Splicing apparatus for splicing curtain material

A splicing device and cord fabric technology, which can be used in application, thin material processing, winding strips, etc., can solve problems such as cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

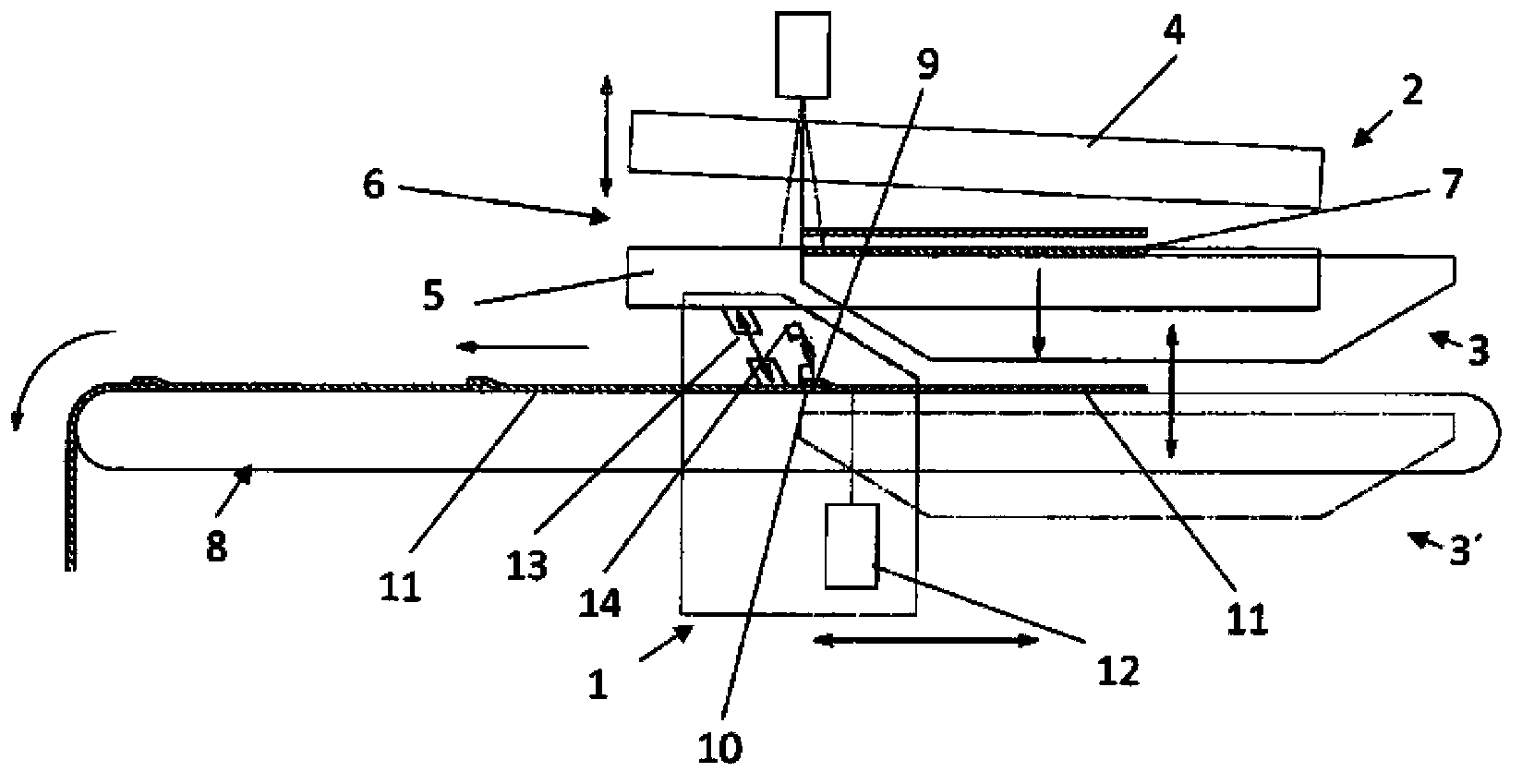

[0043] exist figure 1 The principle for integrating the splicing device 1 into a cutting device for strips of ply material, in particular with textile and / or steel wires, is shown in . The splicing device 1 is designed here as a unit with a cutting machine 2 and a liftable frame 3 that can move up and down.

[0044] The cutter 2 has an upper blade 4 and a lower blade 5 , between which a knife edge 6 is formed, through which the material web is guided through, for example by means of a pulling device. By closing said knife edge 6 in such a way that eg the upper blade 4 is guided downwards, the strip section is cut from the material strip. These strip sections are supported during cutting by the liftable frame 3 , here in its extraction position.

[0045] After the cutting process has ended, the liftable frame 3 is moved vertically downwards into its output position, wherein it transfers the newly cut strip section 7 to the conveyor belt 8 . The conveyor belts 8 are arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com