Water cooling heat dissipation module and charging pile module applying same

A heat dissipation module and charging pile technology, applied in charging stations, electric vehicle charging technology, cooling/ventilation/heating transformation, etc., can solve problems such as pollution, damage to charging pile templates, damage to devices, etc., to avoid dust pollution, avoid The effect of cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

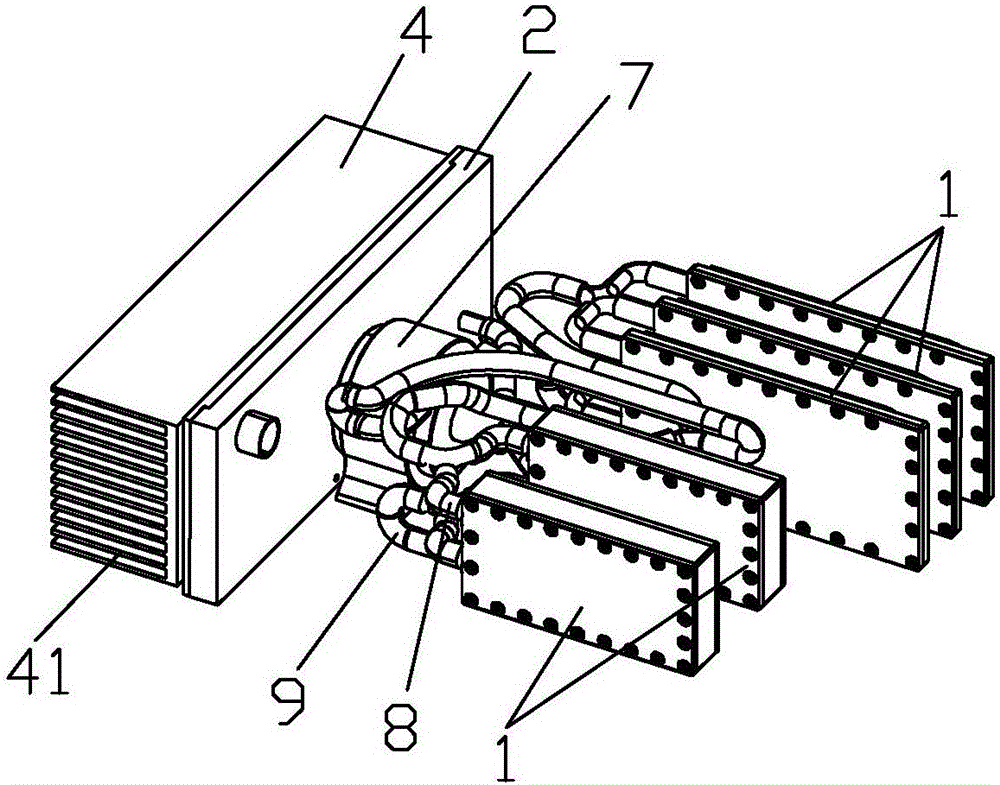

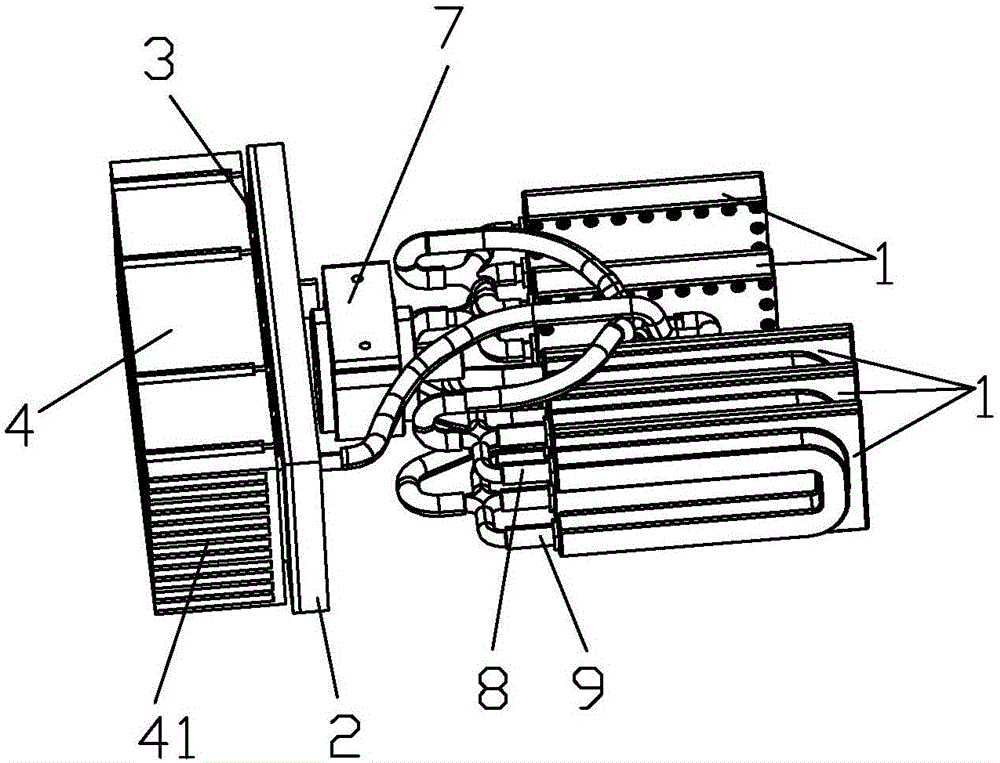

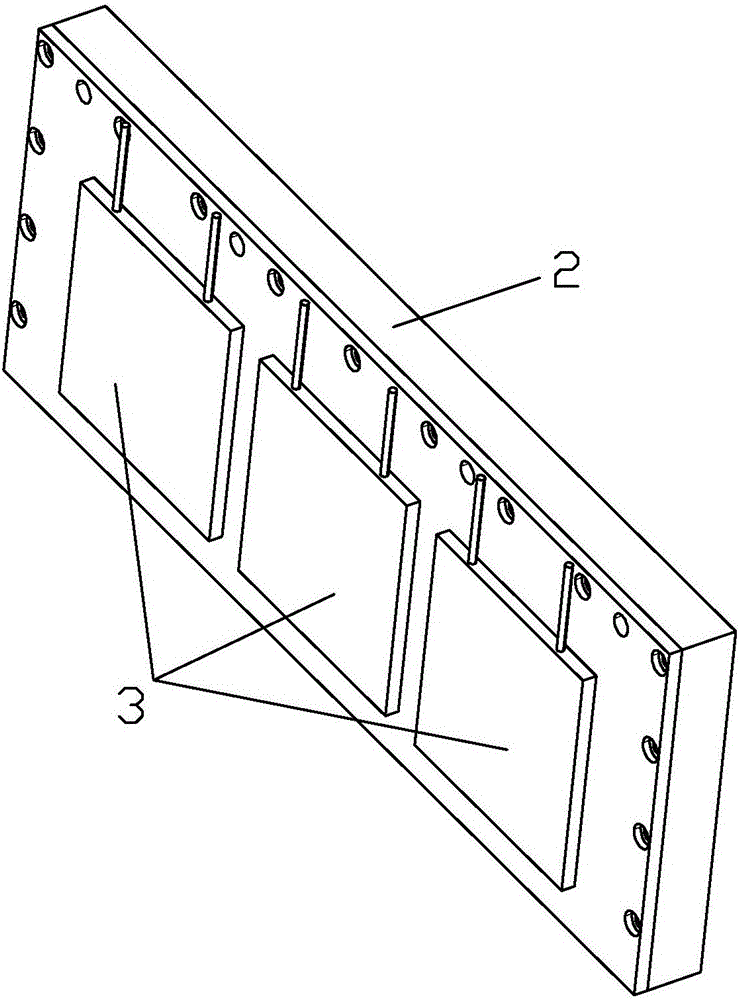

[0034] see Figure 1-7 A water-cooled heat dissipation module shown includes a heat absorbing block 1, a liquid storage block 2, a semiconductor refrigeration chip 3, and a radiator 4. The heat absorbing block 1 is provided with a liquid flow channel 11, and the liquid storage block 2 is provided with a The liquid storage tank, the liquid storage block 2 is connected with the heat-absorbing block 1, the inside of the two is a vacuum environment, and forms a circulation loop, the radiator 4 is located on the side of the liquid storage block 2 away from the heat-absorbing block 1, and between the two At least one semiconductor cooling chip 3 is attached, and the positive poles and negative poles of these semiconductor cooling chips 3 are respectively connected to the power supply.

[0035] As we all know, semiconductor cooling chip 3, also called thermoelectric cooling chip, is a kind of heat pump. Its advantage is that there are no sliding parts, and it is used in some occasio...

Embodiment 2

[0046] see Figure 1-8 As shown, a charging pile module adopting the above-mentioned water-cooled heat dissipation module includes a housing 5, and the housing 5 has an installation cavity 51, and one end of the installation cavity 51 is provided with a plurality of components K, and the installation cavity The other end in 51 is installed with the above-mentioned water-cooled heat dissipation module, the heat-absorbing block 1 is closely attached to or close to at least one component K, and the liquid storage block 2 forms an isolation zone between the radiator 4 and these components K, Therefore, these components K are accommodated in the relatively sealed area H formed by the casing 5 and the liquid storage block 2 .

[0047] The liquid storage block 2 forms an isolation zone between the radiator 4 and these components K, so that these components K are accommodated in the relative sealing area H formed by the housing 5 and the liquid storage block 2. This design can Avoid ...

Embodiment 3

[0050] see Figure 1-7 and Figure 9 The difference between this embodiment and the second embodiment of the charging pile module shown is that the above-mentioned water-cooled heat dissipation module is provided with at least one fan 6 inside the installation cavity 51, and the water-cooled heat dissipation module is located in these An isolation section is formed between the components and the fan 6 to prevent dust from blowing into the components. A cooling hole 53 is opened on the housing 5 at a position corresponding to the fan 6 . Setting the fan 6 can further improve the effect of heat dissipation. For the rest, the parts of the third embodiment that are the same as those of the second embodiment will not be repeated here.

[0051] Preferably, the fans 6 are arranged on the side of the radiator 4 away from the components, and there is a certain gap between them.

[0052] In addition, it should be noted that the water-cooled heat dissipation module provided by the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com