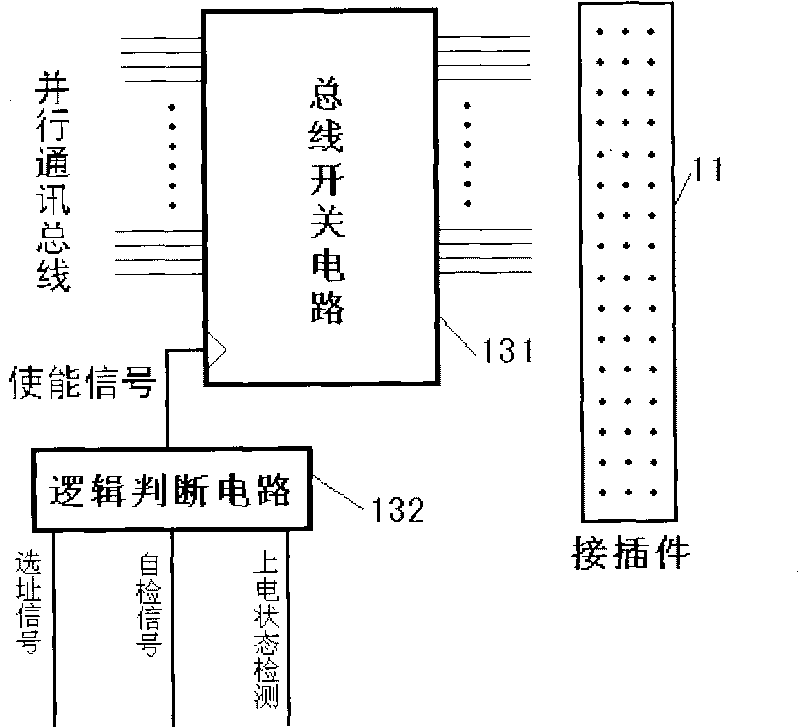

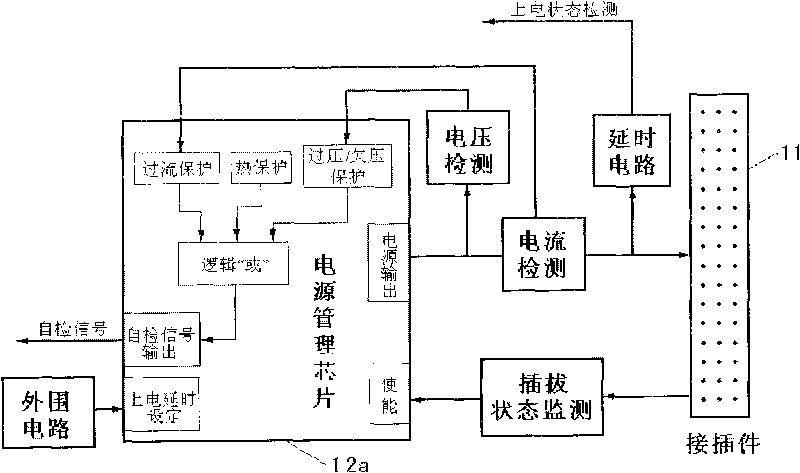

Parallel communication bus interface

ActiveCN101763332ASafe escapeOut of the wayElectric digital data processingElectricitySupply management

The invention provides a parallel communication bus interface. The interface comprises a connector which is arranged for connecting the parallel communication bus, a master unit of the parallel communication bus and a slave unit of the parallel communication bus, a power supply management circuit which is arranged for strictly controlling the connection sequence of an earth wire, a power supply wire and a signal wire and strictly controlling the delay length for connecting the earth wire to the system and electrifying, and a bus management circuit which is arranged for controlling the master unit of the parallel communication bus or the slave unit of the parallel communication bus to be connect with or separate from the parallel communication bus. The bus management circuit is matched with an address selecting signal sent by the master unit of the parallel communication bus and an electrified signal sent by the power supply management circuit so as to ensure only one slave unit of the parallel communication bus is connected with the parallel communication bus at any moment. The invention provides a parallel communication bus interface which is fit for the parallel communication bus, supports safely and unperturbed on-line connection or cut-off of the bus device and overcomes the complexity for matching the software with the chip of the prior art.

Owner:ZHEJIANG SUPCON TECH +1

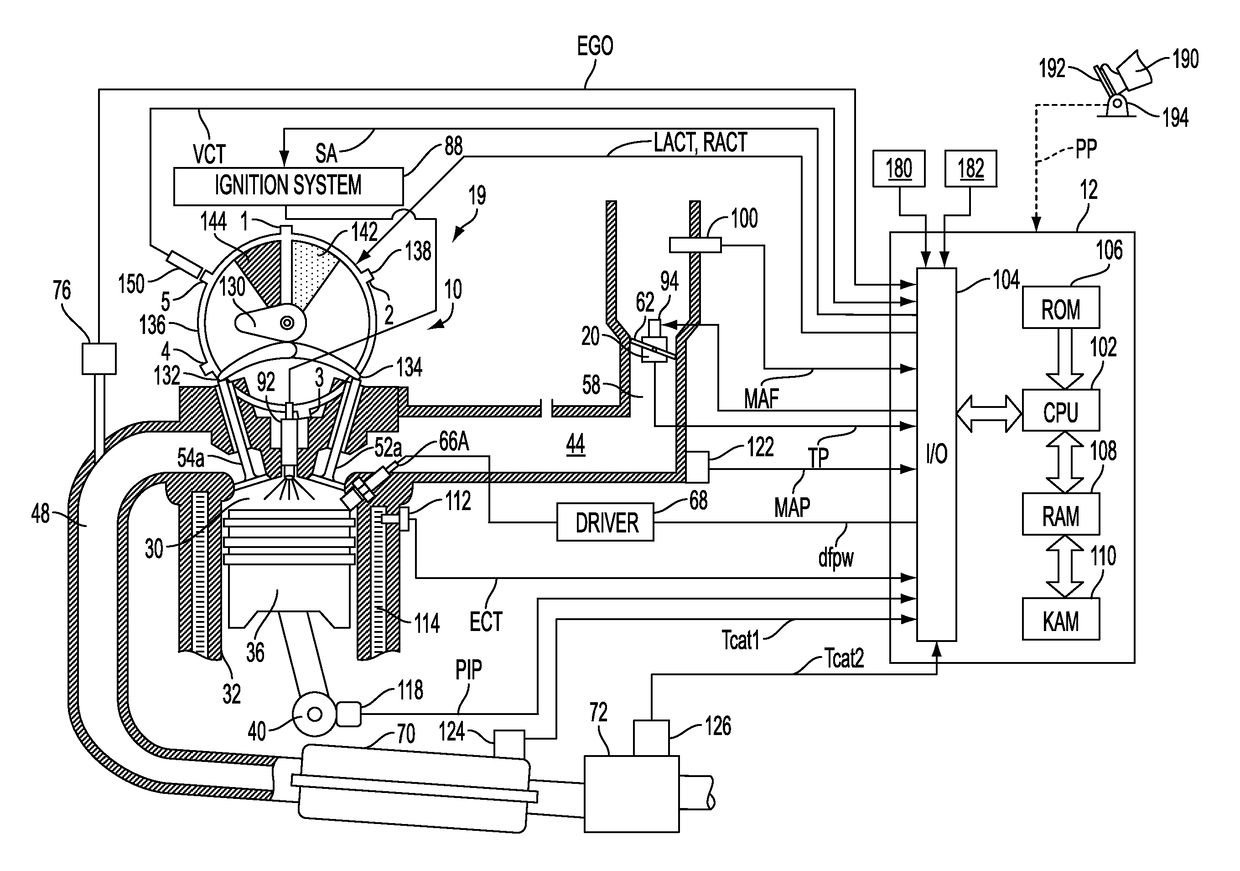

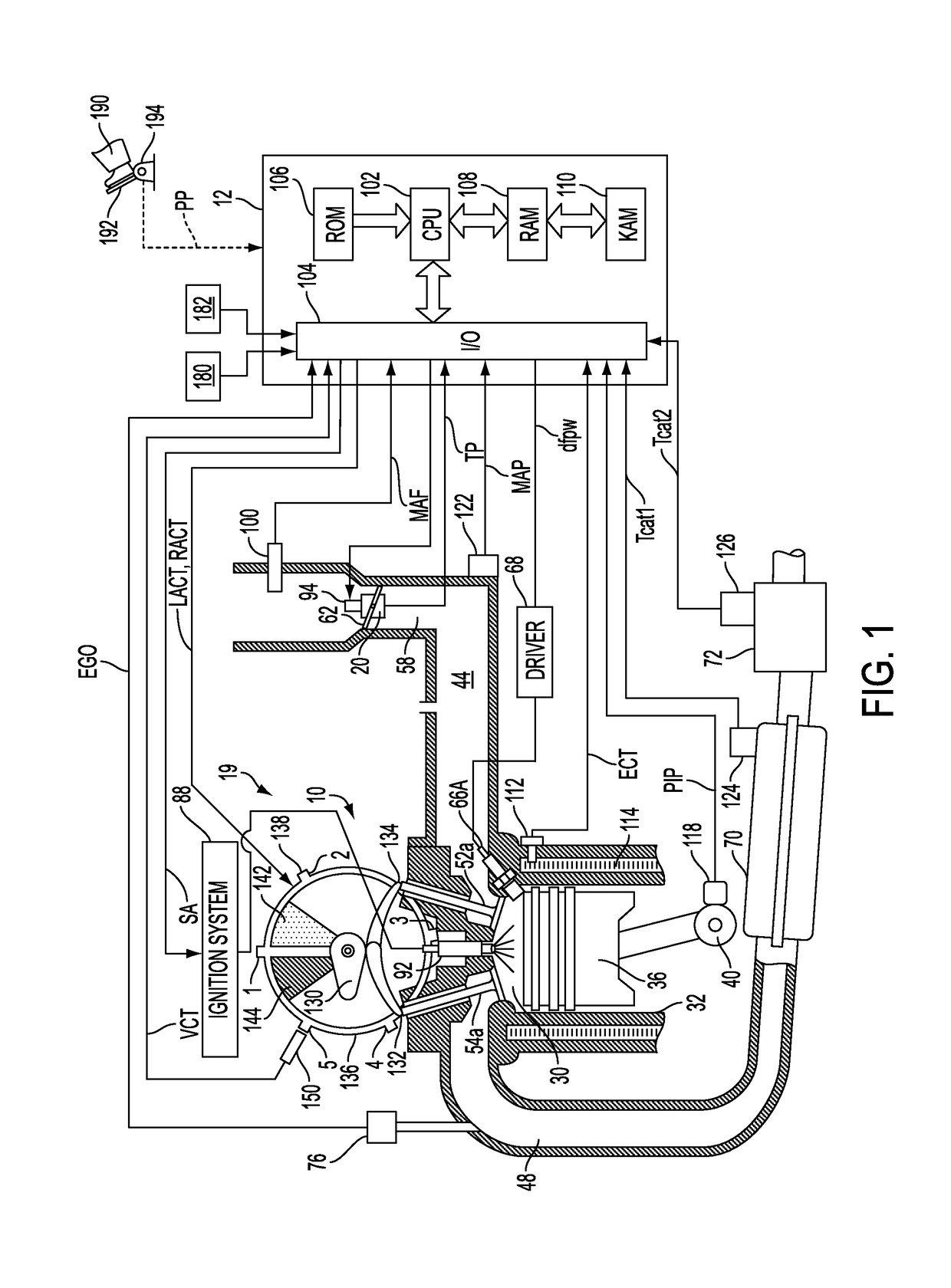

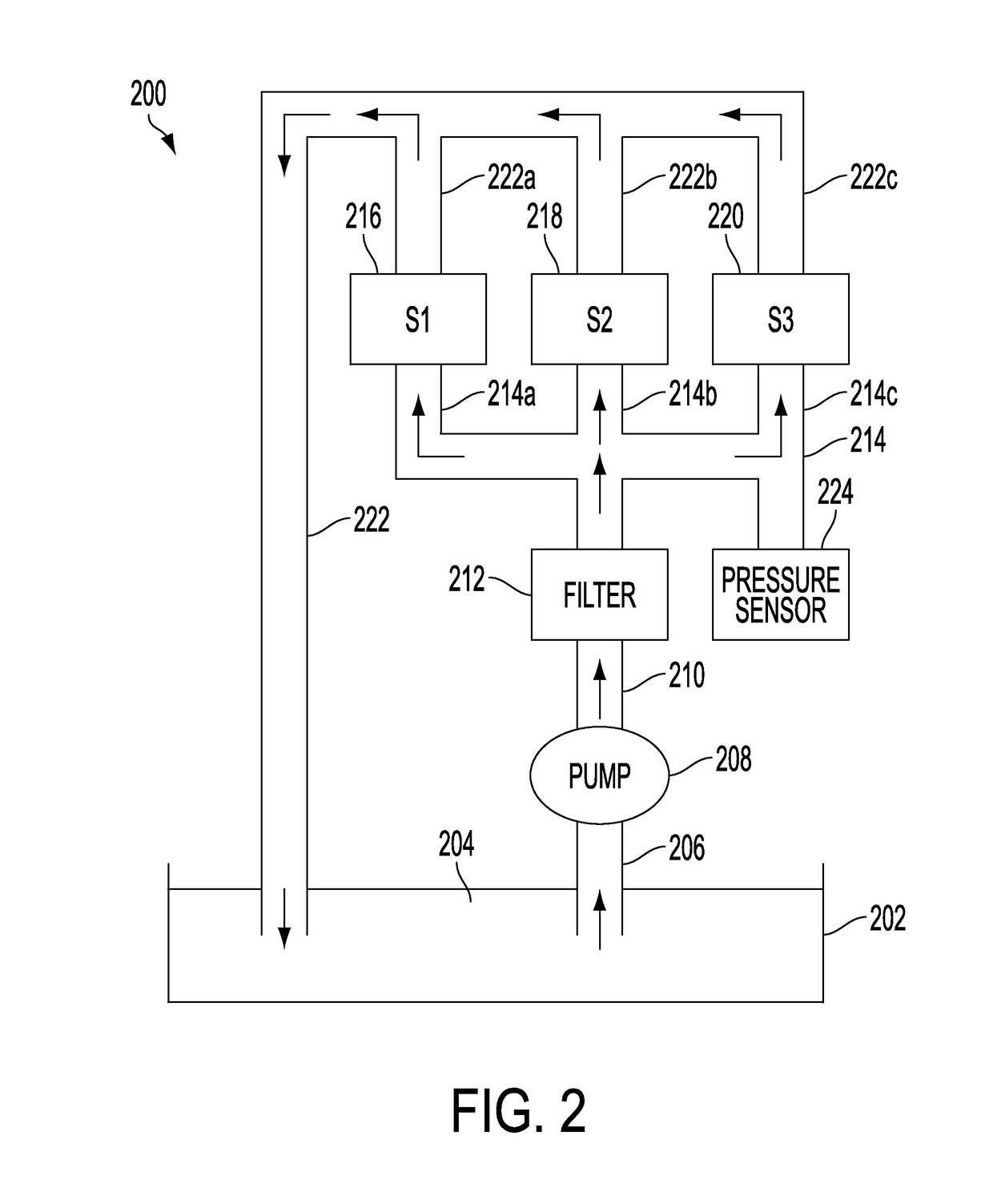

Method and system for variable cam timing device

Methods and systems are described for an engine with a cam torque actuated variable cam timing phaser. Phaser positioning control is improved by reducing inaccuracies resulting from inadvertent spool valve and / or phaser movement when the spool valve is commanded between regions. In addition, improved spool valve mapping is used to render phaser commands more consistent and robust.

Owner:FORD GLOBAL TECH LLC

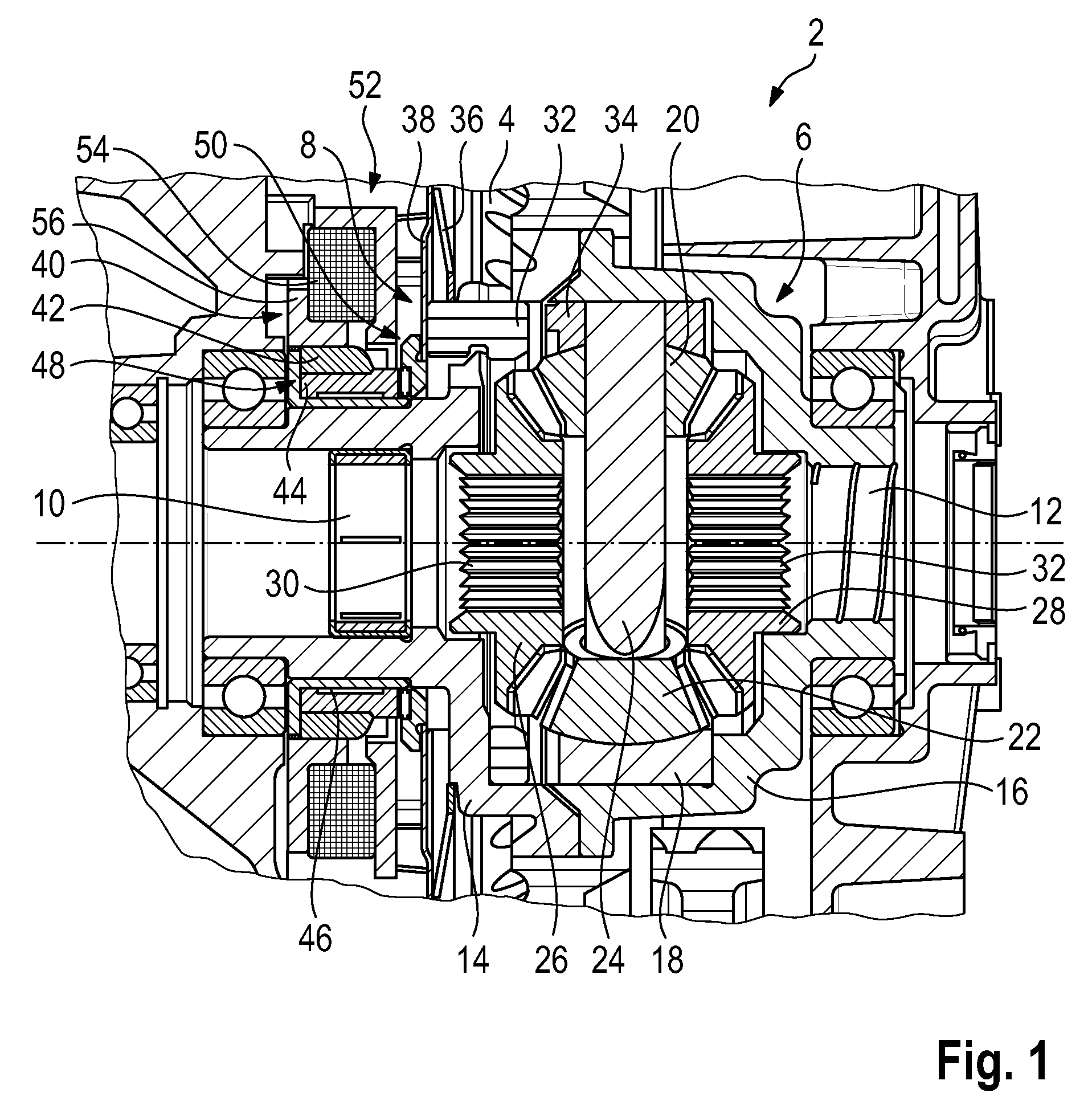

Torque transmission arrangement for a motor vehicle

ActiveUS20140158493A1Reliable disengagementReliable monitoringMagnetically actuated clutchesFriction clutchesTorque transmissionActuator

A torque transmission arrangement for a motor vehicle has a drive element (4) and at least one output element connected to one another via a transmission (6) and a shift clutch arrangement (8). The shift clutch arrangement (8) has an actuator (40) that moves a first clutch element (32) axially in the direction of a second clutch element (34) via a displacement element (42, 44) in such a way that a positive connection can be produced between the drive element (4) and the output element. The first clutch element (32) bears via an axial bearing arrangement (50) against the displacement element (42, 44) as seen in the axial direction. The axial bearing arrangement (50) has a rolling bearing (58) and a bearing disk element (62) directed toward the first clutch element (32).

Owner:DR ING H C F PORSCHE AG

Lightning arrester core body and lightning arrester

PendingCN108428526AEasy to installReduce resistanceOther resistor networksOvervoltage protection resistorsShear stressElectric power system

The invention relates to the technical field of power equipment and provides a lightning arrester core body and a lightning arrester. When the gap between a resistor sheet and the inner wall of an insulating cylinder enables the valve plate part inside or all the part to be damaged by strong thunder shock on the lightning arrester or other reasons, or flashover occurs at the gap between the resistor sheet and the insulating cylinder, high-pressure gas is generated between the resistor sheet and the insulating cylinder, so that an electrode is pushed, a disconnected thread on the insulating cylinder is broken by shear stress, the electrode is separated reliably and a grounding bolt falls off; the disconnected thread of the insulating cylinder can guarantee that the electrode is mounted stably, also can reduce the resistance when the electrode is separated, contributes to reliable separation, guarantees the safety of a power grid and avoids explosion caused by damage to the lightning arrester or failure that a power system is permanently grounded.

Owner:广东安迪普科技有限公司

Splicing apparatus for splicing curtain material

ActiveCN104210122ASimple compression forceReliable disengagementConveyorsTyresEngineeringMechanical engineering

A splicing apparatus (1) for splicing tape sections (7, 11) of a material tap especially prepared from a curtain material. The curtain material is reinforced by textile filament and / or steel wire. The splicing apparatus has a splicing pressure plate (14) which is supported in a manner of pivoting parallel to the longitudinal axis. The tape sections (7, 11) can penetrate and guide between a lower side face and an abutting face of the splicing pressure plate (14) and the splicing pressure plate (14) can manipulate with a hold-down cylinder (40) facing the abutting face to splice and connected the two tape sections (7, 11). The hold-down cylinder (40) is arranged between a transverse joint device (17) and the splicing pressure plate (14). In order to realize simple approaching for maintenance and replacement, an end portion of the hold-down cylinder (40), far away from the splicing pressure plate (14), is fastened on the transverse joint device (17), and the other end portion of the hold-down cylinder is fastened on a fastening section (28) at the front side of the splicing pressure plate (14).

Owner:KARL EUGEN FISCHER GMBH

Dog clutch for a vehicle transmission

ActiveUS10247252B2Easy and more consistentSimple control processInterengaging clutchesCouplingsEngineeringActuator

A dog clutch for a vehicle transmission includes a driving member configured to rotate about an axis and including a cavity extending radially from the axis, a driving tooth slidably movable within the radially extending cavity, a driven member coaxially surrounding the driving member and including a radially inward extending driven tooth, an actuator coaxially positioned within the driving member and movable along the axis to selectively engage the driving tooth with the driven tooth, and a biasing member radially inwardly biasing the driving tooth into contact with the actuator.

Owner:GM GLOBAL TECH OPERATIONS LLC

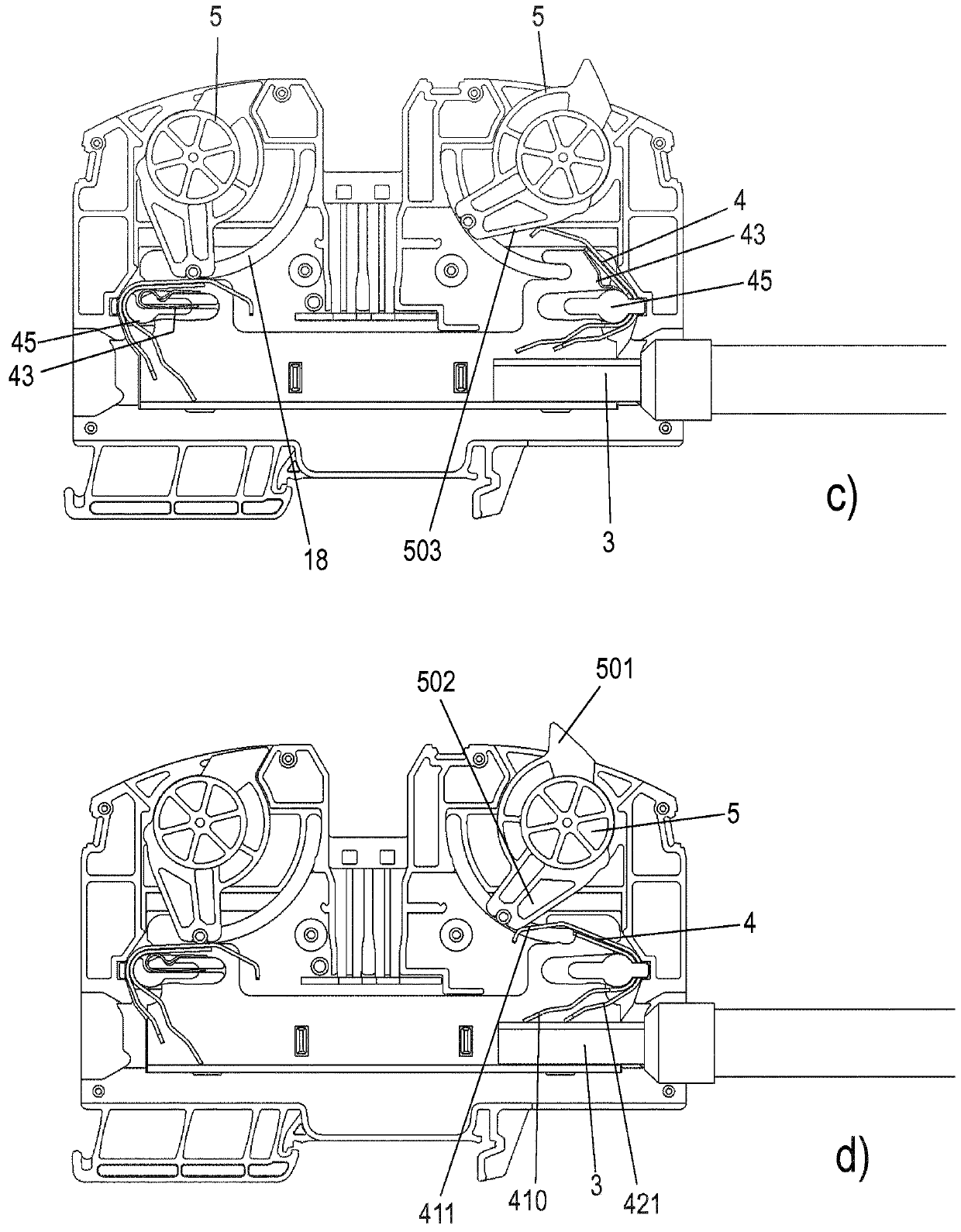

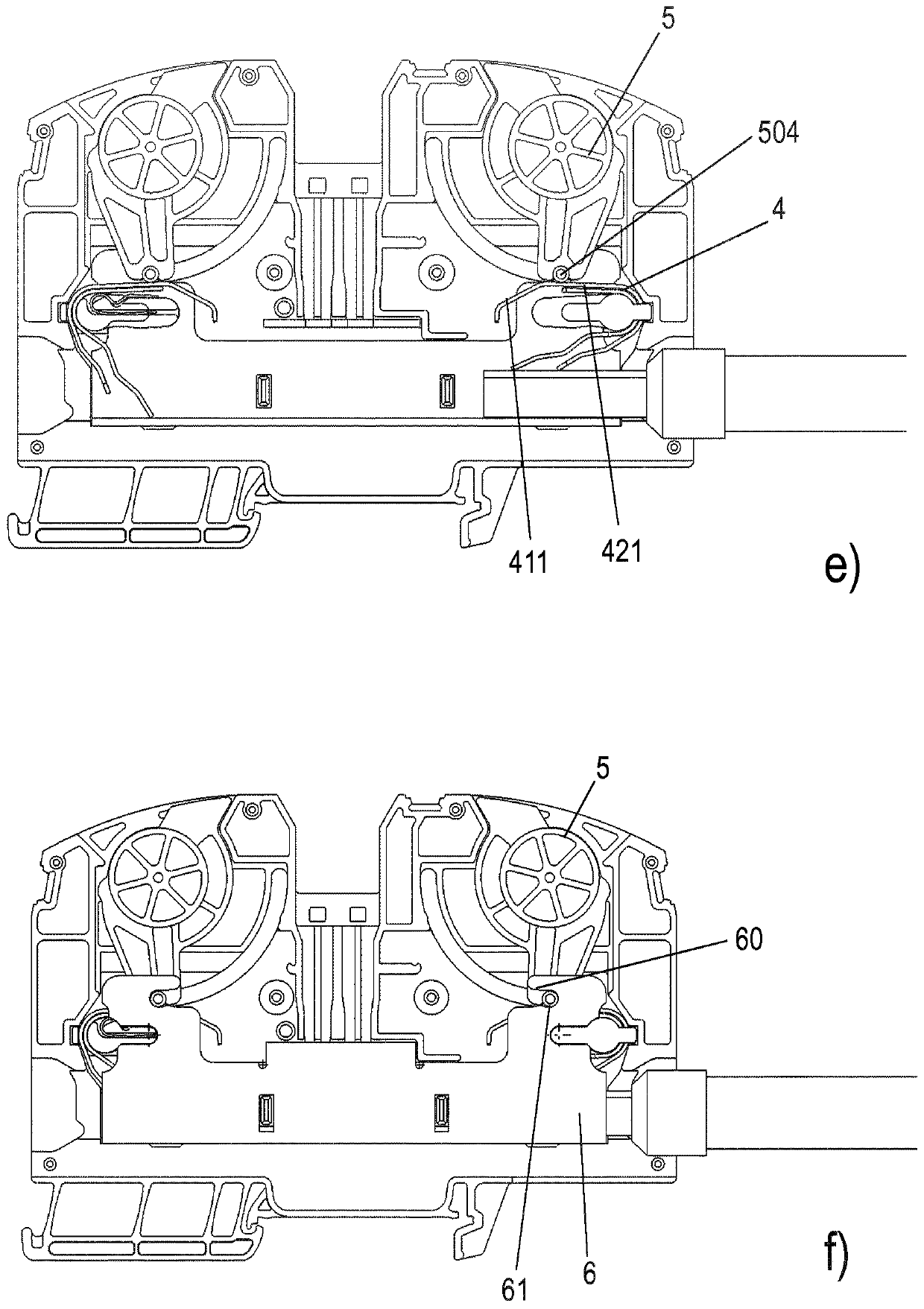

Connection device for connecting conductor end

ActiveCN111466057AReliable contactReliable disengagementElectric connection structural associationsClamped/spring connectionsElectrical conductorClassical mechanics

Connection device for connecting a conductor end (3), which has a housing (1) and, in the housing (1), a busbar portion (6), a clamping spring arrangement (4) and a rotary lever arrangement (5), wherein the clamping spring arrangement (4) can be rotated, with the aid of the rotary lever arrangement (5), from an open position into a contact position in which the conductor end (3) is contacted, wherein the rotary lever arrangement (5) has a rotary lever element (50) which is mounted in the housing (1) so as to be rotatable in or on a preferably central portion (500) and which has the axis of rotation (D2), and wherein the rotary lever element (50) has an eccentric portion (502) which has a control cam (503) along which the clamping spring arrangement (4) slides during a movement into the endcontact position, wherein the eccentric portion (502) engages by way of a guide means, such as by way of a projection or a pin (504) inserted therein or the like, into a slotted link (18) of the housing (1), and wherein a clamping and / or latching means are or is formed on the eccentric portion (502), and wherein the slotted link (18) of the housing (1) is aligned with a slotted link (60) in the busbar portion (6), in which the fixing position for the clamping and / or latching means is formed.

Owner:WEIDMULLER INTERFACE GMBH & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com