Light multifunctional composite structure

A composite structure and multi-functional technology, applied in the direction of layered products, chemical instruments and methods, metal layered products, etc., can solve the problems of high cost, complicated preparation process, and restrictions on wide application, and achieve excellent impact resistance and energy absorption, High chemical stability and weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

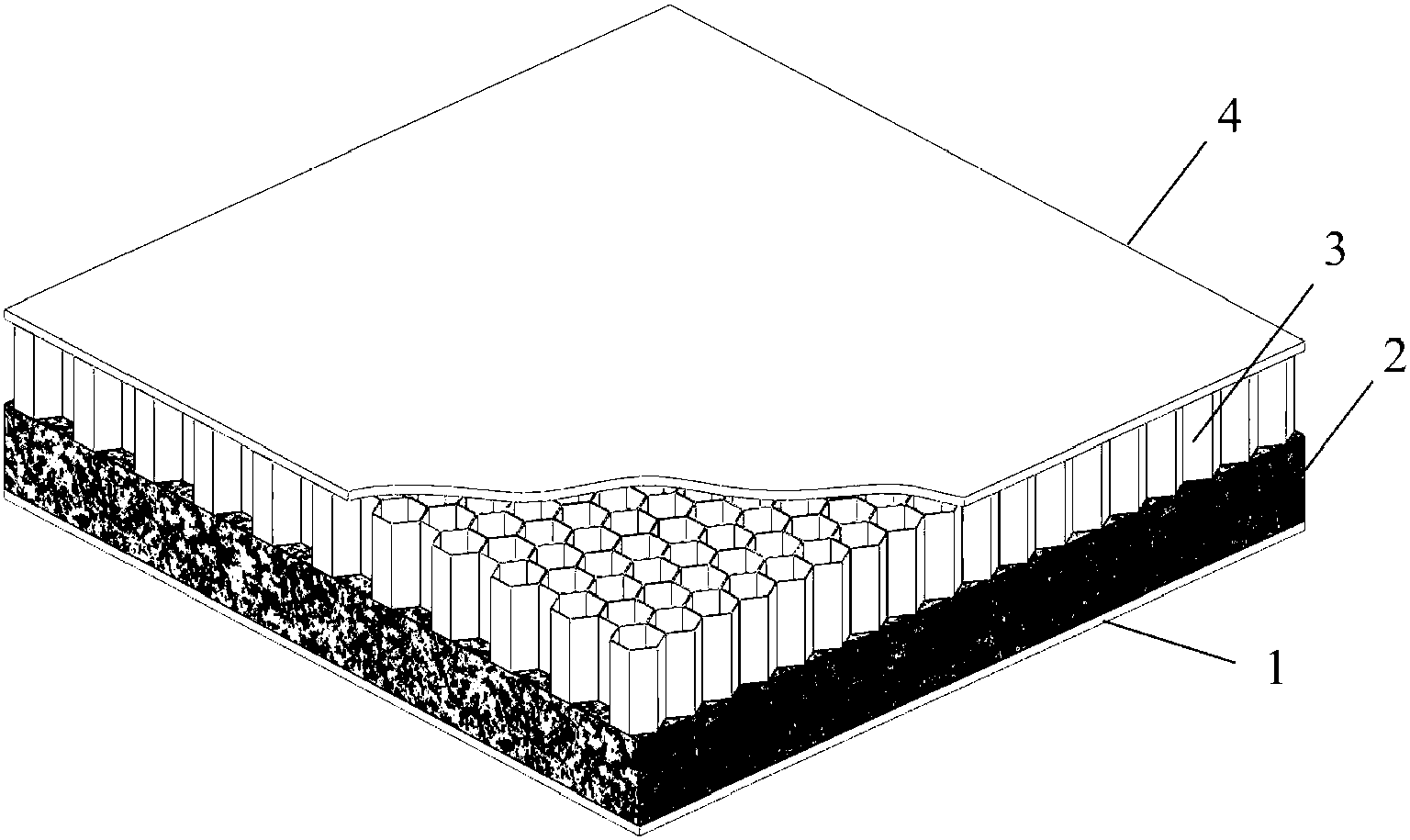

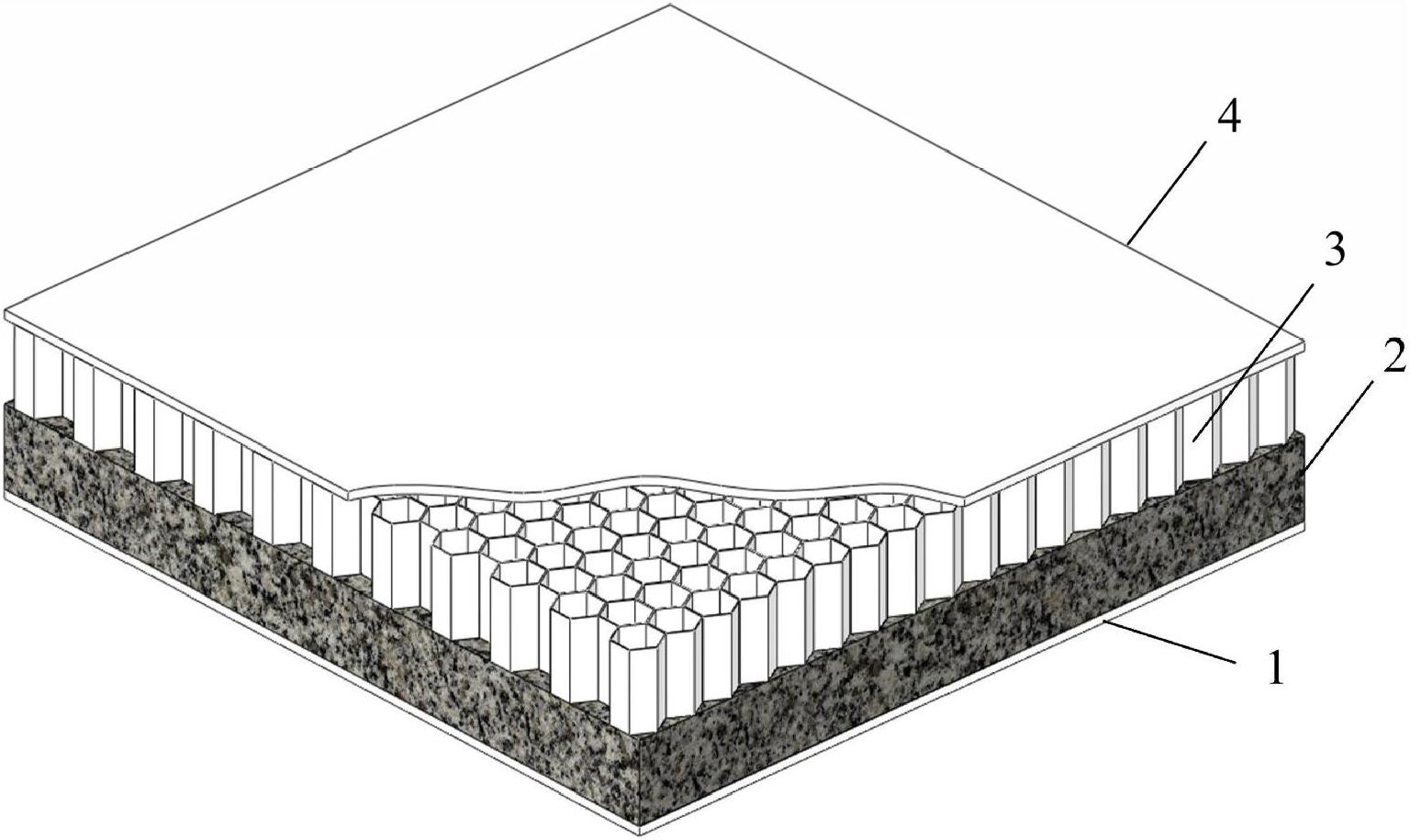

[0022] As shown in the drawings, the present invention is a lightweight multifunctional composite structure, comprising a first outer panel 1, a second outer panel 4, and a metal foam sandwich arranged between the first outer panel 1 and the second outer panel 4 layer 2 and honeycomb sandwich layer 3.

[0023] Preferably, the honeycomb sandwich layer 3 is a hexagonal aluminum honeycomb or a square aluminum honeycomb, and this embodiment uses a hexagonal aluminum honeycomb.

[0024] Preferably, the material of the metal foam sandwich layer 2 is aluminum foam, aluminum alloy foam, copper foam or steel foam.

[0025] Preferably, the material of the first outer panel 1 and the second outer panel 4 is aluminum alloy or steel.

[0026] The thicknesses of the first outer panel 1 and the second outer panel 4 may be the same or different.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com