Rotary lifting-type three-dimensional garage, vehicle carrying plate docking and lifting device and vehicle parking and getting method

A three-dimensional garage, rotary lift technology, applied in the direction of parking buildings, building types, buildings, etc., can solve the problems of complex action mechanism and overall structure, low safety and reliability, and no price competitiveness. Achieve the effect of improving garage space utilization, simple and compact operating mechanism, and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

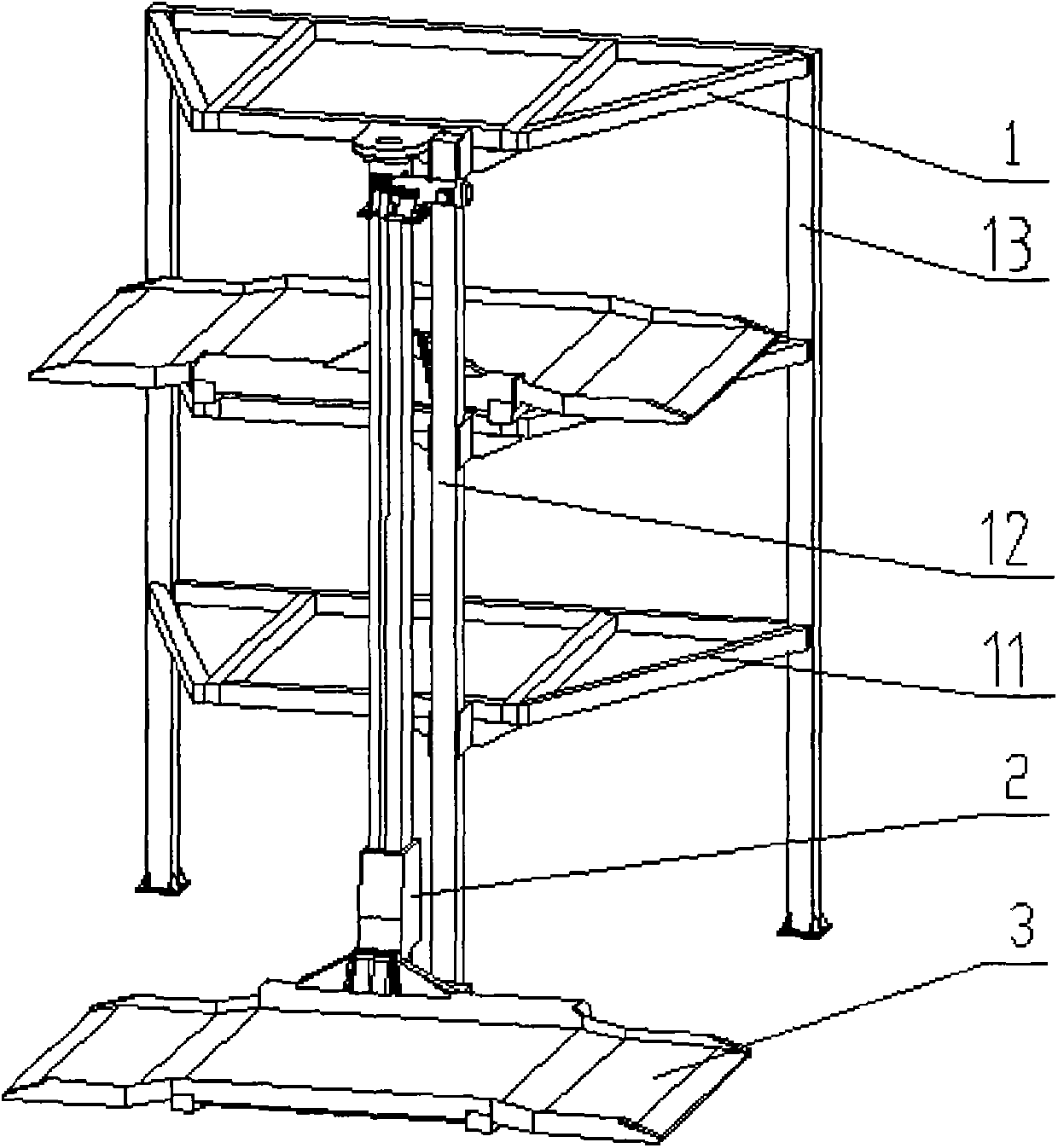

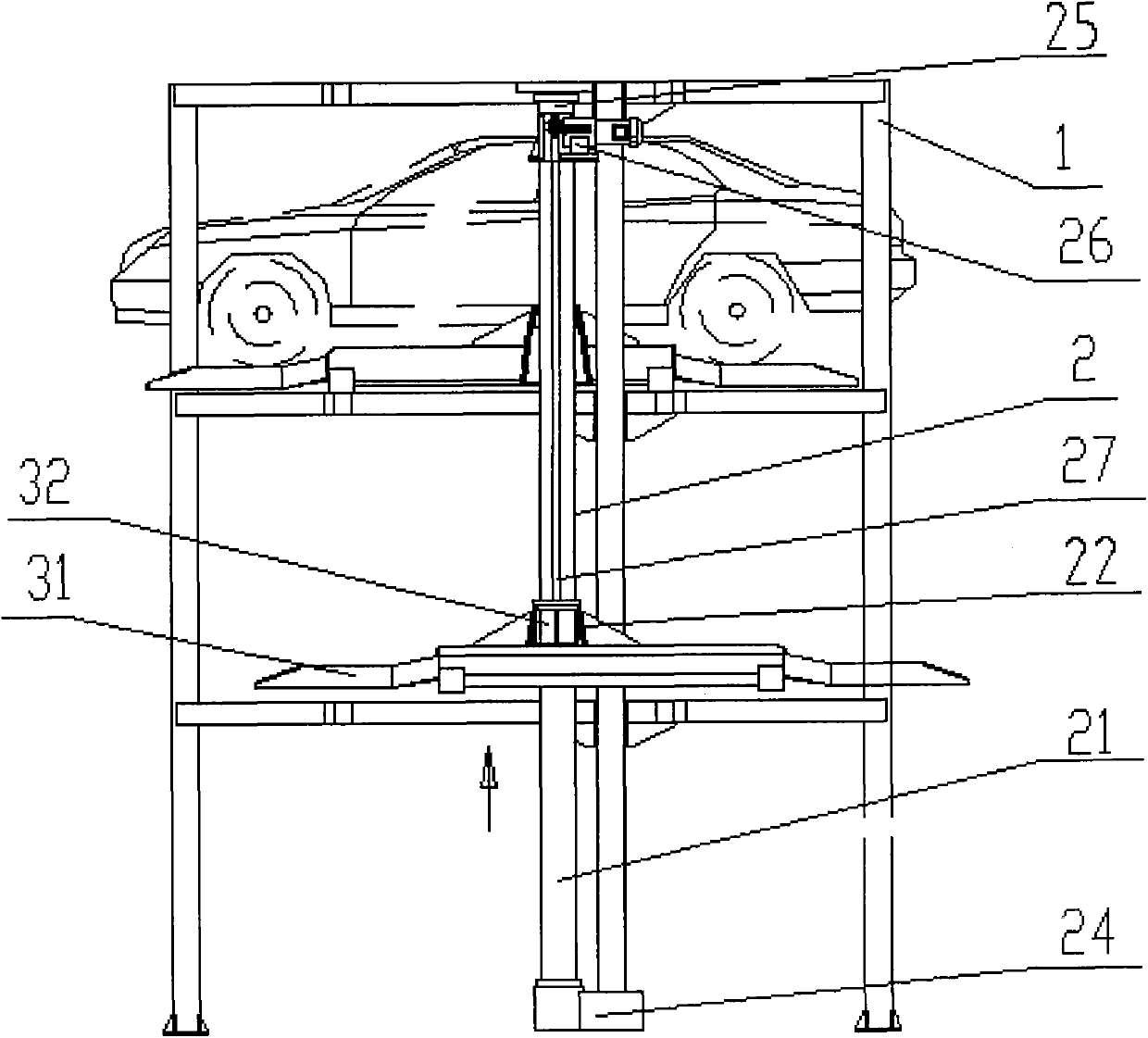

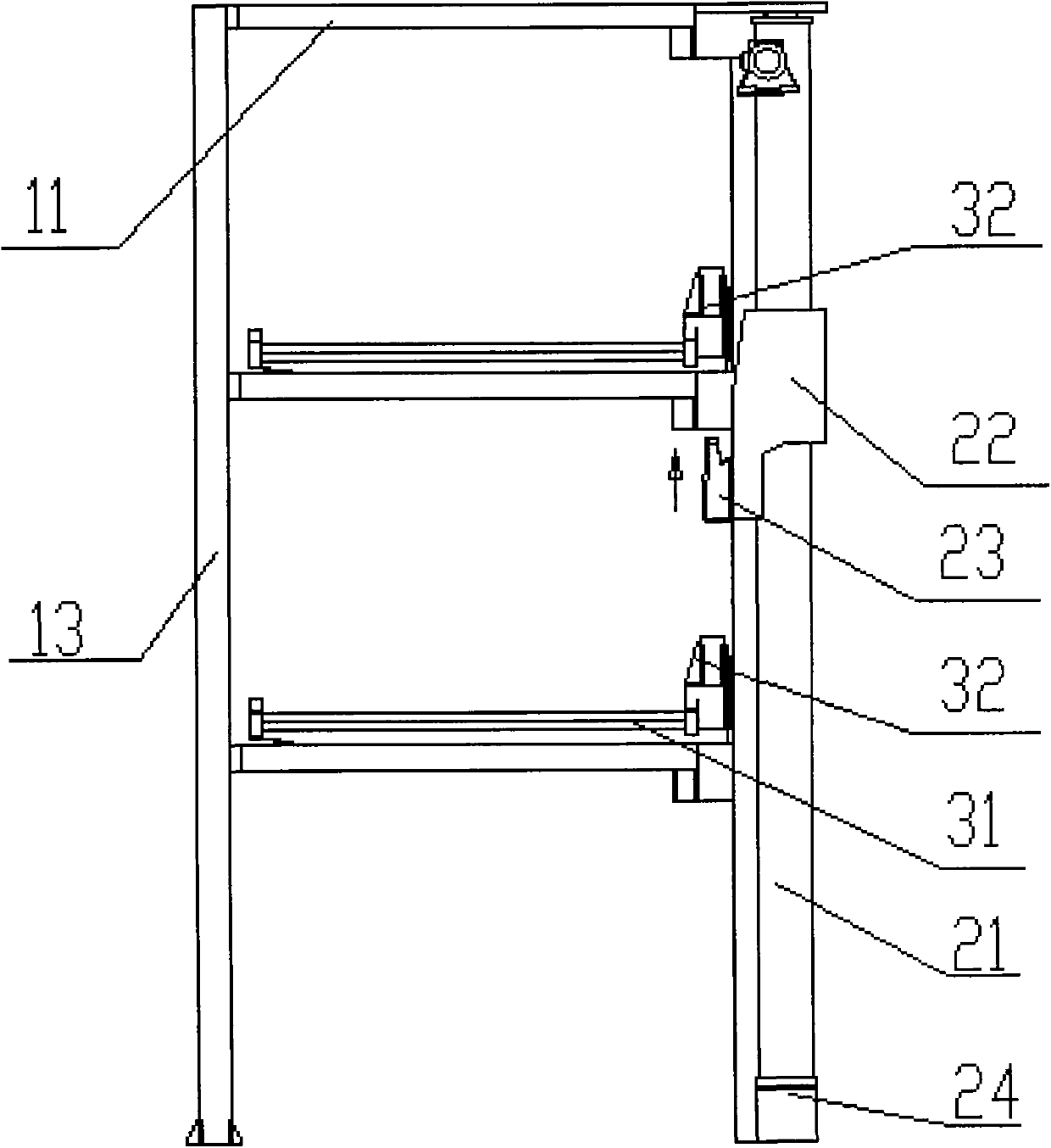

[0034] Such as Figure 1-4 , Figure 7-10 As shown, the rotary lifting three-dimensional garage includes a parking frame 1, a carrier 2 and a vehicle-carrying plate 3;

[0035] The parking rack 1 includes a parking rack column and a parking space load-bearing truss 11 for carrying the vehicle-loading plate 3. The parking space load-bearing truss 11 is a trapezoidal structure with multiple layers, and the parking space load-bearing trusses 12 on each floor are parallel to each other. The multi-storey parking space load-bearing truss 11 is fixed on the parking space column and is perpendicular to the parking space column. The parking space column includes an outer parking space column 12 and an inner parking space column 13, wherein the outer parking space column 12 is fixed on the parking space load-bearing truss. The upper base of the trapezoid, the inner parking frame column 13 is fixed on the lower base of the trapezoid of the load-bearing truss 11 of the parking space;

...

Embodiment 2

[0043] Such as Figure 5 As shown, the rotary lifting three-dimensional garage is a side-by-side double parking rack garage. Two sets of parking racks are installed side by side and share one parking rack column. The load-bearing truss of each parking space is designed as an integral structure, which can park two cars. The garage is arranged on the same side of the aisle. In order to use one carrier to access the two groups of parking racks, the upper rail 4 and the lower rail 5 are fixedly connected to the frame on the side of the parking rack aisle. The lower part of the carrier 2 is equipped with a translational travel drive mechanism 6 , the walking drive mechanism 6 is composed of a driving reduction motor, a transmission gear mechanism and a walking track wheel, and a guide wheel set 7 is added to the top, and the guide wheel set 7 is composed of an upper track guide wheel and a cage, and is installed on the upper track 4, so that the carrier can be on the track. Travel ...

Embodiment 3

[0045] Such as Figure 6 As shown, the rotary lifting three-dimensional garage is a garage with double parking racks in opposite rows. The two sets of parking racks are arranged on both sides of the aisle, oppositely arranged, and the upper rail 4 and the lower rail 5 are arranged on the aisle between the parking racks 1 to connect the two rows. The parking rack is fixedly installed, consistent with the parallel double parking rack garage. The lower part of the carrier is increased with a translational travel drive mechanism 6, and the upper part is increased with a guide wheel set 7, which is installed on the upper track 4, and the carrier 2 travels in translation between the upper and lower tracks.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com