Connection device for connecting conductor end

A technology for connecting equipment and connecting conductors, applied in the direction of connection, conductive connection, electrical component connection, etc., can solve problems such as difficult manipulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

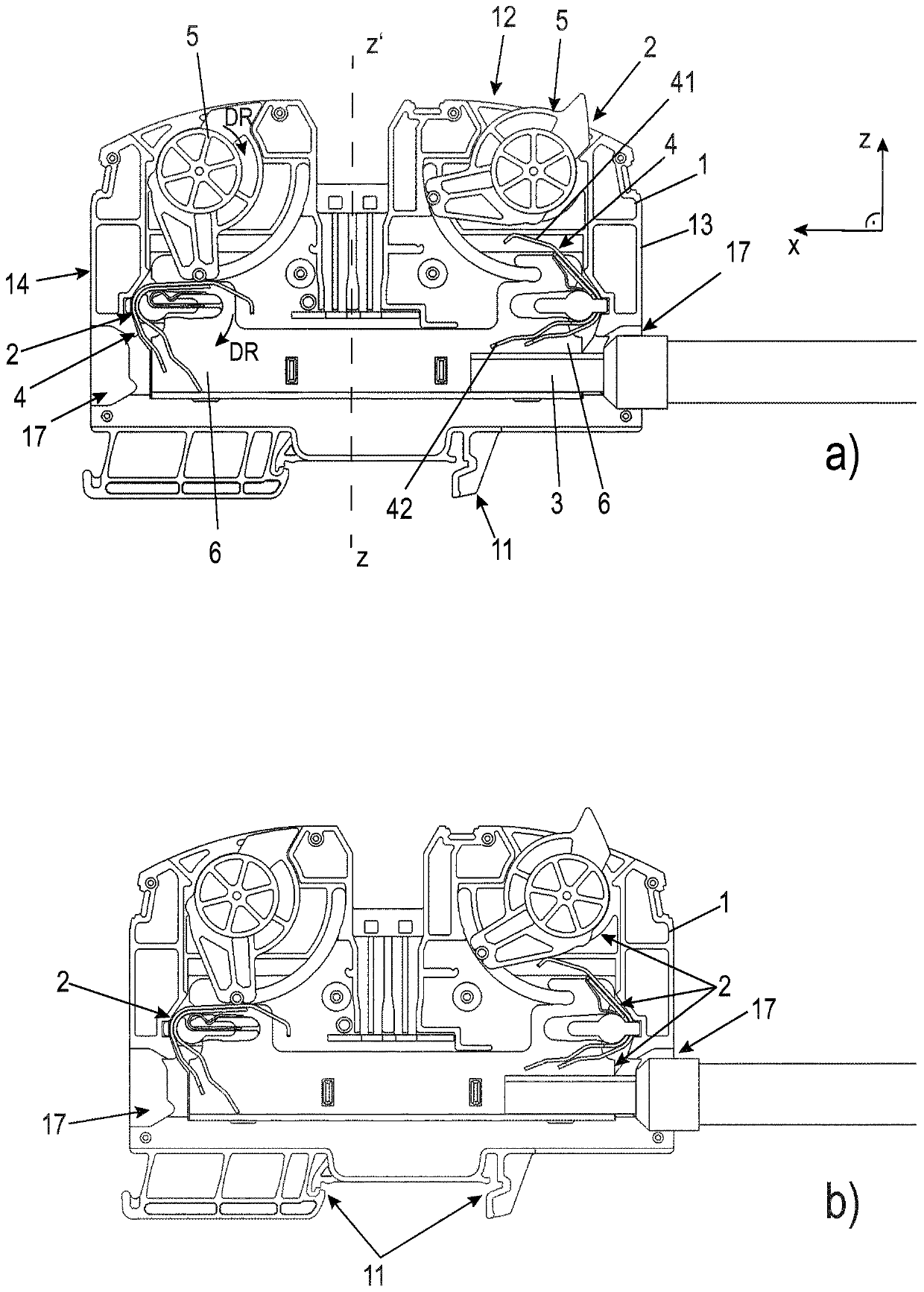

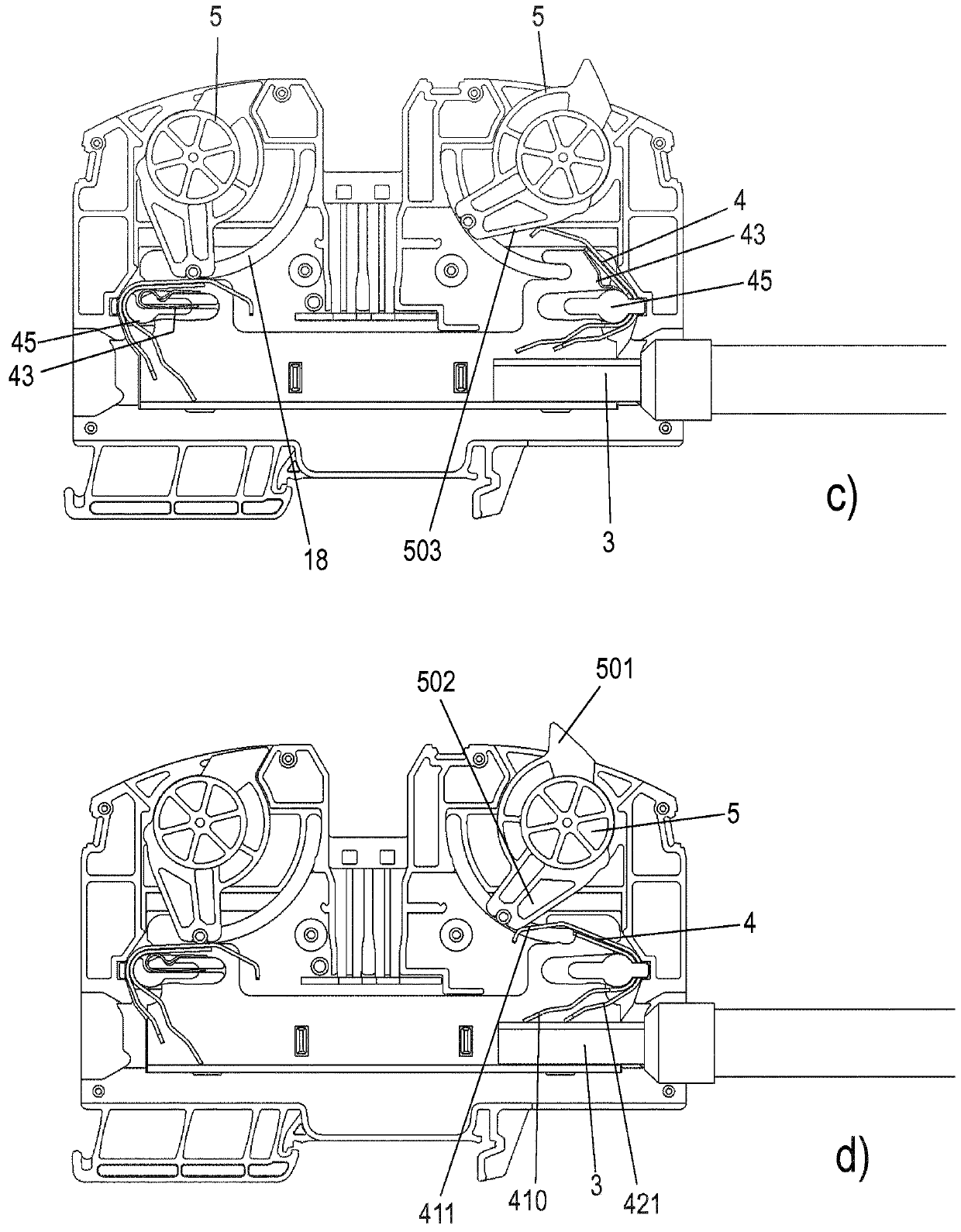

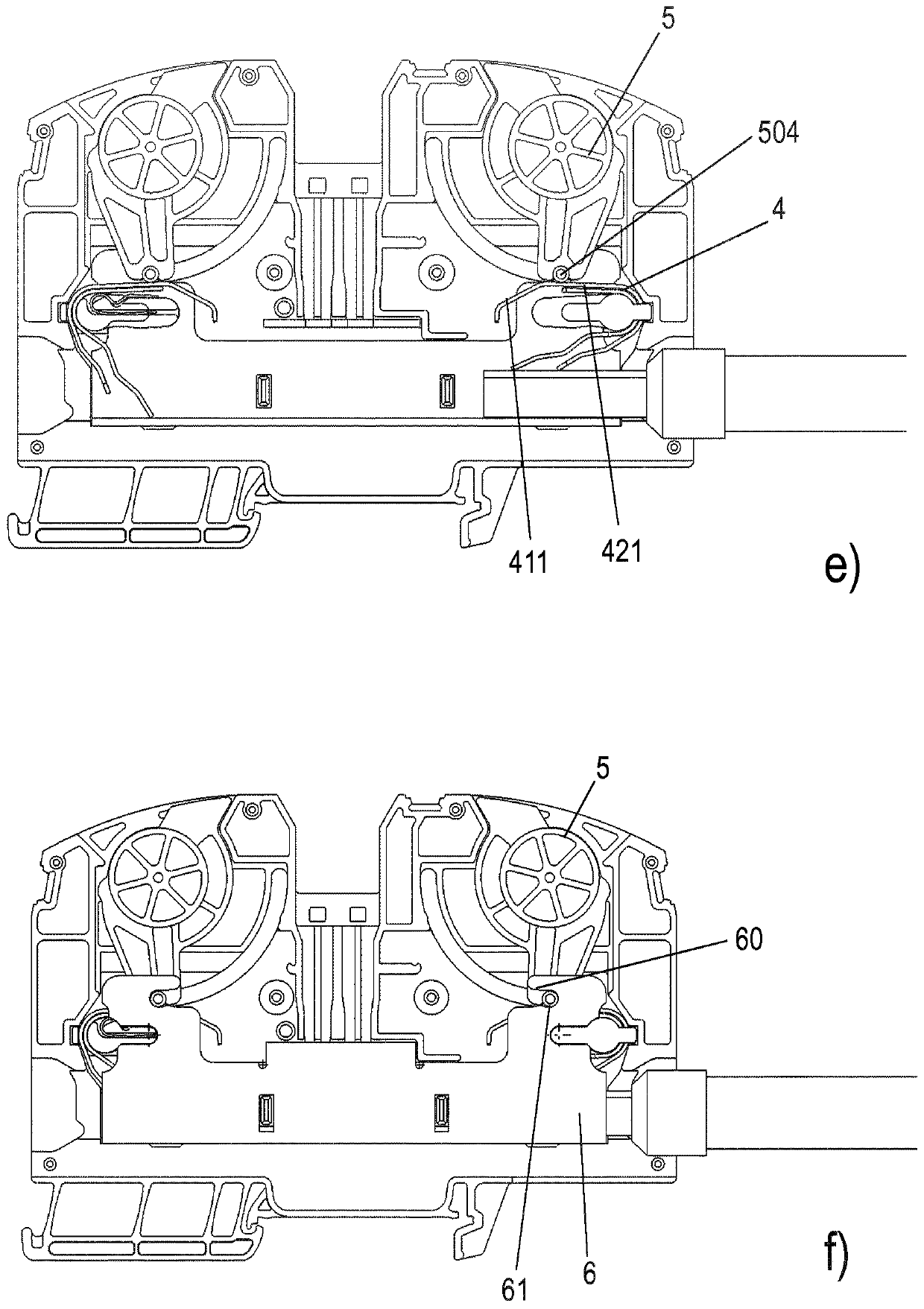

[0031] For simplicity, in figure 1 The Cartesian coordinate system X / Z is marked in , where the direction perpendicular to the paper plane is marked as "Y direction". The conductor insertion direction is marked below as "X direction".

[0032] figure 1 The housing 1 is shown, which is designed here as a clamping housing. One or more (here two) connecting devices 2 for connecting corresponding conductor ends 3 are arranged in the housing. here, in figure 1 Only one of these conductor ends 3 is shown in . The conductor end 3 can be a (preferably de-insulated) single or multi-conductor or stranded conductor or can be, for example, a crimped wire end made of a material that conducts electricity well, such as copper.

[0033] The housing 1 is made of an electrically insulating material, in particular a non-conductive plastic. The housing 1 is designed here in the shape of a plate and is preferably arranged perpendicular to the conductor insertion direction in the Y direction....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com