Method for preparing polyurethane fiber guide wheel used for cutting silicon slice

A technology of polyurethane fiber and polyurethane is applied in the field of silicon wafer cutting equipment, which can solve the problems affecting the processing quality of the guide groove, the yield of the guide wheel, the short service life of the slicer, and the poor thermal insulation performance of the metal, so as to improve the mechanical properties and processing Accuracy, improved hydrolysis resistance, easy detachment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

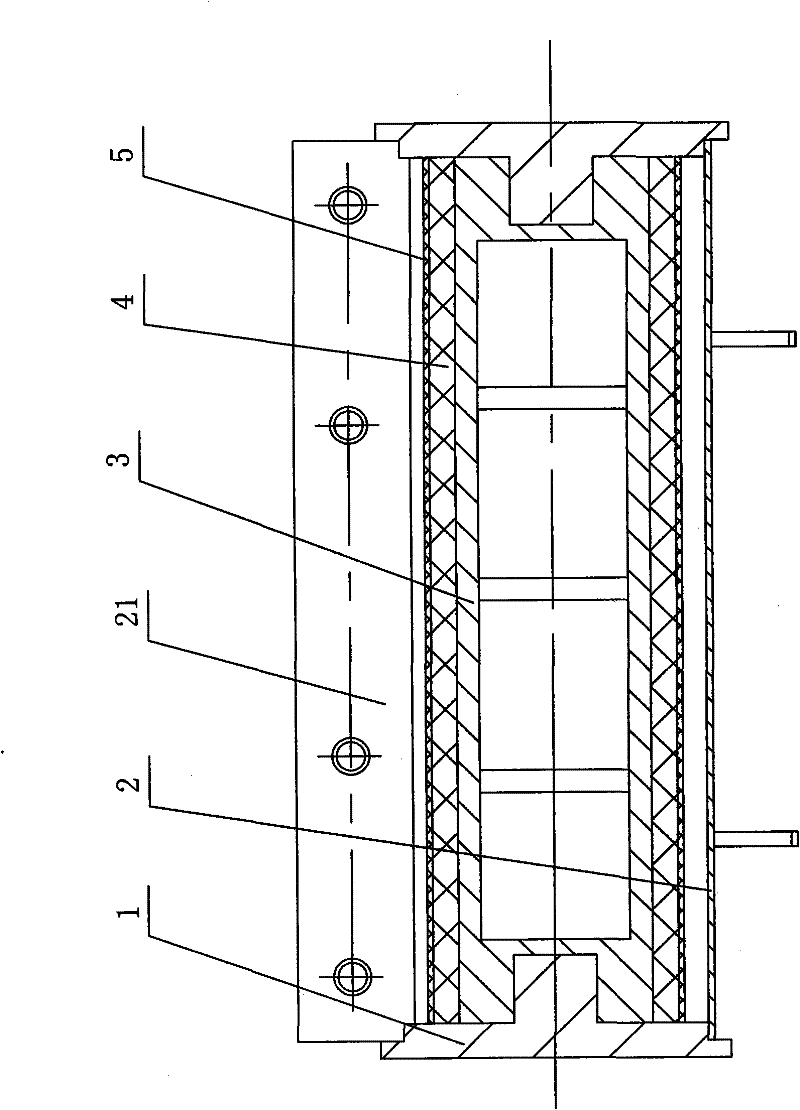

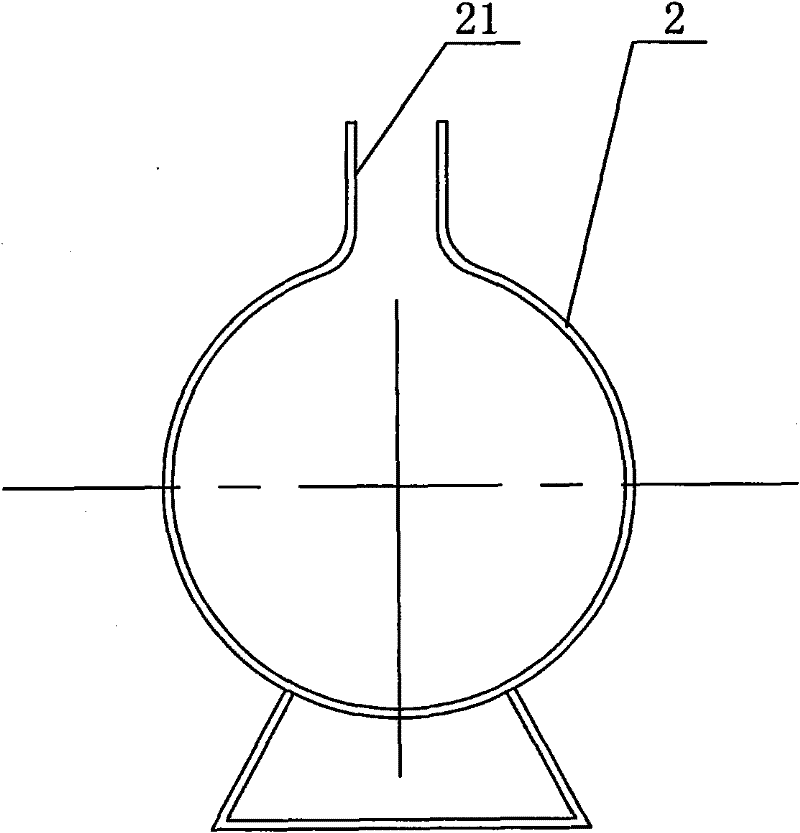

[0016] The present invention is used for the preparation method of the polyurethane fiber guide wheel of cutting silicon chip, specifically as follows:

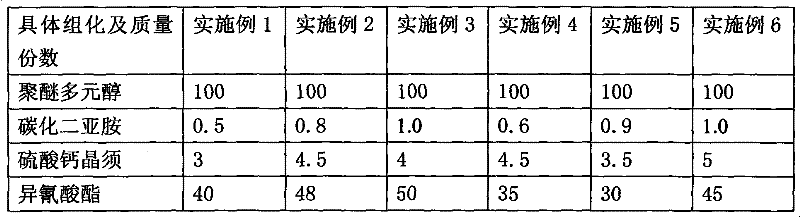

[0017] (1) Production of prepolymer. The component of prepolymer of the present invention comprises polyether polyol, carbodiimide, calcium sulfate whisker and isocyanate, by mass fraction ratio, polyether polyol: carbodiimide: calcium sulfate whisker: isocyanate The ratio is 100:(0.5-1.0):(3-5):(30-50), first mix 0.5-1.0 parts of carbodiimide and 3-5 parts of calcium sulfate whiskers with 100 parts of polyether multi-component Alcohol is mixed evenly, and then the mixed material liquid is added into the reaction kettle and heated and stirred to fully disperse the whisker agglomerates of calcium sulfate whiskers in the material liquid, so that the polyurethane guide wheel can achieve higher wear resistance, and the mixed material Dehydration is carried out when the liquid is heated to 100-110°C. Vacuumize until the pressure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com