Water hammer air valve and water hammer gas discharging method during pipeline use

A technology of air valves and pipelines, which is applied in the direction of valve energy absorption devices, valve details, valve devices, etc., which can solve the problems of not being able to discharge air immediately, unclean exhaust, and water hammer when the valve is closed, so as to avoid The effects of blowing and air blocking, reliable sealing contact and separation, and sensitive action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered.

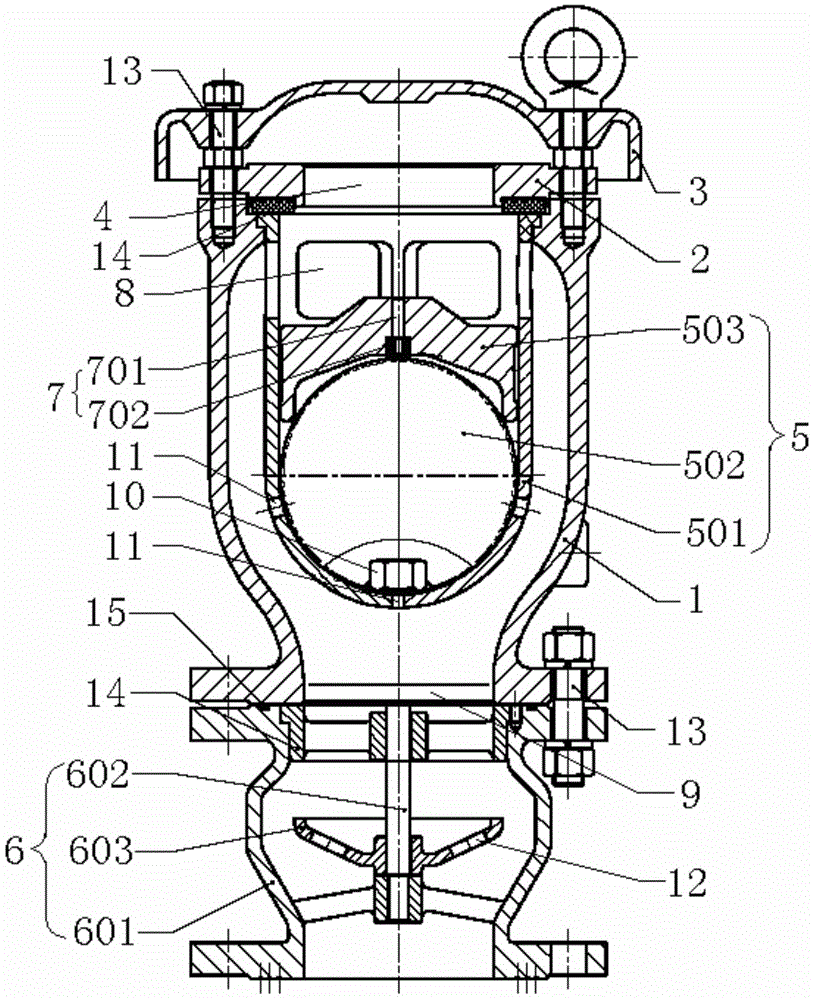

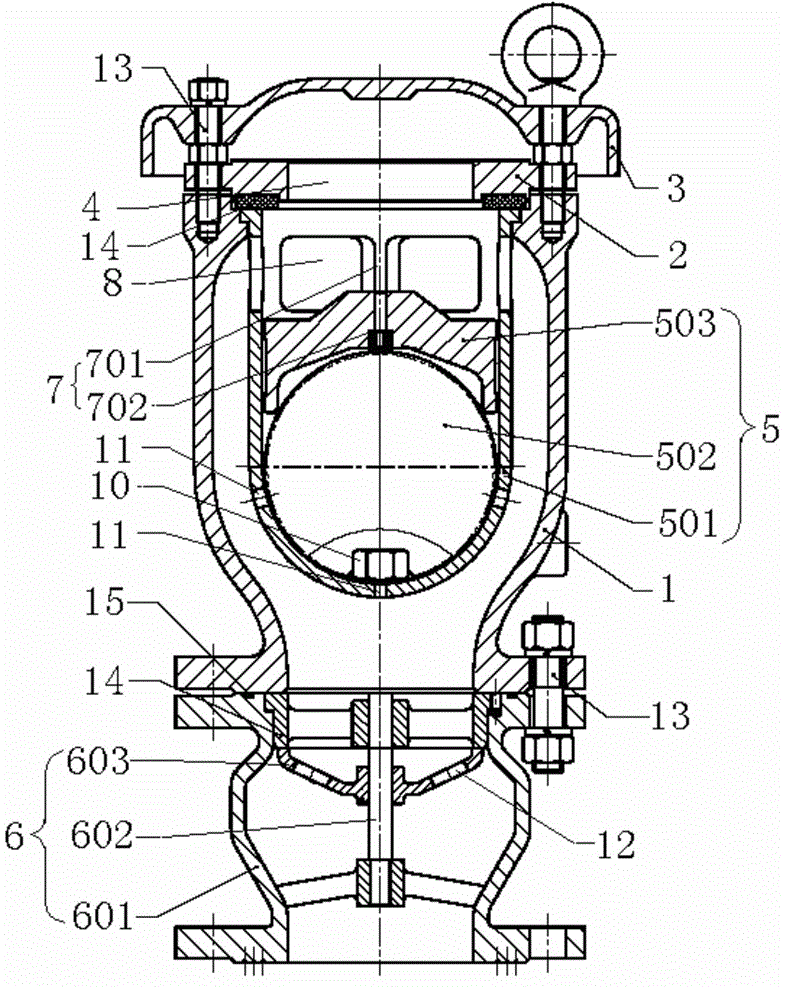

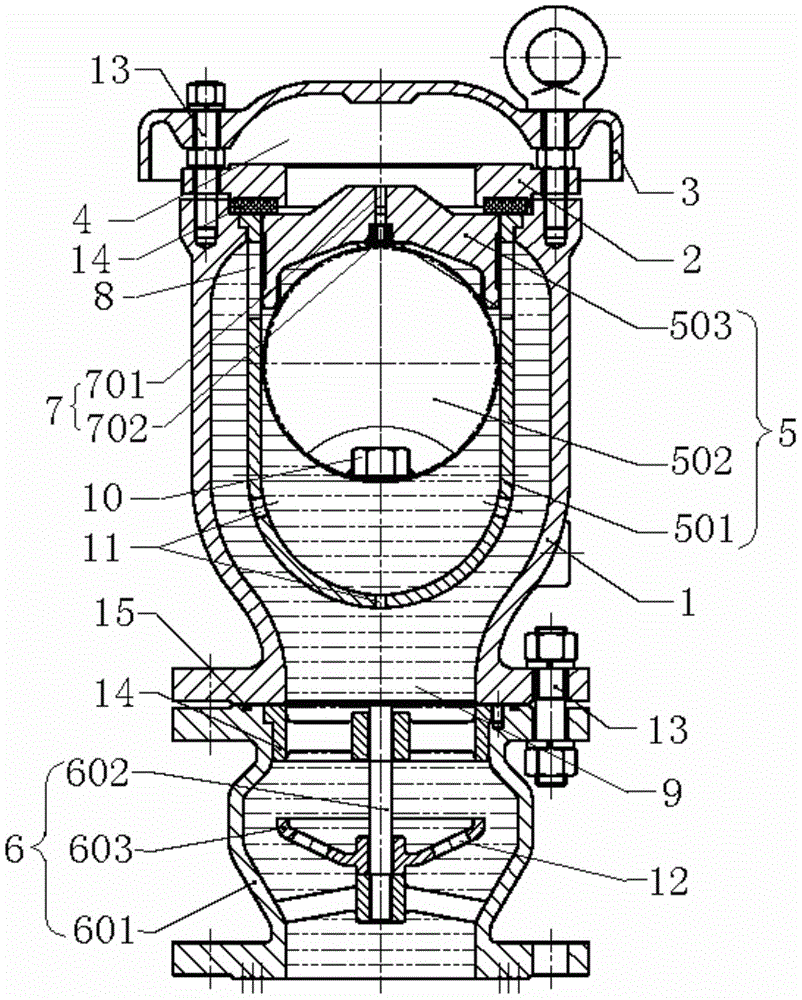

[0028] figure 1 It is a structural schematic diagram of the suction state and exhaust state of the anti-hammer air valve of the preferred embodiment of the present invention; figure 2 It is a structural schematic diagram of the high-speed exhaust and throttling state of the anti-hammer air valve in the preferred embodiment of the present invention; image 3 It is a structural schematic diagram of the closed state of the anti-hammer air valve and the closed state of the micro exhaust device in the preferred embodiment of the present invention; Figure 4 It is a structural schematic diagram of the micro-exhaust state of the anti-hammer air valve of the preferred embodiment of the present invention.

[0029] Such as figure 1 As shown, the anti-hammer air valve of this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com