Top-rod separating device for perforating seamless steel pipe

A technology of ejector device and seamless steel pipe, which is applied in the direction of metal rolling, manufacturing tools, mandrel, etc., to achieve the effect of smooth operation and reduced impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to better understand the purpose of the present invention, in combination with the background of the present invention, drawings and actual working conditions, the process of offline replacement of the ejector pin in the backstage of the seamless steel pipe piercing machine and the process of the seamless steel pipe piercing ejector pin device according to the present invention are described below. The structure and function are described in detail.

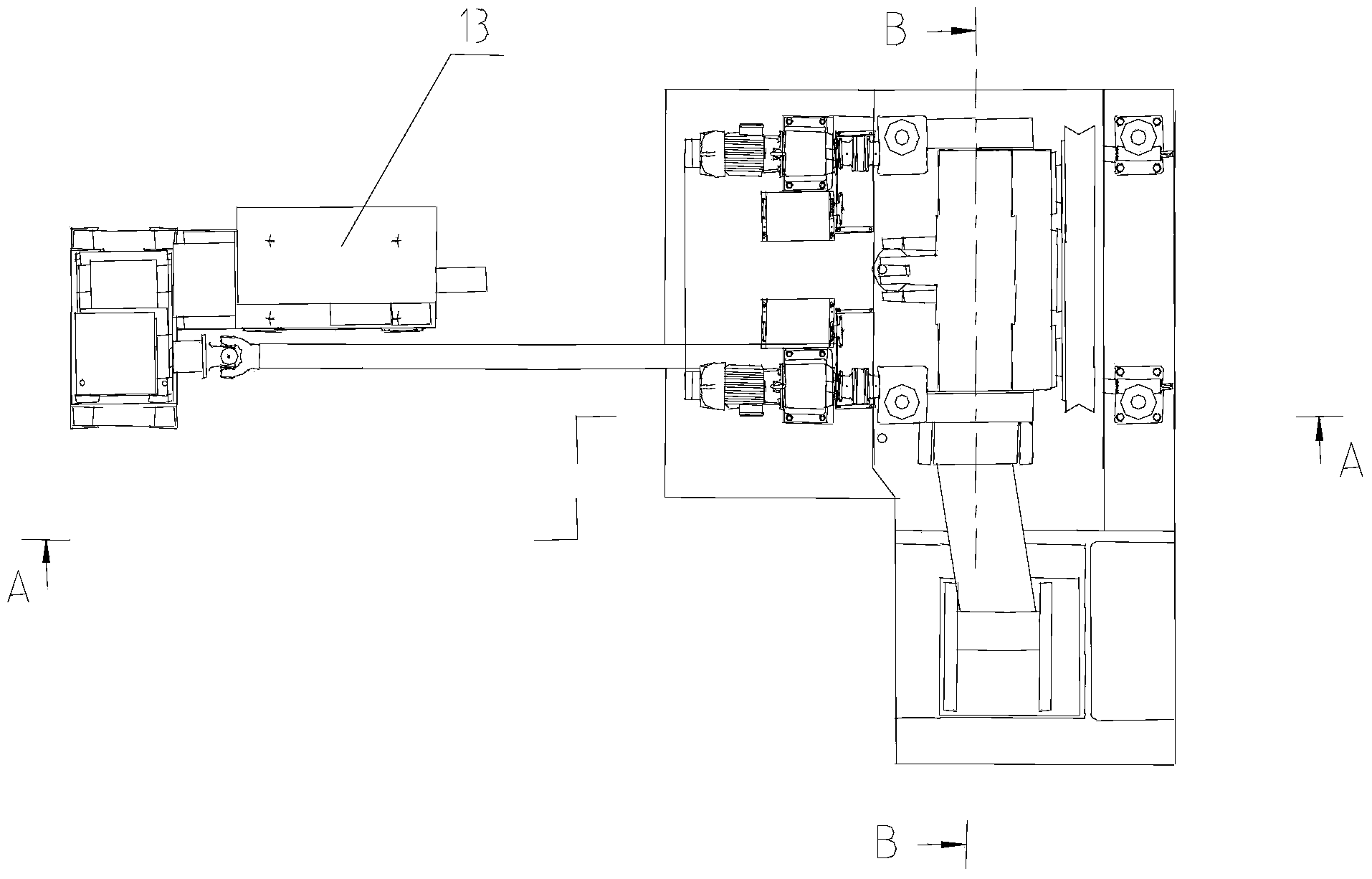

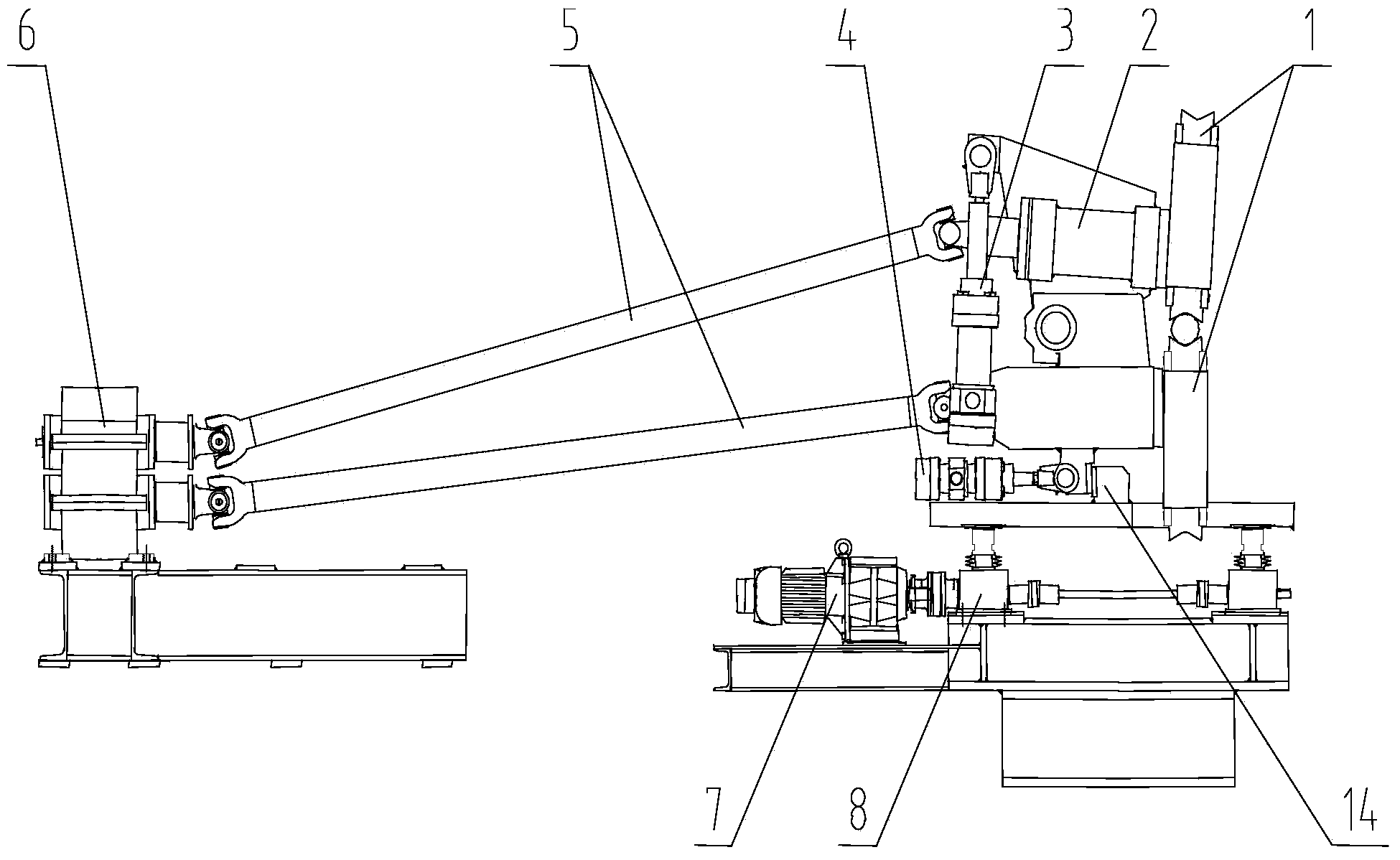

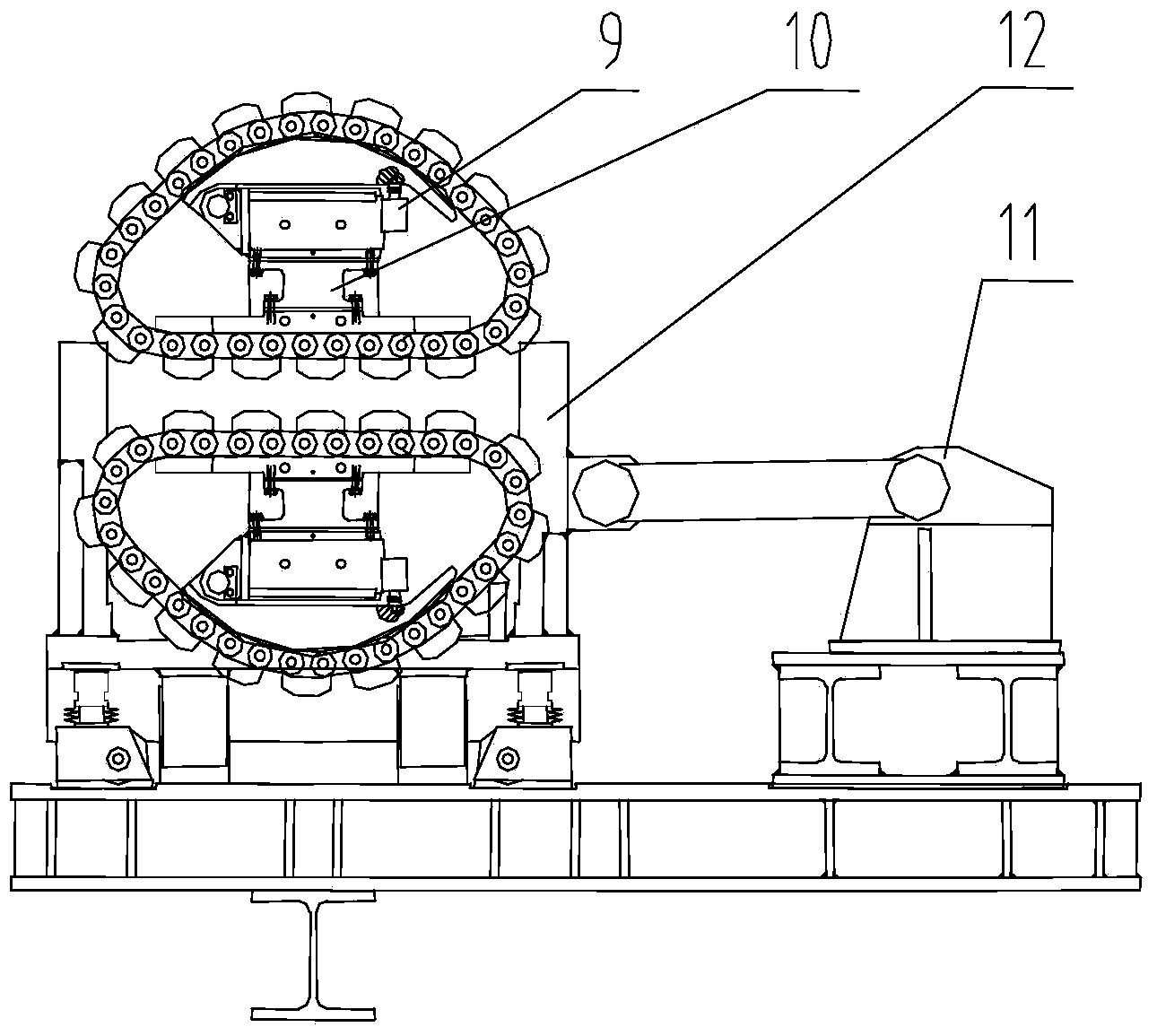

[0023] Depend on Figure 1 to Figure 3 It can be seen that the seamless steel pipe perforation ejector rod device of the present invention comprises:

[0024] Pinching device: closed V-shaped pinching chain group 1, which includes an upper chain 111 and a lower chain 112;

[0025] The opening and closing mechanism 2 that controls the opening and closing of the closed V-shaped pinch chain group is a driving hydraulic cylinder, wherein the upper chain 111 is driven by the upper driving hydraulic cylinder 3, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com