Magnetic liquid based on oxidation-resistant alpha olefin synthetic oil and preparation method thereof

A polyalphaolefin, magnetic liquid technology, applied in the field of nanoscience, to achieve the effects of strong oxidation resistance, stable dispersion and strong magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

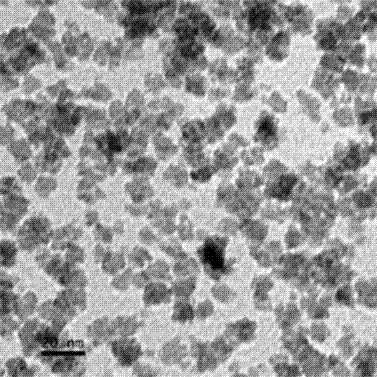

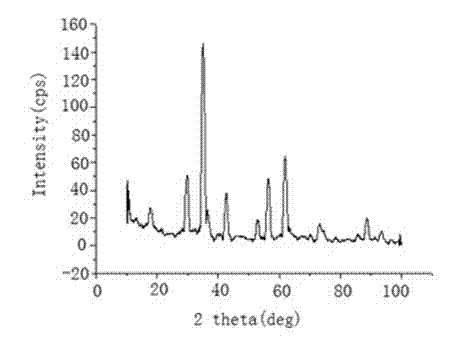

[0060] Example 1 Preparation of Co 0.2 mn 0.8 Fe 2 o 4 Polyalphaolefin synthetic oil-based magnetic fluid

[0061] S1. Preparation of nano-D x m 1-x Fe 2 o 4 Magnetic Particles:

[0062] Prepare 100ml Co 2+ , Mn 2+ , Fe 3+ A mixed solution of diethylene glycol (DEG), placed in a beaker, where Co 2+ The concentration is 0.08 mol / L, Mn 2+ The concentration is 0.32 mol / L, Fe 3+The concentration is 0.8 mol / L. Prepare 120 ml of NaOH aqueous solution with a concentration of 3 mol / L and place it in a 500 ml round bottom flask. Use argon as a protective atmosphere, heat up to the boiling of the NaOH solution (110-130°C), stir at a speed of 500r / min, slowly add the DEG solution of metal ions into the NaOH solution for 10 minutes, and continue the reaction for 5 minutes to prepare Nano Co 0.2 mn 0.8 Fe 2 o 4 magnetic particles;

[0063] S2. The nano-magnetic particles obtained in S1 Co 0.2 mn 0.8 Fe 2 o 4 For purification:

[0064] Nano-Co obtained from S1 0.2 ...

Embodiment 2

[0075] Example 2 Mn 0.5 Zn 0.5 Fe 2 o 4 Polyalphaolefin synthetic oil-based magnetic fluid

[0076] S1. Preparation of nano-D x m 1-x Fe 2 o 4 Magnetic Particles:

[0077] Prepare 100ml Mn 2+ , Zn 2+ , Fe 3+ A mixed solution of diethylene glycol (DEG), placed in a beaker, where Mn 2+ The concentration is 0.2 mol / L, Zn 2+ The concentration is 0.2 mol / L, Fe 3+ The concentration is 0.8mol / L. Prepare 120 ml of NaOH aqueous solution with a concentration of 3 mol / L and place it in a 500 ml round bottom flask. With argon as a protective atmosphere, the temperature was raised until the NaOH solution boiled (110-130°C), and at a stirring speed of 500 r / min, the DEG solution of metal ions was slowly added to the NaOH solution for 10 minutes, and the reaction was continued (110 ~130℃) for 5 minutes to prepare nano-Mn 0.5 Zn 0.5 Fe 2 o 4 magnetic particles;

[0078] S2. Purify the magnetic nanoparticles:

[0079] Nano-Mn obtained from S1 0.5 Zn 0.5 Fe 2 o 4 The ma...

Embodiment 3

[0087] Example 3 Preparation of Mg 0.5 Zn 0.5 Fe 2 o 4 Polyalphaolefin synthetic oil-based magnetic fluid

[0088] S1. Preparation of nano-D x m 1-x Fe 2 o 4 Magnetic Particles:

[0089] Prepare 100ml Mg 2+ , Zn 2+ , Fe 3+ A mixed solution of diethylene glycol (DEG), placed in a beaker, where Mg 2+ The concentration is 0.2 mol / L, Zn 2+ The concentration is 0.2 mol / L, Fe 3+ The concentration is 0.8 mol / L. Prepare 120 ml of NaOH aqueous solution with a concentration of 3 mol / L and place it in a 500 ml round bottom flask. Using argon as a protective atmosphere, raise the temperature until the NaOH solution boils, with a stirring speed of 500 r / min, slowly add the DEG solution of metal ions into the NaOH solution for 10 minutes, and continue the reaction for 5 minutes to obtain nano-Mg 0.5 Zn0.5 Fe 2 o 4 magnetic particles;

[0090] S2. Purify the magnetic nanoparticles:

[0091] Nano-Mg obtained from S1 0.5 Zn 0.5 Fe 2 o 4 The magnetic particles were washed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com