Etching equipment and throttle valve thereof

A technology of reaction equipment and throttle valve, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as cavity pressure instability, bearing damage, and poor operation of transmission mechanisms, so as to improve reliability and avoid Effects of Particulate Pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

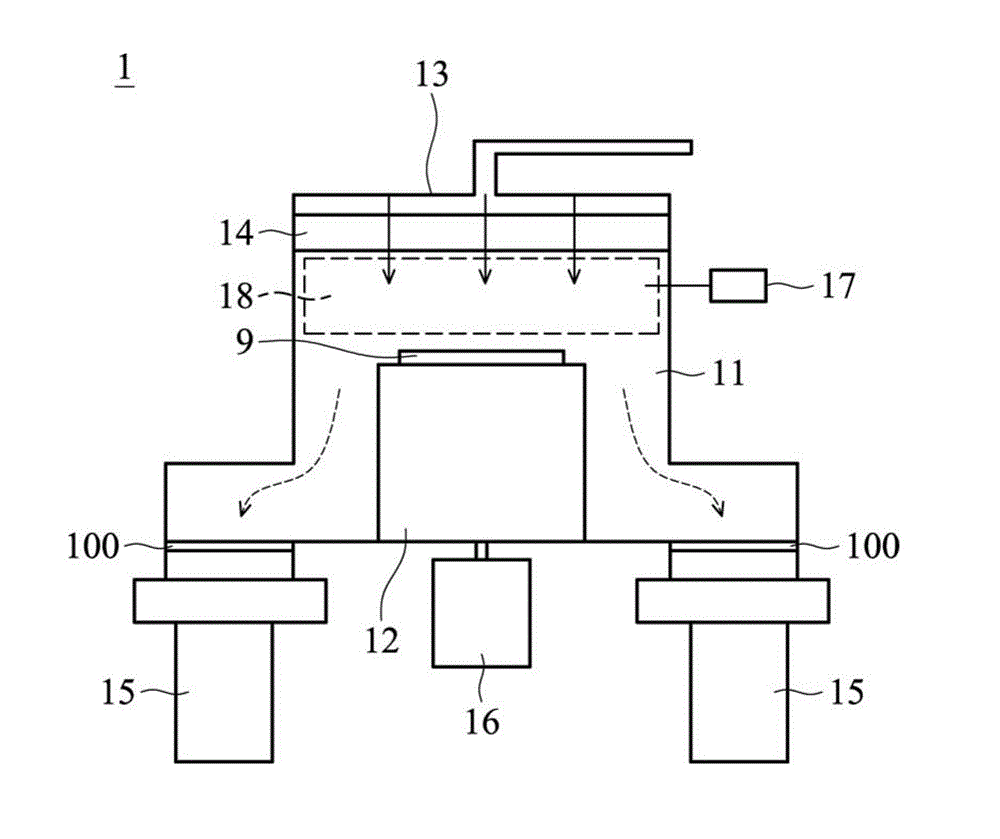

[0028] refer to figure 1 , which shows the etching reaction equipment 1 of the embodiment of the present invention, which is used to etch a wafer 9, including a cavity reaction chamber 11, a crystal seat (lower electrode) 12, a reaction gas inlet 13, and an upper electrode 14 , air pump 15, radio frequency generator 16, pressure sensor 17 and throttle valve 100. The wafer 9 is placed on the crystal base (bottom electrode) 12 via the transfer arm. The reaction gas inlet 13 is arranged on the top of the reaction chamber 11 of the chamber, and the etching gas is injected into the chamber from above through the upper electrode 14 .

[0029] The pressure sensor 17 senses the pressure of the reaction gas in the cavity reaction chamber 11, and provides a pressure sensing value, and the etching reaction equipment 1 controls the air pump 15 and the section according to the pressure sensing value. The action of the flow valve 100 is used to adjust the pressure of the reaction gas in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com