Splicing device for splicing cord materials

A technology of splicing device and curtain fabric, which can be used in application, thin material processing, winding strips, etc., and can solve problems such as consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

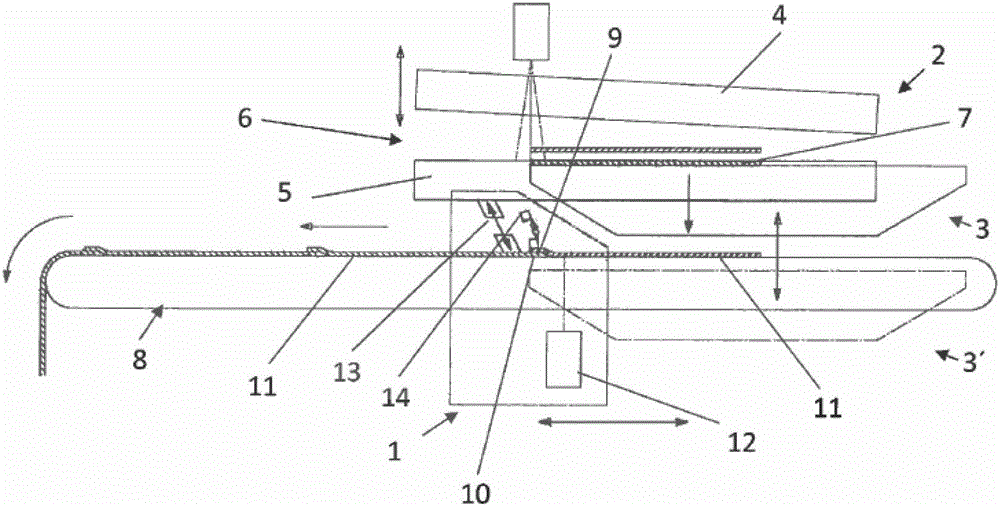

[0043] in figure 1 The principle for integrating the splicing device 1 into a cutting device for strips of cord material, in particular with textile threads and / or steel wires, is shown in. The splicing device 1 is here configured as a unit with a cutting machine 2 and a lifting frame 3 that can move up and down.

[0044] The cutting machine 2 has an upper blade 4 and a lower blade 5, between which a cutting edge 6 is formed, through which the material web is guided through, for example, by means of a pulling device. By closing the knife edge 6 in such a way that the upper blade 4 is guided downward, for example, the tape section is cut from the material tape. These belt sections are supported during cutting by the liftable frame 3, which is here in its extraction position.

[0045] After the cutting process is over, the liftable frame 3 is moved vertically downwards into its output position, wherein the liftable frame transfers the newly cut belt section 7 to the conveyor belt 8....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com