A high-efficiency spraying solvent recovery system and its process

A recovery system and solvent technology, which is applied in the high-efficiency spraying solvent recovery system and its process field, can solve the problems of multiple operating equipment, high maintenance costs, and high noise, and achieve the effects of avoiding air pollution, improving environmental protection benefits, and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

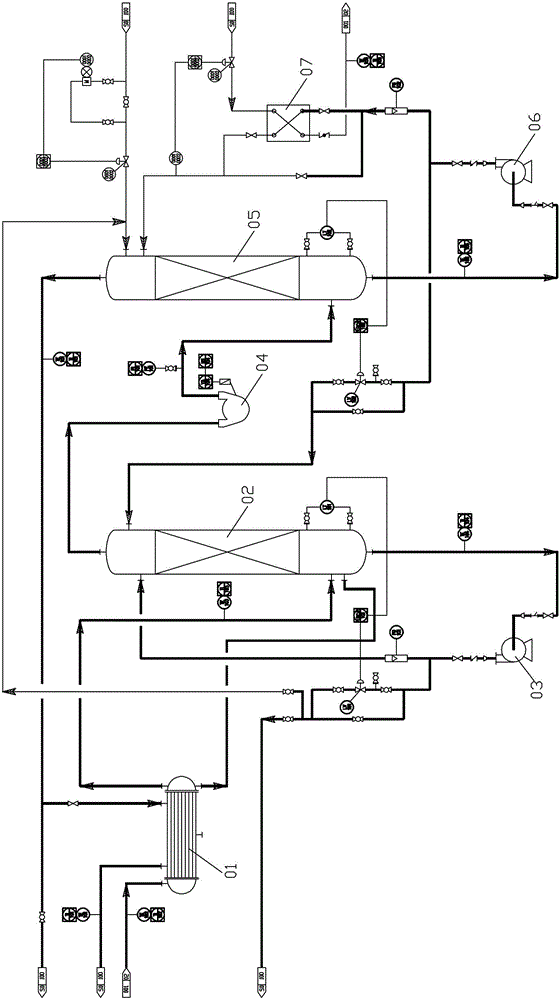

[0027] Now illustrate device of the present invention and process implementation process in conjunction with accompanying drawing:

[0028] Description of main component symbols: gas-gas heat exchanger 01, primary gas absorption tower 02, primary absorption liquid circulation pump 03, fan 04, secondary absorption tower 05, secondary absorption liquid circulation pump 06, liquid-liquid heat exchanger 07 .

[0029] Such as figure 1 As shown, a high-efficiency spraying solvent recovery system of the present invention is mainly composed of a gas-gas heat exchanger 01, a primary gas absorption tower 02, a fan 04, and a secondary gas absorption tower 05 connected in sequence.

[0030] The primary gas absorption tower 02 is connected with a primary absorption liquid circulation pump 03 to form a closed high-concentration spray solvent circulation absorption loop.

[0031] The secondary gas absorption tower 05 is sequentially connected with a secondary absorption liquid circulation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com