Preparation method of phenolic resin-based micro-nano graphite sheet mixture for carbon-containing fire-refractory material with low carbon content

A technology of phenolic resin and refractory materials, applied in the field of refractory materials, can solve the problems of poor thermal shock resistance and slag erosion resistance of refractory materials, lack of reinforcement/toughening mechanism, difficulty in uniform dispersion of bricks, etc., to achieve carbon reduction Content and thermal conductivity, production cost reduction, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

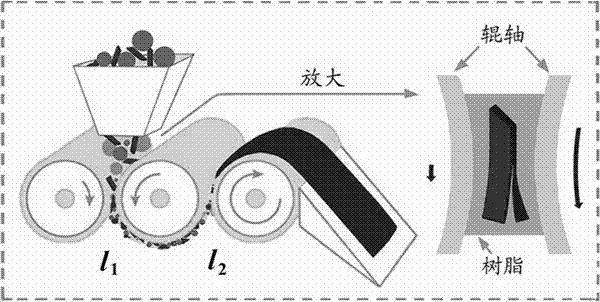

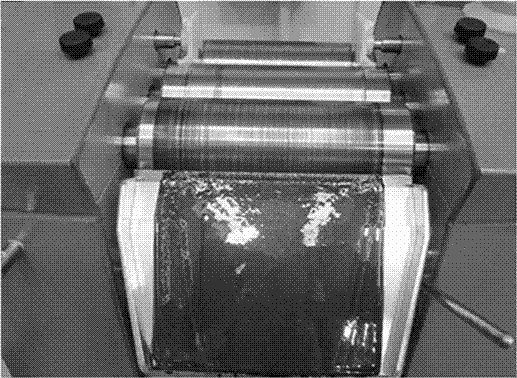

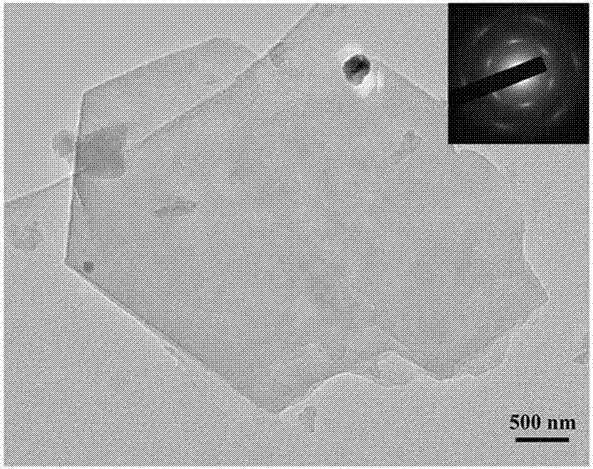

[0023] A phenolic resin-based micro-nano graphite flake compound for low-carbon carbon-containing refractory materials and a preparation method thereof. First, 5wt% expanded graphite with a particle size greater than 0.045mm and less than 5mm is poured into 95wt% thermosetting liquid phenolic resin for pre-mixing, and then the mixture is fed into the three-roller mill from the feed roller for three-roller differential cycle peeling, three The ratio of roll speed is 1:3:9, and the gap between the three rolls is 20μm (such as figure 1 middle l 1 ) and 5µm (as figure 1 middle l 2 ), after 12 cycles of stripping, the phenolic resin-based micro-nano graphite flake mixture prepared by the invention was collected from the discharge roller.

Embodiment 2

[0025] A phenolic resin-based micro-nano graphite flake compound for low-carbon carbon-containing refractory materials and a preparation method thereof. First, pour 8wt% flake graphite with a particle size greater than 0.045mm and less than 5mm into 92wt% thermoplastic liquid phenolic resin for pre-mixing, and then put the mixture from the feed roller into the three-roll mill for three-roll differential speed cycle peeling, three The ratio of roll speed is 1:3:9, and the gap between the three rolls is 30μm (such as figure 1 middle l 1 ) and 8µm (as figure 1 middle l 2 ), after 15 cycles of stripping, the phenolic resin-based micro-nano graphite flake mixture prepared by the invention was collected from the discharge roller.

Embodiment 3

[0027] A phenolic resin-based micro-nano graphite flake compound for low-carbon carbon-containing refractory materials and a preparation method thereof. First, 10wt% expanded graphite with a particle size greater than 0.045mm and less than 5mm is poured into 90wt% thermosetting liquid phenolic resin for pre-mixing. The ratio of roll speed is 1:3:9, and the gap between the three rolls is 20μm (such as figure 1 middle l 1 ) and 5µm (as figure 1 middle l 2 ), after 10 cycles of stripping, the phenolic resin-based micro-nano graphite flake mixture prepared by the invention was collected from the discharge roller.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com